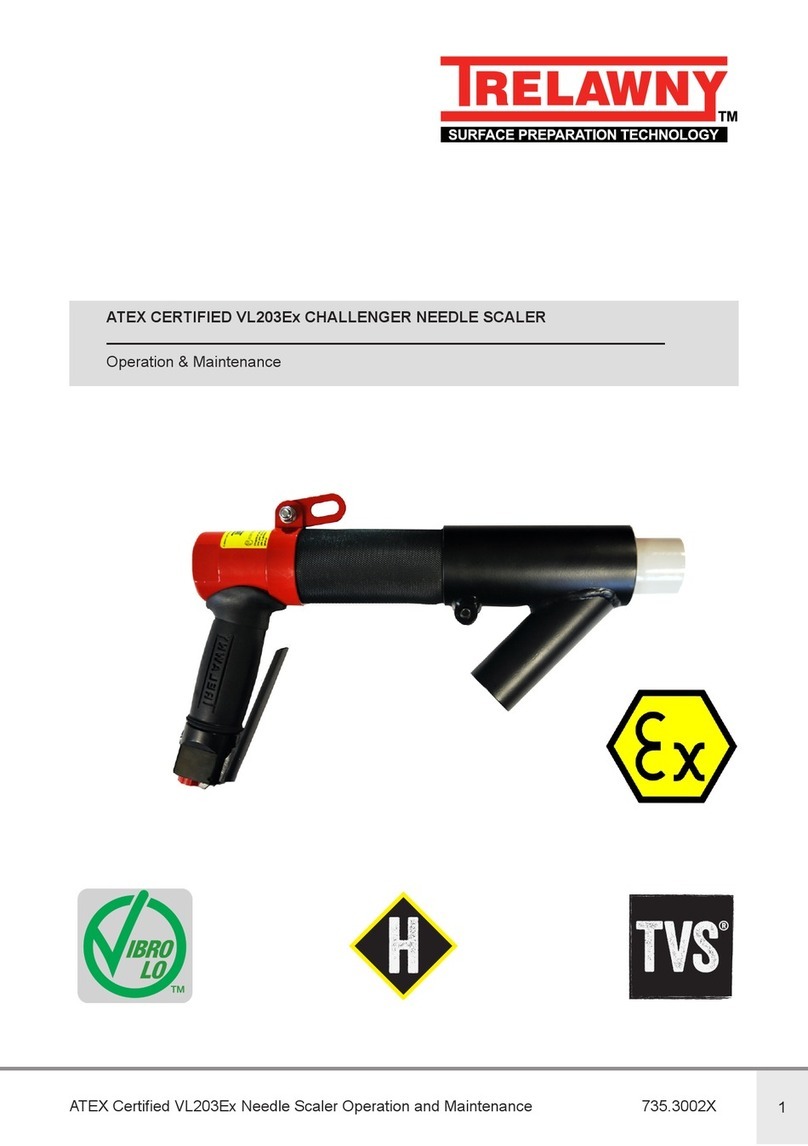

Trelawny VLSF1EX User manual

www.trelawny.co.ukwww.trelawny.co.uk

vlSF1ex Scaling hammer

operations and maintenance manual

www.trelawny.co.uk

PAGE 2

VLsF1Ex SCALING HAMMER

CONTENTS

Introduction ................................................................................................................................................................ 2

Declaration of Conformity..................................................................................................................................... 3

Foreword ...................................................................................................................................................................... 6

General Information ................................................................................................................................................ 6

Safety ............................................................................................................................................................................. 6

Risk of Hand Arm Vibration .................................................................................................................................. 7

Air Supply ..................................................................................................................................................................... 7

Starting Work ............................................................................................................................................................. 7

Maintenance ............................................................................................................................................................... 8

Assembly ...................................................................................................................................................................... 9

Disposal ........................................................................................................................................................................ 9

Exploded ...................................................................................................................................................................... 10

Parts List ....................................................................................................................................................................... 11

Technical Specication........................................................................................................................................... 12

INTRODUCTION

Your new Trelawny SPT tool will more than satisfy your expectations. It has been manufactured under stringent

Trelawny SPT Quality Standards to meet superior performance criteria. You will nd your new tool easy and safe to

operate, and, with proper care, it will give you many years of dependable service.

WARNING

Carefully read through these original instructions before using your new Trelawny tool. Take special

care to read the warnings. Your Trelawny tool has many features that will make your job faster and

easier. Safety, performance, and dependability have been given top priority in the development of

this tool, making it easy to maintain and operate.

ENVIRONMENTAL PROTECTION

The machine, accessories and packaging should be sorted for environmentally friendly

recycling. The plastic components are labelled for categorised recycling.

DISPOSAL

Waste products should not be disposed of with household waste. Please recycle where

facilities exist. Check with your local authority or retailer for recycling advice.

