W415-1466 / 04.21.15

EN

8

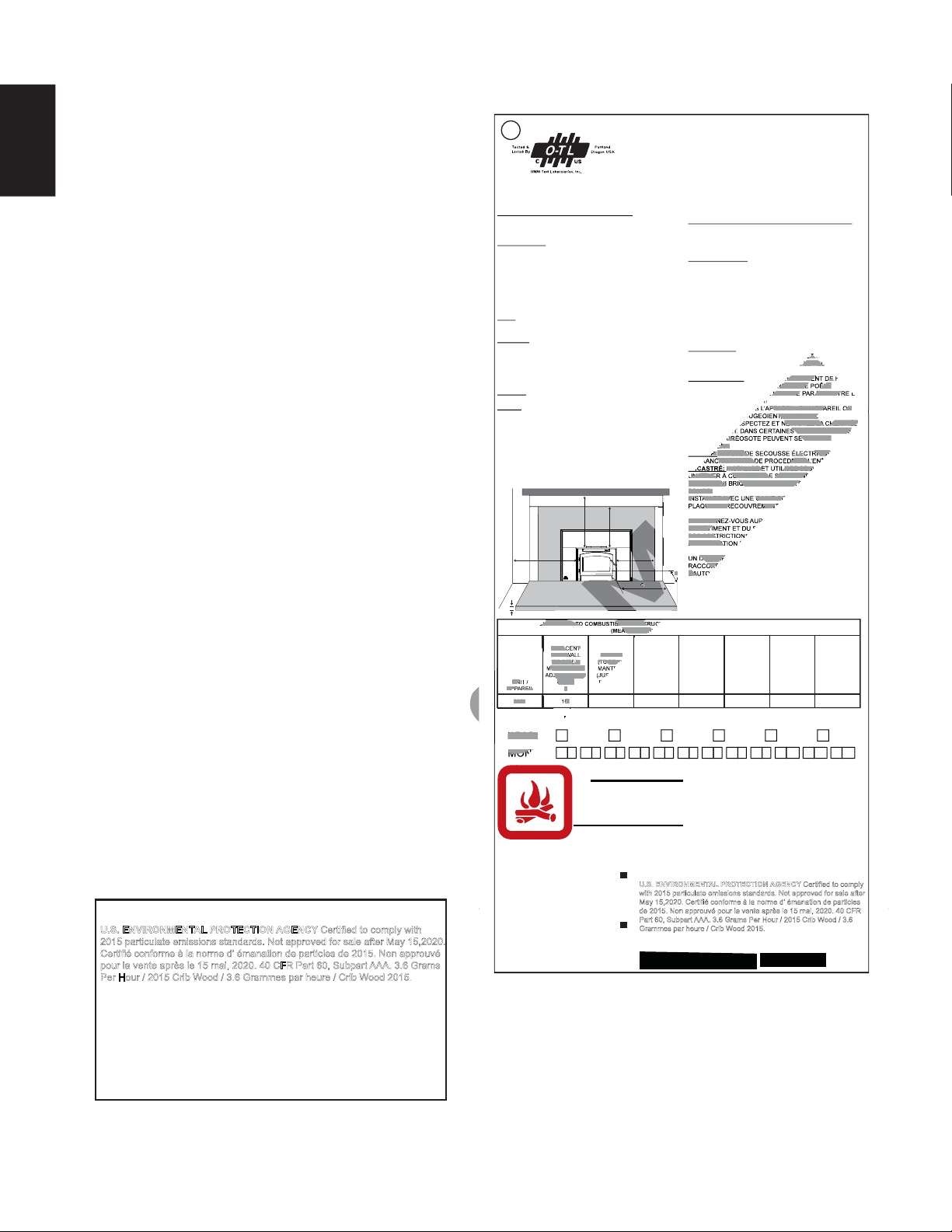

2.6 RATING PLATE LOCATION

INSTALL AND USE ONLY IN ACCORDANCE WITHTHE

MANUFACTURER’S INSTRUCTIONSAND LOCALBUILDING CODES.

MINIMUM CEILING HEIGHT: 7FT (2.13m)

HEARTH EXTENSION / FLOOR PROTECTION: MUST BE

NON-COMBUSTIBLE AND EXTEND 22" IN FRONTOF THE

INSERTAND 8" ON BOTH SIDES WITHA MINIMUM

THICKNESS OF .500" (K=0.84)

CHIMNEY TYPE: MINIMUM 6” (152mm) DIAMETER APPROVED

RESIDENTIAL TYPE FOR MOBILE HOME USEACHIMNEY

LISTED TO ULC S629 IN CANADAOR UL 103HTIN THE USA.

DO NOT OBSTRUCT SPACE UNDER HEATER.

SPECIAL METHODSARE REQUIRED WHEN PASSING A

CHIMNEY THROUGHAWALLOR CEILING. SEE INSTRUC-

TIONS AND BUILDING CODES.

DO NOT CONNECT THIS UNITTOACHIMNEY FLUE SERVING

ANOTHER APPLIANCE.

