Tiger Optics HALO M7000 Series User manual

HALO!Trace Gas Analyzer

Instruction Manual

M7000 Series

Rev G

HALO Users Manual Revision G

ii

Thank You

Dear Customer,

We commend you on your selection of the Tiger Optics HALO™ Trace Gas Analyzer. We

appreciate the time, effort, and money you devoted to selecting the equipment best suited to

your needs. We respect the fact that, by purchasing our equipment, you show your faith in our

technology and our organization. Therefore, we pledge to repay you with exceptional quality,

service, and support.

Tiger Optics provides instrumentation of the highest quality and finest precision for some of

industry's toughest analytical and measurement tasks. As the field of moisture analysis grew

and changed over the past few decades, our experienced design team led in product

innovation. Thus, our second pledge to our customers is to continue to keep pace with market

needs now and long into the future.

Finally, thank you for choosing a Tiger Optics HALO™ Trace Gas Analyzer. Please remember

that we value your opinion as much as your patronage. We welcome your comments,

questions, and suggestions about our equipment.

Sincerely,

The Tiger Optics Staff

" 2006 Tiger Optics, LLC All rights reserved. No part of this publication may be reproduced, transmitted,

transcribed, stored in a retrieval system, or translated into any language in any form by any means

without the written permission of Tiger Optics.

HALO! is a trademark of Tiger Optics LLC.

Teflon® is a registered trademark of E.I. DuPont de Nemours and Company

Snoop® is a registered trademark of the Swagelok Company

VCR® is a registered trademark of the Swagelok Company

Tiger Optics LLC, 250 Titus Avenue, Warrington, PA 18976, U.S.A.

(215) 343-6600, FAX (215) 343-4194 http:// www.tigeroptics.com

HALO Users Manual Revision G

iii

TIGER OPTICS WARRANTY

Tiger Optics, LLC warrants all equipment manufactured and repaired to be free from defects in material

and workmanship, given proper use and service. Tiger Optics’ obligation under this warranty is limited to

repairing or, if necessary, replacing any article of equipment within one (1) year from date of shipment,

without charge, F.O.B. Tiger Optics’ factory. Such equipment or parts must be returned to Tiger Optics

(transportation prepaid). Parts and service repairs are warranted against manufacturer’s defects for 90

days. Please contact Tiger Optics’ Service Department for a Return Authorization (RA) number prior to

returning the unit. All units and/or cells returned without an RA number may be sent back at customer

expense. Units manufactured seven (7) years prior or older, may not be repairable based on available

components. Please contact the Tiger Optics Service Department prior to returning the unit.

Items considered expendable, such as fuses are not under warranty. This warranty shall not apply to

equipment and parts repaired or altered outside of Tiger Optics’ factory or its authorized service centers.

It also does not apply to equipment and parts subjected to negligence, accidental damage or improper

installation, or use not in accordance with the instructions provided in the instruction manual. Tiger Optics

LLC, neither assumes, nor authorizes any other persons to assume for it, any liability in connection with

the sales of its products.

Tiger Optics Service

Phone: (215) 343-6600

250 Titus Avenue

FAX: (215) 343-4194

Warrington, PA 18976

Toll Free: (800) 641-6478

HALO Users Manual Revision G

iv

IMPORTANT CAUTION SYMBOLS

Warning! Labels

NOTE: Before operating the HALO please be sure to read all the warning or caution

notes, which are shown throughout the manual. We have listed all of the warning

notes on this page for your convenience. You must read this instruction manual

completely before operating your HALO. Failure to do so may cause damage to

your unit.

Use of this analyzer with gases that are toxic, explosive, or those which may create explosive

mixtures (like hydrogen and oxygen), requires complete purging with an inert gas. Failure to

remove all gas residue by not purging with an inert gas will expose you to risk of injury or

explosion.

Use only an approved detachable power cord. (1 meter, 120V or 220V, 2 pole, 3 wire, ground,

15 amp power cord)

Disconnect the analyzer from AC power source before performing any maintenance or repair

function inside the case.

This CAUTION symbol alerts the user to information regarding personal safety.

This HIGH VOLTAGE symbol indicates the presence of a high voltage danger.

This CAUTION symbol alerts the user to the presence of laser radiation.

