TIE DOWN TranzVolt G2 Installation manual

404-344-0000 • www.tiedown.com

605 Stonehill Drive SW, Atlanta, GA 30336

US Patent Pending

US Patent Pending

Instruction #08427 (E1930, Rev. 10/28/22)

CRITICAL SAFETY INFORMATION: The greatest exposure to serious bodily injury and or death may occur when the

TranzVolt track sections are located within 10 ft. (left or right or underneath) overhead electric power lines. If a minimum

safe distance (10 ft.) from electrical wires cannot be maintained, contact the local utility company and have the electric

wire unenergized and grounded or guarded effectively by insulating or other means.

A COMPETENT PERSON must be present during any setup, during any repositioning, and during any tear-down

operations of the TranzVolt track sections when the TranzVolt is to be located near electric power lines. A COMPETENT

PERSON must read and understand the Owner’s Manual for setup, operating instructions, and tear down instructions in

order to ensure that all personnel authorized to set up, operate, and tear-down the TranzVolt are made aware of ALL

SAFETY WARNINGS as well as the operating instructions. ALWAYS USE APPROVED ROOF TOP FALL PROTECTION when

setting up, operating, and taking down the TranzVolt.

TranzVolt G2

Safety & Operating Manual

TranzVolt G2

Operations

Manual

Solar Tilt Back

Platform Assembly

Instructions

Collapsible Roofing

Platform Instructions

TranzVolt G2 with

Collapsible Roofing

Platform

TranzVolt G2 with

Solar Tilt Back

Platform

https://www.tiedown.com/pdf/

tranzvolt_g2_assembly_e1930.pdf

https://www.tiedown.com/pdf/

tranzvolt_solar_inst_e1939.pdf

https://www.tiedown.com/pdf/

tranzvolt_roofing platform_inst_e1938.pdf

https://www.tiedown.com/pdf/

tranzvolt_g2_assembly_e1930.pdf

https://www.tiedown.com/pdf/

tranzvolt_solar_inst_e1939.pdf

https://www.tiedown.com/pdf/

tranzvolt_roofing platform_inst_e1938.pdf

https://www.tiedown.com/pdf/

tranzvolt_g2_assembly_e1930.pdf

https://www.tiedown.com/pdf/

tranzvolt_solar_inst_e1939.pdf

https://www.tiedown.com/pdf/

tranzvolt_roofing platform_inst_e1938.pdf

WARNING: This product can expose you

to chemicals including Nickel, which is

known to the State of California to

cause cancer. For more information

go to: www.P65Warnings.ca.gov

WARNING: This product can expose you

to chemicals including Nickel, which is

known to the State of California to

cause cancer. For more information

go to: www.P65Warnings.ca.gov

WARNING: This product can expose you to

chemicals including Nickel, which is known to

the State of California to cause cancer. For more

information go to: www.P65Warnings.ca.gov

WARNING: This product can expose you to chemicals including Nickel, which is known to the

State of California to cause cancer. For more information go to: www.P65Warnings.ca.gov

WARNING: This product can expose you to chemicals including Nickel, which is known to the

State of California to cause cancer. For more information go to: www.P65Warnings.ca.gov

NOTE: Two (2) DeWalt Brand 20V batteries or Two (2) Milwaukee Brand 18V batteries

are required depending on your model TranzVolt. Batteries not included.

2

E1930, 10/28/22

TIE DOWN Safety Products Division • 800-241-1806 • 404-344-0000 • www.tiedown.com

Congratulations on your Purchase of the TranzVolt Cordless Lift Hoist.

Features Include:

• Simple Tool Free, Five Minute Setup • Electromagnetic / Regenerative Braking Systems

• One Press Wireless Remote Operation Control • Automatic Homing System

• Rapid Load Lift at 120 ft per Minute • Maintenance Free All Electric Power-Train System

• Heavy Load Capacity (250 lbs.) • Load Lowering Capability

Roofing Products Division

605 Stonehill Drive SW, Atlanta, Georgia 30336

800-241-1806 • 404-344-0000 • www.tiedown.com

ISO 9001:2015 Certification

Intellectual property of TIE DOWN Inc. ©2019 TIE DOWN, Inc.

Instruction #08315 (E1546 Rev. 10/28/22)

Table of Contents

TranzVolt G2 Laddervator Kit Descriptions 3

TranzVolt G2 Safety Warning 4

Stop Bracket Mounting 5

Top Cap and Tilt Rollers Installation 6

Splice Plates 7

Raising and Lowering the TranzVolt G2 8-9

Track Section Placement 10

Power Box Installation 11-12

Platform Frame Installation 13-14

Synthetic Cable Installation 15

Roofing and Solar Platforms 16

Homing the TranzVolt G2 17

Safety Warnings 18

Warranty Information 19

Homing Quick Reference 20

3

E1930, 10/28/22

TIE DOWN Safety Products Division • 800-241-1806 • 404-344-0000 • www.tiedown.com

Roofing Products Division

605 Stonehill Drive SW, Atlanta, Georgia 30336

800-241-1806 • 404-344-0000 • www.tiedown.com

ISO 9001:2015 Certification

Intellectual property of TIE DOWN Inc. ©2019 TIE DOWN, Inc.

Instruction #08315 (E1546 Rev. 10/28/22) Contact Tie Down @ 404-344-000 if missing any product.

