Timpte hopper User manual

1Date of Origin – 02/01/08

TABLE OF CONTENTS

NORMALTRAILEROPERATION ...................................................................................................................................................................... 3

SAFETY ...................................................................................................................................................................................................... 4

DECALS&WARNINGS....................................................................................................................................................................... 4,5

AIRBRAKESYSTEM ............................................................................................................................................................................. 6

WHEELNUTTORQUE ............................................................................................................................................................................ 6

REARIMPACTGUARDS ........................................................................................................................................................................ 6

ABSBRAKING SYSTEM........................................................................................................................................................................ 7

BACKUPWARNINGSYSTEM................................................................................................................................................................ 7

CONTROLOFSAFEOPERATION .......................................................................................................................................................... 8

INSPECTIONPROCEDURESBEFOREEACHTRIP ............................................................................................................................................ 9

LEGALREQUIREMENTFMCS49CFR392.7 ......................................................................................................................................... 9

TRAPDOORLOCKS .............................................................................................................................................................................. 9

LIGHTSANDREFLECTORS ................................................................................................................................................................. 10

ELECTRICALWIRING ........................................................................................................................................................................... 10

FIFTHWHEELANDKINGPINENGAGEMENT ...................................................................................................................................... 10

TIRES .................................................................................................................................................................................................... 10

MUDFLAPS ......................................................................................................................................................................................... 10

TARPSYSTEM ..................................................................................................................................................................................... 10

LANDINGGEAR ................................................................................................................................................................................... 10

HUBMAINTENANCE ............................................................................................................................................................................ 11

WHEELSANDRIMS ............................................................................................................................................................................. 11

HUBLUBRICANT ................................................................................................................................................................................. 11

SIDESTRUCTURES .............................................................................................................................................................................. 12

SUSPENSIONANDSUSPENSIONSUBFRAME .................................................................................................................................... 12

OPERATINGINSTRUCTIONS .......................................................................................................................................................................... 13

PARKING/EMERGENCYBRAKINGSYSTEM........................................................................................................................................ 13

TRAILERLOADING .............................................................................................................................................................................. 14

TRAILERUNLOADING ......................................................................................................................................................................... 14

TRAPDOOROPERATION .................................................................................................................................................................... 15

SINGLESPEEDTRAPOPENERS ................................................................................................................................................ 15

2SPEEDTRAPOPENERS ........................................................................................................................................................... 15

TRAPDOORLATCH(PAWL)-SETUPANDADJUSTMENT ....................................................................................................... 16

CONTROLBOXOPERATION ............................................................................................................................................................... 18

MANUALOPERATION ................................................................................................................................................................ 18

SETTINGSFUNCTIONSONREMOTE.......................................................................................................................................... 18

PROGRAMMINGEASYFLOWHOPPERDOORS ....................................................................................................................... 19

WIRELESSOPERATION .............................................................................................................................................................. 20

TROUBLESHOOTINGGUIDELINES ............................................................................................................................................ 21

PRESSURERELIEFADJUSTMENT .............................................................................................................................................. 20

EMERGENCYAPPLICATIONWITHDRILL ................................................................................................................................... 23

ROLLTARP .......................................................................................................................................................................................... 24

TARPTENSION..................................................................................................................................................................................... 24

THUNDERELECTRICTARPSYSTEM ................................................................................................................................................... 26

OPTIONALARMADJUSTMENT .................................................................................................................................................. 27

ERRORCODES ........................................................................................................................................................................... 28

SETTINGFUNCTIONSONREMOTE ............................................................................................................................................ 29

THUNDERTARPRFPROGRAMMING ......................................................................................................................................... 30

THUNDERELECTRICTARPSCHEMATIC .................................................................................................................................... 31

LANDINGLEGS ................................................................................................................................................................................... 32

ACCESSSYSTEM ............................................................................................................................................................................... 33

LIFTABLE,REGULATEDAXLE ............................................................................................................................................................. 33

GENERALMAINTENANCE ............................................................................................................................................................................. 34

AVOIDINGCONTAMINATION ............................................................................................................................................................... 34

TRAILERWASHING ............................................................................................................................................................................. 34

CORROSIVEDETERIORATION............................................................................................................................................................. 34

TRAPFRAMEMAINTENANCE ............................................................................................................................................................. 35

ROLLERDOORFIELDADJUSTMENT ............................................................................................................................................ 36, 37

AIRHAMMER(VIBRATOR)MAINTENANCE ........................................................................................................................................ 38

VIBRATORAIRLINESCHEMATIC ......................................................................................................................................................... 39

HUBMAINTENANCE ............................................................................................................................................................................ 40

WHEELBEARINGINSPECTION ............................................................................................................................................................ 40

WHEELBEARINGADJUSTMENT ......................................................................................................................................................... 40

BEARINGLUBRICANT ......................................................................................................................................................................... 40

BRAKES ............................................................................................................................................................................................... 41

AIRBRAKESYSTEM- TROUBLESHOOTING ............................................................................................................................................... 43

BRAKECONTROLS ............................................................................................................................................................................. 43

IN-LINEAIRFILTER ............................................................................................................................................................................... 44

AIRSYSTEMCOLDWEATHEROPERATION ....................................................................................................................................... 44

AIRBRAKEPIPINGSCHEMATIC ....................................................................................................................................................45, 46

SPRINGBRAKES ................................................................................................................................................................................. 47

AUTOMATICSLACKADJUSTERS ....................................................................................................................................................... 47

WHEELASSEMBLIES........................................................................................................................................................................... 48

WHEELINSTALLATION ........................................................................................................................................................................ 48

TIRECHANGEPROCEDURE .......................................................................................................................................................................... 49

AXLEALIGNMENT ............................................................................................................................................................................... 50

AIR-RIDESUSPENSIONSYSTEMS ...................................................................................................................................................... 51

AIR-RIDESUSPENSIONSCHEMATIC ................................................................................................................................................... 52

SPRINGSUSPENSIONMAINTENANCE ................................................................................................................................................ 53

ELECTRICALSYSTEMMAINTENANCE ............................................................................................................................................... 55

LIFTBOX4-WAYWIRINGSCHEMATIC ............................................................................................................................................... 56

ELECTRICALSYSTEMDIAGRAM........................................................................................................................................... 57, 58, 59

LANDINGLEGS ................................................................................................................................................................................... 60

REPORTINGSAFETY DEFECTS- 49CFR575.6 (a)(2)(ii) ................................................................................................................... 61

MAINTENANCESCHEDULE-HOPPER .......................................................................................................................................................... 61

TIMPTE“PEACEOFMIND”LIMITEDWARRANTY .......................................................................................................................................... 64

FILINGAWARRANTYCLAIM ........................................................................................................................................................................ 68

2

Date of Origin – 02/01/08

This manual has been prepared to help you operate your newTimpte trailer successfully, economi-

cally, and safely. Please read your Operator’s Manual carefully and have a full understanding prior

to using your trailer or performing any maintenance. We urge you to contact your Timpte Trailer

Company factory representative or the Vice President of Engineering at Timpte (402-367-3056)

immediately should you have any questions or need an explanation.