HALO Users Manual Revision G

v

Table of Contents

List of Tables vii

1Theory of Operation 1

1.1 Cavity Ringdown Spectroscopy 1

1.2 How it Works 1

2Specifications and Drawings 4

2.1 Specifications 4

2.2 Dimension Drawing 8

2.3 Dimension Drawing of a Single HALO Unit 9

2.4 Front Panel of HALO Unit 10

2.5 Rear Panel of HALO Unit 11

3Installing Your HALO 12

3.1 Overview 12

3.2 Unpacking Your HALO 12

3.3 Serial Number Identification 14

3.4 Preparing the Sample Line 15

3.5 Assembling the Sample Line 16

3.6 Leak-Testing the Sample Line 17

3.7 HALO Location 18

3.8 Pressure and Venting Considerations 19

3.9 Connection Considerations 20

3.10 Connecting to the Sample Inlet and Outlet 21

HALO Users Manual Revision G

vi

3.11 Powering On and Configuration 22

3.12 Capping the Sample Inlet and Outlet to Avoid Contamination 23

4Basic Operation 24

4.1 Introduction 24

4.2 User Interface 24

4.3 Modes of Operation 30

4.4 Other Toolbar Functions 31

4.5 Ringdown Alarm 32

5Data Capture Guide 33

5.1 Setting up the Connection 33

5.2 Saving Data to a Text File 35

5.3 Deleting Data from HALO Memory 35

6Remote Operations 36

6.1 Overview 36

6.2 Interfacing 36

6.3 Commands 37

7Troubleshooting and Maintenance 43

7.1 General Information 43

7.2 Preventive Maintenance 43

7.3 Troubleshooting Guide 44

7.4 Return a Unit for Repair 45

8Special Considerations for H2O Measurement 47

HALO Users Manual Revision G

vii

List of Tables

Table 2-1 HALO-H2O Trace Gas Analyzer Specifications ....................................... 4

Table 2-2 HALO-CH4Trace Gas Analyzer Specifications........................................ 6

Table 3-1 Unpacking Your HALO ............................................................................ 12

Table 3-2 Procedure for Preparing the Sample Line ............................................. 16

Table 3-3 Procedure for Leak-Testing the Sample Line........................................ 17

Table 3-4 HALO Location......................................................................................... 18

Table 3-5 Connecting to the Sample Inlet and Outlet............................................ 21

Table 3-6 Capping the Sample Inlet and Outlet ..................................................... 23

Table 6-1 RS-232 DB-9F Pin Designation ............................................................... 36

Table 6-2 Host to HALO Connections..................................................................... 36

Table 7-1 Troubleshooting ...................................................................................... 44

List of Figures

Figure 1-2 Ringdown Time ....................................................................................... 2

Figure 1-3 Absorption Spectrum.............................................................................. 2

Figure 1-4 Concentration (N) Calculation................................................................ 3