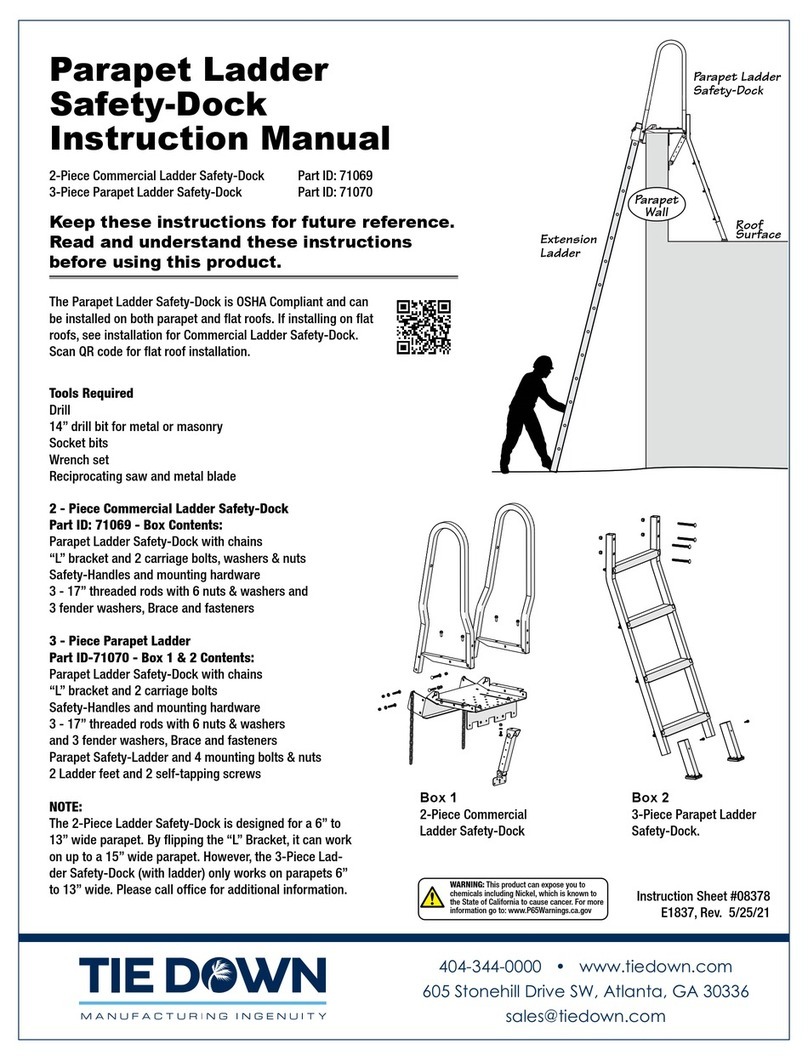

TranzVolt G2 Laddervator “Starter” Kit

Part ID: 40670

Box #1 of 2 Includes:

Power box, two remotes, lower roller stops, top cap w/rollers,

synthetic cable and two safety tie down’s.

NOTE: Two (2) DeWalt Brand 20V batteries or

Two (2) Milwaukee Brand 18V batteries are required

depending on your model TranzVolt. Batteries

not included.

Box #2 of 2 Includes:

Platform frame, quick release pins & retaining knobs.

Shipping Pallet:

Track Section Bundle:

3 - 8 ft. track sections with

splice plates w/nuts & bolts installed

1 - 4 ft. track section with foot stops

STOP

START

JOG

UP

DOWN

HOME

STOP

START

JOG

UP

DOWN

HOME

Box 1 of 2

Box 2 of 2

STOP

START

JOG

UP

DOWN

HOME

STOP

START

JOG

UP

DOWN

HOME

Box 1 of 2

Box 2 of 2

STOP

START

JOG

UP

DOWN

HOME

STOP

START

JOG

UP

DOWN

HOME

Box 1 of 2

Box 2 of 2

STOP

START

JOG

UP

DOWN

HOME

STOP

START

JOG

UP

DOWN

HOME

Box 1 of 2

Box 2 of 2

TranzVolt G2 Laddervator Kits

TranzVolt G2 Laddervator

Collapsible Roofing Platform Kit

Part ID: 40675

Kit Includes: Top cap and platform base

TranzVolt G2 Laddervator

Solar Tilt Back Platform Kit

Part ID: 40676

Kit Includes: Tilt back platform & mounting hardware

Platform Kits (Purchased Separately)

4

E1930, 10/28/22

TIE DOWN Safety Products Division • 800-241-1806 • 404-344-0000 • www.tiedown.com

TranzVolt G2 Safety Warnings

TRANZVOLT G2 Laddervator Installation MANUAL NOTES

These installation instructions are essential for the successful and safe operation of the TranzVolt G2 Hoist. The operating

instructions contain important information. Your attention is required to maintain the TranzVolt G2 is safe, operated properly and

is economically used. Your attention helps avoid dangers and the ensures reliability and lifetime of the TranzVolt G2 Hoist.

Installation Instructions Disclaimer

The TranzVolt G2 instructions must always be available, read and applied to any person who installs/operates the TranzVolt G2 while:

• Operating the Equipment.

• Troubleshooting the Equipment.

• Assisting in the Use of Equipment.

• Assembly of Equipment.

• Storage of Equipment.

• Maintenance, care, repair and/or any operations tasked for the TranzVolt Hoist.

To better understand these instructions, extra care should be given to the following representations and safety symbols:

Warns of hazardous situations or unsafe practices with

high risk of severe injury or death.

Warns of hazardous situations or unsafe practices with

some risk of severe injury or death.

Warns of potential hazards or unsafe practices that could

result in minor to moderate injuries.

WARNING

BATTERIES MUST BE REMOVED

WHEN NOT IN USE.

Leaving the batteries in the

TranzVolt power box could result in

permanently dead batteries.

DO NOT TRANSPORT

ASSEMBLED

LADDERVATOR

THE UNSECURED TRANZVOLT POWER BOX/PLATFORM

MUST BE REMOVED BEFORE TRANSPORTING.

5

E1930, 10/28/22

TIE DOWN Safety Products Division • 800-241-1806 • 404-344-0000 • www.tiedown.com

Lower Stop Bracket Assembly

4 ft. Base Section

Lower Stop Brackets Slice Plates/Hardware Top Cap Tilt Back Rollers

8 ft. Track Section

U-Bolt

1/2” Hex

Flange Nuts

Right

Roller

Stop

Right

Roller

Bracket

Left

Roller

Stop

U-Bolt

1/2” Hex

Flange Nuts

Right

Roller

Stop

Right

Roller

Bracket

Left

Roller

Stop

STEP 1 Full Track Assembly

• Lay out on a flat surface all the tracks needed for the job. Beginning with the 4 ft base section, add up to 4 - 8 ft. tracks.

• Do not operate the TranzVolt higher than 36 ft. without replacing the standard synthetic cable with extended

length synthetic cable #40674. Maximum hight shall not exceed 44 ft.

• Locate the lower stop brackets and hardware, lay out the hardware at the base of the tracks.

• Locate and place the splice plate mounting nuts and platform bolts beside the track section joints.

• Locate the top cap and tilt back roller brackets and lay them out at the end of the end of the track sections.

STEP 2 Lower Stop Bracket Assembly (one time installation)

• Working from the side, slide a 1.5”x4.75” u-bolt over the track side frame above the lowest ladder rung.