Timpte has provided several warnings in your Operator’s Manual and on your trailer to help pre-

vent personal injury. Timpte can not foresee all use or misuse of the trailer. Always use common

sense judgment while using or performing maintenance to your trailer. Your safety is our primary

concern.

This safety alert symbol is used throughout this manual to indicate potential personal

safety hazards. Failure to heed the warnings associated with the safety alert symbol can

result in property damage, serious injury or death.

Safety decals appear at various locations on your new Bulk Commodity trailer. The decals are

provided for your safety and should be kept clean. Replace any decal that has become worn or

damaged, painted over, or otherwise difficult to read. Replacement decals are available at no

cost through Timpte by calling 402-367-3056.

Information contained in this Operator’s Manual is based on the latest information available at the

time of publication. Changes are continually being made to improve our product lines.

In addition to this Operator’s Manual, there is a set of informational manuals supplied with your

trailer from the manufacturers of the various components used to build this trailer including but not

limited to; • the suspension

• the anti-lock brake system

• the axles, brakes, wheel ends

• the tarp system

• the spring brakes chambers

Please read these manuals carefully as they contain detailed information on these different trailer

components as well as safety and maintenance information that is important to you.

We want to thank you for purchasing a Timpte trailer and to let you know that it was designed to

meet your specific needs for a Bulk Commodity trailer and was built for long life and low cost of

operation. However, regular and proper maintenance of the trailer and your common sense use of

it are required to extend the life of the trailer.

IMPORTANT

!

3Date of Origin – 02/01/08

ThisTimpte trailer is designed for operation within legalhighwayspeedlimitsonreasonableroad

surfacesforthetypeofserviceitwasbuilttoperform,inaccordancewiththenotedweightrestric-

tions.

“NormalService”meanstheloadingandtransportationofuniformlydistributedlegal loads of

properlysecured, noncorrosive cargo, inaccordancewithanyapplicable factory instructions and

inamannerwhich does not subject the trailer or parts of the trailer to (a) concentrated loads;(b)

loadsinexcessoftheGrossAxleWeightRating(GAWR) or Gross Vehicle WeightRating

(GVWR)statedon the Certification Plate affixedtothetrailerbyTimpte; and (c) accidentaldam-

age,or(d) stresses, impacts or shocks greater than thosecommensuratewithnormal,reason-

ablelawfuluse.

TheGAWR(grossaxleweightrating)is the structural capability ofthelowestratedmember of the

runninggear components: suspensionsystem,hubs, brake drums,wheels,bearings, axles, brake

liningsortires.

TheGVWR (gross vehicle weightrating)isthestructural capability of thetrailerwhensupportedby

thekingpin and axleswiththeload uniformly distributedthroughoutthecargo space.

NORMAL TRAILER OPERATION

The maximum load indicated on the identification plate

may not be a legal load on the highway you plan to use.

States have differing laws and regulations affecting vehicle

lengths and weights on roads that are not a part of the

primary interstate road system.

Modification of the Trailer – Anymodificationmadetothe trailer must comply with DOTand

NHTSAregulations and must notcompromisethegrossvehicle weight rating (GVWR)ofthe

trailer. Anymodificationmadetothe trailer without prior approval ofTimpte mayvoidthewarranty.

Anyoperationof the trailer outside the limitations stated inthismanualwillvoidany responsibility

ofTimpteTrailerCompanyforanyofitsresults.

NOTICE:

4

Date of Origin – 02/01/08

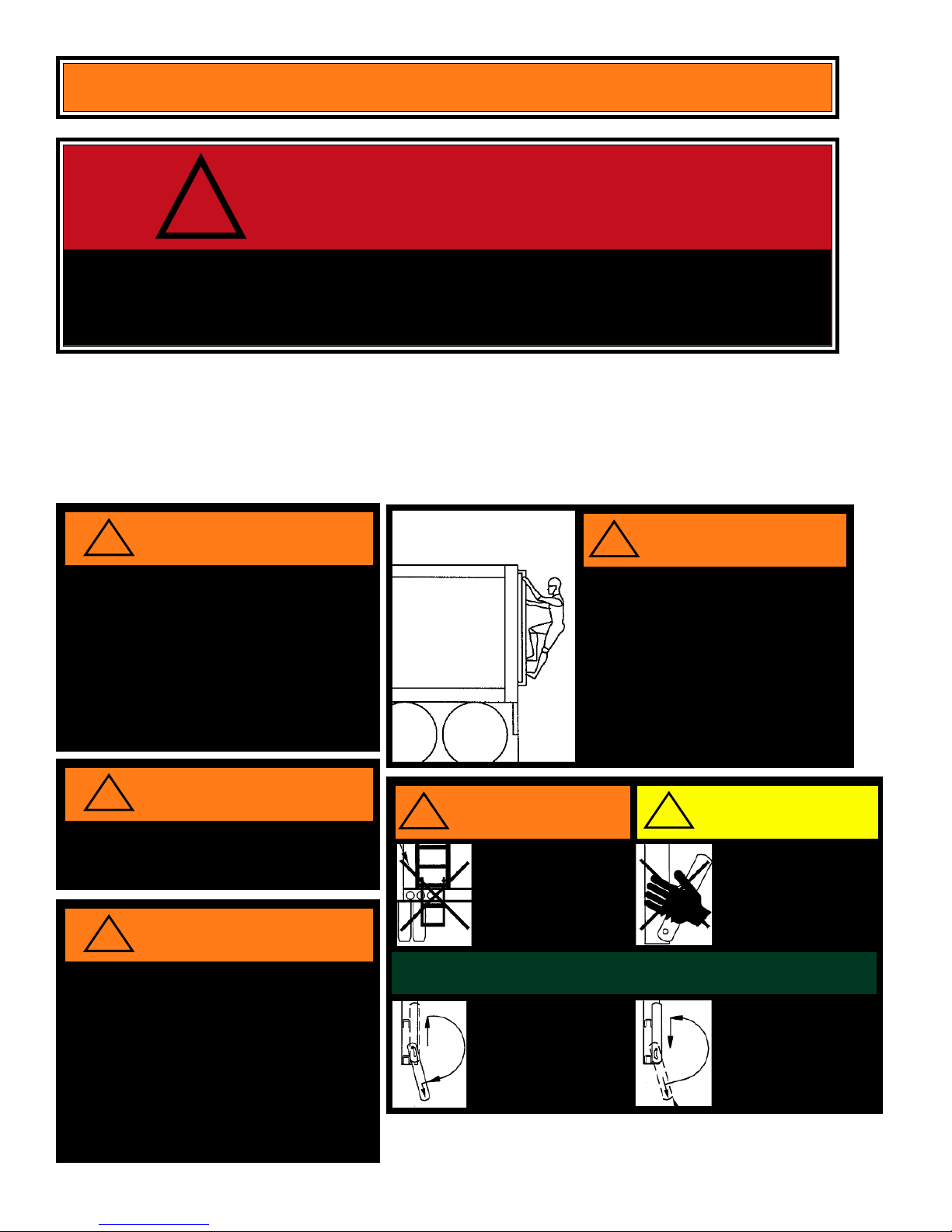

WARNING

!

PERSONAL INJURY, DEATH,AND PROPERTY DAMAGE MAY RESULT FROM

IMPROPER OPERATION OR UNSAFE PRACTICES. BE SURE TO READ AND

FOLLOW ALL DECALSAND EMBLEMS CAREFULLY.