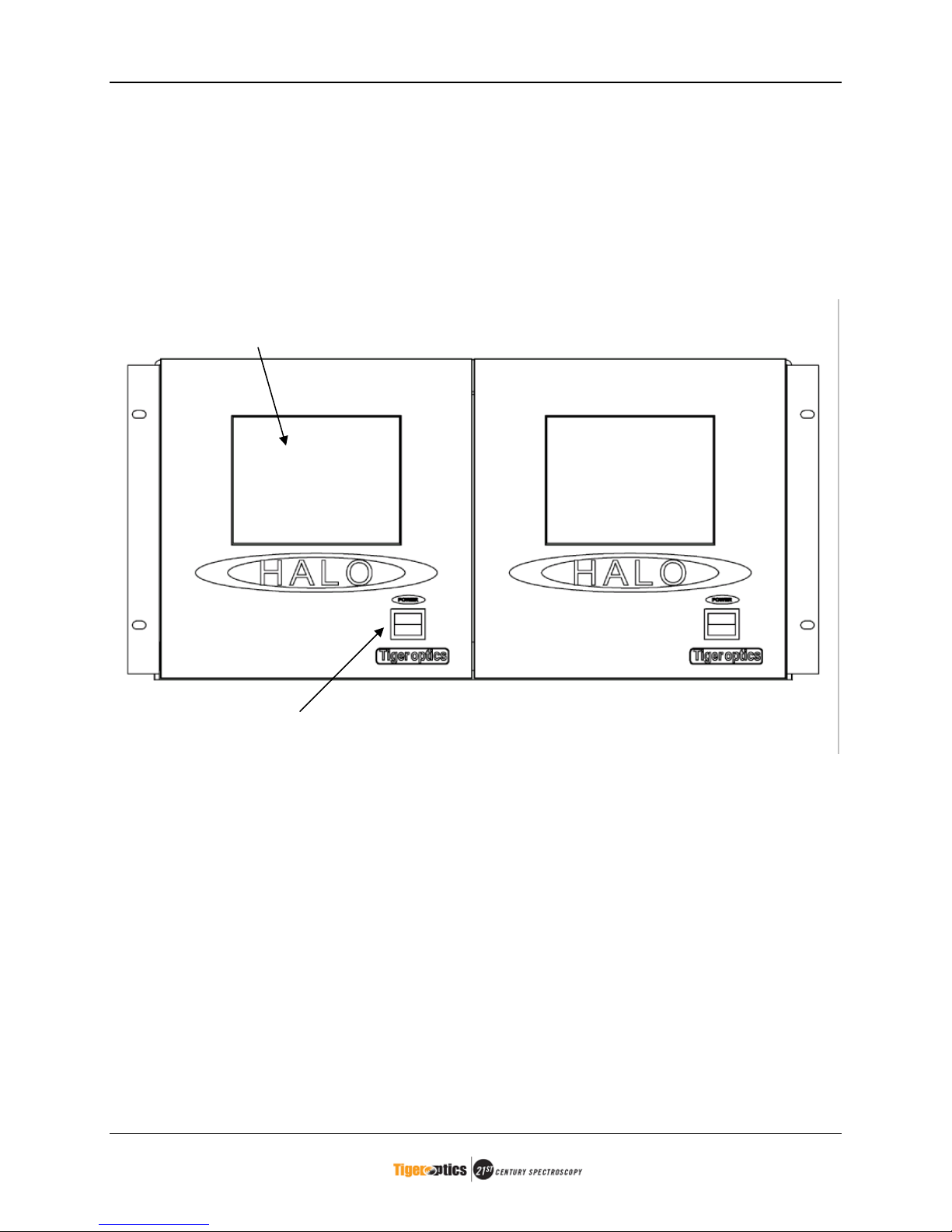

Figure 2-1 HALO Two Unit Dimension Drawing ..................................................... 8

Figure 2-2 HALO Single Unit Dimension Drawing.................................................. 9

Figure 2-3 HALO Two Unit Front Panel ................................................................. 10

Figure 2-4 HALO Two Unit Rear Panel .................................................................. 11

Figure 3-1 Serial Number Identification................................................................. 14

HALO Users Manual Revision G

viii

Figure 3-2 Alarm Relay and mA Output Connector.............................................. 18

Figure 3-3 Flow Diagram......................................................................................... 20

Figure 4-1 Virtual Keypad ....................................................................................... 24

Figure 4-2 Main Display .......................................................................................... 25

Figure 4-3 Gas Type Setup Tab of the Settings Window ..................................... 26

Figure 4-4 Output and Communications Tab of the Settings Window ............... 27

Figure 4-7 Operating Mode Select Window........................................................... 30

Figure 4-8 Trend Graph........................................................................................... 31

Figure 4-9 Ringdown Signal ................................................................................... 32

Figure 5-1 Connection Setup Windows................................................................. 33

Figure 5-2 Port Settings, HALO Properties, and ASCII Setup ............................. 34

Figure 5-3 Connection Test .................................................................................... 34

Figure 5-4 Capture Text .......................................................................................... 35

HALO Users Manual Revision G

1

1 Theory of Operation

1.1 Cavity Ringdown Spectroscopy

Based on absorption spectroscopy, Cavity Ringdown Spectroscopy (CRDS) works by

attuning light rays from a Continuous Wave (CW) laser to a wavelength within the IR

spectrum where a contaminant absorption peak occurs (Figure 1-3). By measuring the time

it takes for the light to fade, or “ringdown” an accurate molecular count is calculated that is

not pressure sensitive. The time of light decay, in essence, provides an exact, non-invasive,

and rapid means to detect contaminants in gases.

1.2 How it Works

# A Continuous Wave (CW) diode laser emits a directed beam of light energy through an

ultra-high reflective mirror into the absorption cell (cavity).