• The u-bolt will rest on the lowest ladder rung. Slide a lower roller stop bracket over the u-bolt shown in Fig 5-3.

Make sure the roller is between the ladder sides with the amber roll facing upward see Fig. 5-2.

• Lossly fasten with two 1/2” hex flange nuts.

• Square the roller bracket to the track section with the bracket resting on the lowest ladder rung.

• Tighten both flange nuts.

• Repeat for opposite side roller bracket

Fig. 5-2 Fig. 5-3

NOTE: Under normal working conditions’ parts will wear out. TIE DOWN sells replacement parts in kits only and will not sell

individual pieces or parts. Most common hardware described is available at your local hardware store.

TranzVolt G2 Track Section Assembly

DANGER: DO NOT CLIMB ON TRACK SECTIONS. Track Sections are not designed to be used as a ladder. Serious injury may

occur when track sections are not used for their original purposes. Do not operate the TranzVolt higher than 36 ft.

without replacing the standard synthetic cable with extended length synthetic cable #40674.

6

E1930, 10/28/22

TIE DOWN Safety Products Division • 800-241-1806 • 404-344-0000 • www.tiedown.com

Top Cap -

Aaches on the

outside of

frame

3/8”x 3/4”

Carriage Bolts

Tighten 3/8”

Keeper Nuts

Tighten 3/8”

Keeper Nuts

STEP 1 Attaching Top Cap (one-time installation)

• Attach the top cap to the end of the last track section

you intend to use.

• Make sure that the top cap end slides into the outside

of the track section completely and securely

(shown right). Note: The Top Cap will only mount in

one direction.

• Assemble with (2) 3/8”x 3/4” carriage bolts passing

through the inside tracks with keeper nuts provided.

• Ensure bolts and nuts are torqued to 30 ft. lbs.

STEP 2 Attaching the Tilt Rollers

• Working on the top end of the tracks, hold one

tilt roller assembly at a slight counterclockwise

angle shown in Fig. 6-2.

• Slide the mounting tab into the mounting slot located

on the front left/right of the top cap. See Fig. 6-2

• Once the tab is secured in the mounting slot give the

roller assembly a slight clockwise turn as

show inf Fig 6-3. It may be necessary to pull the

bracket out some to fit over the edges of the

ladder tracks.

• Align the lower roller bracket with the square

mounting hole located in the track section.

• Place a 3/4” platform bolt from the inside of the

ladder through the roller bracket.

• Tighten with 3/8” keeper nut.

• Repeat of opposite side roller bracket.

Mounting Tab

Fig. 6-1

Fig. 6-3 Fig. 6-4

Fig. 6-5

Fig. 6-2

TranzVolt G2 Track Section Assembly

7

E1930, 10/28/22

TIE DOWN Safety Products Division • 800-241-1806 • 404-344-0000 • www.tiedown.com

STEP 1 Laying Track Section Out

• Lay track sections on a flat surface with the “front” side facing up.

• “Front” of track has largest space between the track

crossbar and the track section edge as shown to right.

• Determine the number of track sections required

• Track sections can be laid out in the following

combinations: 12 ft., 20 ft. or 28 ft. high

• Two addition track section can be purchased separately

for hight up to 44 ft.

• Place selected track in order with 4 ft. section at the base

• 4 ft base track should be lined up parallel to the loading

point for your project

Front

Back

3/8” x 3/4” Carriage Bolts

3/8” Keeper Nuts

Step 2 Connecting Track Sections

• Splice plates are attached to the end section of the tracks.

• Splice plates are mounted on the outside track section.

• Attach provided (2) keeper nuts and bolts per side (shown right).

• Ensure bolts and nuts are torqued to 30 ft. lbs.

• Repeat this step for each track section required

NOTE: DO NOT SUBSTITUTE NUTS AND BOLTS.

Use 3/8”x 3/4” carriage bolts and 3/8” keeper nuts

(lock washer and nut combined).

Step 3 Connecting the Synthetic Cable

• Locate and unwind the blue synthetic cable. Fully

stretch out the cable the full length of the track assembly.

• Attach the safety link to the back of the top cap

as shown in Fig 7-3. IMPORTANT: The cable must

lie on the front side of the tracks.

• At the opposite end of the track assembly, pull the

synthetic cable to removing any slack. Lightly tie a knot

around the 2nd to the end rung on the track section.

The TranzVolt laddervator track assembly is now

ready to be lifted into its work location.

3/8” x 3/4” Carriage Bolts

positioned “Inside Tracks”

3/8” Keeper Nuts

3/8” Keeper Nuts

Fig. 7-1

Fig. 7-2

Fig. 7-3

TranzVolt G2 Track Section Assembly

Connect Synthetic Cable to the Top Cap

Safety link aaches

to the back of the top cap

Over Frame

Tube

Install 2 Dewalt

brand baeries

Under Rope

Roller

Press DOWN

and hold to

release rope

STOP

START

JOG

UP

DOWN

HOME

Do not operate the TranzVolt higher than 36 ft. without

replacing the standard synthetic cable with extended

length synthetic cable #40674. Maximum hight shall

not exceed 44 ft.

8

E1930, 10/28/22

TIE DOWN Safety Products Division • 800-241-1806 • 404-344-0000 • www.tiedown.com

WARNING: KEEP TRACK SECTIONS MINIMUM 10 FT. CLEAR OF ALL ELECTRICAL WIRES AND EQUIPMENT. BE AWARE OF

OVERHEAD WIRES BEFORE RAISING TRACK SECTIONS. ELECTRICITY KILLS!

The hoist assembly is extremely top heavy and must be kept under control at all times. Two alternate methods are suggested for

raising the platform hoist to the operating position. ALWAYS USE APPROVED ROOF TOP FALL PROTECTION when setting up,

operating and taking down the TranzVolt Hoist.

Procedure “A”

This procedure requires two or preferably three men.

1. Lay the assembled track sections with the platform attached parallel to the building

wall that is to support the hoist.

2. Tie a rope to the head bracket and have the man on roof pull up the hoist while the

other man on the ground braces the shoes on the bottom base section to prevent

slippage of the hoist shoes. The third man on the ground may aid in erecting by

“walking” the hoist up hand over hand by the rungs.

