TigerStop SawGear Touch User manual

User Manual

SawGear Touch™

iii

Table of Contents

1 Contact Us

2 Parts Inventory

2 Power Head ToucH

2 Saw Gear Beam

2 FliP-away SToP aSSemBly

3 SToPS

3 BencH mounT aSSemBly

4 TaBle aSSemBly (oPTional)

6 SawGear Touch Installation

6 elecTrical requiremenTS

6 SawGear TaBle inSTallaTion

10 SawGear BencH mounT BrackeTS

12 connecTinG THe FliP-away SToP

12 aTTacHinG THe SToP Bar

13 connecTinG THe Power Head ToucH

15 SawGear Touch Setup

15 1ST Power-on

17 SawGear Touch Operation

17 SawGear ToucH Home Screen

18 normal Power-on

18 manual movemenT

20 SawGear Touch Navigating

Menus

20 main menu Screen

20 naviGaTinG SeTuP & mySawGear menuS

21 SawGear Touch Setup

Menu

21 Scale

21 uniTS

21 caliBraTion

21 auToTeST rouTine

22 minmax rouTine

22 Home rouTine

22 orienTaTion

22 lanGuaGeS

23 oPTimizaTion

23 PrinTinG

23 incremenT

23 kerF

24 cSv lenGTH column

24 cSv quanTiTy column

24 uniT ToGGle viSiBle

24 minimum limiT

25 maximum limiT

25 adjuST PivoT PoinT

26 SawGear Touch My

SawGear Menu

26 conTacT inFormaTion

26 Serial numBer

26 enaBle code

26 inTerFace verSion

27 Firmware verSion

27 deBuG mode

28 SawGear Touch Lists

28 download aliST

28 make aliST

29 ediT aliST

31 deleTe aliST

31 run aParT liST

32 run an oPTimized ParT liST

33 SawGear Touch Crown &

Miter Pro

36 SawGear Touch Framing

38 Maintenance Schedule

39 Maintenance Log

40 Appendix A: Scale

41 Appendix B: Printer Kit

41 PrinTer kiT ParTS

42 PrinTer SeT-uP and oPeraTion

43 PrinTer STand aSSemBly

iv

SAFETY FIRST!

IMPORTANT SAFETY INFORMATION. READ ALL WARNINGS BEFORE OPERATING THIS PRODUCT.

WARNING: Installation of your TigerStop® Product must be done by a person trained in the safe design and installation of

automation products, and in the safe operation of power equipment. Ensure that such installation meets all legally required

safety requirements and guidelines, and that proper guarding and safety devices are provided on all sides of the equipment to

preclude unintended access during operation. Consult with and follow the recommendations of a qualified safety engineer.

WARNING: TigerStop® Products are components intended for use in conjunction with potentially dangerous machinery.

The use of TigerStop® Products does not make other machinery safe. TigerStop® Products are not intended to substitute,

in any manner, for safe operating practices in general, or for safety features present in other machines designed to make

those machines as safe as possible. TIGERSTOP® PRODUCTS, IF USED OR INSTALLED IMPROPERLY, MAY CAUSE

PERSONAL INJURY OR DEATH AND SHOULD ONLY BE OPERATED BY PERSONS TRAINED IN THEIR SAFE OPERATING

PROCEDURES. Illustrations of TigerStop® Products in use do not show, and are not intended to show, all safety features and

practices necessary for their safe operation.

WARNING: TigerStop® Products must be installed in accordance with all local, state, and federal regulations. Only personnel

properly trained in the safe design and installation of automation machinery and related power equipment should install

TigerStop® Products onto other equipment, to ensure a safe and proper work station. TigerStop® Products should not be

operated without proper training, both in the operation of TigerStop® Products, and in the operation of related equipment.

IMPORTANT CAUTION:

The motor box (compartment) contains DC voltage with potentially FATAL amperage. NEVER attempt any unauthorized actions

inside the motor box.