The following section contains the decals and emblems used on the Timpte Hopper

Trailers. Due to differences in configurations and equipment, your trailer may or may not

use all the decals and emblems shown. Newer trailers may also have decals and em-

blems that differ from older trailers. Replace damaged or missing decals promptly.

Replacement decals for this trailer are available without charge by calling Timpte Trailer

Company at 402-367-3056.

TIMPTE INC

CAUTION

WARNING

!

FAILURE TO USE PROPERLY MATCHED WHEELS, STUDS, BRAKE

DRUMS OR CAP NUTSWILL RESULT IN EQUIPMENT DAMAGE

AND COULD RESULT IN SERIOUS INJURY OR DEATH IFWHEEL

COMES OFF.

WARNING

!

1. CHECK PIN TO ASSURETHAT IT IS PROPERLY

ENGAGEDWITH FIFTHWHEEL.

2. KEEPTHE UPPER COUPLER LUBRICATED AND FREE

OF DEBRISTO PREVENT GALLING OFTHE FIFTH

WILL PLATE.

3. INSPECT THE KING PIN ANDTHE PLATE ASSEMBLY

REGULARLY FOR WEAR AND CRACKS.

FAILURE TO FOLLOWTHESE WARNINGS COULD RESULT

IN SERIOUS INJURY OR DEATH.

WARNING

!

1. EXERCISE EXTREME CAUTIONWHILE CLIMBING

ON ACCESS SYSTEM.

2. ALWAYS MAINTAIN 3-POINT CONTACT.

(2 HANDS & 1 FOOT OR 2 FEET AND 1 HAND)

3. DO NOT WEAR RINGS OR ANYTHINGTHAT

CAN CATCH ON LADDER.

4. USE LADDER SIDE RAIL FOR HAND HOLD, NEVER

USETHE RUNG.

5. NEVER CLIMB OVERTHETOP OFTHE TRAILER.

NEVER ENTERTHE INSIDE COMPARTMENTS FOR

ANY REASON.

FAILURE TO FOLLOW THESEWARNINGS COULD

RESULT IN SERIOUS INJURY OR DEATH.

WARNING

!

• FEDERALLY REQUIRED LAMPS

MUST NOT BE OBSTRUCTED

• ALWAYS RAISE AND STORE

LOWER LADDER SECTION

BEFORE MOVING TRAILER.

• FAILURE TO COMPLY CAN

CAUSE INJURY OR DEATH.

WARNING

!

THIS TRAILER IS EQUIPPEDWITH A REGULATED LIFT

AXLE.

*LIFTAXLEMUSTBE ACTIVATEDINDOWNPOSITION

WHENTRAILERISLOADED.FAILURETOCOMPLY

WILLRESULTINDETERIORATIONOFBRAKING

PERFORMANCEANDREDUCEDROLLSTABILITY.

*LIFTAXLEMUST BE ACTIVATED IN RAISED POSITION

WHENTRAILER IS EMPTY.

FAILURETOFOLLOWTHESEWARNINGSCOULD

RESULTINPERSONALINJURYORDEATH.

SAFETY

SWING-DOWN LADDER OPERATION

CAUTION

!

• MOVING PARTS HAVE

PINCH POINTS.

• STAY CLEAR OF SIDE

RAILSWHEN OPERATING

SWING-DOWN LADDER.

• FAILURE TO COMPLY CAN

CAUSE INJURY.

TO LOWER AND USE LADDER:

1. GRASP RUNG FIRMLY & LIFT.

2. ROTATE LADDER DOWNWARD.

3. MAKE SURE LADDER IS

SECURELY ENGAGED IN

UPPER ENDS OF SLOTS.

TO RAISE AND STORE LADDER:

1. GRASP RUNG FIRMLY, ROTATE

LADDER UPWARDWHILE

HOLDING RADIALLY OUTWARD.

2. SLIDE DOWNWARD IN SLOTS.

3. MAKE SURE LADDER IS FULLY

ENGAGED (STORED SECURELY).

5Date of Origin – 02/01/08

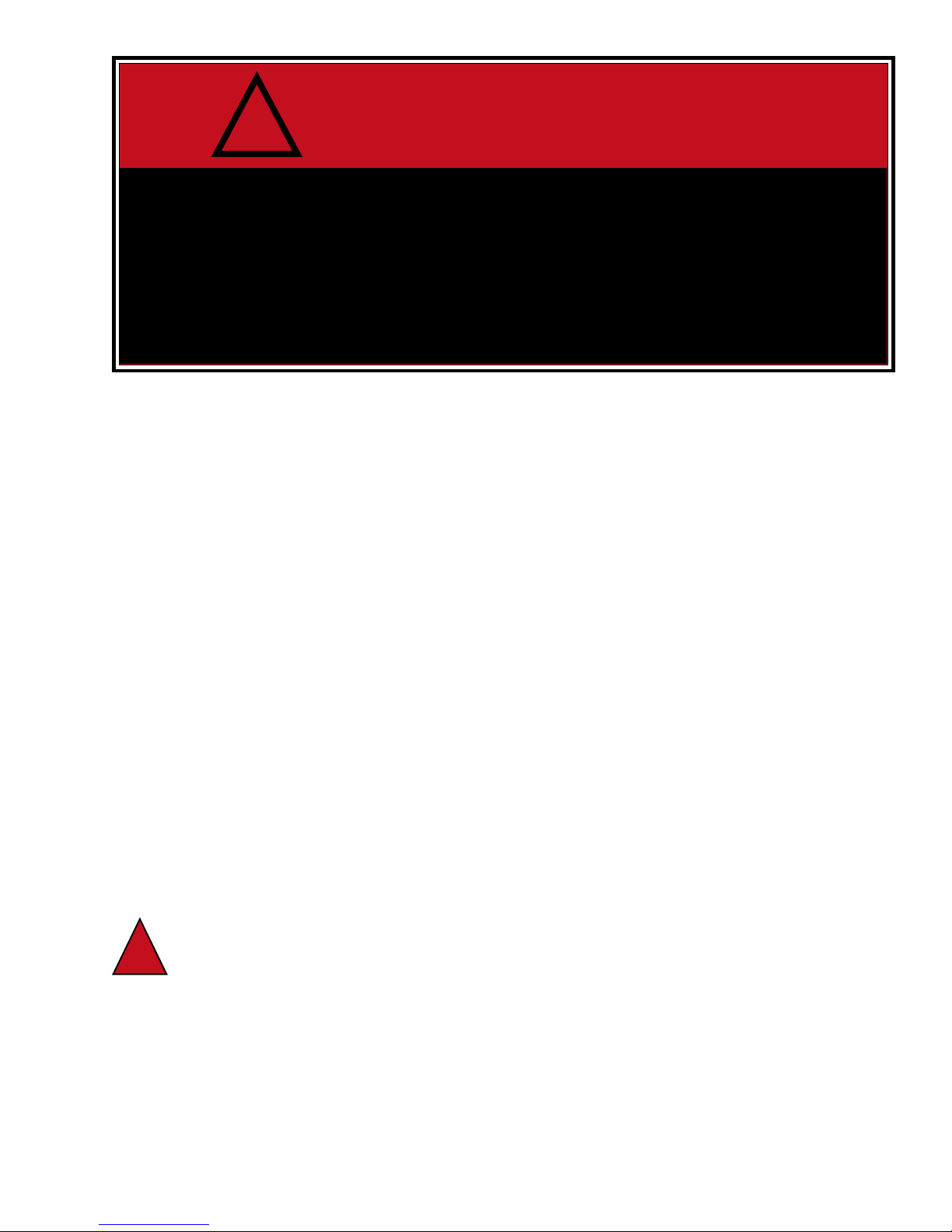

DANGER

!

