Chapter 3 Description

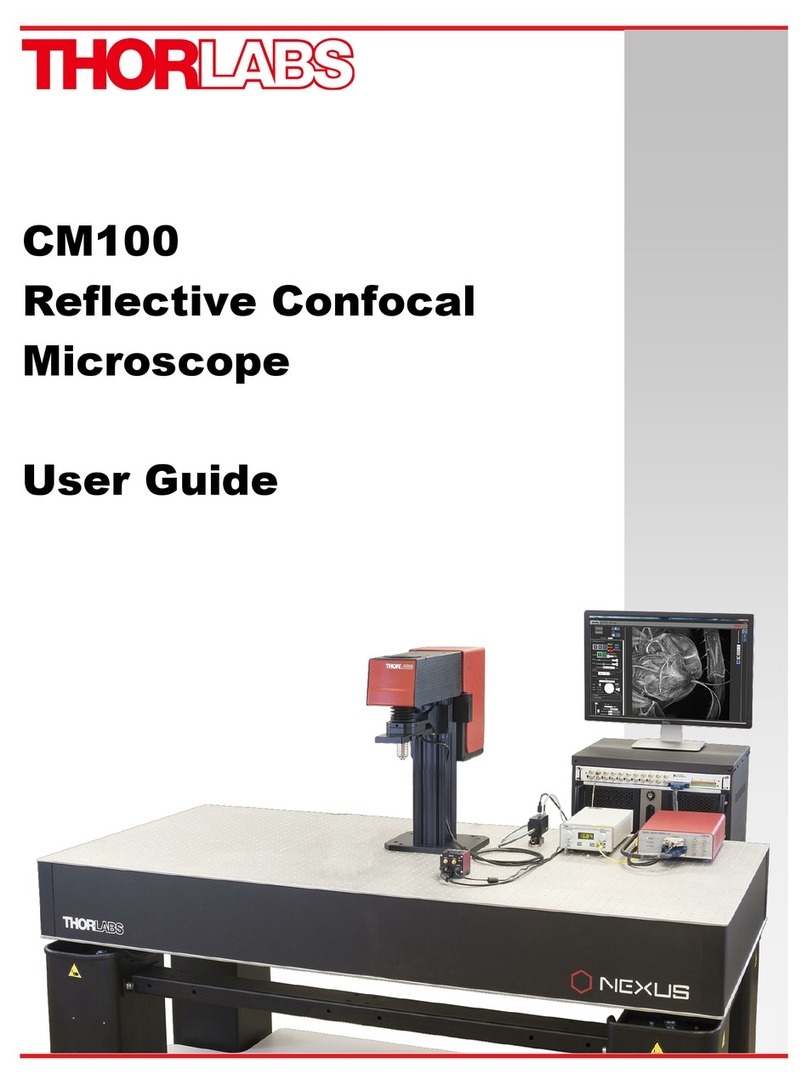

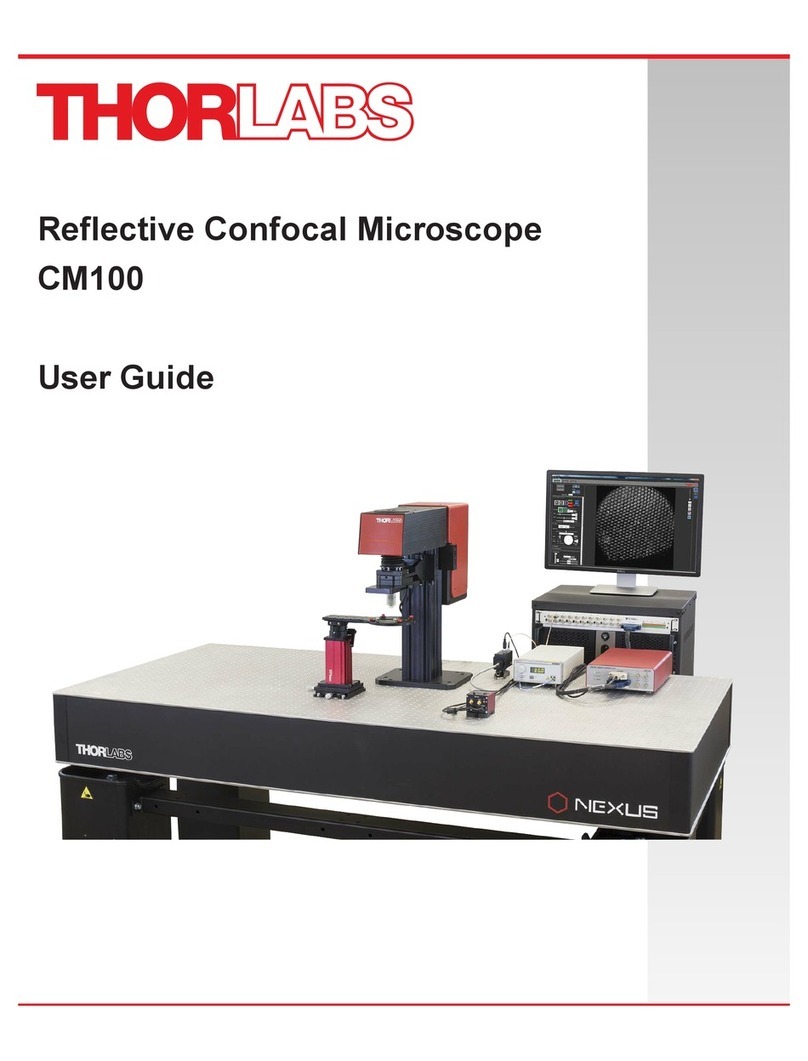

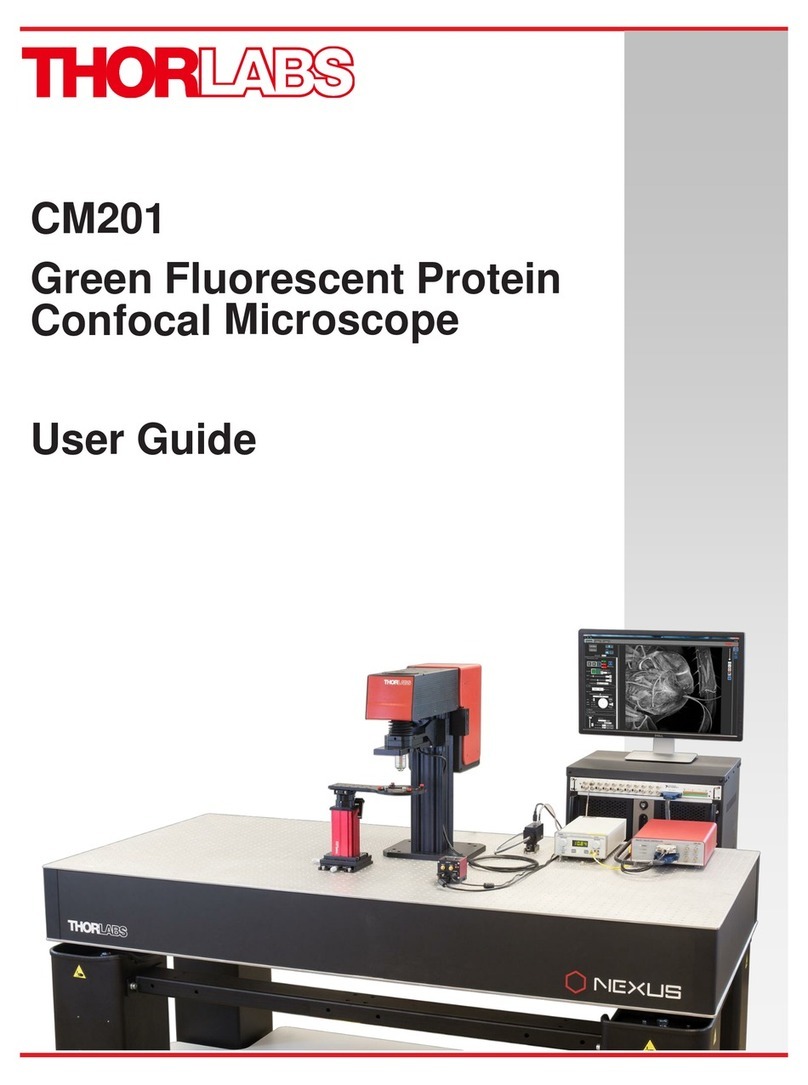

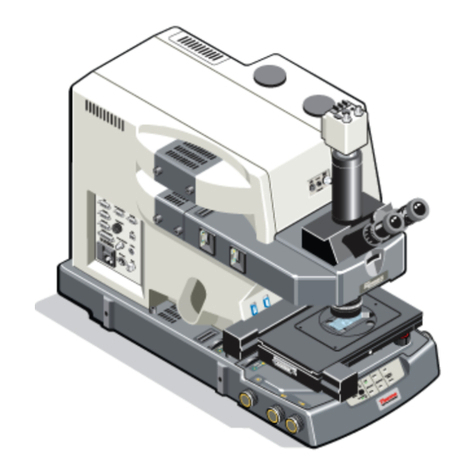

Thorlabs' Entry-Level Upright Reflective Confocal Microscope is a complete single-

channel system. By eliminating signals that originate from outside the focal plane,

confocal microscopy provides the ability to acquire high resolution, optically sectioned

images from within a thick sample. The CM100 supports reflected-light confocal imaging

for viewing the surface structure of biological samples or for inspection applications.

The CM100 has a 35 mm x 52 mm x 3 mm silver-coated mirror at the front of the scan

path that directs light from the scanners to the objective. In order to use this microscope

for widefield as well as confocal imaging, you can replace this mirror with a beamsplitter.