DECLARATION OF CONFORMITY

Adam Dickinson,

Managing Director

We,

Trelawny SPT Limited of

Trelawny House, 13 Highdown Road, Sydenham Industrial Estate, Leamington Spa, Warwickshire,

CV31 1XT, United Kingdom,

Declare that under our sole responsibility for supply/manufacture of the product

Name of product: Scaling Hammer

Model: VLSF1Ex

to which this document relates is in conformity with the provisions of the following Directive(s),

Normative Documents and their relevant Standards:

2006/42/EC MACHINERY DIRECTIVE

EN ISO 11148-4:2010 HAND HELD NON-ELECTRIC

(Non-Rotary Percussive Tools)

EN ISO 4414:2010 General rules and safety requirements

EN ISO 4414 SAFE PNEUMATIC EQUIPMENT OF MACHINERY

Conformity with the following relevant legislation:

2014/34/EU ATEX DIRECTIVE

Based on following harmonised standards:

EN 60079-0:2018

EN ISO 80079-36:2016

EN ISO 80079-37

II 2 G Ex h IIC T4 Gb

II 2 D Ex h IIIC T135°C Db

www.trelawny.co.uk

Email: sales@trelawny.co.uk

Tel: +44 (0) 1926 883781

Fax: +44 (0) 1926 450352

Year and place of issue,

2020

Leamington Spa, England

________________________

Registered Oce: Trelawny SPT Ltd, Trelawny House, 13 Highdown Road, Sydenham Industrial Estate, Leamington Spa, Warwickshire, CV31 1XT, United Kingdom

DOCUMENT No. Q:57/8

________________________________________________________________________________________________________

www.trelawny.co.uk

PAGE 4

VLsF1Ex SCALING HAMMER

CZ Prohlášenl o přizpüsobení

My, společnost Trelawny SPT Limited

podajemy daňové přiznáni. že výrobek a dodávka výrobku

název výrobku

Model, výrobni čislo

Rok výroby

Pro které se průkaz týkajici, je přizpůsobeni s zásoby od následujici přikazov a jejich pohotovostni:

98/37/EC Přikaz soustroji

73/23/EC Přikaz nizkého napéti (upotřebitelne jediné do výrobku použiti elektnckej energie)

LT ATITIKTIES DEKLARACIJA’

Mes, Trelawny SPT Limite

Prisiimdami visą atsakomybę deklaruojame, kad tiekiamas / gaminamas produktas

Produkto pavadinimas

Modelis, serijos numeris

Pagaminimo

Kuriam taikoma ši deklaracija, atitinka šių direktyvų, norminių aktų ir su jais susijusių. standartų reikalavimus:

98/37/EC ļtrangos direktyva

73/23/EC Zemos įtampos direktyva (taikoma tik elektriniams įrengimams)

DE Ubereinstimmungserklarung

Wir, Trelawny SPT Limited

erklaren, dass unter unserer alleinigen Verantwortung fur die Lieferung und Herstellung des Produktes

Name des Produktes

Model, Seriennummer

Jahr der Herstellung

auf welches sich dieses Dokument bezieht. stimmt mit den Vorgaben der folgenden Direktive, normativen Dokumente und deren

jeweiligen Masstabe ein:

98/71/EC Maschineriedirektive

73/23/EC Niederspannungsdirektive (nur zutreffend auf Produkte, die Strom benutzen)

MT DIKJARAZZJONI TA KONFORMITA

Aħna, Trelawny SPT Limited

Niddikjaraw li aħna responsabbli kompletament għal provista / manifattura tal-prodott hawn 1msemmi:

lsem ll-Prodott

Mudell, Serial number

Sena Ia 'produzzjoni

Dan id-dokument magħmul għal prodott imsemmi hawn fuq, li huwa skond il-provizjonijiet imsemmija d-dokumenti tal-klassi tax-

xogħol:

98/37/EC Machinery Directive

73/23/EC Low Voltage Directive (tapplika biss għal prodotti li jaħdmu bl-eletrkiu)

DK Erklæring om overensstemmelse

Vi, Trelawny SPT Limited

Erklærer hermed at under vores ene forhandling ansvar for vores forhandling/produktion af produktet

Produkt navn

Model, serie nummer

Produktionsár

For hvilket delle dokument referer, at deler i overensstemmelse med bestemmelser af følgende direktiver, normative dokumenter

og deres relevante standart:

98/37/EC Machinery directive

73/23/EC Low voltage directive

NL EENVORMIGHEIDSVERKLARING

Wij. Trelawny SPT Limited

Verklaren dat wij de volledige verantwoordelijkheid dragen voor het leveren/fabriceren van het volgende product:

Naam van het product

Type, Serienummer

Productiejaar

En verklaren dat het product waarnaar dit document verwijst eenvormig is met de voorzieningen van de volgende Richtlijn(en),

Normatieve Documenten en hun relevante Standaarden:

98/37/CE MACHINERICHTLIJN

73/23/CE LAAGSPANNINGSRICHTLIJN (uitsluitend van toepassing bij producten die elektrische stroom gebruiken)

EE TOOTE VASTAVUSE DEKLARATSIOON

Meie, Trelawny SPT Limited

Deklareerime, et vastutame jägmise varustuse/toote müügi eest

Toote nimetus

Mudel, Seeria number

Aasta toodangu

Antud dokument töendab toote vastavust järgmistele direktiivi(de)le, normatiivaktidele ja nendega samaväärsetele standarditele:

98/37/EC MASINA DIREKTIIVID

73/23/EC MADALPINGE DIREKTIIVID (Kohandatakse vaid toodetele, mis kasutavad elektrivoolu

PL Deklaracja Zgodnosci

My, Firma Trelawny SPT Limited.

oświadczamy w naszej odpowiedzialności, ze produkcja i dostawa urzctdzenia

Nazwa produkta

Model, numer seryjny

Rok produkcji

do którego ten dokument należy, jest zgodne z klauzulami nastąpujacych zarządzen i ich istotnych standartów:

98/37/EC Zarządzenie mechaniczne

73/23/EC Zarządzenie niskiego napięcia elektrycznego (Zastosowanie tylko przy urządzeniach elektrycznoych)

ES Declaración de Conformidad

Nosotros, Trelawny SPT Limited

Declaramos que bajo nuestra completa responsabilidad de Ia fabricación/suministro del producto

Nombre del Producto

Modelo, No de Serie

Año de producción

A quién este documento se refiere, está de acuerdo con lo relacionado en Ia Directriz, Normativa Documentada y sus relevantes

standards:

98/37/EC Directorio de Maquinaria

73/23/EC Directorio de Bajo Voltaje (Aplicable solamente a productos que funcionen con electricidad)

PT DECLARAÇÄO DE CONFORMIDADE CE

A empresa TRELAWNY SPT LIMITED

Declara, sob sua inteira responsabilidade, que o fornecimento/fabrico do seguinte produto:

Designaçáo do produto

Modelo, Nümero de Série

Ano de produçáo

a que esta declaraçáo se refere. está em conformidade com o preceituado nas Directivas e Normas Comunitárias abaixo indicadas:

98/37/EC DIRECTIVA DE MÁQUINAS

73/23/EC DIRECTIVA DE BAIXA VOLTAGEM (Aplicável apenas a produtos que utilzi am energia eléctrica)

FI ILMOITUSVAHVISTUS

Me. Trelawny SPT Limited

Vahvistamme tuotteiden toimittamisesta/valmistamisesta

Tuotenimi

Malli, sarjanumero

Valmisttusvuosi

Tällä todistuksella vahvistamme säädökset seuraviin ohje/ohjesiin, Yleisiin papereihin ja niihin liittyvät vaatimukset:

98/37/EC KONEISTON OHJEET

73/23/EC PIENJÄNNITE OHJEET (tarvitaan ainoastaan tuotteille jotka käyttävät sähkovoimaa)

RU CBИдETEПЬCTBO O COOTBETCTBИИ

Mьι, Trelawny SPT Limited

3aявляем, что несем полную ответственость эа поставκу/производство нижеукаэанной

продуκцим

Hаименоване изделия

Mодель, серийньιй номер

Год вьιлуска

на котоеую вьιдано настящее Cвидетельство, и которая соответствует положениям слдующей(иx) директив(ьι),

нормативньιм доκументам и относящимся к ним стандартам:

98/37/EC ДИРЕКТИВА ПО MEXAHИ3MAM

73/23/EC ДИРЕКТИВА ПО HИ3KOBOЛЬTHOMУ OЪOPУДOBAHИЮ (распространяется только на изделия с

злектропитанием)

FR DÉCLARATION DE CONFORMITÉ

Nous, soussignés Trelawny SPT Limited

déclarons que le produit sous-nommé

Nom du produit

Modèle et Numéro de Serié

Année de production

et pour lequelnous prenons entière responsabilité pour sa fourniture et manufacture, est conforme aux clauses des directives

suivantes documents norminatifs et normes qui s'y appliquent:

98/37/EC DIRECTIVE POUR LA MACHINERIE

73/23/EC DIRECTIVE POUR BAS VOLTAGE (n'est applicable qu'aux produits utilisant l'énergie électrique)