3. When the hoist reaches a vertical position, carefully turn the hoist 90 degrees with

the platform pointing away from the building. Move the bottom of the hoist away

from the building 1/4 of the height of the building where the top of the hoist is to be

supported. Make allowances for overhang.

4. Tie the track section to the roof with a rope fastened to a cross tie on the top bracket to

prevent slippage of the track section. See below.

DO NOT TIE ROPE TO THE RAILS - THIS WILL PREVENT THE PLATFORM FROM

OPERATING PROPERLY.

5. Make certain the shoes on the steel bottom section are firmly resting on level ground.

This will help to prevent track section slippage or uneven loading of the track section

which could cause damage or injury to personnel and/or to equipment.

Secure the Top Cap

Option 1 Low Top Cap

Attach with the Safety Pull Straps

(included). Place the hooks through the

holes in top cap. Attach to a mounted

2x4 on the side of the roof top.

NEVER ALLOW ANYTHING TO WRAP

AROUND THE FRONT OF THE

TRACK SECTION

Option 2 High Top Cap

Pass rope through the track

section rungs. Tie rope around

the mounted 2x4 on the side of

the roof top.

NEVER ALLOW ANYTHING TO

WRAP AROUND THE FRONT OF

THE TRACK SECTION

Raising and Lowering the Track Section Assembly

9

E1930, 10/28/22

TIE DOWN Safety Products Division • 800-241-1806 • 404-344-0000 • www.tiedown.com

Option 1 Low Top Cap

Attach with the Safety Pull

Straps (included). Place the

hooks through the holes in top

cap. Attach to a mounted

2x4 on the side of the roof top.

NEVER ALLOW ANYTHING TO

WRAP AROUND THE FRONT

OF THE TRACK SECTION

Option 2 High Top Cap

Pass rope through the track

section rungs. Tie rope around

the mounted 2x4 on the side of

the roof top.

NEVER ALLOW ANYTHING TO

WRAP AROUND THE FRONT OF

THE TRACK SECTION

Procedure “B”

This procedure requires two or preferably three men.

1. Place track section assembly perpendicular to the building with the bottom shoes

of the steel bottom section resting against the building to prevent slipping.

2. Tie a rope to the top bracket and have the man on the roof pull up the

hoist while the other man on the ground braces the shoes on the steel bottom

base section to prevent slippage of the hoist shoes. The third man on the ground

may aid in erecting by “walking” the hoist up hand over hand by the rungs.

3. When the hoist reaches a vertical position, carefully turn the hoist 180

degrees with the platform pointing away from the building.

4. Move the bottom of the hoist away from the building 1/4 of the height of

the building where the top of the hoist is to be supported. Angle of track

sections from building should be between 18 and 20 degrees. Make

allowances for an overhang.

5. Tie the track section to the roof with a rope fastened to a cross tie on

the top bracket to prevent slippage of the track section. See below.

DO NOT TIE ROPE TO THE RAILS - THIS WILL PREVENT THE

PLATFORM FROM OPERATING PROPERLY.

6. Make certain the shoes on the steel bottom section are firmly resting

on level ground. This will help to prevent track section slippage or

uneven loading of the track section which could cause damage or

injury to personnel and/or to equipment.

WARNING: KEEP TRACK SECTIONS MINIMUM 10 FT. CLEAR OF ALL ELECTRICAL WIRES AND EQUIPMENT. BE AWARE OF

OVERHEAD WIRES BEFORE RAISING TRACK SECTIONS. ELECTRICITY KILLS!

ALWAYS USE APPROVED ROOF TOP FALL PROTECTION when setting up, operating, and taking down the TranzVolt Hoist.

Secure the Top Cap

Raising and Lowering the Track Section Assembly

10

E1930, 10/28/22

TIE DOWN Safety Products Division • 800-241-1806 • 404-344-0000 • www.tiedown.com

TranzVolt G2 Placement

Track Section Chart:

Brace Support and Proper

Set Up Distance at Job Site

This table provides the suggested information for the distance

of the bottom track from the building and the location of the

track support for various conditions. Track lengths in excess

of 28 feet require the use of the telescoping brace (#60005).

Building Length of Base To Track Brace Attach Synthetic Cable

Height Track Building To Rung: Extension

12’ 16’ 4’-6” Not Required Not Required

16’ 20’ 5’-0” Not Required Not Required

20’ 24’ 6’-6” Not Required Not Required

24’ 28’ 6’-6” Not Required Not Required

28’ 32’ 7’-6” 11th and 13th Not Required

32’ 36’ 8’-0” 14th and 16th Not Required

36’ 40’ 9’-0” 19th and 21st Extension Required*

40’ 44’ 10’-0” 24th and 25th Extension Required*

42’ 44’(max) 10’-6” 25th and 27th Extension Required*

Building

Height

Length

of Track

Base to

Building

Remember to

always erect

your laddervator

using the 4:1 rule

1

4

Do not operate the TranzVolt higher than 36 ft. without

replacing the standard synthetic cable with extended

length synthetic cable #40674. Maximum hight shall

not exceed 44 ft.

https://www.tiedown.com/pdf/e134.pdf

Support Brace Assembly Instructions

11

E1930, 10/28/22

TIE DOWN Safety Products Division • 800-241-1806 • 404-344-0000 • www.tiedown.com

Fig. 11-1

Fig. 11-2

Fig. 11-3

Fig. 11-4

TranzVolt G2 Power Box Installation

STEP 1 Attaching the Power Box

• Attaching the power box must be done with the ladder

tracks secured to the roofing in its final working area.

• While standing in front of the tracks - hold the power

box just above the track sides. Tilt the power box

clockwise with the left side of the power box upward

toward the top of the tracks. As shown right Fig. 11-1.

• Lower the power box down between the sides of the

track aligning the guide wheels with the side of the

tracks as shown in Fig 11.2.

STEP 2 Attaching the Power Box

• Once the guide wheels are aligned with the track sides,

give the power box a counterclockwise turn.

• Double check the guide wheels are aligned with the track

side by looking down the side of the power box shown

in Fig. 11-3.

• If the power box if properly aligned with the track sides it

should roll freely up and down the assembled tracks.

• Lower the power box down resting against the stop rollers.

12

E1930, 10/28/22

TIE DOWN Safety Products Division • 800-241-1806 • 404-344-0000 • www.tiedown.com

Step A - out of box Step B

Step C

Step D Step E

Step A - out of box Step B

Step C

Step D Step E

1/2” Gap

Between Tubes

Angled Tube

Platform Frame Installation

STEP 1 Opening the Platform Frame Box

NOTE: The platform frame is folded

backwards for shipping purposes.