IF SPRING BRAKES ARE CAGED, DEACTIVATED OR REMOVED,

THISVEHICLEWILL HAVE NO EMERGENCY PARKING BRAKES AND

MUST NOT BE PARKEDWITHOUT BLOCKINGWHEELS OR DRIVEN.

NEVER STAND BETWEENTHE BACK OFTHE TRAILER AND ANY

STATIONARY OBJECT.

FAILURE TO FOLLOWTHIS SAFETY PRECAUTION WILL RESULT IN

DEATH OR SERIOUS INJURY

THIS PRODUCT IS PROTECTED BY

US & FOREIGN PATENTS ANDTRADEMARKS INCLUDING:

PATENT # 6,736,297 B2

6,059,372

6,814,532B1

2,255,368

REGISTRATION # 1,411,224

TIMPTE TRAILER CO.

1827INDUSTRIAL DRIVE

DAVID CITY, NE 68632

WARNING

!

THIS TRAILER IS EQUIPPEDWITH TRAILING BEAM AIR

RIDE SUSPENSION.

1. MANUALLY EXHAUST ALL AIR IN THE SUSPENSION

SYSTEM PRIOR TO SUPPORTING A LOADED TRAILER

ON THE SUPPORT LEGS. FAILURE TO COMPLY CAN

CAUSE STRUCTURAL DAMAGE TO THE SUPPORT LEG

BRACES.

2. DO NOT USE EXCESSIVE FORCE WHEN COUPLING THE

TRACTOR TO THE TRAILER (EMPTY OR LOADED)

CONTINUING TO BACK-UP A TRACTOR/TRAILER WITH

THE TRAILER BRAKES LOCKED CAN ROTATE THE

TRAILING BEAMS AND OVEREXTEND THE SUSPEN-

SION. OVEREXTENSION WILL CAUSE DAMAGE TO THE

SUSPENSION SYSTEM.

3. MANUALLY EXHAUST ALL AIR IN THE SUSPENSION

SYSTEM PRIOR TO AND DURING UNLOADING THE

TRAILER. AFTER UNLOADING THE TRAILER, IMMEDI-

ATELY ACTUATE THE AIR AND WAIT FOR THE SUSPEN-

SION TO RETURN TO THE NORMAL RIDE HEIGHT

BEFORE MOVING THE VEHICLE.

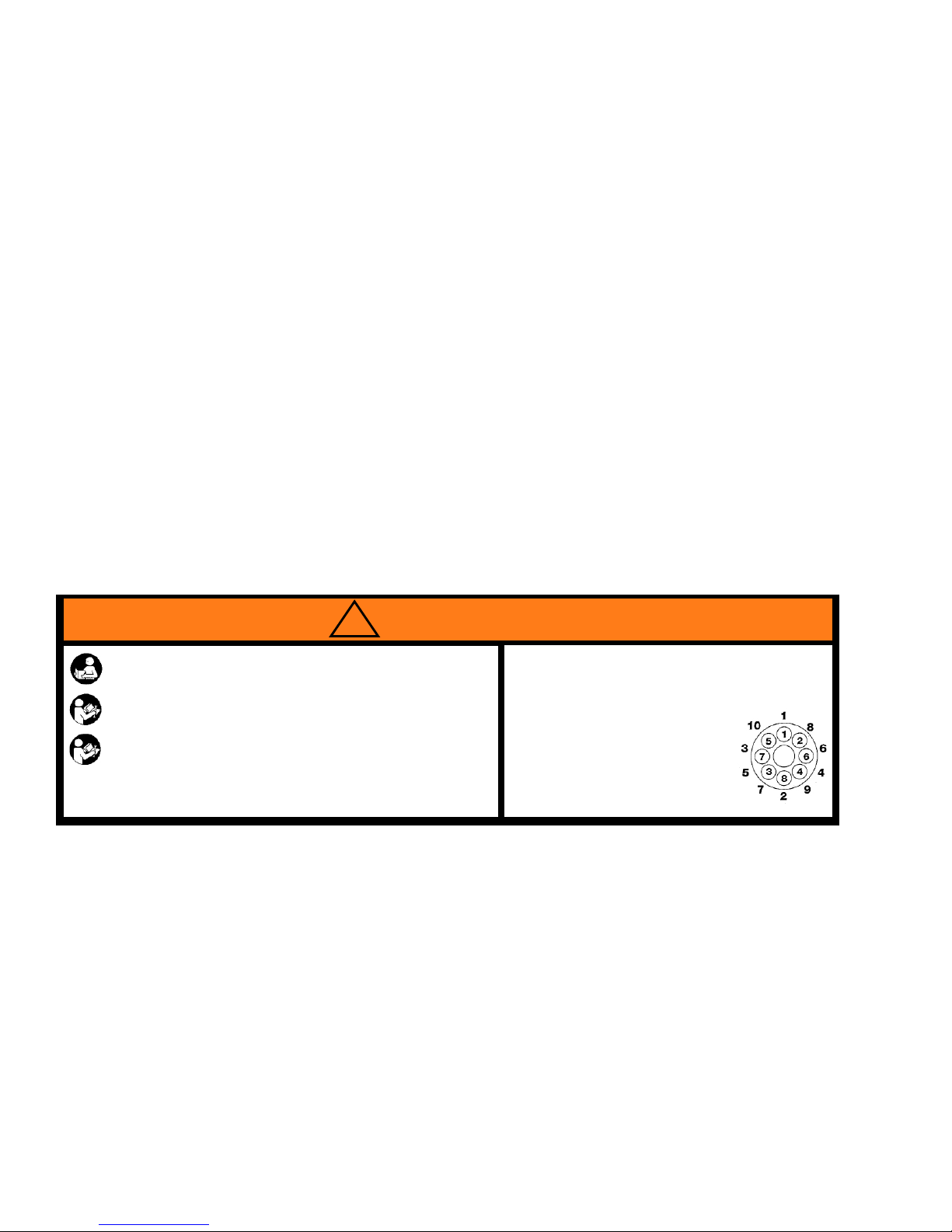

WARNING

!

THIS TRAILER IS EQUIPPED WITH ANTILOCK BRAKE SYSTEM (ABS).

D.O.T. REGULATION FMVSS-121 REQUIRE ABS RECEIVE CONSTANT

POWER FROM THE CENTER AUXILIARY PIN ON THE 7-WAY CONNECTOR.

INSPECT YOUR TRACTOR! TRACTOR MUST SUPPLY CONTANT POWER

FOR THE ABS ON THE CENTER AUXILIARY PIN WHEN THE KEY SWITCH

IS ON. DEACTIVATE ANY SWITCH IN THE TRACTOR THAT WILL TURN THE

AUXILIARY POWER OFF (MUST SUPPLY CONSTANT POWER).