SE FÖRSÄKRAN OM ÖVERENSSTÄMMELSE

VI, TRELAWNY SPT LIMITED

FÖRKLARAR ATT VI MED ENSAMT ANSVAR ANSKAFFAT / TILLVERKAT PRODUKTEN PRODUKTNAMN

MODELL och SERlE NUMMER

Tillverkningsár

TILL VILKEN DETTA DOKUMENT HÄNVISAR ÄR I ÖVERENSSTÄMMELSE MED FÖLJANDE DIREKTIV, NORMATIVA

DOKUMENT OCH DERAS RELEVANTA STANDARDER

98/37/EC MASKINDIREKTIV

73/23/EC LÄGSTRÖMSDIREKTIV (TILLÄMPLIG PÄ ELEKTRISK DRIVNA PRODUKTER)

GR ΔΗΛΩΣΗ ΠΙΣΤΟΤΗΤΑΣ

Η εταιρεια Trelawny Spt Limited

Δηλωνει ότι έχει τη μονδικη ευθυνη ως κατασκευαστρια / προμηθευτρια του παρακατω προιοντος περιγραφη προιοντος

μοντελο, αριθμος σειρας

έτος παραγωγής

και στο οποιο αναφερεται αυτη η δηλωση, ειναι συμβατο με τις προδιαγαφες που οριϚονται στιϚ ακολουθεϚ Koινοτικες

OδηγιεϚ EλεγκτικεϚ ΔιαταξειϚ κι αλλεϚ σχετικες προδιαγραφεϚ

98/37/EC OΔHΓΙΑ ΠΕΡΙ ΜΗΧANHMATΩN

73/23/EC OΔHΓΙΑ ΠΕΡΙ XAMHΛHΣ TAΣHΣ (αφορα μονον προιοντα που λειτουργουν με ηλεκτρικο ρευμα)

SI IZJAVA O SKLADNOSTI

Trelawny SPT Limited

pod polno odgovornostjo izjavljamo, da so spodaj navedeni proizvodi, ki jih dobavljamolproizvajamo:

lme proizvoda

Model. serijska številka

Leto proizvodnje

na katere se ta dokument nanaša. proizvedeni v skladu z določili naslednjih direktiv, normativnih dokumentov in njihovih relevant-

nih standardov:

98/37/EC DIREKTIVA O STROJIH

73/23/EC DIREKTIVA O STROJIH Z NIZKO VOLTAŽO (nanaša se samo na proizvode na električni pogon)

HU MEGFELELŐSÉGI NYILATKOZAT

Mi. A "Trelawny SPT Limited" cég

Felelösségünk tudatában kijelentjük, hogy mint a termék szállitója/gyartója

Termék neve

Tipus, Sorozatszáma

Gyártási év

amelyre jelen dokumentum vonatkozik, megfelel az alábbi lrányelv(ek), lrányadó Dokumentumok elöirásainak, és az azokat

meghatározó szabvanyoknak:

98/37/EC GÉPÉSZETI IRÁNYELVEK

73/23/EC KISFESZÜLTSÉGÜ IRÁNYELVEK (Csak az elektromos meghajtásů gepeknél)

TR UYGUNLUK BEYANI

Trelawny SPT Limited

AÞaöýdaki, üretim ve tedarikinden tek baÞýna sorumlu olduöu ürünün

Ürün ady

Modei/Seri no

Üretim yili

bu belgenin ilgili olduöu apaöýdaki yönetmeliklerin, norm belgelerinin ve ilgili standartlarýnýn koÞullarýna uygun olduöunu beyan

eder:

98/37/EC MAKŶNALAR YÖNETMELŶDŶ

73/23/EC DÜÞÜK GERŶLŶM YÖNETMELŶDŶ (Yalnýýz elektrikle çalyÞan ürünlerde geçerlidir)

IT DICHIARAZIONE Dl CONFORMITA

La Società Trelawny SPT Limited

Dichiara, sotto Ia propria responsabilità, che Ia fornitura / produzione del prodotto

Nome prodotto

Modello, codice

Anno di produzione

a cui si riferisce tale documento è conforme aile seguenti Direttive, ai documenti della Normativa ed ai relativi standard:

98/37/EC DIRETTIVA SULLE APPARECCHIATURE

73/23/EC DIRETTIVA SUL BASSO VOLTAGGIO (applicabile esclusivamente peri prodotti che utilizzano energia elettrica)

DECLARATION OF CONFORMITY DECLARATION OF CONFORMITY

Appendix 1 - Hazardous Area Certication

The VLSF1Ex Scaling Hammer certied compliant to the ATEX Directive (2014/34/EU) for safe use within a

hazardous area and has been assessed so by Element Materials Technology.

This product conforms to the Standards:

EN 60079-0:2018

EN ISO 80079-36:2016

EN ISO 80079-37

And is attributed with the product certication codes:

II 2 G Ex h IIC T4 Gb

II 2 D Ex h IIIC T135°C Db

With ATEX Certicate Number: EMT19ATEX0020X

Special Conditions of Safe Use

1. Air compressors used in conjunction with the Scaling Hammers shall incorporate means to prevent the ingress

of dust or other foreign material into the air supply i.e a lter on the compressor intake.