• Remove the platform frame by sliding

the frame from side of the box.

• Rotate the long angled tube 360

degrees up and over the roller tube

frame. Follow the steps shown

in Fig 12-1.

STEP 2 Attaching the Platform Frame

• Attaching the platform frame must be done with

the ladder tracks secured to the roofing in its final

working area.

• While standing in front of the tracks - hold the

platform frame just above the track sides. Tilt the

platform frame counter clockwise with the

right side of the platform frame upward toward

the top of the tracks. As shown right Fig. 12-1.

• Lower the platform frame down between the sides

of the track aligning the track rollers with the side

of the tracks.

• Once the track rollers are aligned with the track

sides, give the power box a clockwise turn.

As shown in Fig 12-3

• Double check the track rollers are aligned with the

track side by looking down the side of the platform

frame

• If the platform frame is properly aligned with the

track sides, the platform frame will freely roll up

and down the assembled tracks.

Fig. 12-1

Fig. 12-2 Fig. 12-3

13

E1930, 10/28/22

TIE DOWN Safety Products Division • 800-241-1806 • 404-344-0000 • www.tiedown.com

1/2” Gap

Between Tubes

Angled Tube

Platform Frame Installation

STEP 3 Attaching the Platform Frame

• Working above the power box - take hold of the

lower tubes of the Platform frame.

• Using both hands grab the top (angled tube)

Shown in Fig. 13-1.

• Raise the angled tube about 1/2-1” above

the roller tube frame as shown right.

• Roll the carriage frame downward to the

power box.

• Slide the roller tube frame into the side mounting

tube on the lower side of the power box. At the

same time the angled tube will slide into the

upper mounting tube on each side of the power

box. See Fig 13-2 show right.

• Weight and gravity will slide the platform frame

into its final working position.

Fig. 13-1 Fig. 13-2

Fig. 13-3 Fig. 13-4

STEP 4 Securing the Platform Frame

• Locate two black rubber knobs (with 3/8” studs) from the hardware supplied from the power box kit.

• Working from behind the TranzVolt attache the rubber hand knob on the ends of the power box passing through the

platform frame. See Fig. 13-2.

• Secure the platform frame with the power box with a firm hand tightening of the rubber hand knob.

• Repeat for opposite side hand knob. See Fig 13-3.

• Locate the 4 - quick release pins from the hardware supplied.

• Insert a release pin in each of the four mounting hole located on each corner of the top of the carriage frame. See Fig. 13-4.

14

E1930, 10/28/22

TIE DOWN Safety Products Division • 800-241-1806 • 404-344-0000 • www.tiedown.com

TranzVolt G2 Synthetic Cable Installation

Fig. 14-2

Fig. 14-3

Insert 2 baeries

Under Roller

Guide

STEP 1 Routing the Synthetic Cable

• Untie the synthetic cable from the ladder rung.

• Feed the knotted end of the cable through the

back of the platform frame between the feed roller

and the roller guide plate.

• Remove any slack by pulling the entire length of

the synthetic cable.

• Insert two fully charged batteries. When the batteries are

first inserted, listen for a beep/tone – Power Box is ready.

STEP 2 Locating the Cable Retaining Clip

• Working from the front - look down, through the cable

slot, locate the cable spool. See Fig. 14-3

• Using the remote control:

> Press the START button

> Press the UP button to rotate the cable spool

• Release the UP button when the cable retaining clip

(located on the right side of the spool) is visible and

positioned towards to top of the power box. Fig. 14-3

Fig. 14-1

Knot

Cable Retaining

Clip

TranzVolt

Front

Cable Spool

Synthetic Cable

Knot

Cable Retaining

Clip

TranzVolt

Front

Cable Spool

Synthetic Cable

NOTE: The synthetic cable will have a loop on one end and tied knot

on the opposite end. DO NOT USE THE CABLE WITHOUT THE KNOT.

NOTE: Two (2) DeWalt Brand 20V batteries or Two (2)

Milwaukee Brand 18V batteries are required depending

on your model TranzVolt. Batteries not included.

Do not operate the TranzVolt higher than 36 ft. without

replacing the standard synthetic cable with extended

length synthetic cable #40674

15

E1930, 10/28/22

TIE DOWN Safety Products Division • 800-241-1806 • 404-344-0000 • www.tiedown.com

TranzVolt G2 Synthetic Cable Installation

Raise and lower

at least 2 times

Raise and lower

at least 2 times

Raise and lower

at least 2 times

Fig. 15-1

Fig. 15-2

Fig. 15-3

STEP 3 Winding/Loading the Synthetic Cable

• Place the knotted end of the synthetic cable between

two fingers and insert the cable in through the cable slot.

• Using your fingers, guide the knotted cable end through

the bottom of the cable retaining clip located on the right

side of the cable spool. See Fig 15-1.

• Pull the synthetic cable tightly making sure the cable is

securely attached.

STEP 4

• Firmly maintain tension on the cable.

• Using the remote control - press the UP button.

• While holding tension on the cable, allow the cable to

spool going from the right to the left and back

as shown in Fig 15-2.

• Release the UP bottom once the platform begins

moving upward.

STEP 5 Tensioning the TranzVolt

Stand back from the TranzVolt 6-7 feet,

Do Not stand under the track assembly.

• Using the remote control:

> Press the START button

> Press and hold the UP button

• Allow the TranzVolt to travel the full length

of the track assembly.

• Using the remote control:

> Release the “UP” once the platform

reaches the top.

> Press the “Down” button to return

• Repeat the up and down process for a

second time.

The synthetic cable should be fully wound

and ready to load the platform.

16

E1930, 10/28/22

TIE DOWN Safety Products Division • 800-241-1806 • 404-344-0000 • www.tiedown.com

TranzVolt G2 Platform Installation

The Collapsible Roofing Platform Kit (Part #40675) and the

Solar tilt Back Platform Kit (Part #40676) are purchased

and assembled separately.