DO NOT MODIFY THE TRAILER ELECTRICAL SYSTEM TO POWER

OPTIONAL EQUIPMENT OFF THE AUXILIARY CIRCUIT. FEDERAL LAW

MANDATES THIS CIRCUIT IS DEDICATED FOR ABS ONLY.

CONTACT TIMPTE ENGINEERING IF YOU HAVE ANY QUESTIONS ABOUT

YOUR PRESENT WIRING OR HOW TO REWIRE FOR AUXILIARY EQUIP-

MENT.

FAILURE TO FOLLOW THESE WARNINGS COULD RESULT IN SERIOUS

INJURY OR DEATH.

WARNING

!

– DO NOT ATTEMPT TO WALK ON

TOP RAILS, THEY ARE NOT AN

APPROVED WALKWAY

– FAILURE TO COMPLY CAN CAUSE

SERIOUS INJURY OR DEATH

WARNING

!

NEVER CLIMB INSIDE THE HOPPER COMPARTMENT!

FAILURE TO FOLLOW THIS WARNING COULD RESULT IN

SERIOUS INJURY OR DEATH.

WARNING

!

CHECK WHEEL NUTS AFTER INITIAL 50 TO 100 MILES OF

SERVICE. SEE OWNERS MANUAL FOR CORRECT TORQUE

REQUIREMENTS. FAILURE TO FOLLOW THIS WARNING

COULD RESULT IN SERIOUS INJURY OR DEATH.

WARNING

USE KNOCK RAILS TO DISLODGE COMMODITY,

POUNDING ON SLOPE SHEETS VOIDS WARRANTY.

P/N 035-03082

NEW FMVSS-121 REGULATIONS MANDATE HIGHER

PRESSURE LEVELS IN THE SUPPLY LINE.

TRAILER BRAKE PERFORMANCE WILL BE

IMPAIRED IFTRACTOR COMPRESSOR

ADJUSTMENT ISTOO LOW.

CHECK YOUR TRACTOR!

COMPRESSOR CUT-IN PRESSURE, ADJUST TO 105

PSI CUT-IN GOVERNOR

COMPRESSOR CUT-OUT PRESSURE: RECOMMENDED

MORETHAN 120 PSI CUT-OUT GOVERNOR

NOTE:THE USE OF ADDITIVES INTHE

AIR BRAKE SYSTEM IS NOT RECOMMENDED.

CAUTION

P/N 035-29182

!

DO NOT ATTEMPT

TO HOIST TRAILER

AT THIS FRAME

STRUCTURE.

P/N035-27163

CAUTION

6

Date of Origin – 02/01/08

AIR BRAKE SYSTEM

Your new Timpte trailer is equipped with an air brake system which meets or exceeds the require-

ments of the federal regulation FMVSS-121 for grade-holding ability and emergency stopping in

the event of an air supply failure in the service brake system. Air pressure is required to release

the parking/emergency brake. As of 10/8/92-FMVSS 121 requires that the supply line for the air

brake system be protected to 70 psi. This pressure level requires that supply line pressure levels

are achieved before the pressure protection valve opens (opening pressure must be higher than

the closing pressure by design).

Keeping your compressor cut-in pressure at maximum levels (over 100 psi) is a clear advantage

for peak operation of your entire system, we recommend using a 105 psi cut-in governor setting.

Governor cut-out pressure should be at 120 psi minimum. Low compressor cut-in pressure may

result in poor performance of the system, for example slow parking brake release time.

Should you still have a problem with your brake system after working through all of the inspection

items and tests listed in this manual’s maintenance section or in the brake manufacturer’s manual

supplied with the trailer, contact your Timpte factory representative.

WHEEL NUT TORQUE

Proper torquing and retorquing the wheel nuts are critical to prevent the loss of wheel equipment.

Wheel nuts should be torqued to 450 to 500 ft. lbs. (dry). Refer to the manufacturer’s decal on the

side of the trailer or manufacturer’s maintenance information supplied with the trailer for proper

torque specifications and tightening sequence.

Wheels must be checked and retorqued after the first 50 to 100 miles of use. This is important

every time you change a wheel. Check the fastener torque on a regular on-going basis.

WARNING

!

1.Read and understand this warning and the installation, Service and Safety Instruction Manual to understand

all safety precautions, proper operation, and maintenance of yourWebb hub. Failure to do so could result in

death or serious injury and could result in a compromise of your vehicle’s safe operation through loss or failure

of a wheel or the compromise of the braking system.Copies of the installation, Service and Safety Instruction

Manual are available, free of charge, from Webb Products, Inc., upon request.

2.Always use a properly installed calibrated torque wrench to assure proper torque.Under torque and over

torque can cause thread and/or nut damage and could result in the loss of a wheel.Failure to ensure proper

torque could result in death or serious injury and could shorten the expected life of this product.

3.Recheck torque after the first 50 to 100 miles of service. Parts may seat naturally, causing the torque to drop.

A drop in torque could result in the loss of a wheel.Proper torque is essential to avoid damage or compromise

of your vehicles safety. Failure to ensure proper torque could result in death or serious injury.

2310 INDUSTRIAL DRIVE, S.W.

CULLMAN, ALABAMA 35055

256-739-6660 WWW.WEBBWHEEL.COM

HUBS

(FOR PILOT MOUNTED DISC WHEELS)

8 - 10 STUD HUBS

APPLIES TO M22 X 1.5 STUDS / TWO PIECE FLANGE NUT.

All threads are right hand metric.

Tighten Flange Nuts to 50 ft.lb.using sequence

shown.

Check Disc-Wheels for proper positioning on pads

and proper seating against flange.

Tighten Flange Nuts to recommended torque using

sequence shown.

RECOMMENDED TORQUE: 450 - 500 FT.LBS.

REAR IMPACT GUARDS

Asof1/26/98,alltrailersmustcomply with FMVSS 223 and 224, which specify equipment and

performancestandardsfor rear impact guards on new semi-trailers. If requiredbythisstatute,a

RIG(rearimpactguard)hasbeeninstalledonyourtrailer that has been designed to resist speci-

fiedforces and absorb energy at a specificrate in the event of a rear collision with the trailer per

thestandard. Trailer RIG’sare subject to impactsand stressindockingandloadingoperations.

Itistherefore importantthatyouinspectthemregularly for signs of damage or wear. Failure to

follow this warning could result in serious injury or death.

7Date of Origin – 02/01/08

Pre-trip inspections should be made of the guard to assure its integrity and strength. Broken

welds, bent components, or other damage will likely affect its performance.

For these reasons, RIG inspection, service and repair records should be maintained. Repairs

and replacements must be in accordance with the original design specifications of the guard. Any

questions regarding repair or replacement should be directed to the Vice President of Engineer-

ing at Timpte.

ABS BRAKING SYSTEM

As of 3/1/98 all trailers manufactured with air braking systems are required to have an ABS (Anti-

Lock Braking System).

The system used on your trailer meets or exceeds the FMVSS 121 requirement forABS. The

ABS system on your Bulk Commodity trailer is a 4S/2M system (4 wheel sensors - 2 modulator

valves) or a 2S/1M (2 wheel sensors - 1 modulator valve). The intended purpose ofABS is to help

maintain control and reduce the likelihood of jackknife situations.