FUEL: FOR USE WITH SOLID WOOD FUEL ONLY. DO NOT

USE GRATE OR ELEVATE FIRE. BUILD WOOD FIRE DIRECTLY

ON HEARTH.

WARNING: RISK OF SMOKE SPILLAGE. OPERATE ONLY WITH

DOOR FULLY CLOSED.

REPLACE GLASS ONLY WITH CERAMIC GLASS.

DO NOT OVERFIRE. IF HEATER OR CHIMNEY CONNECTORS

GLOW,YOU ARE OVERFIRING. INSPECTAND CLEAN

CHIMNEY FREQUENTLY. UNDER CERTAIN CONDITIONS OF

USE CREOSOTE BUILD-UP MAY OCCUR RAPIDLY.

DANGER: RISK OF ELECTRICAL SHOCK. DISCONNECT

POWER BEFORE SERVICING UNIT.

INSERT: INSTALLAND USE ONLY IN SOLID FUEL BURNING

FIREPLACES. DO NOT REMOVE BRICKS OR MORTAR FROM

SOLID FUEL BURNING FIREPLACE. INSTALL WITHA

POSITIVE FLUE CONNECTORAND FACEPLATE.

CONTACT LOCAL BUILDING FIRE OFFICIALS ABOUT RESTRIC-

TIONS AND INSTALLATION INSPECTION IN YOUR AREA.

A MINIMUM CLEARANCE OF 18” (457mm)TO THE CHIMNEY

CONNECTOR MAY BE REQUIRED BY THEAUTHORITY

HAVING JURISDICTION.

POUR INSTALLATION ET UTILISATION CONFORMÉMENT

AUX INSTRUCTIONS DU FABRICANTETAUX CODES

LOCAUX DU BÂTIMENT.

HAUTEUR DE PLAFOND MINIMAL: 7PI (2,13m).

BASE DE PROTECTION/PROTECTION DE PLANCHER :

DOIT ÊTRE DE NATURE INCOMBUSTIBLE ET SE

PROLONGER DE 22" À L’AVANT DE L’ENCASTRÉ ET 8"

SUR LES CÔTÉS, ETAVOIR UNE ÉPAISSEUR MINIMALE

DE 0,500" (K = 0,84).

TYPE DE CHIMNÉE: DIAMÈTRE MINIMAL DE 6” (152mm)

APPROUVÉE POUR USAGE RÉSIDENTIEL. MAISON

MOBILE EMPLOYEZ UNE CHEMINÉE HOMOLOGUÉE ULC

S629 AU CANADAOU UL 103HTAUX ÉTATS-UNIS.

NE RIEN ENTREPOSER SOUS L’APPAREIL.

DES MÉTHODES SPÉCIALES SONT REQUISES

LORSQU’UNE CHEMINÉE TRAVERSE UN MUR OU UN

PLAFOND. VOIR LES INSTRUCTIONS ET LES CODES DU

BÂTIMENT.

NE PAS RACCORDER À LA CHEMINÉE D’UN AUTRE

APPAREIL.

COMBUSTIBLE: POUR USAGE AVEC LE BOIS

SEULEMENT. N’UTILISEZ PAS DE CHENETOU NE

SURÉLEVEZ PAS LE BOIS. PRÉPAREZ LE FEU DIRECTE-

MENT SUR L’ÂTRE.

AVERTISSEMENT: RISQUE D’ÉCHAPPEMENTDE FUMÉE.

TENIR LA PORTE FERMÉE LORSQUE LE POÊLE

FONCTIONNE. REMPLACEZ LA VITRE PAR UNE VITRE EN

CÉRAMIQUE SEULEMENT.

NE SURCHAUFFEZ PAS L’APPAREIL. SI L’APPAREIL OU

LES RACCORDS ROUGEOIENT, L’APPAREIL

SURCHAUFEE. INSPECTEZ ET NETTOYEZ LACHEMINÉE

FRÉQUEMMENT. DANS CERTAINES CONDITIONS, DES

DÉPÔTS DE CRÉOSOTE PEUVENT SE FORMER

RAPIDEMENT.

DANGER: RISQUE DE SECOUSSE ÉLECTRIQUE.

DÉBRANCHEZ AVANT DE PROCÉDER À L’ENTRETIEN.

ENCASTRÉ: INSTALLEZ ET UTILISEZ SEULEMENT DANS

UN FOYER À COMBUSTIBLE SOLIDE. NE RETIREZ PAS DE

MORTIER, NI BRIQUES DU FOYER À COMBUSTIBLE

SOLIDE.

INSTALLEZ AVEC UNE GAINE CONFORME ET UNE

PLAQUE DE RECOUVREMENT.

RENSEIGNEZ-VOUS AUPRÈS DES AUTORITÉS LOCALES

DU BÂTIMENT ET DU SERVICE DES INCENDIESAU SUJET

DES RESTRICTIONS ET DES INSPECTIONS

D’INSTALLATION DANS VOTRE RÉGION.