Tilt Platform Cap

Front Release Pin

Front

Release

Pin

Rear

Release

Pin

Rear

Release Pin

Roong Platform

Base

Side Arm

Side Arm

Panel Rest

Solar Tilt Back

Platform Assembly

Instructions

Collapsible Roofing

Platform Instructions

https://www.tiedown.com/pdf/

tranzvolt_g2_assembly_e1930.pdf

https://www.tiedown.com/pdf/

tranzvolt_solar_inst_e1939.pdf

https://www.tiedown.com/pdf/

tranzvolt_roofing platform_inst_e1938.pdf

https://www.tiedown.com/pdf/

tranzvolt_g2_assembly_e1930.pdf

https://www.tiedown.com/pdf/

tranzvolt_solar_inst_e1939.pdf

https://www.tiedown.com/pdf/

tranzvolt_roofing platform_inst_e1938.pdf

17

E1930, 10/28/22

TIE DOWN Safety Products Division • 800-241-1806 • 404-344-0000 • www.tiedown.com

• The TranzVolt must be in its final work site location and secured at the root top as instructed on pages 7-8.

• The TranzVolt should be equipped with either the Collapsible Roofing Platform or the Solar Tilt Back Platform.

• Prior to the Homing operation the synthetic cable must be installed on winding spool as instructed on pages 12-13.

• When the batteries are first inserted, listen for a beep/tone – Power Box is ready.

Setting the HOME position:

1. Press “START” on remote – you will hear an audible “click” as the remote connects to power box.

2. Press the up and down buttons to choose a comfortable working height

3. Press and release the “HOME” button one time. The TranzVolt will begin to climb the ladder very slowly until it bumps the top cap and

then return to the starting position you choose.

• If you need to change the TranzVolt position after the homing sequence, press and hold “JOG” button while pressing up or down.

• If it is desired to have the unit stop at an upper position below the top cap, the “HOME” button can be pressed at any time during the

slow climb. Either way, the unit will then return quickly back down to the lower position.

Loading and Unloading

1. Pressing the “STOP” button disarms the TranzVolt. This allows for safe loading and prevents accidental movement of the machine

during loading.

2. Load the materials onto the platform. If your loading the solar panel platform secure load with bungee cords.

3. To re-activate the system press “START”, you will hear an audible “click” as the remote connects to power box.

Press and release the “UP” button a single time to send the unit to the top position.

In case of emergency, press the “STOP” button.

4. The TranzVolt will stop at the top position set during homing. Unload the materials carefully.

5. Press and release the “DOWN” button to send the unit to the bottom.

NOTE: After homing, the platform positions will be saved until the unit is reset by removing and reinstalling the batteries.

Lower Home Position

Track Stop Brackets

Top Cap/Rollers

Upper Home Position

STOP

START

JOG

UP

DOWN

HOME

Press the START buon to

connect to the power box.

Press the UP and DOWN buons

to position the platform at a

comfortable level for loading

from the ground.

STOP

START

JOG

UP

DOWN

HOME

Press the HOME buon one time.

The unit will begin to climb the track

very slowly until it bumps the top

cap or the HOME buon is

pressed again.

HOME

TranzVolt G2 HOMING Process

18

E1930, 10/28/22

TIE DOWN Safety Products Division • 800-241-1806 • 404-344-0000 • www.tiedown.com

Safety Warnings

WARNING

BATTERIES MUST BE REMOVED

WHEN NOT IN USE.

Leaving the batteries in the

TranzVolt power box could result in

permanently dead batteries.

DO NOT TRANSPORT

ASSEMBLED

LADDERVATOR

THE UNSECURED TRANZVOLT POWER BOX/PLATFORM

MUST BE REMOVED BEFORE TRANSPORTING.

19

E1930, 10/28/22

TIE DOWN Safety Products Division • 800-241-1806 • 404-344-0000 • www.tiedown.com

TRANZVOLT G2 LADDERVATOR PRODUCT LINE LIMITED WARRANTY

Tie Down will repair or replace, free of charge, any part, or parts of the TranzVolt G2 Laddervator that are defective in material or

workmanship or both. The limited warranty is in effect for two (2) years for the TranzVolt G2 electrical power box and

six (6) months for all other TranzVolt G2 equipment. Warranty takes effect from date of purchase. Return the defective unit to

the dealer or contact Tie Down direct at 800-241-1806, (404) 344-0000.

This warranty does not apply to damage or loss caused by any or all of the following circumstances or conditions:

• Damage caused during assembly or installation.

• Parts, accessories, materials or components used with or replacing any TIE DOWN lift hoist part not obtained from or approved in

writing by TIE DOWN.

• Misapplication, misuse and failure to follow the directions or observe cautions and warnings on installation, operation, application,

inspection or maintenance specified in any TIE DOWN quotation, acknowledgment, sales literature, specification sheet or installation

instruction and service manual (“applicable literature”).

• Use of product in any other application other than those described in TIE DOWN’s product information materials.

If any TIE DOWN products are found upon TIE DOWN’s examination to have been defective when supplied, TIE DOWN will either: credit

the purchaser’s account for the purchase price of the TIE DOWN product; replace the TIE DOWN product; or repair the product. TIE DOWN

has sole discretion in choosing which option to provide. For this LIMITED WARRANTY to apply, TIE DOWN must receive notice of the

alleged defect within 30 days of either the discovery of the alleged defect or the expiration of the warranty period, whichever is earlier.

Any claim not made within this period shall conclusively be deemed waived.

If requested by TIE DOWN, purchaser shall return the alleged defective product to TIE DOWN for examination at purchasers’ expense. TIE

DOWN will not pay for expenses incurred in returning a product to TIE DOWN without TIE DOWN’s prior written authority. TIE DOWN shall

not be liable for any other expenses the purchaser incurs to remedy any defect. Purchasers waive subrogation on all claims under any

insurance.

Limitation of Liability: It is expressly agreed that the liability of TIE DOWN is limited. TIE DOWN does not function as an insurer. THE

REMEDIES SET FORTH IN THIS WARRANTY SHALL CONSTITUTE THE EXCLUSIVE REMEDIES AVAILABLE TO THE PURCHASER OR USER AND

ARE IN LIEU OF ALL OTHER REMEDIES, EXPRESS OR IMPLIED. THE LIABILITY OF TIE DOWN, WHETHER IN CONTRACT, IN TORT, UNDER

ANY WARRANTY OR OTHERWISE, SHALL NOT EXCEED THE PURCHASE PRICE OF THE PARTICULAR PRODUCT MANUFACTURED, SOLD OR

SUPPLIED BY TIE DOWN.