Figure 1-1 Cavity Ringdown Spectroscopy

# The light reflects back and forth between two ultra-high reflective mirrors multiple times

# On each successive pass, a small amount of light or ringdown signal emits through the

second mirror and is sensed by the light detector

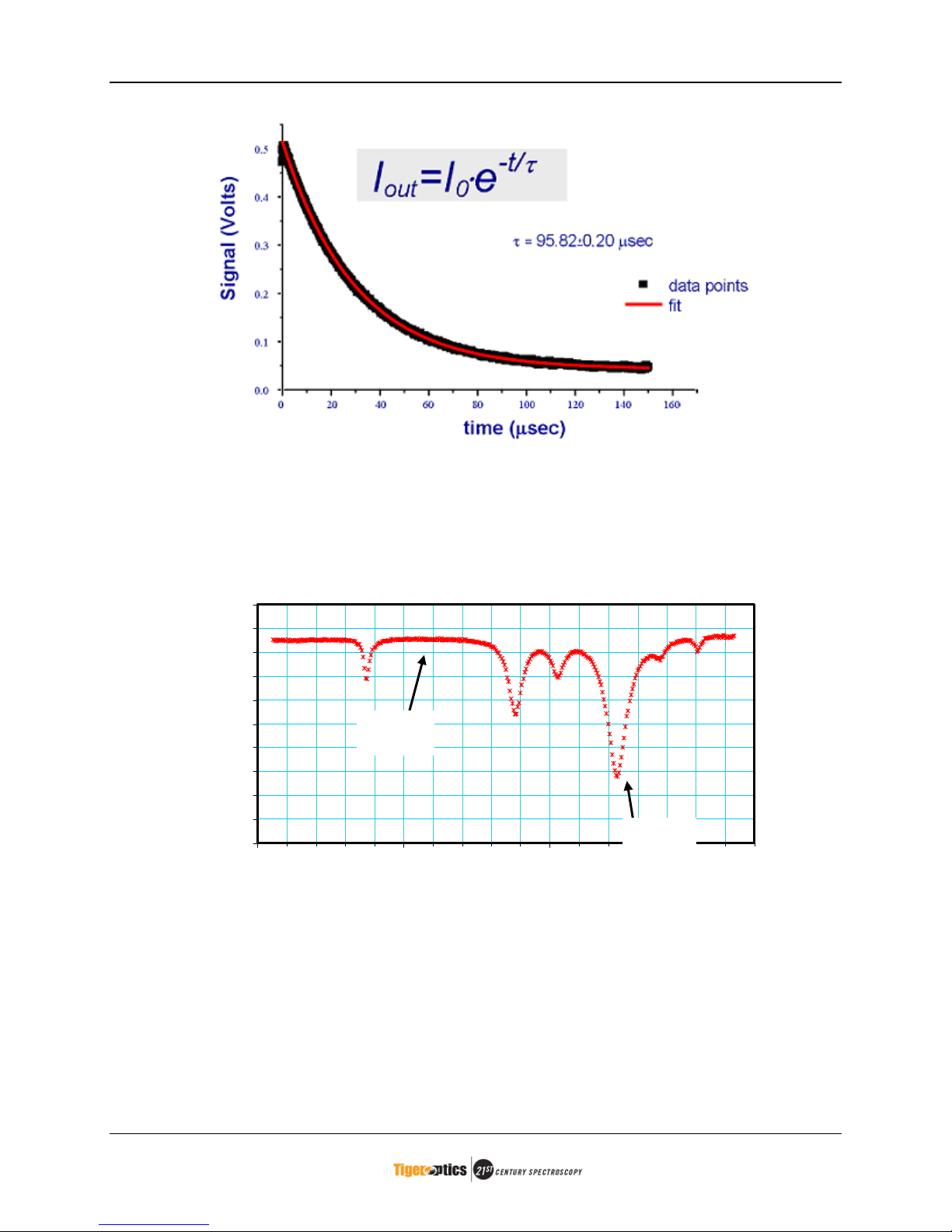

# Once the photodiode detector “sees” a preset level of light energy, the light source is

shuttered, or diverted from the cavity (time ~ 0 Figure 1-2)

# Once the light decays, or “rings down”, the detector achieves a point of zero light energy

in microseconds, and the measurement is complete (time ~ 150 Figure 1-2). This decay

is exponential, and described by the equation listed in Figure 1-2.