WARNING: Using a TigerStop® interconnect does not relieve you of the responsibility for making sure that your saw or other

tool has all the necessary safety equipment in place. All installations must meet all legally required safety requirements and

guidelines. Installation and training should be done following the recommendations of a qualified safety engineer.

DANGER: This machine can start, move and stop automatically. Keep hands and loose clothing clear of moving parts while

operating. Moving parts can crush and cut. When used with a saw or other cutting equipment, bodily injury and death may result

if operated without safety guards on all machines. Do not operate with guards removed. Operators must wear adequate eye and

ear protection.

GENERAL WARNINGS

INSTALLATION WARNINGS

INTERCONNECTS

OPERATION

v

IMPORTANT SAFETY INFORMATION. READ ALL WARNINGS BEFORE OPERATING THIS PRODUCT.

DANGER! Don’t get pinched by the push feeder. Keep your hands away when in motion!

Keep the work area clean and well lighted to avoid accidental injury.

Do not operate near flammable liquids or in gaseous or explosive atmospheres!

Use only 3-wire extension cords that have 3-prong grounding type plugs and 3-pole

receptacles that accept the tools plug for 120VAC. Use only 5-wire cords and plugs

when using 3 phase.

Do not open motor compartment or controller keypad. DC Voltage with potentially

FATAL amperage! Disconnect power before servicing. No user-serviceable parts inside.

DO NOT operate this or any machine under the influence of drugs or alcohol!

No one should operate this machine except for fully qualified personnel.

READ THE MANUAL!

Do not use TigerStop® machines in a dangerous environment. Using power tools in damp

or wet locations or in rain can cause shock or electrocution.

Wear proper apparel, no loose clothes, long hair or jewelry which could get pulled into

moving machinery or materials. Wear non slip footwear, safety glasses, ear protection

and a dust mask.

vi

Enable your SawGear Touch

SawGear Touch won’TfuncTion unTil iT iS enabled.

1. Fill out the warranty registration form at TigerStop.com/service-center/#warranty-registration.

2. TigerStop®Customer Service will email you the enable code during business hours, Monday-Friday 6am-

4pm PST. You can also request the code by phone.

3. After installing SawGear Touch, power it on and follow the '1st Power-On' (page 15) instructions.

1

Contact Us

12909 NE 95th Street

Vancouver, WA 98682-2426

TigerStop Global Headquarters

Bedrijvenstraat 17 NL-7641 AM

Wierden, Netherlands

TigerStop Europe

Oces

Phone: +1 (360) 448 6102

TigerStop Customer Service

TigerStop Sales

Phone: +1 (360) 254 0661 ext 2

TigerStop Headquarters

Phone: +1 (360) 254 0661

Fax: +1 (360) 260 0755

TigerStop Europe

Phone: +31 546 575 171

TigerStop Mexico

Phone: +1 (360) 254 0661

Call Us

TigerStop Europe | Sales

Phone: +31 546 575 171 (option 2)

TigerStop Europe | Service

Phone: +31 546 575 171 (option 1)