TheABS status indicator light is located on the driver side of the trailer near the rear corner post.

It indicates the system status upon initial startup by turning on and then turning off once the vehicle

begins to move. If a malfunction in theABS system occurs, theABS system status light will come

on and stay on until the problem is repaired. Anytime the system status light comes on and stays

on, have the ABS system serviced as soon as possible.

WARNING! ABS (Anti-Lock Braking System) is a safety item and must be

properly maintained. To operate an ABS equipped truck and trailer properly,

during braking- constant pedal force must be applied. All ABS systems require

clean, dry air to operate properly. Use of airline deicers or leakage of oil into the

air system may diminish the performance of the system and will void the warranty.

BACKUP WARNING SYSTEM

A backup warning system consisting of an audible alarm is available as an option on your Timpte

Bulk Commodity trailer. The system is intended to indicate that the vehicle is backing up.

WARNING

!

A DAMAGED REAR IMPACT GUARD MAY NOT BE AS STRONG AS THE ORIGI-

NALLY MANUFACTURED GUARD AND MAY NOT SATISFYTHE PERFORMANCE

STANDARDS OF FMVSS 223 AND 224. ALTERATIONS OR REPAIRS TO THE RIG

COULD HAVE THE SAME EFFECT. PRIOR TO REPAIRING OR MODIFYING ANY

TIMPTE RIG, CONTACT THE VICE PRESIDENT OF ENGINEERING AT TIMPTE AT

402-367-3056. FAILURE TO FOLLOW THIS WARNING COULD RESULT

IN SERIOUS INJURY OR DEATH.

!

8

Date of Origin – 02/01/08

1. You, the operator, have control of the most important factors that affect safe trailer opera-

tion and vehicle stability. Trailers are a tool and, like any tool, are safe only when properly

used by a conscientious, trained and qualified operator.

2. The fifth wheel should be securely mounted to the tractor frame and proper connection

between the tractor and trailer verified.

3. The driver should be familiar with the characteristics of the particular trailer and of the

load to be transported.

4. The driver should be familiar with the nature of the roads and traffic which may be en-

countered during the trip.

5. Stability – Caution - like any other vehicle, semi-trailers can tip or slide out of

control if turns are negotiated at too high a speed or when making violent ma-

neuvers such as abrupt lane changes or other evasive actions to avoid ob-

stacles.

6. Within the relatively narrow confines of road laws limiting vehicle size and weight, to-

gether with the characteristics of available tires, suspensions, and other components,

there is little that a manufacturer can do to affect the inherent stability of a trailer other

than keeping the load as low as feasible, considering the requirements for loading space

and adequate tire clearance. This means that the major factors affecting operational

stability are the knowledge and skill of the driver. The predominant causes of rollover

accidents are:

a. Excessive speed

b. Violent swerving or turning

c. Application of brakes or tractor power while turning.

d. Entering curves at too high a speed

7. Tire Characteristics: High pressure truck/trailer tires have different characteristics under

high speed cornering conditions than do passenger car tires. Truck/trailer tires are

designed for carrying high loads over long distances. Their lateral stability becomes

unpredictable when lateral forces approach .04g. This means that commercial vehicles

must be operated in a conservative manner when cornering.

8. Braking and Acceleration: Either braking or accelerating while cornering can significantly

reduce the stability of the vehicle and should be avoided. The best driving practice is to

decelerate to a safe conservative speed before entering a corner or approaching con-

gested traffic, and then to apply only moderate power until a straight path has been re-

established.

You, the operator, have the Greatest Control

over Safe Operation.

9Date of Origin – 02/01/08

WARNING! Be careful when making inspections, hookups and repairs to

avoid personal injury. Make sure parking brakes are properly activated or that

wheel chocks are in place to avoid sudden or unexpected movement of the

trailer which could result in bodily injury.

It is the Operator’s responsibility to conduct a safe and accurate pre-trip

inspection of the vehicle. Per Federal Motor Carrier Statute 49 CFR 392.7

Equipment, Inspection and Use - No motor vehicle shall be driven un-

less the driver thereof shall have satisfied himself that the following parts

and accessories are in good working order, nor shall any driver fail to

use or make use of such parts and accessories when and as needed

Service Brake, including trailer brake connections

Parking Brake

Steering Mechanism

Lighting devices and reflectors

Tires/Tire Pressure

Horn

Windshield Wiper or wipers

Rear-vision mirror or mirrors

Coupling devices

Hoses andAirlines

Fifth Wheel Plate

Gladhand Connections

Hub Maintenance

Mud Flaps

RIG (Rear Underride Guard)

NOTICE:

Additional Federal Requirements for the Operator can be found in the Federal Motor Carrier Safety

Regulations (FMCSR’s) in the Code of Federal Regulations (CFR) Title 49 Parts 392, 393 and 396.

These can be found on-line at http://www.access.gpo.gov/nara/ then scroll down to (CFR Sections by

Citation).

Failure to regularly inspect the trailer may also void the warranty.

While it is ultimately the operator’s responsibility to properly perform and document the pre-trip

inspection, Timpte provides the following recommendations and suggestions.

TRAP DOOR LOCKS

Check all trap door locks before each trip to insure that they are in proper working order. Any trap

door components which show excessive wear should be replaced immediately. Care should be

taken to keep the area around the door frame clear of any debris. Abuild-up of refuse may result

in the doors not completely closing.

Make sure all doors are closed and secured prior to departure.

Inspection Procedures Before Each Trip

!

10

Date of Origin – 02/01/08

LIGHTS AND REFLECTORS

The surfaces of the lights and reflectors need to be checked and cleaned. Inspect all lights to

see if they are working and check all brake and signal functions.

ELECTRICAL WIRING

Inspect all visible wiring to see that it is not frayed and is properly supported and protected, and

that all connections are tight. Inspect the electrical hookup for a clean and secure connection.

FIFTH WHEEL AND KING PIN ENGAGEMENT

Inspect the kingpin and its structure on the trailer for damage or unusual wear. After hook up,

make a direct visual inspection to assure proper coupling, then check for positive engagement of

the lower fifth wheel and king pin. Apply the trailer brakes and attempt to move the tractor forward

to insure that the fifth wheel and king pin are positively locked.

CAUTION! Plastic King Pin Liners (Lube Plate) cannot be installed onto Timpte Trailer

upper coupler/king pin assemblies unless the trailer was purchased with that specifi-

cation. Alube plate changes the king pin interface dimensions relative to the fifth

wheel lock. This may result in coupling difficulties, premature lock wear, and a poten-

tial for a dropped trailer.

TIRES

WARNING! DO NOT OVERLOAD! Check tires frequently for cuts and abrasions.

Check tire pressure daily and keep inflated as recommended by the tire manufacturer.

Remove foreign objects that may be lodged in the tire treads or between dual tires.

MUD FLAPS

Be sure the mud flaps are securely in place and in good condition.

!

!

TARP SYSTEM

Check to be sure the tarp is in serviceable condition. Insure that the latching system is in good

working order and that the tarp is properly secured for travel to prevent being blown about by the

wind.