2. For air compressors used in conjunction with the Scaling Hammers, only lubricants that are resistant to

carbonisation shall be used.

3. The external painted surfaces of the equipment are not to be exposed to charging mechanisms stronger than

manual rubbing.

4. Air supply hoses used in conjunction with the equipment must be manufactured from anti-static material with

a surface resistance no greater than 10°Ω.

5. Equipment is to be lubricated before as detailed in the Operations & Maintenance Manual.

6. Any lubricating oil used must have an auto ignition temperature of > 185°c.

7. The equipment must not be stored in an explosive acetylene atmosphere (to prevent the formation of

acetylides on the copper heads).

Equipment must only be installed & maintained by suitably qualied and competent personnel in accordance

with the instructions provided and the terms of the applicable product services.

www.trelawny.co.uk

PAGE 6

VLsF1Ex SCALING HAMMER

RISK OF HAND-ARM VIBRATION INJURY

air supply

STARTING WORK

These tools may cause Hand-arm Vibration Syndrome injury

if their use is not adequately managed. We advise you to

carry out a risk assessment and to implement measures

such as; limiting exposure time [i.e. actual trigger time, not

total time at work], job rotation, ensuring the tools are used

correctly, ensuring the tools are maintained according to

our recommendations, and ensuring that the operators wear

personal protective equipment [PPE] particularly gloves and

clothing to keep them warm and employers should consider

setting up a programme of health surveillance to establish

a benchmark for each operator and to detect any early

symptoms of vibration injury.

We are not aware of any PPE that provides protection against

vibration injury by attenuating vibration emissions.

See ‘Specications’ section for vibration emission data.

Further advice is available from our Technical Department.

The compressed air must be free from water and dirt.

The installation of a lter/regulator/lubricator air

preparation set (with moisture trap) adjacent to the tool

is strongly recommended.

Always clear the air hose before connection to the tool.

Ensure that no moisture (condensation) is present in the air

hose. Ensure that a minimum 10mm (3/8”) bore antistatic air

hose is used and that all couplings are secure, leak free and in

good condition.

Limit the length of air hose to 10M (33ft). Where extra length

is necessary, for each additional 15M (50ft) of air hose used,

the pressure drop is approximately 0.16bar (3psi). Correct

operating pressure is 6.2bar (90psi).

Do not let the operating pressure fall below 5.5bar (80psi.)

or rise above 6.9bar (100psi) absolute maximum.

The compressor must be able to supply a minimum of

7.0 lps (15cfm) for Single Scalers, (Free air, not displaced as

quoted by some compressor manufactures).

In particularly cold weather it is recommended that a

proprietary anti-freeze lubricating oil is used.

Always use Trelawny Beryllium Copper heads.

Prior to operating the tool check that all ttings are secure,

free from leaks and air hoses are in good condition.

That the air pressure is correct for this tool 6.2 bar (90psi.). Put

a few drops of recommended lubricant into the air inlet of the

tool. To operate the tool, which is dependant on the type of

lever tted, for those tted with a safety lever, rst push thumb

button forwards and then for both styles of lever, pull the lever

towards the handle grip to start the tool, then apply the cutter

heads to the surface being prepared.

To switch o, simply release the throttle lever.

Care must be taken to avoid damaging or tripping over the air

hose. Maintain contact with the work surface with sucient

pressure only to keep the tool from bouncing o. Excessive

pressure can prevent the tool from working to its full capacity.

Handled correctly the Scaler will work quickly and eciently.

FOREWORD

GENERAL INFORMation

SAFETY

Thank you for your purchase of a Trelawny VLSF1Ex Scaling

Hammer. This manual contains the necessary maintenance

information for you to ensure proper operation and care for

this machine. Also see the manual that is supplied by the

engine manufacturer. It is essential for you to read through

this manual thoroughly. In the unlikely event that you

experience problems with your Trelawny VLSF1Ex Scaling

Hammer, please do not hesitate to contact your local

Trelawny dealer or agent. We always welcome feedback and

comments from our valued customers.

Before operating Trelawny Scaling Hammers, this manual

must be read and understood by the operator, if in any doubt,

ask your supervisor before using this equipment. Local safety

regulations must be followed at all times. Failure to follow

these instructions could result in damage to the Scaler and/or

personal injury.

Trelawny SPT Ltd disclaims all responsibility for damage to

persons or objects arising as a consequence of incorrect

handling of the tool, failure to inspect the tool for damage or

other faults that may inuence it’s operation prior to starting

work, or failure to follow the safety regulations listed or

applicable to the job site.

