Tigercat X870C User manual

Other Tigercat Construction Equipment manuals

Tigercat

Tigercat 822C User manual

Tigercat

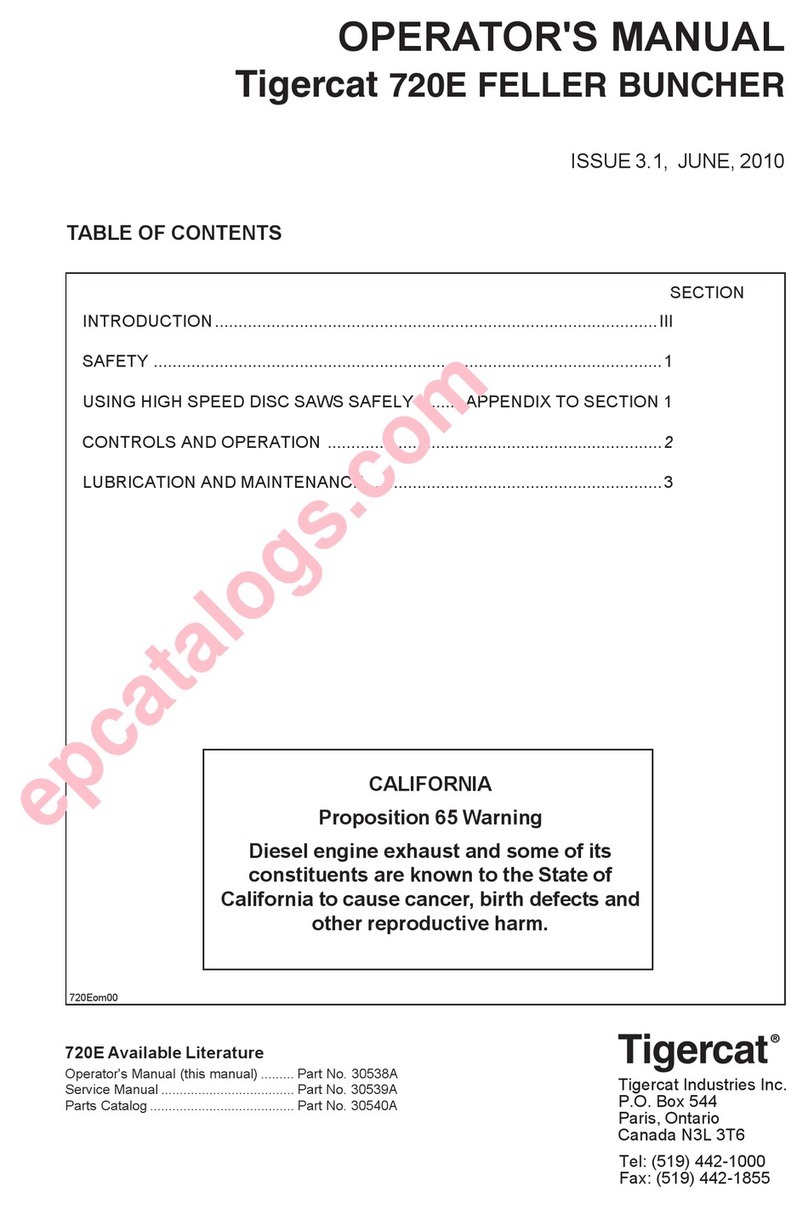

Tigercat 720E User manual

Tigercat

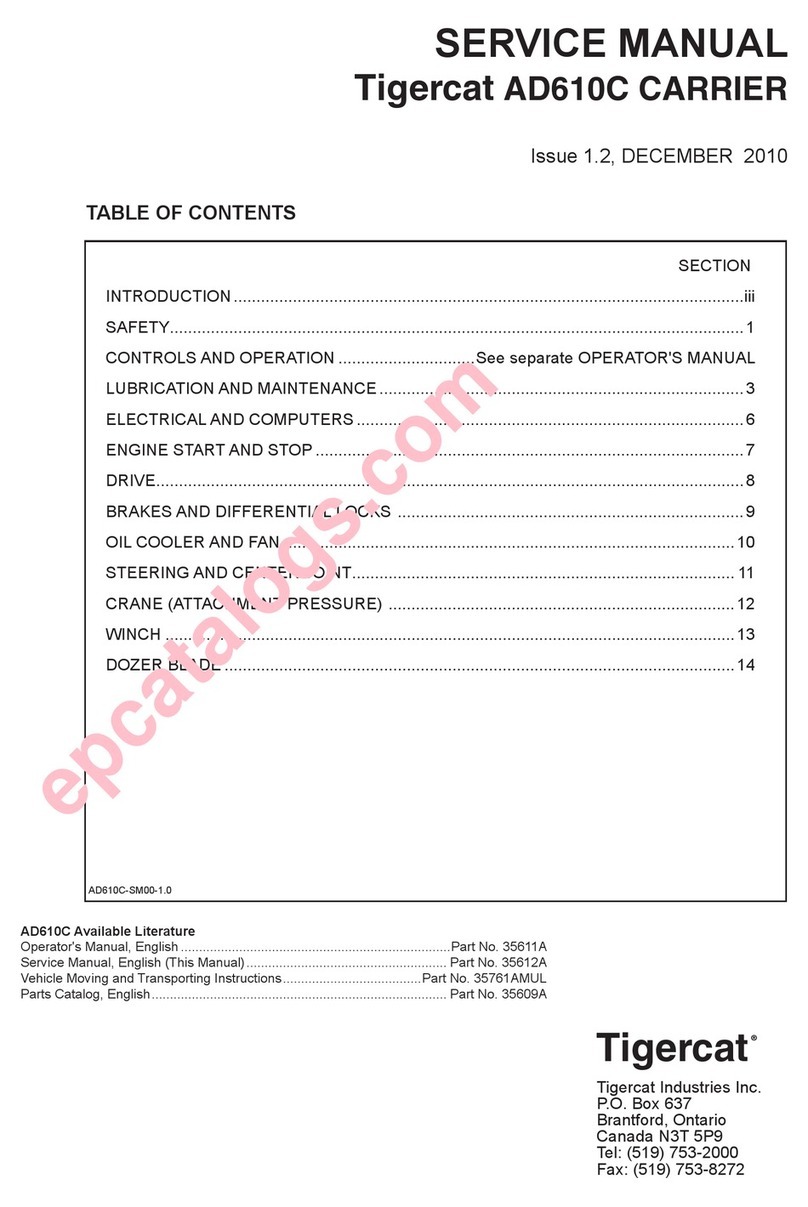

Tigercat AD610C User manual

Tigercat

Tigercat T234 User manual

Tigercat

Tigercat 615C User manual

Tigercat