LANDING GEAR

Always raise the landing gear legs completely before moving the trailer. Make sure that the crank

handle is properly secured. Prior to trailer transport, lock landing legs into low side gear ratio.

11 Date of Origin – 02/01/08

HUB MAINTENANCE

Check wheel studs for good condition – no stripped threads – no bent or loose studs. Replace

any broken or bent studs or studs with damaged threads. When a broken stud is replaced, the

stud on each side of it should be replaced at the same time. If more than two studs on the same

hub are broken, replace all of the studs. NOTE: Hub cap mounting bolts (6) torque 10 to 15 ft. -lbs

torque per bolt.

WHEELS AND RIMS

Check all wheel nuts for tightness. Wheel flange nuts should be torqued to 450 to 500 ft. lbs (dry).

Check all metal surfaces thoroughly while making tire inspections and during tire changes.

Look for:

• Excessive rust or corrosion build-up

• Cracks in the metal

• Bent flanges or components

• Loose, missing, or damaged nuts

• Bent or stripped studs.

• Incorrectly matched rim parts

Replace damaged components, making sure that replacements are made with proper sized and

type parts.

WARNING

!

EXCESSIVELY CORRODED OR CRACKED RIMSARE DANGEROUS, PARTICU-

LARLY DURING REMOVAL. DEFLATE TIRES PRIOR TO REMOVAL OF RIMS AND

WHEELS FROM THE VEHICLE OR PERSONAL INJURY COULD RESULT.

HUB LUBRICANT

Check and maintain proper level of lubricant in hubs.

Hubs using oil lubricant will have clear hub windows and the oil level will be clearly visible. Be sure

the oil level is at the fill line noted on the hub window.

Hubs equipped with synthetic grease will retain the grease between the bearings and no lubricant

visual check is possible. Trailers equipped with this option will not have a clear hub window or a

fillplug.

Do not add oil to hubs equipped with synthetic grease lubricant. If mixing of lubricants occurs,

remove the lubricant and re-install the proper lubricant as soon as possible.

12

Date of Origin – 02/01/08

SIDE STRUCTURES

Check the trailer sides for inconspicuous damage to the top and bottom rails as well as the side

structure – cracks, contusions, sharp bends, ripples, or missing fasteners. Any problems ob-

served in the side structure should be corrected immediately to prevent the damage from extend-

ing further. Unrepaired damage could affect the safe load carrying capacity of the side structure.

SUSPENSION AND SUSPENSION SUBFRAME

Check the suspension and suspension subframe structure for damage or unusual wear. Any type

of damage, cracks in the welds or structural members or loose fasteners need to be addressed

immediately. Check spring suspensions for free movement of equalizer, condition of bushings,

torque of fasteners and for any type of cracking or damage to the spring leafs. Check air ride

suspensions for condition of bushings, air leaks, condition of shock absorbers, for proper opera-

tion of ride height leveling valve, and for proper inflation of the air springs.

NOTE: Never move an air ride trailer without first fully inflating the air springs – failure to

do so could cause damage to the trailer and suspension and will void the warranty.

13 Date of Origin – 02/01/08

PARKING/EMERGENCY BRAKING SYSTEM

This portion of the air brake system makes provision for parking a vehicle on a grade and for

emergency stopping in the event of a failure of air supply in the service brake system.

Air pressure within the parking brake chamber is required to release the spring brake. An air

reservoir is provided to store enough air to release the brakes at least once by means of the

tractor parking brake control, if there is an air line failure. In addition to the normal release of

spring brakes using air, a built-in manual release is provided. It allows easy release of the spring

brakes for relining the brakes or for moving the trailer in the absence of air pressure.

WARNING

!

DO NOT ATTEMPT TO MOVE THE TRAILER UNTIL PARKING BRAKE IS FULLY

RELEASED. FAILURE TO FOLLOW THIS SAFETY WARNING WILL

RESULT IN EQUIPMENT DAMAGE AND COULD RESULT IN SERIOUS

INJURY OR DEATH.

DANGER

!

MANUAL RELEASE OF THE PARKING BRAKE SHOULD ONLY BE USED TO MOVE

THE TRAILER TOA SAFE LOCATION WHERE REPAIRS CAN BE PERFORMED.

ALWAYS INSTALL WHEEL CHOCKS IN FRONT OF AND BEHIND TIRES BEFORE

MANUALLY RELEASING SPRING BRAKES. FAILURE TO FOLLOW THIS

SAFETY WARNING COULD RESULT IN DEATH OR SERIOUS INJURY.

WARNING!

NEVER ATTEMPT TO USE THE TRAILER FOR THE MAJORITY OF THE BRAKING

EFFORT BY BACKING OFF THE TRACTOR BRAKES.THIS IS ILLEGAL, UNSAFE,

AND WILL CAUSE PREMATURE FAILURE OF THE TRAILER BRAKE SYSTEM.

FAILURE TO FOLLOW THIS SAFETY WARNING COULD RESULT IN

DEATH OR SERIOUS INJURY.

OPERATING INSTRUCTIONS

14

Date of Origin – 02/01/08

• Set parking brake on the tractor prior to loading the commodity onto the trailer.

• The trailer should be loaded evenly from front to rear, maintaining all state bridge laws.

DO NOT Overload the trailer as this action could void the trailer warranty.

• Use the air system air gauge (Air Ride only) to determine legal load conditions. Calibrate

the air gauge by comparing the gauge pressure to loaded trailer scale weight.

• The tarp bows can be swung to the side to facilitate loading as needed. Be sure to use a

safe, approved walkway or scaffold to reach and manipulate bows.

• Balance the load between front and rear hoppers.

• Roll the tarp closed and lock the crank handle into place before proceeding to another

location.

TRAILER UNLOADING

CAUTION! USE EXTREME CAUTION when attempting to dislodge commodity

through the trap doors during the unloading process as this could result in

serious personal injury or death.

• Position trailer at a point so commodity can be discharged properly and safely.

• Set parking brake on the tractor prior to discharging the commodity.

• Dump air bags (Air Ride only) prior to discharging commodity. Failure to discharge air

from lift bags when unloading could cause damage due to over extension of the

air bags and flexing of landing legs. This action could void the trailer warranty.

• Confirm discharge point is clear of any pedestrians or obstructions.

• Roll tarp to open position prior to unloading. Failure to open the tarp could result in

damage to tarp bows and trailer walls. This action could void trailer warranty.

• Open hopper trap doors, one at a time, to begin discharging commodity. Always Use

knockrails to assist with dislodging commodity.

• Confirm that all commodity has been discharged from both hoppers.

• Close trap doors, latch and lock, prior to departing to your next destination.

• Remove and properly store crank handle.

• Roll the tarp closed and lock the crank handle into place before proceeding to another

location.

• Inflate the air-ride suspension system prior to moving the trailer.

NOTE: Timpte trailers are designed to transport free flowing commodity. Knockrail and

pneumatic (air) hammer (vibrator) options are available to be installed to assist with

unloading commodity, if needed. Speak with a Timpte Sales Representative with any

question you may have with respect to knockrail and pneumatic (air) hammer options.

TRAILER LOADING

• Roll tarp to open position and lock crank handle in place,

• Check trap doors for closure, locks and latches for proper engagement before loading.

• Position trailer to receive commodity.

!

