INSTRUCTIONS FOR:

PALLET TRUCK 2200KG 1150 X 525MM

MODEL No: PT2200

1. SAFETY

2. INTRODUCTION

3. SPECIFICATION

DO NOT use a faulty or damaged pallet truck.

Before using the pallet truck, all parts and working mechanisms should be checked for wear or damage. Pay particular attention to the

wheels, handle, fork lifting and lowering mechanism. Any parts found to be worn, damaged or suspect should be repaired or replaced

before the truck is used.

All repairs must be carried out by an authorised Sealey service agent.

Personnel who operate the pallet truck and those in the vicinity of operation should wear safety shoes with reinforced toe caps at all times.

Never place any part of your body in the lifting mechanism or under the forks or load.

DO NOT allow others to ride on the pallet truck.

DO NOT lift or move unstable or loosely stacked loads.

Take special care when moving long, high or wide loads in order not to dislodge the load by striking any structures, permanent fixtures,

vehicles or people in the area of operation.

Always ensure that the load is evenly distributed across the forks with the centre of the load being at the halfway point of the length of the

forks.

DO NOT overload the pallet truck - refer to the specification for maximum permitted load.

If a load is left unattended or if not in use (even for a very short period of time) it should be lowered to the ground.

Ensure that the width and length of the forks is correct for the pallet to be lifted.

Ensure that the pallet truck is sufficiently inserted into the pallet to lift the full depth of the pallet.

Use the pallet truck on level, flat, hard surfaces.

The operator of the pallet truck must be physically capable of controlling the load selected; particularly in relation to stopping a rolling load.

When the pallet truck is not in use, lower the forks and park it where it will not be a hazard.

The pallet truck is designed for indoor use +5°C and +40°C.

DO NOT use on sloping or uneven ground and do not attempt to negotiate curbs, steps or ramps.

4. ASSEMBLY

Heavy-duty trucks suitable for warehouse and general handling duties. Polyurethane, non-marking wheels and tandem loading rollers with

sealed-for-life bearings all round. Robust and durable galvanised hydraulic unit with chromed ram and piston for resistance to corrosion.

Features euro pallet depth indicators.