These scaling tools are designed for removal of heavy rust

and scale.

Do:

- Be aware that this tool is not electrically insulated.

- Be aware that the tool can create dust and ying debris.

- Keep hands and clothing away from moving parts.

- Be aware of others working around you.

- Ensure that this tool is lubricated daily.

- Store this tool in a secure and dry environment.

- Wear Personal Protective Equipment including safety

goggles, footwear, ear defenders and gloves. In some

environments it will be necessary to wear facemasks or

breathing apparatus.

- Always observe safe-working practices at all times.

Do not:

- Allow the tool to run unattended.

- Modify this tool in any way, this will invalidate the warranty

and could also lead to serious injury.

- Drag the tool by the air hose.

- Use petrol (gasoline), thinners or any other high ash point

solvent to clean the tool.

WARNING! Before operating, performing maintenance

or repairing the scaling hammers this manual must be

read and understood. If in any doubt, ask your supervisor

before using this equipment.

WARNING! Always observe safe-working practices at

all times. VERY IMPORTANT

Only Trelawny Beryllium Copper Heads must be used in

this tool. DO NOT substitute with any other head.

www.trelawny.co.uk

PAGE 8

VLsF1Ex SCALING HAMMER

Valve Body assembly (Workshop)

Clamp the handle (10) assembly rmly in a soft faced vice

(valve body end), insert new valve stem ‘O’Ring (5) into valve

body (6), followed by the valve stem (4), spring (3), then the

valve cap (1) complete with its ‘O’Ring (2), tighten the valve cap

with a screwdriver. Rotate assembly 180 degrees in vice. Using

a 3mm diameter pin punch locate and align the throttle lever

(7) in position, then drive in the throttle lever roll pin (8) into the

pin location.

FINAL ASSEMBLY (Workshop)

Assemble the end cap (17), t spring (18) into the end cap and

t spring cap (19) into the end cap as shown in the service

layout. Select as required, a piston/cutterhead, insert into the

body (24) and apply a few drops of air tool lubricant to the

top of the piston(s). Hold the handle (10) in a soft faced vice

ensuring the screw cap threads are uppermost. Remove all

traces of oil from the screwed cap threads and threads of the

body by cleaning with suitable oil free solvent. Apply a bead

of Loctite 243 sealant to the rst 3 threads of the end cap.

Screw end cap assembly into the body until nger tight and

using a suitable spanner torque down to 55N.m. (40 lbs.ft).

DISPOSAL

When the tool and its accessories are taken out of service

for disposal, it is recommended that: - They are rendered

unusable to prevent improper re-use.

They are dismantled into component form, segregated

according to material composition and disposed of using

waste recycling processes specied by local regulations.

VERY IMPORTANT

Only Trelawny Beryllium Copper Heads must be used in

this tool. DO NOT substitute with any other head.

MAINTENANCE

Excessive operator pressure will not improve the tool

eciency but will cause premature tool failure and operator

fatigue. Never allow the tool to run continuously whilst not in

contact with the surface being prepared.

Please be aware: that this tool will reduce in power or stop

working if the end cap (17) has become unscrewed.

Maintenance must only be carried out by a competent person.

Disconnect the tool from the air supply before carrying out any

of the following operations. Clean all debris from the exterior

of the tool.

Recommended lubricants

Oil the tool daily before use. Put a few drops of one of the

following zinc free air tool lubricants through the air inlet.

SHELL S22 or R10

CASTROL Hyspin ZZ32

Always use clean oil from a sealed container and ensure

ignition temperature is above 185degC°.

Cleaning

At intervals of no more than 40 hours or if operation becomes

unproductive and the piston shows signs of sticking, dismantle

and clean with a highly rened paran.

Immediately after cleaning, thoroughly oil the tool with one of

the recommended lubricants.

Head removal - Taper Fit (On site)

Lay the scaling hammer on a solid surface with the cutter

head (25) facing uppermost. Place the head removal washer

(32) between the cutter head and the body; insert the removal

pin (31), into cutter head hole (refer to diagram for pictorial

illustration). Wearing safety glasses and using a medium size

hammer give a sharp blow to the head of the pin, which will

release the cutter head from the piston.

Piston/Cylinder Assembly removal (Workshop)

Hold the scaler body (24) in a vice, using the ats provided and

with the end cap uppermost. On triple scalers, secure the tool

in a vice, clamping on all three cutter heads. Unscrew the end

cap (17). Remove spring cap (19) and spring (18) from the end

cap. From the bottom of the body, push up the cutter head to

remove the piston assembly.

Head Removal - Taper Fit (Workshop)

Lay the piston and cylinder assembly on a solid surface with

the cutter head facing uppermost. Place the head removal

washer (32) between the cutter head and the cylinder; insert

the removal pin (31), into cutter head hole (refer to diagram

for pictorial illustration). Wearing safety glasses and using a

medium size hammer, give a sharp blow to the head of the

pin, which will release the cutter head from the piston. Inspect

all components for wear, replace as necessary.