Email: service@tigerstop.com

TigerStop Customer Service

TigerStop Sales

Email: sales@tigerstop.com

TigerStop Headquarters

Email: careers@tigerstop.com

Follow Us

Email Us

TigerStop Europe

Email: info@tigerstop.nl

TigerStop Europe | Sales

Email: info@tigerstop.nl

TigerStop Europe | Service

Email: sos@tigerstop.nl

2

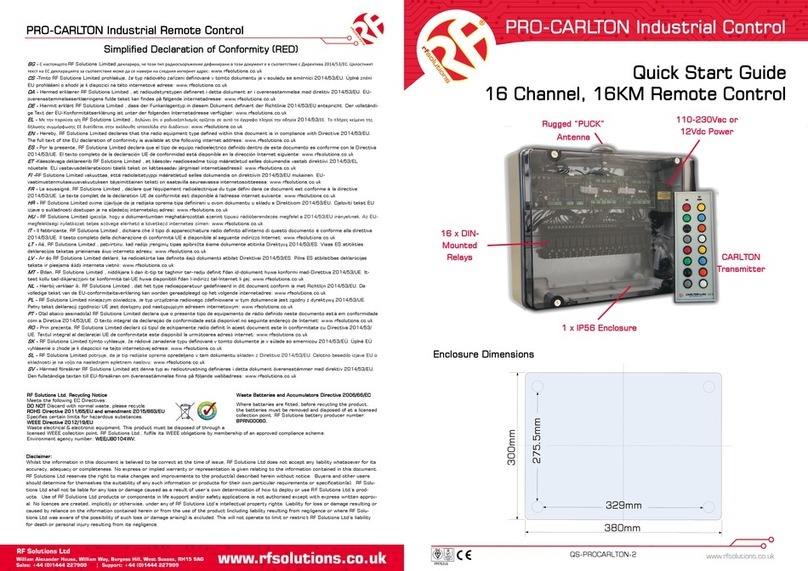

Parts Inventory

PART DESCRIPTION

(NUMBER) QUANTITY

Power Head Touch

(SA2521) 1

Power Cable

(PC) 1

Power Head Touch

Flip-Away Stop Assembly

PART DESCRIPTION

(NUMBER) QUANTITY

Flip-Away Stop

(SA2545) 1

M6 Adjustable Handle

(F7306) 2

Saw Gear Beam

PART DESCRIPTION

(NUMBER) QUANTITY

Saw Gear Beam

(SGXX) 1

3

PART DESCRIPTION

(NUMBER) QUANTITY

Stop Bar

(SA2555) 1

Crown Moulding Foot

(Optional)

(SG-CMF)

1

Stops

PART DESCRIPTION

(NUMBER) QUANTITY

Bench Mount Bracket

(M1016) 5

M8 Star Knob

(F7304) 5

Bench Mount Hardware

Pack

(F0038)

1

Bench Mount Assembly

Parts Inventory

4

Parts Inventory

PART DESCRIPTION

(NUMBER) QUANTITY

SawGear Table

(SGTABXX) Varies

Tool Bracket

(M1035) 2 per table

Saw Bracket Left/Right

(M1042/3) 1 per table

Table Spacer

(M1041) 2 per table

M6x16mm Carriage Bolt

(F0183) 4 per table

M6 Washer

(F7620) 4 per table

M6 Hex Nut

(F2004) 4 per table

M8 Knob

(F2252) 1 per table

Table Assembly (Optional)

5

Parts Inventory

PART DESCRIPTION

(NUMBER) QUANTITY

M8x35mm T-Bolt

(F0184) 3 per table

M8 Positioning Pin

(M1044) 2 per table

M8x8mm Set Screw

(F9811) 2 per table

M8 Weld Nut

(F0406) 2 per table

Table Leg

(SB2120) Varies

M10 Washer

(F3009) 2 per table

M6x10mm Button Flange

Cap Screw

(F7207)

2 per table

M10 Disc Spring

(F1682) 2 per table

6

SawGear Touch Installation

Electrical Requirements

VOLTS CIRCUIT BREAKER

120V 15A

208/230/240V 20A (USA)/16A (EU)

SawGear Touch requires a dedicated, grounded circuit.

Operating SawGear Touch without proper grounding risks electrocution.

SawGear Table Installation

Not

Included

aTTac h Too l brackeTS

1. Place a Tool Bracket under

both corners on one side of

the tool.

7

SawGear Touch Installation

2. Place a Table Spacer between each Tool Bracket and the tool.

3. Fasten the tool, Table Spacers, and Tool Brackets together.

1. Place the Saw Bracket between the Tool

Brackets and the tool.

