Chapter 4 Getting Started

4.1. Unpacking and Inspection

Open the package, and carefully remove the MFC1 and its accessories. The table lists the standard

accessories shipped with the device.

Name Quantity

Motorized Focus Controller 1

MFC1 Software CD 1

USB Male A to Mini ROHS 1

MFC1 Grounding Cable 1

40 Watt 24 VDCAC/DC Adapter 1

Power Cord 1

M6 Socket Head Cap Screw 6

1/4-20x1/2" Socket Head Cap Screw 6

M6 Flat Washer 6

L-Shaped Clamp 4

Inspect the device and its accessories for any missing parts or damage. If there is any problem,

please contact our nearest office (see Thorlabs Worldwide Contacts Chapter on Page 20 for

details).

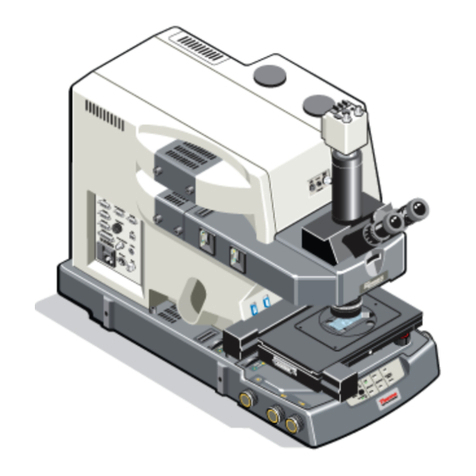

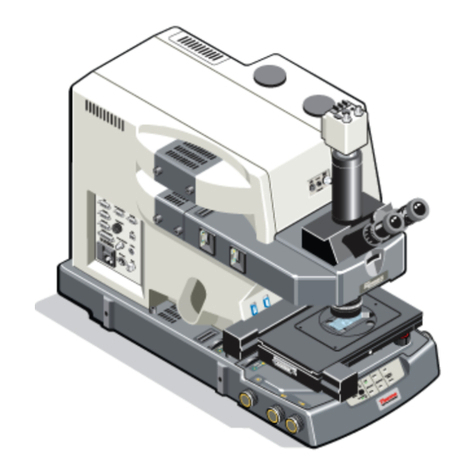

4.2. Setting up MFC1

4.2.1. Minimum Computer Requirements

Operating System Windows 7, 64-bit

Other Software .NET 4.5.2 or later, Visual C++ Redistributable Package (2012)

Driver TRINAMIC Stepper Device

4.2.2. Preparation

1. Use 3 mm hex key to loosen the Socket Head Cap Screws (3x) on the Gearhead Yoke.

2. Remove the Front Tube from the unit for easy alignment with the microscope's knob.

3. Use two Socket Head Cap Screws (M6 for metric / 1/4-20x1/2" for imperial) to mount the unit

on the optical table.

Note:Do not tighten the screws on the base plate until the final alignment.

Rev B, February 01, 2018 Page 5

MFC1 Chapter 4: Getting Started