UN DÉGAGEMENT MINIMAL DE 18” (457mm) JUSQU’AU

RACCORD DE LA CHEMINÉE PEUTÊTRE EXIGÉ PAR

L’AUTORITÉ AYANT JURIDICTION.

W385-2029

DATE CODE / DE DATE

TI-2201

LISTED SOLID FUEL BURNING FIREPLACE INSERT

TESTED TO: / TESTÉ SELON :

UL1482 - 1996 / ULC S628 - 1993

MODEL / MODÈLE: 2201

ENCASTRÉ ÀCOMBUSTIBLESOLIDEHOMOLOGUÉ

CAUTION:

ATTENTION:

HOTWHILE INOPERATION. DONOT

TOUCH.KEEPCHILDRENCLOTHINGAND

FURNITUREAWAY. CONTACTMAYCAUSE

SKINBURNS.

QUAND L’APPAREILFONCTIONNE, LA

SURFACE DEVIENT CHAUDE. NE PAS

TOUCHER. TENIR LES ENFANTS, LES

VÊTEMENTS ET LES MEUBLES À

L’ÉCART. LE CONTACT PEUT CAUSER

DES BRÛLURES À LAPEAU.

A

BC

D

E

F

G

WOLFSTEELLTD.

24 NAPOLEON ROAD,

BARRIE, ON, L4M 0G8 CANADA

NACGUANGZHOUP.R.C.

NO.69 HEFENG ROAD,

GUANGZHOU,CHINA

CLEARANCE TO COMBUSTIBLE CONSTRUCTION / DÉGAGEMENTS AUX MATÉRIAUX COMBUSTIBLES:

(MEASURED TO UNIT / À PARTIR DE L’APPAREIL)

UNIT /

APPAREIL

ADJACENT

SIDE WALL

(TO SIDE) /

MUR LATÉRAL

ADJACENT (AU

CÔTÉ)

A

MANTLE

(TO TOP) /

MANTEAU

(JUSQU’AU

DESSUS)

B

TOP FACING

(TO TOP) /

HAUT DE LA

FAÇADE

(JUSQU’AU

DESSUS)

C

SIDE FACING

(TO SIDE) /

CÔTÉ DE LA

FAÇADE (AU

COTÉ)

D

MINIMUM

HEARTH

EXTENSION /

BASE DE

PROTECTION

MINIMALE

E

MINIMUM

HEARTH

THICKNESS /

ÉPAISSEUR

MINIMALE DE LA

BASE DE

PROTECTION

F

MINIMUM

HEARTH SIDE

EXTENSION /

BADE DE

PROTECTION

LATÉRALE

MINIMALE

G

2201 8”1”22”10”22”30”16”

REPORT NO. 415-S-08-2

MANUFACTURE DATE: / DATE DE FABRICATION:

YEAR: 2015 2016 2017 2018

MONTH: 2019 2020

243658710912111

U.S. ENVIRONMENTAL PROTECTION AGENCY Certified to comply

with 2015 particulate emissions standards. Not approved for sale after

May 15,2020. Certifié conforme à la norme d’ émanation de particles

de 2015. Non approuvé pour la vente après le 15 mai, 2020. 40 CFR

Part 60, Subpart AAA. 3.6 Grams Per Hour / 2015 Crib Wood / 3.6

Grammes par heure / Crib Wood 2015.

For rating plate location, see “INSTALLATION

OVERVIEW” section.

NOTE: The rating plate must remain with

the appliance at all times. It must not be

removed.

This illustration is for reference only. Refer to the

rating plate on the appliance for accurate information

PPAREIL. SI L’APPAREIL OU

CRÉOSOTE PEUVENT SE FORMER

RISQUE DE SECOUSSE ÉLECTRIQUE

CHEZ AVANT DE PROCÉDER À L’ENT

INSTALLEZ ET UTILISEZ SEUL

UN FOYER À COMBUSTIBLE SOLIDE. NE

MORTIER, NI BRIQUES DU FOYER À C

INSTALLEZ AVEC UNE GAINE CO

CLEARANCE TO COMBUSTIBLE CONSTR

This wood appliance needs periodic inspection and repair for proper operation.

Consult the owner’s manual for further information. it is against federal

regulations to operate this wood appliance in a manner inconsistent with the

operating instructions in the owner’s manual. / Cet appareil au bois doit faire

l'objet d'une inspection et d'un entretien périodiques pour un fonctionnement

adéquat. Consultez le manuel d'instructions pour plus d'information. Les

règlements fédéraux interdisent d'utiliser cet appareil de chauffage d'une

manière allant à l'encontre des instructions de fonctionnement contenues dans

ce manuel.

U.S. ENVIRONMENTAL PROTECTION AGENCY Certified to comply with

2015 particulate emissions standards. Not approved for sale after May 15,2020.

Certifié conforme à la norme d’ émanation de particles de 2015. Non approuvé

pour la vente après le 15 mai, 2020. 40 CFR Part 60, Subpart AAA. 3.6 Grams

Per Hour / 2015 Crib Wood / 3.6 Grammes par heure / Crib Wood 2015.

W385-2050

MODEL / MODÈLE: EPI22