Model No.: ..............................................PT2200

Capacity: ................................................2200kg

Minimum height: ...........................................85mm

Maximum height: ..........................................200mm

Forks (Length x Overall Width): ........................1150 x 525mm

Fork Spread: .............................................225mm

Original Language Version

©Jack Sealey Limited PT2200 Issue No.1 - 20/11/14

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE THE PRODUCT

CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR PERSONAL INJURY AND WILL

INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

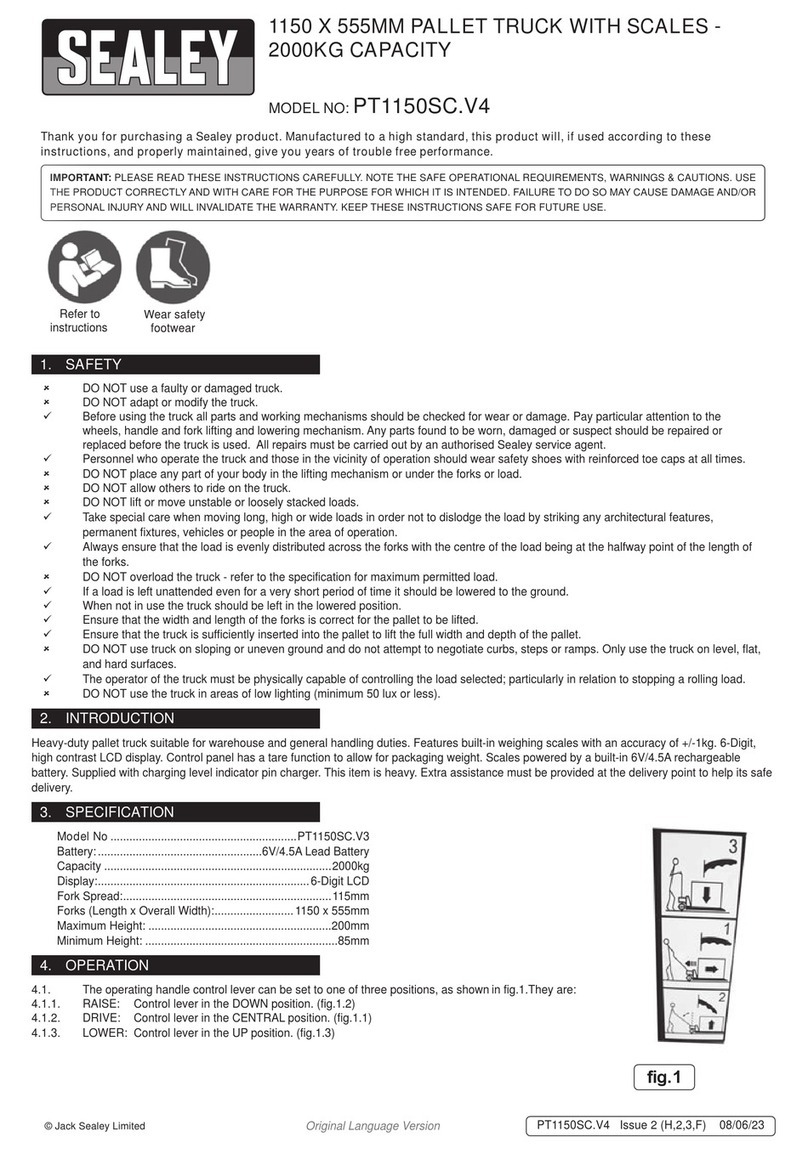

Refer to

Instructions

Wear Safety

Footwear

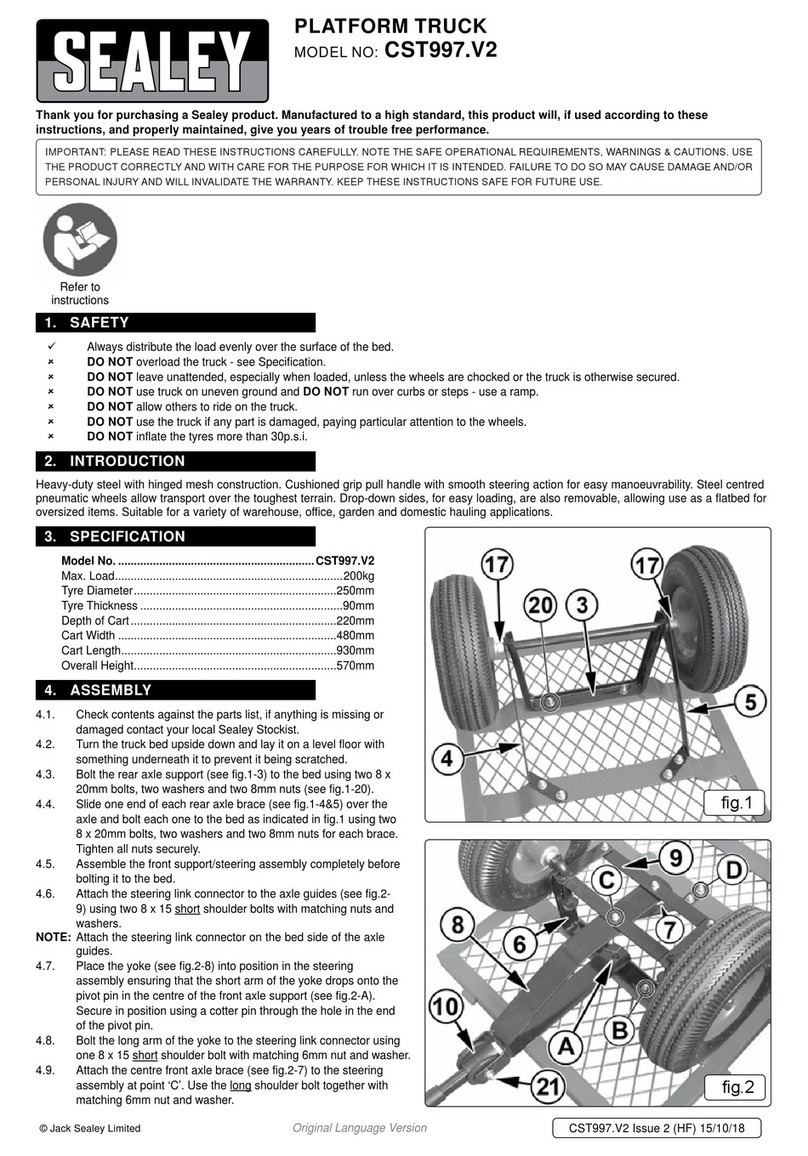

fig.1

4.1. Take the handle and thread the pin and chain through the

aperture(g.1.1)inthecrossshaft.

4.2. Place the handle base on the pump bracket and secure by screwing

thehexheadedscrewsintotappedholes(gs.1.2,1.3and1.4.)

4.3. Ensure that the control lever is in its lowest (raise) position.

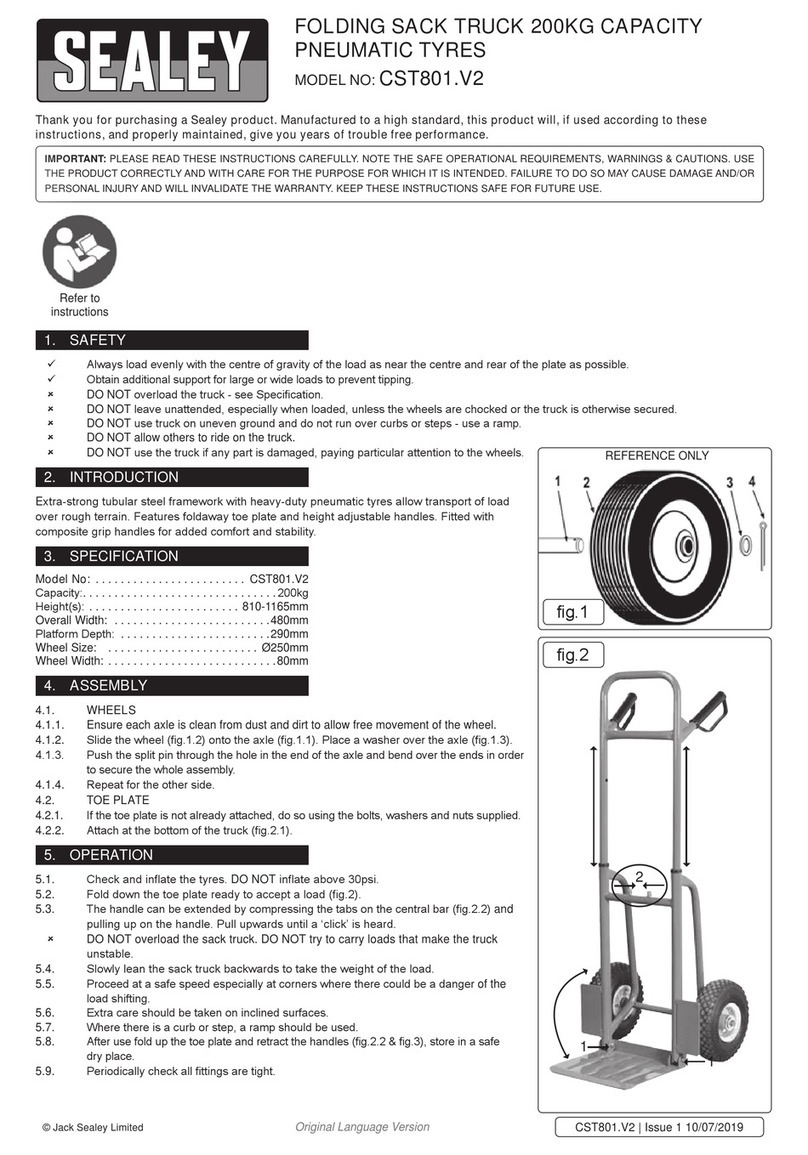

4.4. Lookingbelowthepumpbracket,raisethevalvefork(g.2.1)and

engagetheheadofthepin(g.2.2)intothefork.

4.5. Release the valve fork., which will engage with the head of the pin.

fig.2