IMPORTANT SAFETY INSTRUCTIONS

2

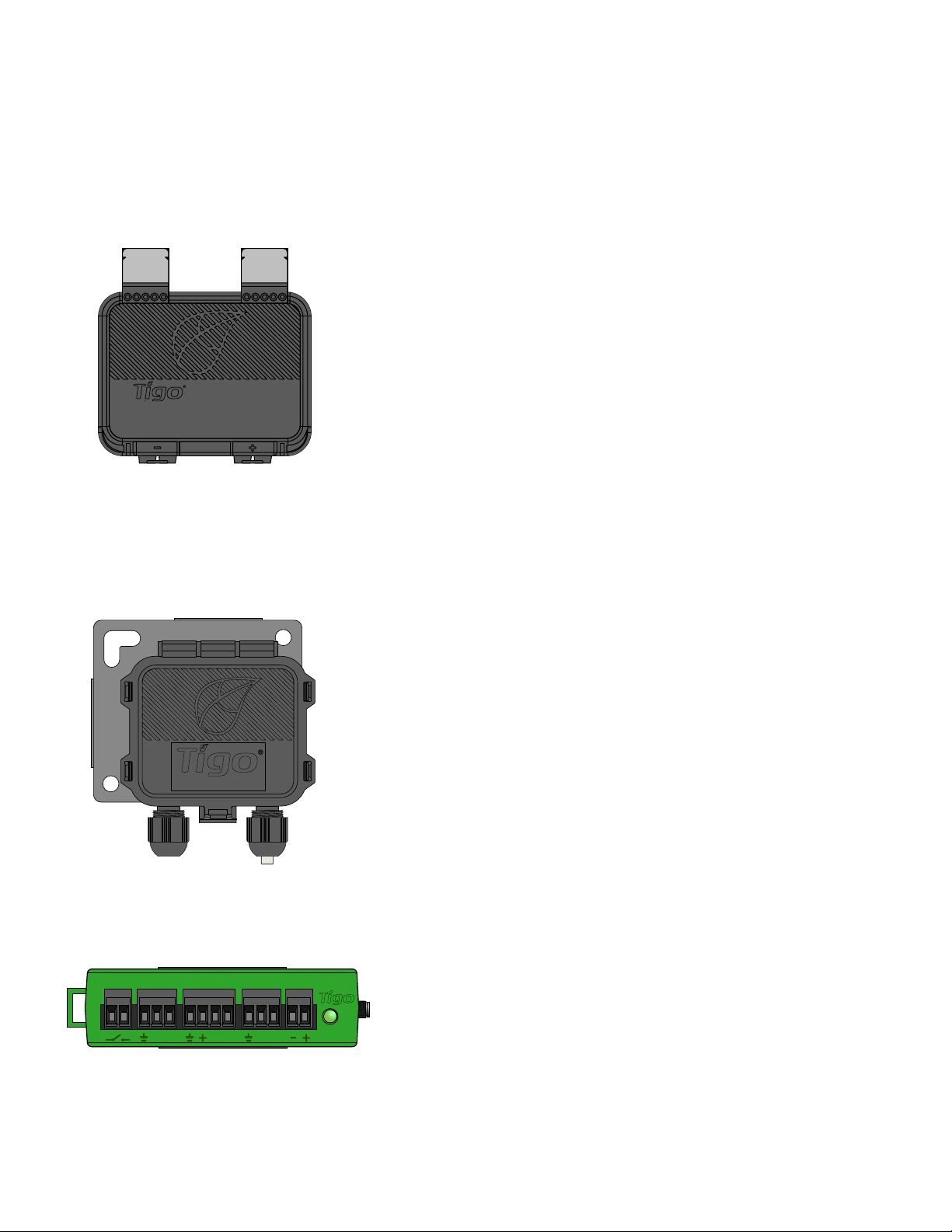

• This manual contains important instructions for installation and maintenance of the Tigo

product models TS4-A-O, TS4-A-S, TS4-A-M, Tigo Access Point (TAP), Cloud Connect

Advanced (CCA), and related Tigo software and mobile applications.

• Risk of electric shock, do not remove cover, disassemble, or repair, no user serviceable

parts inside. Refer servicing to qualied service personnel.

• Before installing or using the Tigo System, please read all instructions and warning

markings on the Tigo products, appropriate sections of your inverter manual,

photovoltaic (PV) module installation manual, and other available safety guides.

• Failure to adhere to these instructions may result in injury or death, damage to the

system, or voiding the factory warranty.

• To reduce risk of re and shock hazard, install this device with strict adherence to

National Electric Code (NEC) ANSI/NFPA 70 and/or local electrical codes. When the

photovoltaic array is exposed to light, it supplies a DC voltage to the Tigo TS4 units. The

TS4 units start in the “ON” state and their output voltage may be as high as the PV

module open circuit voltage (VOC) when connected to the module. The installer should

use the same caution when handling electrical cables from a PV module with or without

the TS4 units attached.

• Installation must be performed by trained professionals only. Tigo does not assume

liability for loss or damage resulting from improper handling, installation, or misuse of

products.

• Remove all metallic jewelry prior to installing the Tigo TS4 units to reduce the risk of

contacting live circuitry. Do not attempt to install in inclement weather.

• Do not operate the Tigo TS4 units if they have been physically damaged. Check existing

cables and connectors, ensuring they are in good condition and appropriate in rating.

Do not operate Tigo TS4 units with damaged or substandard wiring or connectors. Tigo

TS4 units must be mounted on the high end of the PV module backsheet or racking

system, and in any case above ground.

• Do not connect or disconnect under load. Turning off the Inverter and/or the Tigo

products may not reduce this risk. Internal capacitors within the inverter can remain

charged for several minutes after disconnecting all power sources. Verify capacitors

have discharged by measuring voltage across inverter terminals prior to disconnecting

wiring if service is required. Wait 30 seconds after rapid shutdown activation before

disconnecting DC cables or turning off DC disconnect.

• Always assume TS4 units are in “ON” state, or may turn on when restarting.

• The CCA must be on the same AC branch circuit as the inverter to meet rapid shutdown

requirements.

LETHAL VOLTAGE MAY BE PRESENT IN ANY PV INSTALLATION

SAVE THESE INSTRUCTIONS

03/04/2021