Valve body servicing (Workshop)

Clamp the handle (10) assembly rmly in a soft face jawed

vice (valve body end) throttle lever upper most. Using a 3mm

diameter pin punch, remove the throttle lever roll pin (8), and

then remove the throttle lever (7). Rotate the tool 180 degrees

in the vice to access the valve. Unscrew the valve cap (1) using

a screwdriver, check the valve cap ‘O’Ring (2), remove the

spring (3), push out the valve stem (4) and remove the ‘O’Ring

(5). Check the valve and ‘O’Ring for wear.

Assembly (Workshop)

Before any assembly takes place, ensure all parts are clean

and have a lm of air tool oil lubrication unless otherwise

stated. Avoid lubricating oil or grease contaminating the

threads of the end cap (17), the threads within the bore of the

bodies (24) and the tapers on piston and cutter heads. The

end caps will require securing with a thread-locking adhesive.

It is good practice to renew all ‘O’ Rings (2/5) and the brush

seals (22). Replace any parts showing signs of wear; paying

particular attention to the small bore of the cylinder.

Head Assembly - Taper Fit (On-Site)

Thoroughly clean around area of cutter head and piston.

Remove all traces of debris/oil from the taper on the piston

(20) and internal taper of the cutter head (25) by cleaning with

suitable oil free solvent. Place the tool in a position where the

end cap is on a solid surface; Select one of the cleaned new

cutter heads and place onto the taper of the piston. Using a

soft-faced hammer deliver a sharp blow to the cutter head.

Head Assembly - taper t (Workshop)

Remove all traces of oil and dirt etc, from the taper diameter

on the piston (20) and cutter head (25) by cleaning with

suitable oil free solvent. Fit the piston into the cylinder (21) as

shown in the service layout. Place the assembly onto a solid

surface; t a new brush-seal (22) over the piston and into the

recess of the cylinder. Select one of the cleaned new cutter

heads and place onto the taper of the piston. Using a

soft-faced hammer deliver a sharp blow to the cutter head.

Note: If you are re-tting a used cutter head to the piston it

is essential that the internal diameter of the cutter head is

re-surfaced using a medium grade of emery cloth - this will

ensure a good t between cutter head and piston, do not

use adhesive of any description on the taper. If the taper has

expanded too much on the old cutter heads, they may not

stay on the piston, replacements will be required.

Piston/Cylinder assembly (Workshop)

Lubricate the piston (20) and cylinder bore (21) and push the

piston into the cylinder bore. Lay the tool on a bench with the

body (24) on its side and insert the cylinder assembly into the

body.

www.trelawny.co.uk

PAGE 10

VLsF1Ex SCALING HAMMER

Trouble Shooting Cause Action

Poor performance or lack of power.

Low air pressure. Ensure that the air pressure is correct at 90psi, max 100psi.

If tool has been left for some time without use, the oil may dry out

slightly, causing a sticky residue. Strip tool down, clean and re-oil.

Tool worn out, can you feel side ways movement between the piston

and cylinder bore. Replace the piston and cylinder, along with a new bush seal.

Tool continues to run with trigger released. Valve seal may have become dislodged through the tool being

disconnected with the trigger in the open position.

Ensure that the trigger has not been taped or wired in the

open position.

Tapered cutterhead will not stay on piston.

Air pressure too high, piston hits bottom of cylinder

causing head to be jettisoned. Ensure that the air pressure is correct at 90psi, max 100psi.

Traces of oil remained on the tapered surfaces when replacing

cutter head.

Ensure that the cutterhead and pistons tapers are completely free of

oil, use a good degreasing agent and clean cloth prior to assembly.

Item NO. PART NO. DESCRIPTION

1 615.3021 Valve Cap

2809.0139 Valve Cap O’Ring

3 712.3022 Valve Spring

4618.3022 Valve Stem

5809.0089 Valve Seat O’Ring

6*423.5321 Valve Body Assembly (inc 1-8)

7 716.3000 Throttle Lever

8 813.0108 Roll Pin

9 711.5301 Adaptor

10 624.5350 Main Handle (Vibration Reduced)

11 717.5301 Rubber Grip

17 615.5341 Screwed Cap

18 712.5301 Compression Spring

19 615.5361 Spring Cap

20 612.5301 Piston (Std taper t)

21 613.5301 Cylinder (Std taper t)

22 614.5301 Brush Seal

24 411.5121 Single Scaler Body (Vibration Reduced, Std and H/Duty)

25 606.5303 Beryllium Copper Head (Taper Fit)