Light

Source

Light

Detector

Highly

Reflective

Mirrors

HALO Users Manual Revision G

2

Figure 1-2 Ringdown Time

# The computer-controlled system tunes the laser off the absorption peak for the sample

species to determine the “tau zero” value, equivalent to a zero baseline (Figure 1-3).

Figure 1-3 Absorption Spectrum

# The concentration of the sample species is calculated (Figure 1-4) by comparing this “tau

zero” value to the ”tau measured” ringdown time.

# These calculations are based on first principles and follow the Beer-Lambert Law.

0

10

20

30

40

50

60

70

80

90

100

1391.3 1391.8 1392.3 1392.8

Wavelength (nm)

$(%sec)

&'(&$zero

&'(&$peak

HALO Users Manual Revision G

3

)1( Rc

d

zero )

*

$

))()1((

)( NdRc

d

+,

+

$

-)

*

)

1

)(

1

(

)(

1

z

ero

c

N

$+$+,

)*

c = Speed of Light != Absorption Cross Section

d = Cell Length $(+)="Ringdown Time

R = Reflectivity of the Mirror += Laser Frequency

N = Molecular Density

(concentration)

Figure 1-4 Concentration (N) Calculation

HALO Users Manual Revision G

4

2 Specifications and Drawings

2.1 Specifications

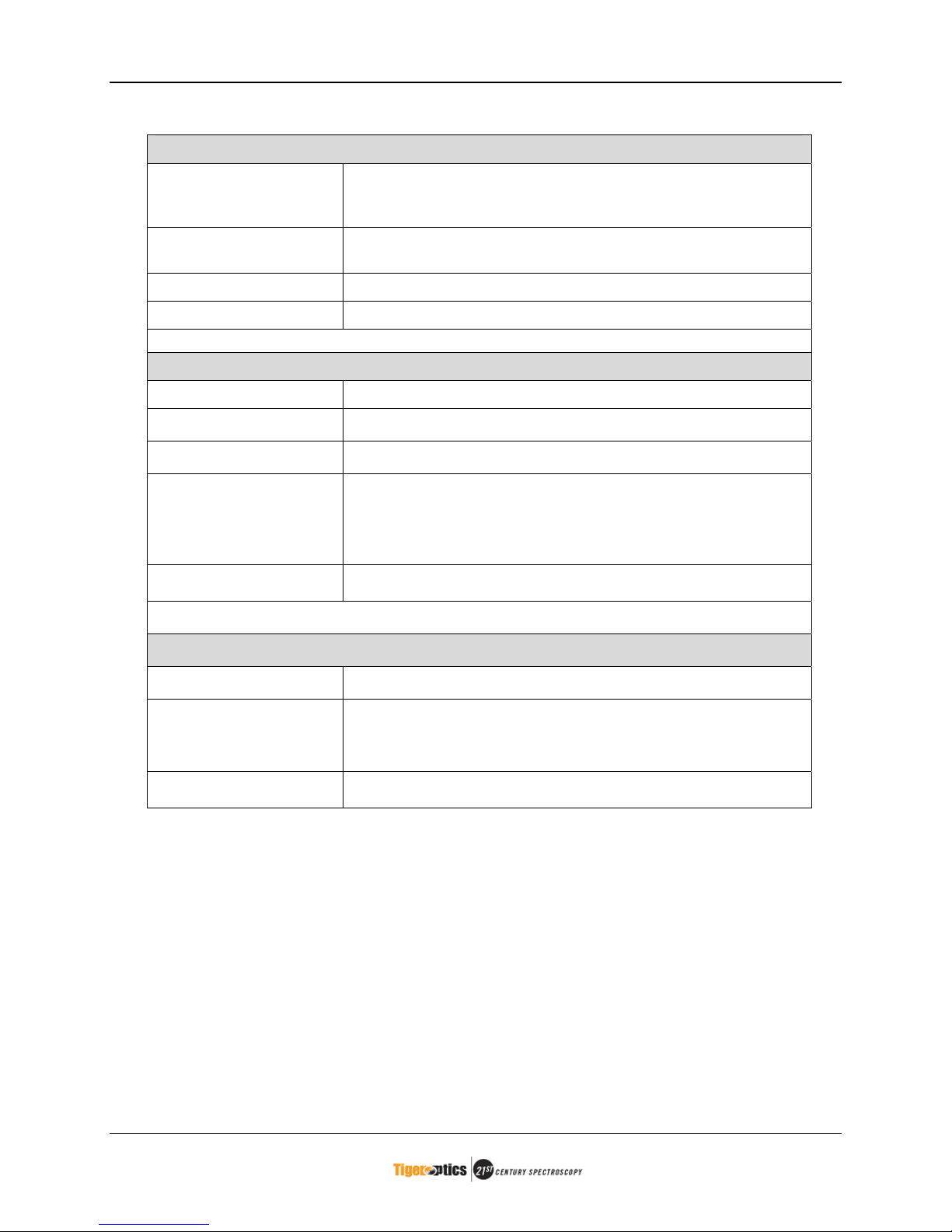

Table 2-1 HALO-H2O Trace Gas Analyzer Specifications

Performance

Lowest Detection Limit 2 ppb

Sensitivity 1 ppb

Accuracy 4% of reading or +/- 1 ppb if greater

Speed of Response

(typical)

Dry down response from 1ppm intrusion to 90% of final value in

<3min

Wet up response to 1ppm intrusion – 90% of final value in <2min

Operating Range 0 – 20000 ppb

Environmental Conditions 10º - 40ºC - - - 30% to 80% R.H. Non-condensing

Storage Temperature -10°C to 50°C

Technology