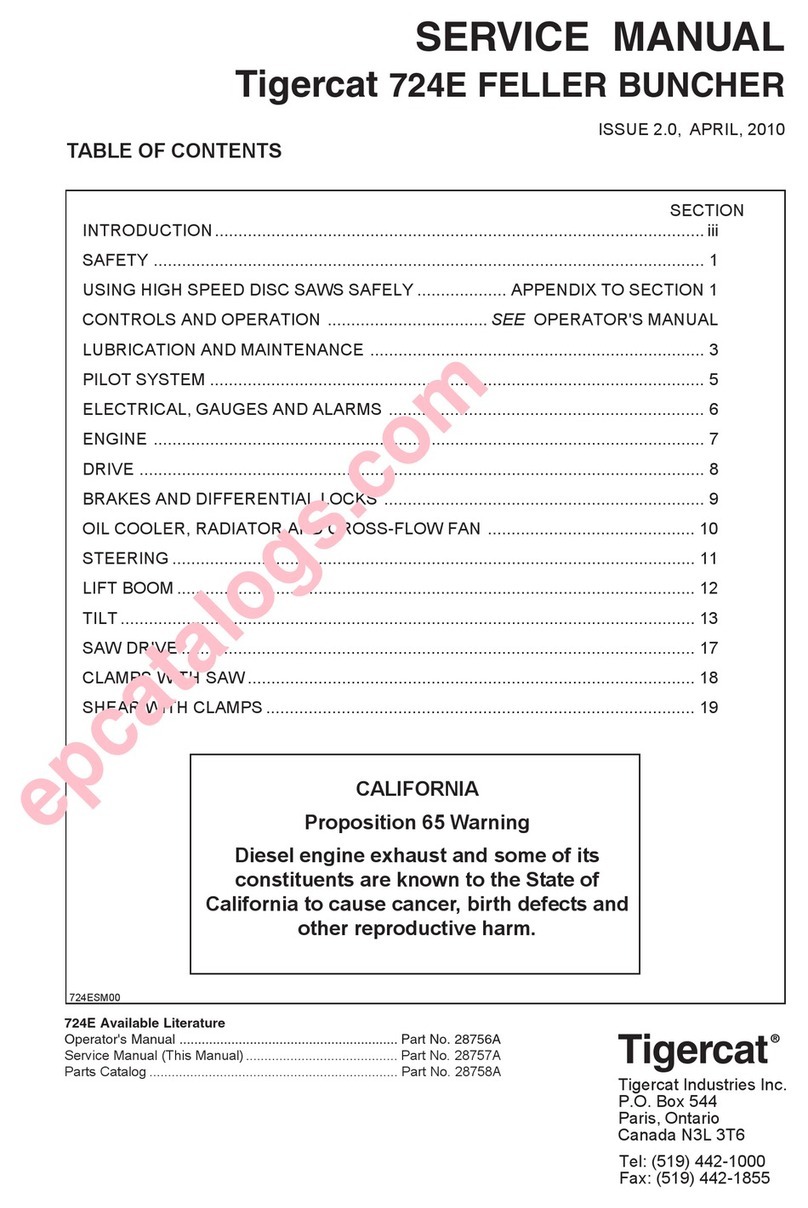

Tigercat 724E User manual

Tigercat

Tigercat X822C User manual

Tigercat

Tigercat F610C FORWARDER User manual

Tigercat

Tigercat LH830 User manual

Tigercat

Tigercat C640C User manual

Tigercat

Tigercat 234 Series User manual

Tigercat

Tigercat 1135 User manual

Tigercat

Tigercat 244 User manual

Tigercat