To Obtain Technical Assistance: To enable TIE DOWN to respond to a request for assistance or evaluation of customer or user operating

difficulty, please provide at a minimum the following information by calling 404-344-0000:

• Model number, serial number and all other data on the specific component which appears to be involved in the difficulty.

• The date and from whom you purchased your TIE DOWN product.

• State your difficulty, being sure to mention at least the following: application, nature of load involved, and weight of the load.

THIS WARRANTY DOES NOT COVER NOR EXTEND TO INCIDENTAL OR CONSEQUENTIAL DAMAGE. Some states do not allow the

exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you. This warranty

gives you specific legal rights, and you may also have other rights which vary from state to state.

No representative has authority to make any representation, promise or agreement except as stated in this Limited Warranty. TIE DOWN

reserves the right to make design and other changes upon its products without any obligation to install the same on any previously sold

or delivered products.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THOSE DESCRIBED ABOVE. EFFECTIVE OCTOBER 2022 THIS WARRANTY

SUPERSEDES ALL PRIOR WARRANTIES, WRITTEN OR IMPLIED.

Safety Products Division

605 Stonehill Drive SW, Atlanta, Georgia 30336

800-241-1806 • 404-344-0000 • www.tiedown.com

ISO 9001:2015 Certification

Intellectual property of TIE DOWN Inc. ©2022 TIE DOWN, Inc.

Instruction #08427 (E1930 Rev. 10/28/22)

The TranzVolt must be equipped with either the Collapsible Roofing Platform or the Solar Tilt Back Platform.

Setting the “HOME” Ground Level Work Position:

1. Press “START” on remote – you will hear an audible “click” as the remote connects to power box.

2. Press the “UP” and “DOWN” buttons to choose a comfortable working height.

3. Press and release the “HOME” button one time. The TranzVolt will begin to climb the ladder very slowly until it

bumps the top cap and then return to the starting position you choose.

• If you need to change the TranzVolt position after the homing sequence, press and hold “JOG” button while

pressing up or down.

• If it is desired to have the unit stop at an upper position below the top cap, the “HOME” button can be pressed

at any time during the slow climb. Either way, the unit will then return quickly back down to the lower position.

Loading and Unloading

1. Pressing the “STOP” button disarms the TranzVolt. This allows for safe loading and prevents accidental movement

of the machine during loading.

2. Load the materials onto the platform. If your loading the solar panel platform secure load with bungee cords.

3. To re-activate the system press “START”, you will hear an audible “click” as the remote connects to power box.

Press and release the “UP” button a single time to send the unit to the top position.

In case of emergency, press the “STOP” button.

4. The TranzVolt will stop at the top position set during homing. Unload the materials carefully.

5. Press and release the “DOWN” button to send the unit to the bottom.

NOTE: After homing, the platform positions will be saved until the unit is reset by removing and

reinstalling the batteries.

TranzVolt G2 Quick Reference HOMING Process

STOP

START

JOG

UP

DOWN

HOME

Press the START buon to

connect to the power box.

Press the UP and DOWN buons

to position the platform at a

comfortable level for loading

from the ground.

STOP

START

JOG

UP

DOWN

HOME

Press the HOME buon one time.

The unit will begin to climb the track

very slowly until it bumps the top

cap or the HOME buon is

pressed again.