15 Date of Origin – 02/01/08

2 Speed Operators (Gear Reductions)

• Choose gear box mode you want to operate; direct drive or gear reduction. Drive nut

assembly without locking latch is the gear reduction side.

• Raise the locking latch to free the operator.

• Couple the socket end of the crank handle completely and securely over the hex drive nut on

the trap operator shaft.

• Rotate crank arm clockwise or counterclockwise to open trap door per instruction decal

(direction of rotation is dependent upon mode chosen). The crank handle swings in a large arc

so be sure the area is clear.

• Rotate crank arm opposite direction to close the trap door.

• Lower locking latch to lock the operator.

• Rear trap door operates opposite of front trap door.

Single Speed Trap Openers (Ratchet and Pawl)

• Couple the socket end of the crank handle completely and securely over the hex drive nut on

the trap operator shaft.

• On the front tub, rotate the crank handle slightly clockwise, this will release the pressure on the

ratchet pawl and allow you to rotate it out of the ratchet gear.

• Once the pressure on the pawl is released, rotate the pawl counterclockwise until it comes

to rest on the other side of the ratchet gear.

• Rotate the crank handle counterclockwise to open the trap door. The crank handle swings in a

large arc so be sure the area is clear.

• The door can be stopped at any point in the travel and the pawl will hold it from opening further.

• If you determine that you have opened the door too far and need to partly close the door to

meter the speed of the discharge, release and rotate the pawl back clockwise before rotating

the crank handle clockwise to close the door.

• Rear trap door operates opposite of front trap door.

TRAP DOOR OPERATION

16

Date of Origin – 02/01/08

• Use the trap door operator shaft to close the trap door.

• Locate a torque wrench onto the hex drive nut on the operator shaft.

• Rotate the wrench to close the trap door until the door is completely closed (decals).

• Locate the pawl lock to a position approximately 1/2 tooth away from the next gear ratchet

wheel locking position (pictured).

TRAP DOOR LATCH (PAWL) - Setup and Adjustment

• Rotate the torque wrench in the ‘close’ direction, torque wrench set point at 80 ft-lbs

(max), until pawl drops into gear ratchet wheel tooth to lock door closed. Pawl lock must be

set to drop into the gear ratchet wheel lock at a torque < or = 80 ft-lbs latching torque.

• Adjust pawl position side to side to fine-tune pawl latching torque set point.

• Release the door lock by rotating the operator shaft toward the ‘close’ direction, easing the

locking pressure on the pawl. Raise the pawl lock out of the ratchet wheel tooth and rotate the

pawl in the opposite direction. Open the trap door by rotating the operator shaft, with the crank

arm, opposite the ‘close’ direction (decals). Unlatching torque should not exceed 80 ft-lbs

torque.

17 Date of Origin – 02/01/08

NOTE

• The pawl lock should be centered on the gear ratchet, front to back, to assure proper

alignment between ratchet and pawl for locking.

• Use set screws, located in flange bearing (behind operator shaft mounting plate), to adjust

clearance for pawl and gear ratchet centering. (See figures below for clarification).

• Adjust the pawl and ratchet centering position as follows:

• Loosen adjustment set screws (2) to allow operator shaft/mounting plate

movement(in and out,push/pull).

• Confirm clearance between gear ratchet and mounting plate (push/pull)

• Adjust gear ratchet and pawl for centering (in and out movement, push/pull).

• Re-tighten set screws on flange bearing once centering and clearance are corrected.

DO NOT over-tighten set screws to avoid damage to operator shafts.

18

Date of Origin – 02/01/08

CONTROL BOX OPERATION, MANUAL OPERATION

1. Turn on Master Disconnect Switch in the tractor.

2. Power up Control Box. (Hold the Front Hopper “Open” or “Close” buttons on the control box

for 3 seconds or until control box light comes on to indicate the control box is activated.)

3. Select button to perform the required operations.

4. Power off Control Box when finished. (Hold the Front Hopper “Open” or “Close” buttons on

the control box for 3 seconds or until control box light goes off.)

SETTING FUCTIONS ON REMOTE:

Setting function allows functions to be blocked if not required/not going to be used.

1. Opentransmitter.Observeflashinglight.

2. Press and hold “MODE” button for 10-12 seconds until the top light stays lit.

3. Press the “ON/OPEN” button if this function will be used. Select and press the “OFF/CLOSE”

button if you want this function to be skipped.

4. Repeat Step 3 for all five functions.

a.1 LIGHT - TARP SYSTEM

b. 2 LIGHTS - FRONT HOPPER

c. 3 LIGHTS - REAR HOPPER

5. When the last function has been selected, the light on the first mode function will stay lit for

approximately 3 seconds to indicate active and return to flashing when process is complete.

d.4 LIGHTS -AUXILIARY

e.5 LIGHTS -AUXILIARY

OFF/CLOSE Button

Control Box Light

OPEN Button

CLOSE Button

MODE Lights

ON/OPEN Button

MODE Selection

Button

!WARNING! Make sure all power supply to trailer is disconnected and the ground

wire in the nose of the trailer and on the receiver box is disconnected prior to any

welding on trailer. Failure to do so could result in damage to receiver control box!!

19 Date of Origin – 02/01/08

PROGRAMMING EASY FLOW HOPPER DOORS

1. Power up the control box. (Hold the Open and Close” buttons on the control box for 3 seconds

or until control box light comes one to indicate the control box is activated.)

2. Open transmitter and observe flashing light.

3. Push “MODE” button to select “Front Hopper” Mode (First two lights flashing).

4. Repeat steps 1 and 2 for each transmitter to be programmed. One to four transmitters can be

programmed. All transmitters are to require to be programmed while light is flashing.

5. Push and hold “Programming /Work Light” button on control box, for approximately 8 seconds,

untiltheilluminated light on the control box starts flashing.

6. Press the “ON/OPEN” button on each transmitter to be programmed. Four transmitters can be

programmed to each control box so four inputs are required. If one transmitter is being

programmed, the “ON/OPEN” button will required to be pushed four times. If two transmitters are

being programmed then the last transmitter will be required to press the “ON/OPEN” button

three times. The light on the control box will stop flashing and stay illuminated when the four

inputs have been received.

7. Close lid of programmed transmitters to power down transmitters.

8. Power down control box. (Hold the Front Hopper “Open and Close” buttons for 3 seconds or

until control box light goes off.)

20

Date of Origin – 02/01/08

CONTROL BOX OPERATION, WIRELESS OPERATION

1. Turn on Master Disconnect Switch in the tractor.

2. Power up Control Box using transmitter. Open transmitter and Push “MODE” button to select

the “Front Hopper” Mode (First two lights flashing).

3. Push and hold the “Open and Close” buttons at the same time for 3 seconds or until control

box light comes on to indicate the control box is activated.

4. Select button to perform the required operations for the front hopper.

5. To use the rear hopper, push “MODE” button to select Rear Hopper (First three lights flashing).

6. Select button to perform the required operations for the rear hopper.

7. Power off Control Box when finished. (Push “MODE” button to select “Front Hopper” Mode

(First two lights flashing). Hold the “Open and Close” buttons on the transmitter for 3 seconds

or until control box light goes off.

Button

Table of contents

Other Timpte Truck manuals