Method Cavity Ring-Down Spectroscopy (CRDS)

Laser Light Source Continuous Wave (CW) Near-IR diode laser

Approvals CE Marked – LVD and EMC approved

Patents U.S. Patent # 5,528,040

U.S. Patents Pending

Gas Sample Conditions

Sample Inlet Pressure 10 – 125 psig (1.7 – 9.6 bara)

Sample Outlet Pressure < 2.0 psig back pressure (or vacuum)

Flow Rate 0.5 to 1.8 slpm depending on gas type

Sample Gases

Ar, H2, HBr, HCl, He, N2, O2, SF6, CF4, Cl2, CO2, CDA, and CO

(contact Tiger Optics for additions to the list of sample gases).

Sample line temperature Up to 60ºC

HALO Users Manual Revision G

5

Gas Flow System

Wetted Components 316L stainless steel (optional: Hastelloy ®), Elgiloy, PCTFE, 304

stainless steel, fused silica, nickel plated stainless steel, and

nickel plated copper.

Surface Finish of Wetted

Components

10 Ra

Fittings and Connections ¼” VCR-type

Leak tested to: < 2 x 10-8 mbar · liter /sec

Electrical

Power Requirements 90-250 VAC 50/60 Hz

Power Consumption 40 Watts max

Alarm Indicators User programmable alarm set points

Output Signals

Recorder

Alarm

Isolated 4-20 mA output

2-Form-C relay (user configurable)

1-Form-C relay for system fault monitoring (Laser status &

ringdown status)

802.11g Wireless (optional)

User Interface 5.6” Color LCD display with touch screen

10BaseT Ethernet, RS-232 (can be changed to RS-422)

Mounting and Hook-up Considerations

Configuration 2 Units per 19” relay rack or mobile cart mount

Dimensions Individual Module –

8.73”h x 8.57”w x 23.58”d (22.2cm x 21.7cm x 59.9cm)

Two Modules in rack housing –

8.73”h x 17.5”w x 23.58”d (22.2cm x 44.5cm x 59.9cm )

Weight Individual Module –

28 lbs. (12.7 kg)