Table of contents

Other TIE DOWN Ladder manuals

Popular Ladder manuals by other brands

Mitsutomo

Mitsutomo 02364 user manual

Hailo

Hailo HobbyStep Duo Aluminium 7285-801 Use and Operating Instructions

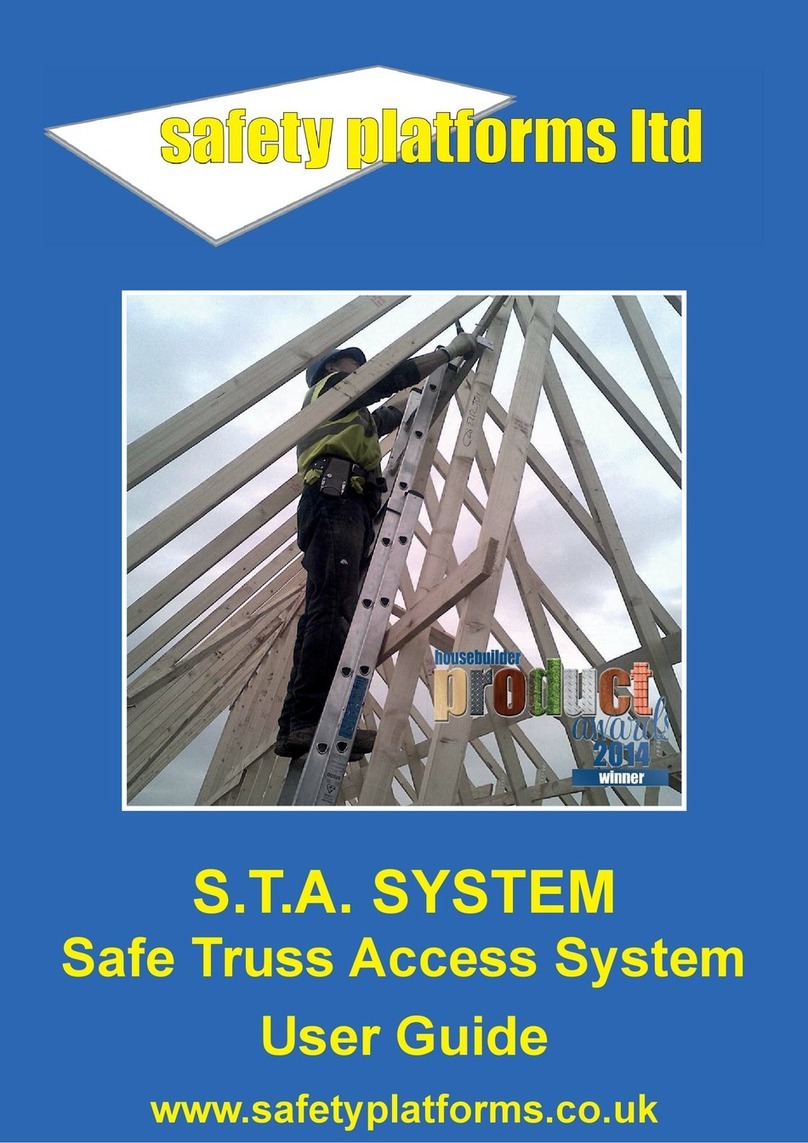

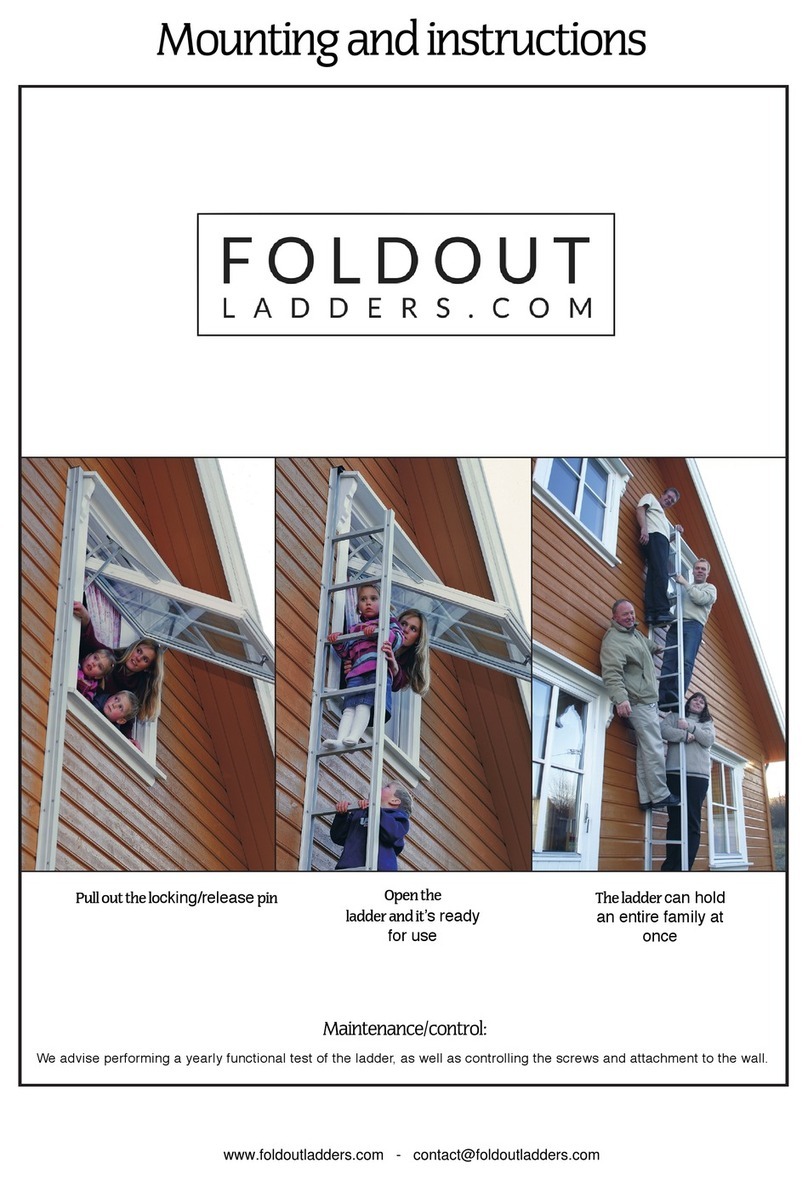

FOLDOUT LADDERS

FOLDOUT LADDERS 4,8 m Mounting and Instructions

Dolle

Dolle Gardentop Installation instruction

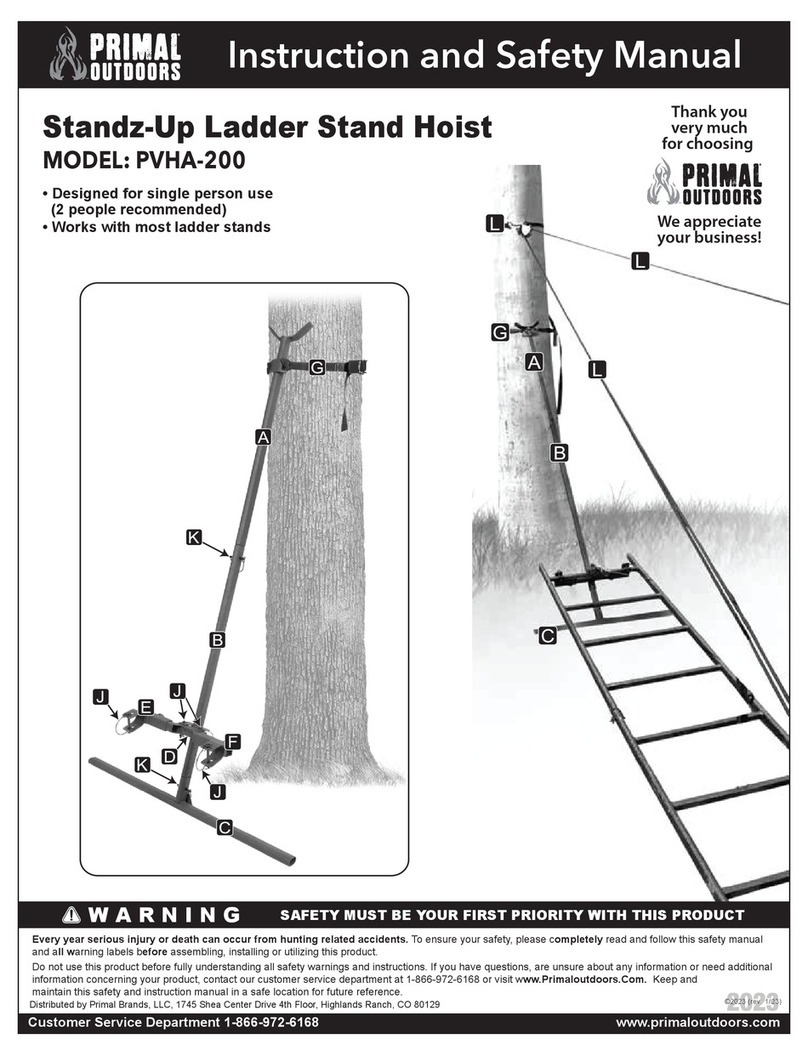

PRIMAL TREESTANDS

PRIMAL TREESTANDS PVHA-100 Instruction and safety manual

BorMann

BorMann PRO BHL5710 manual