31 827.0428 Cutterhead Removal Pin

32 633.5301 Cutter Head Removal Washer

36 719.1380 Flexible Connector

37 821.2000 Hose Clamp

446.1510X Service Kit (2,4,5,7,8,17,18,19,20,22,25,31,32)

parts list

EXPLODED DIAGRAM

www.trelawny.co.uk

PAGE 12

VLsF1Ex SCALING HAMMER

technical specication

Machinery Directive Information:

This tool has been designed and produced in accordance with the following directives: 2006/42/EC Machinery Directive

and applicable harmonised standard: EN ISO 1 1148-4:2012

EN ISO 11148-4: 2010 Hand Held Non-Electric (Non-Rotary

Percussive Tools)

This tool conforms with the following EC legislation: ATEX DIRECTIVE 2014/34/EU

Based on the following harmonised standards: EN60079-0:2018

EN ISO 80079-36:2016

EN ISO 80079-37

Notied Body: Element Material Technology LTD

Certicate Number: EMT19ATEX0020X

If your company has any problem with our products or would like to discuss the possibility of an improvement being made to them, then please do not hesitate to

contact us. Your comments are both important and appreciated.

Trelawny tools are thoroughly tested under specied conditions in accordance with applicable internationally recognised standards. When a tool is used on site the

conditions may not be the same as those used in our tests.

Trelawny Surface Preparation Technology operates a policy of continuous product development and renement and therefore reserves the right to change technical

specications and product designs without giving prior notice.

© Copyright 2015, Trelawny SPT Limited, CV31 1XT. UK All rights reserved. Any unauthorised use or copying of the contents or part thereof is prohibited. This applies

to trademarks, model denominations, part numbers and drawings. Use only genuine Trelawny spares.

The use of non-Trelawny spare parts will invalidate the ATEX certication and also the warranty.

Trelawny SPT Ltd

13 Highdown Road, Sydenham Industrial Estate, Leamington Spa, Warwickshire, CV31 1XT, United Kingdom

Telephone: +44 (0) 1926 883781 – Fax +44 (0) 1926 450352

Email: sales@trelawny.co.uk

Model Piston

Diameter

Piston

Length

Piston

Stroke

Blows Per

Minute

Air

Consumption

Air

Pressure Length Working

Height Weight

Noise

Level LpA

dB (A)

Noise Level

LwA bD (A)

Vibration Level

m/s2

Primary

Vibration Level

m/s2

Secondary

VL Single Scaler

Standard 27mm (1.06”) 68.6mm

(2.7”)

26.0mm

(1.023”) 3000 3.3 lps (7.0

cfm) 6.2 bar (90psi) 515mm

(20.3”) 140mm (5.5”) 2.46kg

(5.42lbs) 92.5 106.3 3.7 (k) 9.9 (k)

Noise Levels: Noise level measured in accordance with: EN ISO 15744: 2008

Vibration Levels: Vibration measured in accordance with: EN ISO 28927-9:2012 and EN ISO 20643:2005. (k) Equals the factor of uncertainty, which allows for variations in

measurement and production. Vibration Data gures are tri-axial, which gives the total vibration emission. Because of various factors, the range of vibration from these

tools may vary between -0% +40% (9.9 m/s2 -13.86 m/s2). The vibration is dependent on the task, the operators grip and feed force employed etc.

NOTE: The above vibration levels were obtained from tri-axial measurements to comply with the requirements of “The Control of Vibration at Work Regulations 2005*” and

the revisions to the (8662) now EN ISO 28927-9:2012 and EN ISO 20643:2005 series of standards. These values are at least 1.4 times larger than the values obtained from

single axis measurements. *Based on European Union Council Directive 2002/44/EC (Physical Agents (Vibration) Directive)).

notes

www.trelawny.co.uk

PAGE 14

VLsF1Ex SCALING HAMMER

notes notes

PAGE 16

VLsF1Ex SCALING HAMMER

DEALER STAMP:

need to contact us?

Trelawny SPT Limited

Trelawny House, 13 Highdown Road, Sydenham Industrial Estate,

Leamington Spa, Warwickshire, CV31 1XT, United Kingdom

Manual Part Number:

735.3603

Telephone: +44 (0)1926 883781 Fax: +44 (0)1926 450352

Email: sales@trelawny.co.uk

Website: www.trelawny.co.uk

Table of contents

Other Trelawny Tools manuals

Trelawny

Trelawny Vibro Lo Troubleshooting guide

Trelawny

Trelawny SF11EX User manual

Trelawny

Trelawny Single Scaler Standard Duty User manual

Trelawny

Trelawny SF3EX User manual

Trelawny

Trelawny Trident Neptune User manual

Trelawny

Trelawny VL203Ex Troubleshooting guide

Trelawny

Trelawny VL223EX Series User manual

Trelawny

Trelawny LPS55 User manual