HALO Users Manual Revision G

6

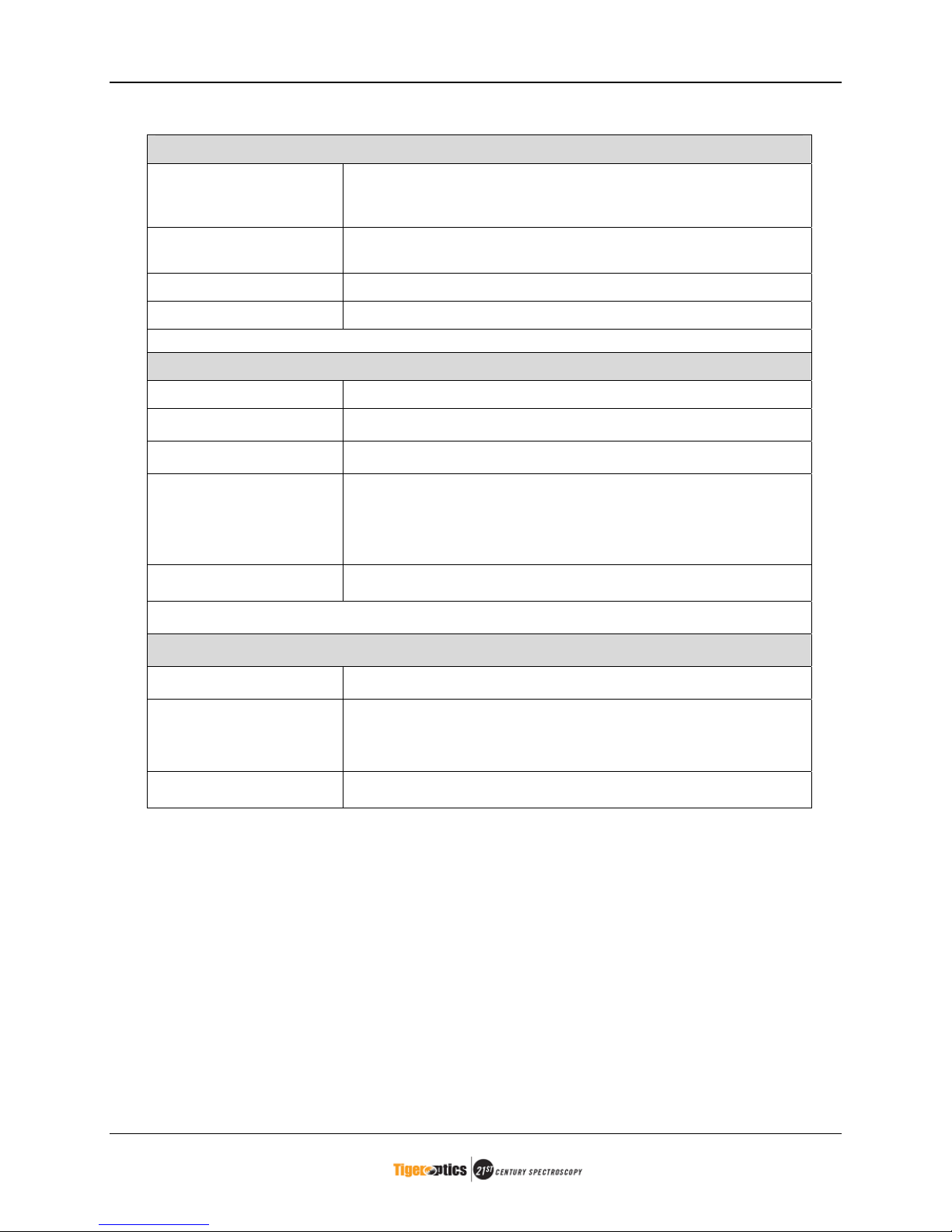

Table 2-2 HALO-CH4Trace Gas Analyzer Specifications

Performance

Lowest Detection Limit 4 ppb

Sensitivity 2 ppb

Accuracy 4% of reading or +/- 2 ppb if greater

Speed of Response

(typical)

Dry Down Response to 50ppb intrusion - 90% of final value in

<1min

Operating Range 0 – 8000 ppb

Environmental Conditions 10º - 40ºC - - - 30% to 80% R.H. Non-condensing

Storage Temperature -10°C to 50°C

Technology

Method Cavity Ring-Down Spectroscopy (CRDS)

Laser Light Source Continuous Wave (CW) Near-IR diode laser

Approvals CE Marked – LVD and EMC approved

Patents U.S. Patent # 5,528,040

U.S. Patents Pending

Gas Sample Conditions

Sample Inlet Pressure 30 – 125 psig (3.1 – 9.6 bara)

Sample Outlet Pressure < 2.0 psig back pressure (or vacuum)

Flow Rate 0.5 to 1.8 slpm depending on gas type

Sample Gases

N2, He, Ar, H2, and O2 (contact Tiger Optics for additions to the

list of sample gases).

Sample line temperature Up to 60ºC

HALO Users Manual Revision G

7

Gas Flow System

Wetted Components 316L stainless steel (optional: Hastelloy ®), Elgiloy, PCTFE, 304

stainless steel, fused silica, nickel plated stainless steel, and

nickel plated copper.

