Timberline Tool TopSide Clamp TC1-SR User manual

Table of contents

Other Timberline Tool Tools manuals

Timberline Tool

Timberline Tool TRTW5 User manual

Timberline Tool

Timberline Tool TopSide Clamp TC1-S User manual

Timberline Tool

Timberline Tool TC2 User manual

Timberline Tool

Timberline Tool TopSide TC2-S User manual

Timberline Tool

Timberline Tool TR650 User manual

Timberline Tool

Timberline Tool TopReach Clamp TR250 User manual

Timberline Tool

Timberline Tool TR50-CTS User manual

Timberline Tool

Timberline Tool FFV-2 User manual

Popular Tools manuals by other brands

Gesswein

Gesswein Power Hand 2X Z-STX instruction manual

BGS technic

BGS technic 99910 instruction manual

Textron

Textron GREENLEE 7646 instruction manual

ete

ete IR1759-MK5-AT3130-EDCont Operation and maintenance manual

BGS technic

BGS technic 1721 quick start guide

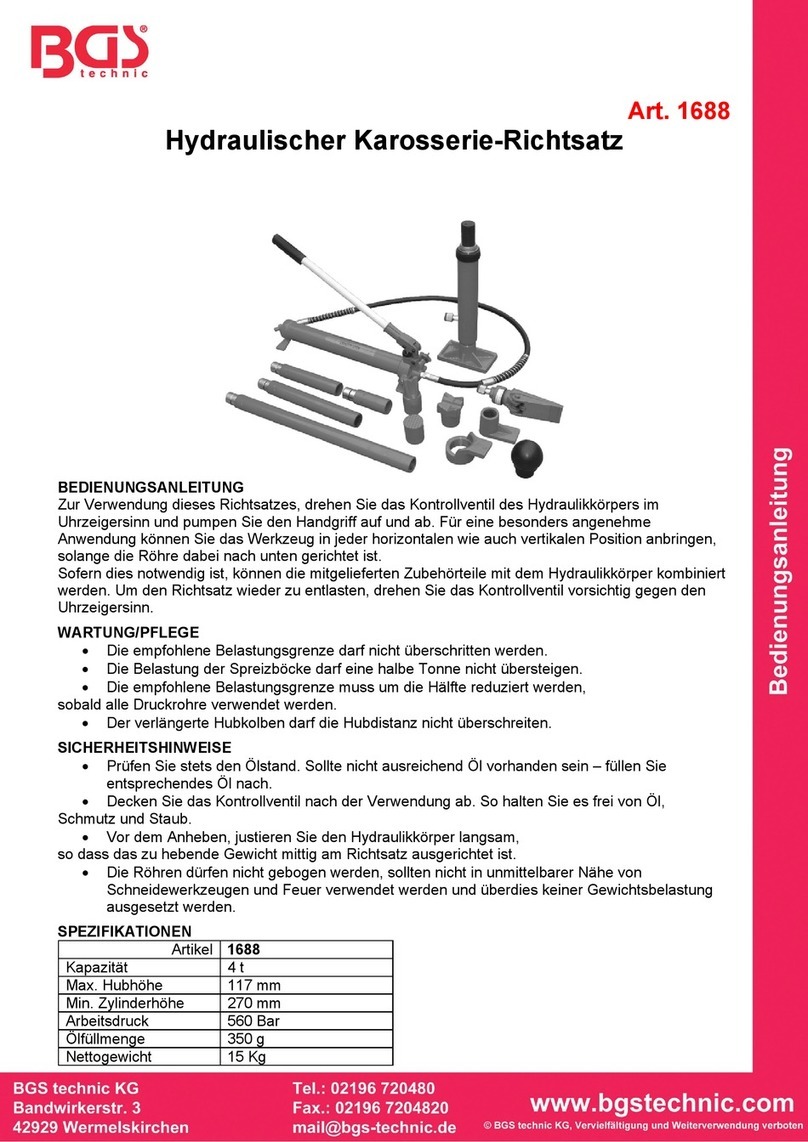

BGS technic

BGS technic 1688 operation instruction