Tigercat S860 User manual

Tigercat

Tigercat M726E User manual

Tigercat

Tigercat 855C User manual

Tigercat

Tigercat 880 User manual

Tigercat

Tigercat T250B User manual

Tigercat

Tigercat T234B User manual

Tigercat

Tigercat 220C User manual

Popular Construction Equipment manuals by other brands

Batavia

Batavia CROC LOCK BT-CL001 operating instructions

probst

probst SRG-UNI-1.5 operating instructions

Komatsu

Komatsu GALOE WA320PT-5L Operation and maintenance manual

Conquip

Conquip FA811AC-03000 user guide

CertainTeed

CertainTeed VAC-MATIC 48P-4-14 manual

Dynapac

Dynapac SD2500C Operation & maintenance manual

Komatsu

Komatsu D65EXi-18 Operation & maintenance manual

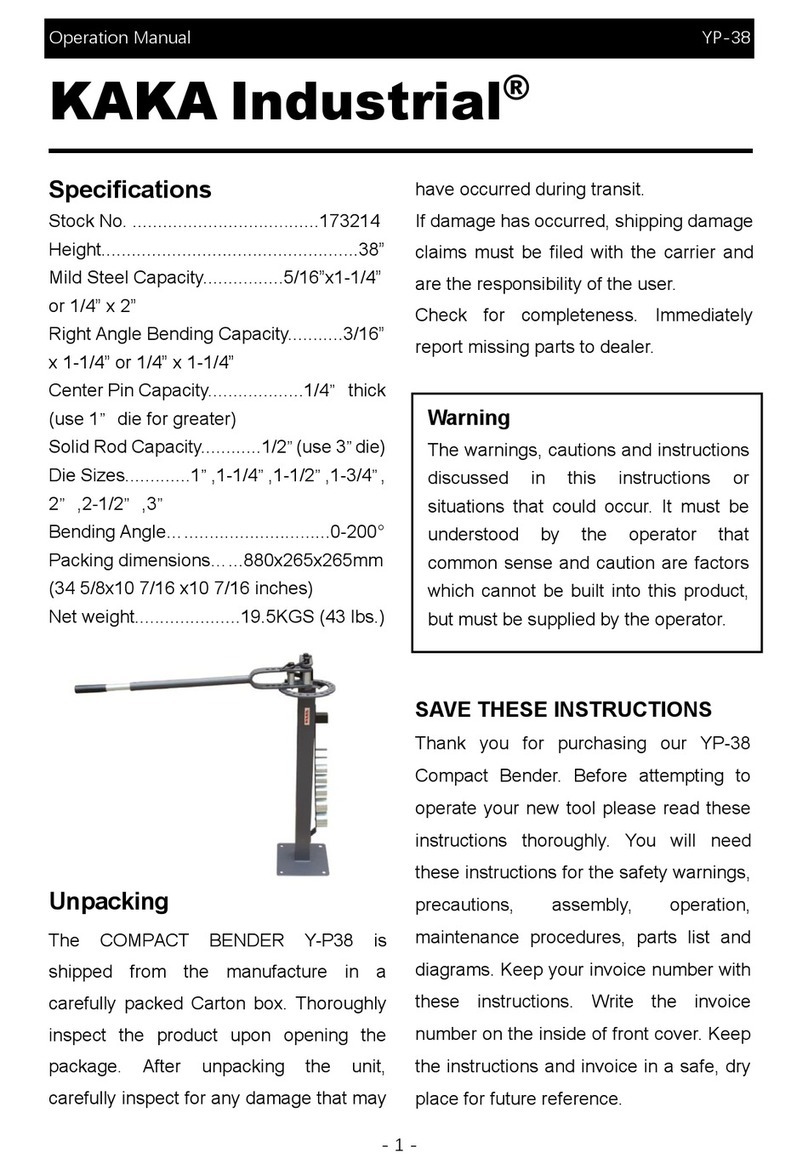