2. Fasten the Saw and Tool Brackets together with

M6 Carriage Bolts, M6 Washers, and M6 Nuts.

aTTac h Saw br ac k e T

8

SawGear Touch Installation

1. Insert an M8 Weld Nut into the middle track and fasten it with an M8x8mm Set Screw about 12” (305mm) from

the tool end of the table.

2. Insert an M8 T-bolt into each track on the tool end of the table.

3. Insert an additional M8 Weld Nut into the middle track and fasten it with an M8x8mm Set Screw flush with the

tool end of the table.

aTTac h Table To Saw br ac k eT

4. Screw an M8 Knob onto the middle T-bolt and an M8

Positioning Pin onto both outer T-bolts. Do not tighten.

9

5. Insert the Positioning Pins through the top of the Saw

Bracket and slide the table to make it flush with the

tool. Tighten the Positioning Pins.

6. Slide the Knob into the Saw Bracket’s top slot and

fasten the table to the bracket.

SawGear Touch Installation

1. Use two M6x10mm Button Flange Cap Screws, M10

Disc Springs, and M10 Washers to attach the Table

Leg to the bracket axed to the underside of the

table.

aTTac h Table leGS

10

SawGear Touch Installation

2. Press in the metal buttons on the legs to adjust the

table height. Make it level.

3. Secure the legs with the orange handles.

SawGear Bench Mount Brackets

1. Make sure both Bench Mount Brackets are approximately

in line. Fasten them in place with the supplied hardware.

Sec u re SawGe a r i n Th e b r ackeTS

11

SawGear Touch Installation

2. Lay the SawGear Beam across the Bench Mount

Brackets.

3. There is an angled channel running along the

full length of the Beam’s bottom; pivot the Beam

so the curled front edge of the Bench Mount

Brackets fit into this channel.

4. Make sure the Beam is seated flat on top of the

Bench Mount Brackets. Turn the locking knobs to

secure the Beam.

Always firmly tighten the locking knobs and all

fasteners before using SawGear.

Dismount SawGear from the saw stand by loosening the locking knobs and pivoting it o the brackets.

diSmo u nTi n G SawGear fr o m Th e Saw STand

12

Connecting the Flip-Away Stop

1. Insert the Stop Bar into the Flip-Away Stop.

2. Secure the Stop Bar with the Adjustable Handles.

SawGear Touch Installation

Attaching the Stop Bar

1. Remove the rod from the Flip-Away Stop.

2. Insert the Adjustable Handles and tighten with their supplied

hardware.

3. Align the cylinders of the Flip-Away Stop and SawGear carriage

and insert the rod’s washers between them.

4. Re-attach the rod to connect them.

5. Tighten the rod until the Flip-Away Stop holds its position when

raised.

13

1. Insert the Power Head Touch into either of the SawGear Touch Beam’s attachment

points. Ensure it is rotated slightly counter-clockwise when inserting.

2. Rotate into place, clockwise. 3. Turn the knobs on both sides to

secure the Power Head Touch to

the Beam.

SawGear Touch Installation

Connecting the Power Head Touch

14

SawGear Touch Installation

Pivot the saw to its furthest left and right positions.

If the table blocks the saw’s pivot, trim the corner of the SawGear table to accommodate the saw.

If the Power Head Touch blocks the saw’s pivot, either move the Power Head Touch to the other end of

the beam or scoot the beam away from the saw until the saw can move through its full range-of-motion.

If scooting the beam away from the tool, move the Stop Bar toward the tool to compensate.

Remember to re-tighten the adjustable handles before moving on.

Checking Pivot Range of Movement

Table of contents

Other TigerStop Control System manuals

Popular Control System manuals by other brands

auer

auer Thorix EVOLUTION 2C Installation and operating instructions

Digitrax

Digitrax DS78V instructions

Riello

Riello ricloud user manual

PS Engineering

PS Engineering PAC45 System With MultiTalker Pilot's guide and operation manual

Lutron Electronics

Lutron Electronics PJ2-3BRL quick start guide

Invacare

Invacare LiNX REM110 user manual