Surface Finish of Wetted

Components

10 Ra

Fittings and Connections ¼” VCR-type

Leak tested to: < 2 x 10-8 mbar · liter /sec

Electrical

Power Requirements 90-250 VAC 50/60 Hz

Power Consumption 40 Watts max

Alarm Indicators User programmable alarm set points

Output Signals

Recorder

Alarm

Isolated 4-20 mA output

2-Form-C relay (user configurable)

1-Form-C relay for system fault monitoring (Laser status &

ringdown status)

802.11g Wireless (optional)

User Interface 5.6” Color LCD display with touch screen

10BaseT Ethernet, RS-232 (can be changed to RS-422)

Mounting and Hook-up Considerations

Configuration 2 Units per 19” relay rack or mobile cart mount

Dimensions Individual Module –

8.73”h x 8.57”w x 23.58”d (22.2cm x 21.7cm x 59.9cm)

Two Modules in rack housing –

8.73”h x 17.5”w x 23.58”d (22.2cm x 44.5cm x 59.9cm )

Weight Individual Module –

28 lbs. (12.7 kg)

HALO Users Manual Revision G

8

2.2 Dimension Drawing

The HALO dimensions of the front, rear and side views are shown in Figure 2-1. Two analyzers

will fit into a 19” relay rack.

Figure 2-1 HALO Two Unit Dimension Drawing

HALO Users Manual Revision G

9

2.3 Dimension Drawing of a Single HALO Unit

Figure 2-2 HALO Single Unit Dimension Drawing

HALO Users Manual Revision G

10

2.4 Front Panel of HALO Unit

Figure 2-3 HALO Two Unit Front Panel

Color LCD Display and

Touch Screen

Power Switch

HALO Users Manual Revision G

11

2.5 Rear Panel of HALO Unit

Figure 2-4 HALO Two Unit Rear Panel

Sample Inlet Sample Outlet

RS-232 Connection I/O Connection

Power Connection Ethernet Connection

HALO Users Manual Revision G

12

3 Installing Your HALO

3.1 Overview

Once you receive the HALO analyzer, the basic steps to install it are:

# Unpack and inspect the unit

# Identify serial number

# Prepare the sample line

# Make electrical connections

# Connect the sample inlet and outlet

3.2 Unpacking Your HALO

Table 3-1 Unpacking Your HALO

Step Action

1 Inspect the shipping carton prior to opening. If any damage is

apparent, immediately notify the shipping company and Tiger

Optics. Do not proceed with installation.

2 Remove the analyzer from its carton and again, examine the unit

for damage. If damage is apparent, immediately notify the

shipping company and Tiger Optics. Do not proceed with

installation.

3 Check the carton contents against the packing slip to ensure the

shipment is complete. Each HALO will include separately at least

the following items:

- Power cord

- Certificate of calibration

- Quick Start Guide

- RS-232/USB converter cable

Any missing items should be reported to Tiger Optics

immediately.

4 The HALO is shipped ready for use. To keep the Ring-Down

Cavity dry and clean during shipping the gas inlet and outlet

connections are capped. To avoid contamination these caps

must stay in place until the unit is connected to the gas supply.

5 Record the model number and serial number in your permanent

record file. You will need these numbers for any future communication

with Tiger Optics. A description of the serial number follows this

section.

ATTENTION: Save Caps!

Save the gas inlet and outlet caps. Whenever the unit is not connected to gas, put

these caps back on the inlet and outlet fittings to keep the Ring-Down Cavity and

internal tubing clean and free of contamination.

Table of contents

Popular Measuring Instrument manuals by other brands

Endress+Hauser

Endress+Hauser COM 381 operating instructions

MAGEE Scientific

MAGEE Scientific Aethalometer AE33 user manual

Solinst

Solinst 9700 SolSat 5 quick start guide

Omega

Omega LVCN-40 Series user guide

Fema Electronica

Fema Electronica BDF Series user manual

Seikom Electronic

Seikom Electronic RLSW 8 LCD user manual

Hy-Gain

Hy-Gain 421A Installation and operation instruction

Emerson

Emerson World Class 3000 instruction manual

Keysight Technologies

Keysight Technologies N9320A RF Configuration guide

oxford diffraction

oxford diffraction Xcalibur A user manual

Sonic Meter

Sonic Meter Sonic AO operating manual

HBM

HBM KMR Mounting instructions