KAKA Industrial

KAKA Industrial YP-38 Operation manual

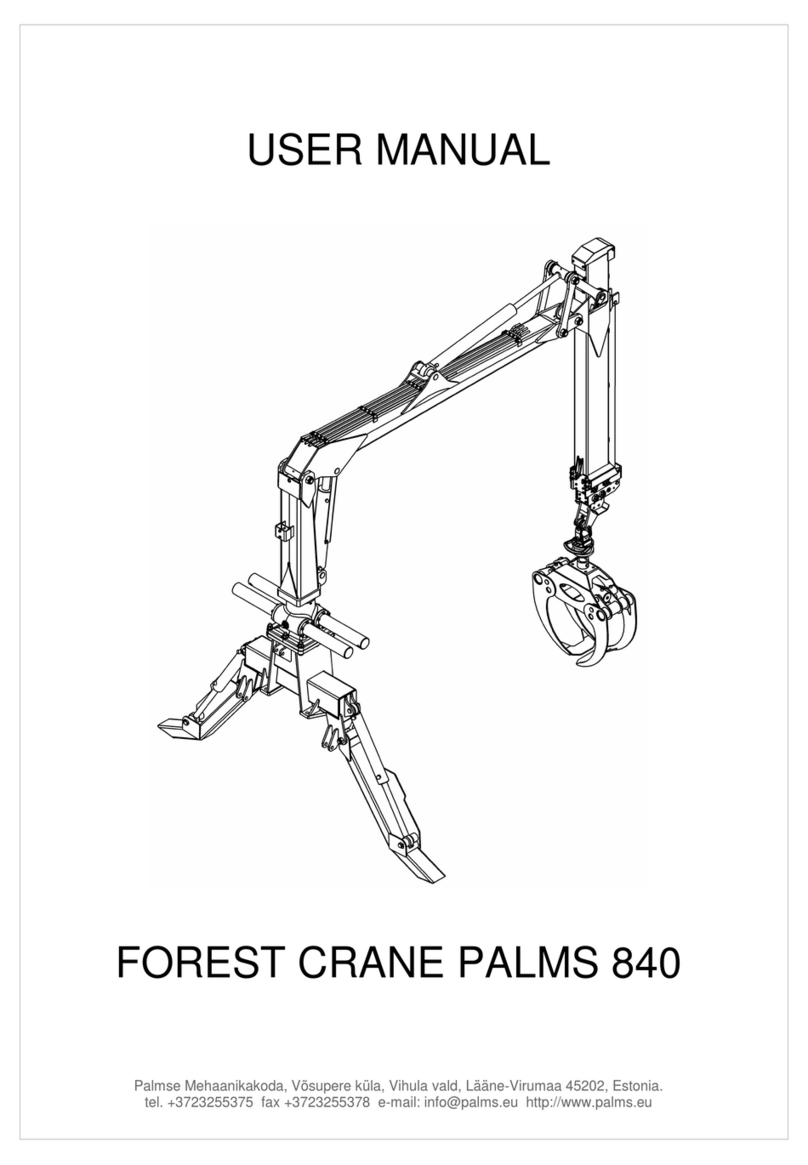

Palms

Palms 840 user manual

babcockdavis

babcockdavis eleGRIL BGE38H Installation, operation and maintenance manual

Graco

Graco LineLazer 200HS Installation, operation & parts

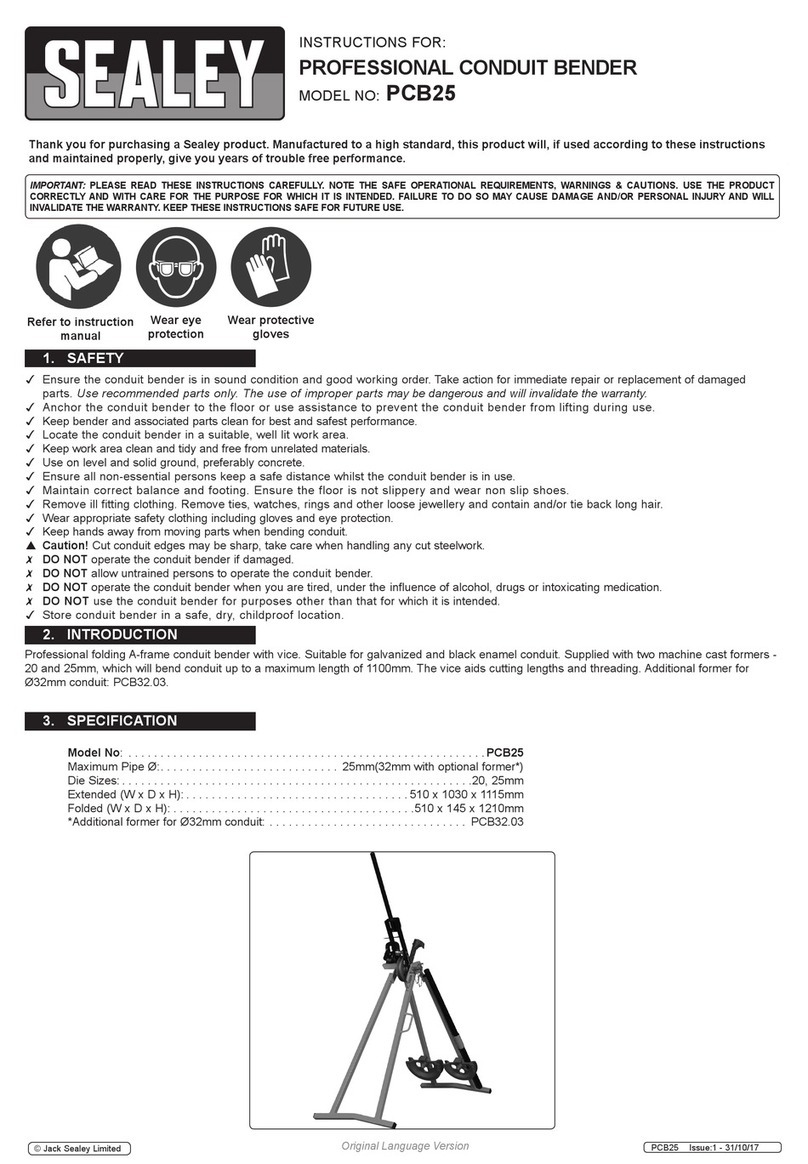

Sealey

Sealey PCB32 instructions