The CM100 is designed to provide a cost effective entry point to owning a modular

confocal microscope that can be upgraded to an advanced confocal microscope.

3.1. Features at a Glance

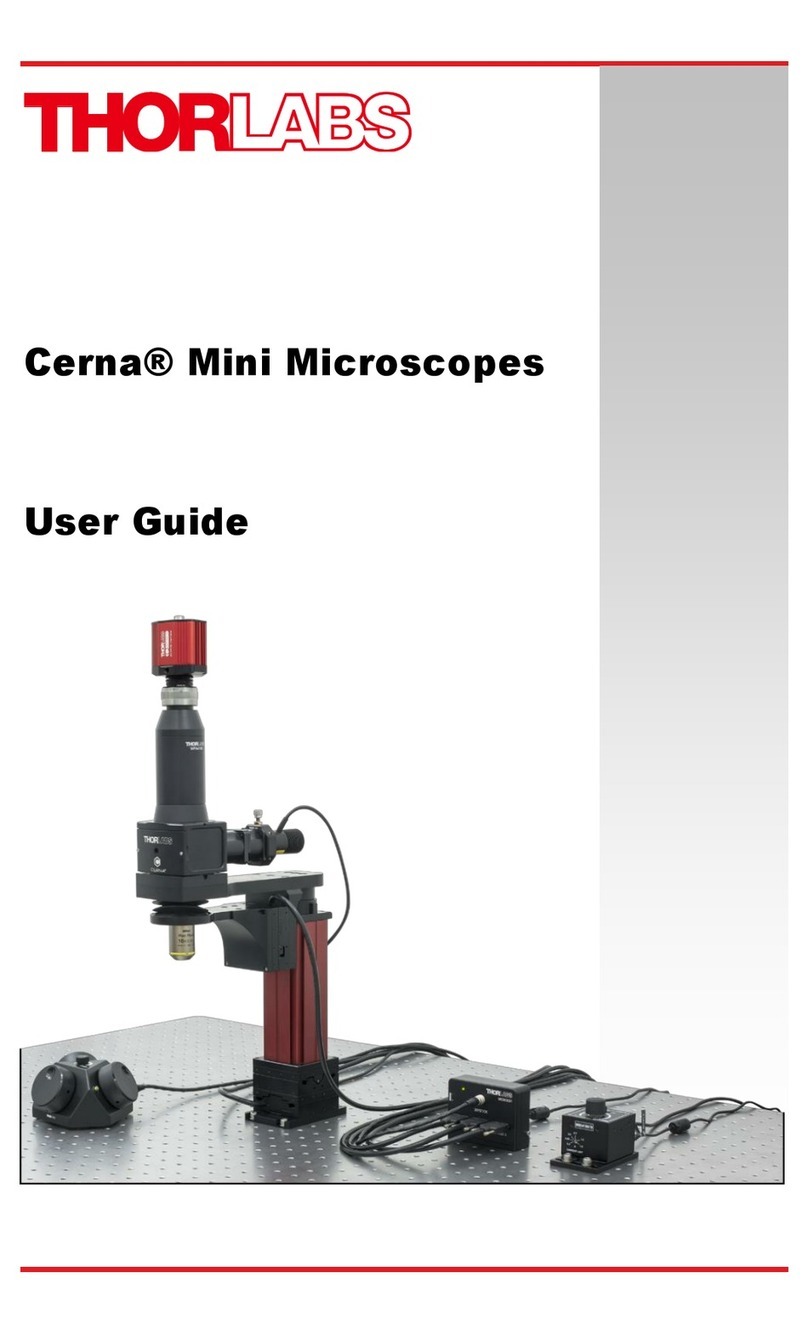

● Upright Microscope Based on the Cerna DIY Microscopy Platform

♦95 mm Dovetail on Rail Accepts Cerna Accessories

♦D1N Dovetail on Top of Scan Path for Cerna Widefield Imaging Modules

● Confocal Scan Path with Galvo-Galvo Scanners

● One Benchtop Excitation Laser (660 nm SMLaser)

● One Multialkali PMT (Photomultiplier Tube)

● Filter Set for Reflected-Light: One Beamsplitter, One Quarter-Wave Plate,

and Two Polarizers

● Rigid Stand Slide Holder on Manual XYStage, 1/2" Travel

● 20X Olympus Objective

● PC with DAQ and ThorImageLS®Software

3.2. Imaging Capabilities

● Full frame 4096 x 4096 Pixel Images (Uni-Directional Scan)

● 2 FPSfor 512 x 512 Pixel Bi-Directional Scans

● Galvo/Galvo Scan Head with 1.0 to 10 µs Pixel Dwell Times

● 796 µm x 796 µm Field of View (FN25)

CM100 Chapter 3: Description

Page 3 TTN118785-D02