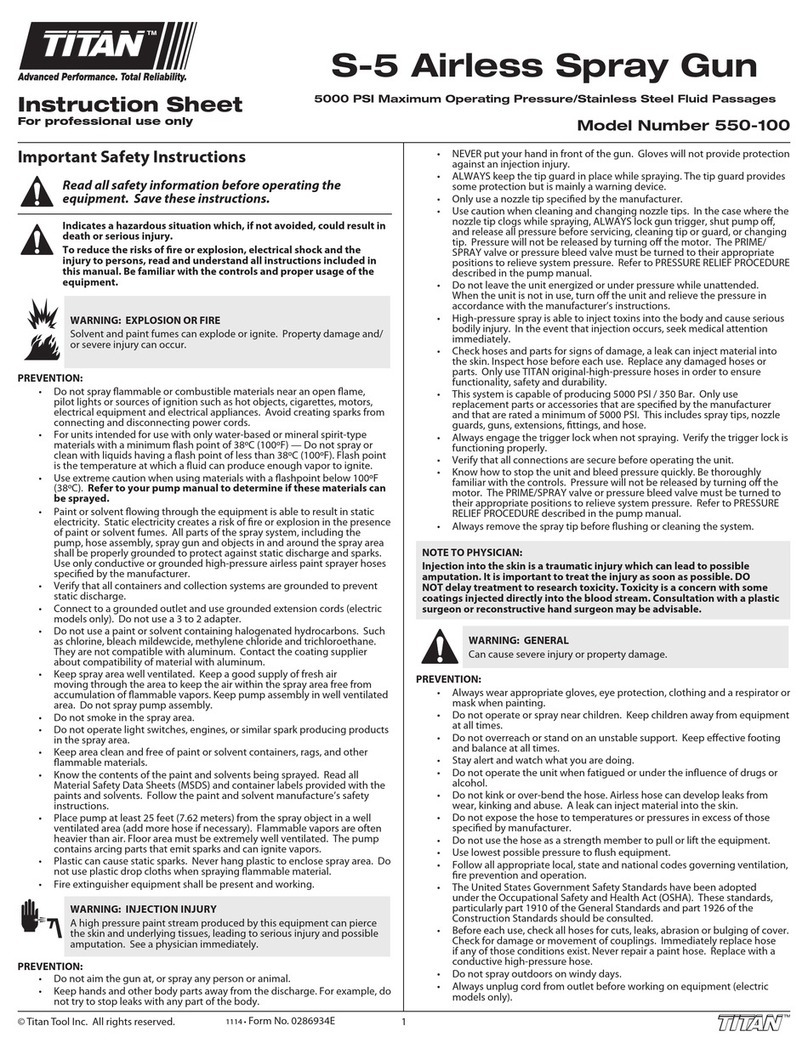

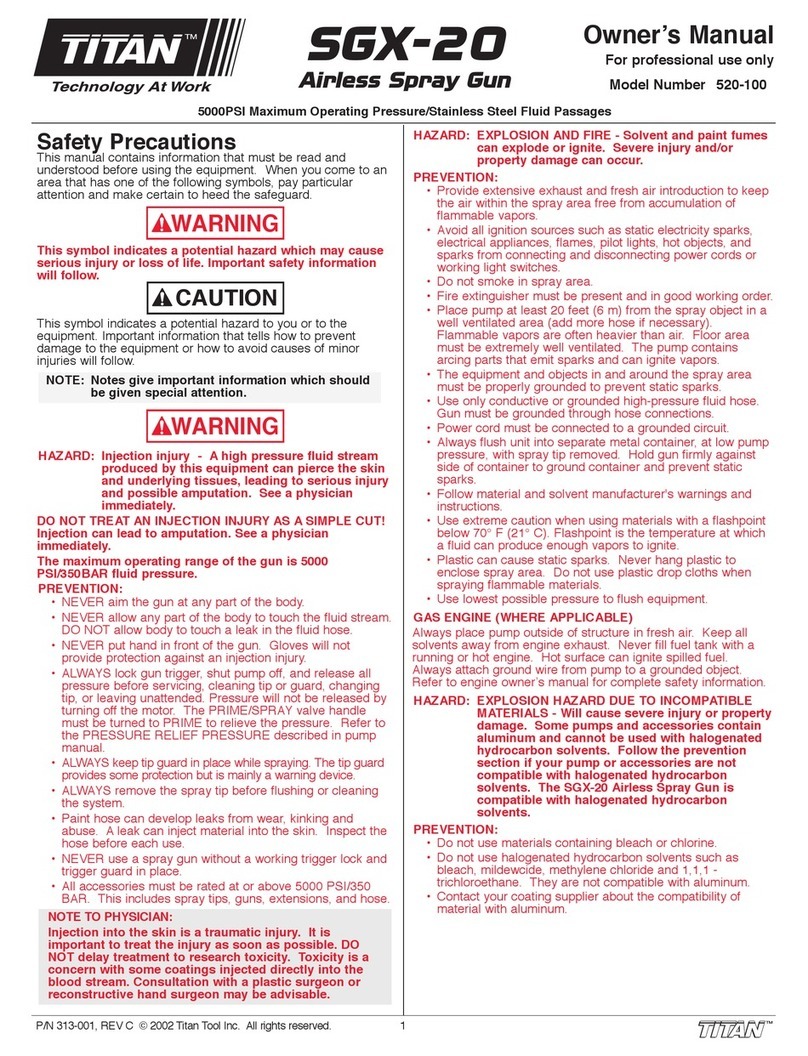

FIRE OR EXPLOSION HAZARD

Static electricity

is

created by

th~

high velocity of fluid through the pump, hose and tip. If every part

of

the

spray

element

is

not properly

groundE¥f,

sparking may occur and the system may become hazardous.

Sparking

may

also occur when plugging in or' unplugging a power supply cord, or starting a gas engine. Sparks

can

ignite

fumes from solvents or the fluids being sprayed. Always plug the sprayer into

an

outlet at least 25'

away

from the

spray area. WARNING: Always

flush

the

unit

Into

aseparate

metal

container

with

the

spray

tip

removed

and

the

gun

held

firmly

against

the

side

of

the

container

to

assure

proper

grounding and

prevent

static

discharge

which

could cause

serious

bodily

Injury.

If

you

experience any static sparking or slight shock while using this equipment stop spraying immediately.

Check the entire system for propergrounding. Do not use the system again until the problem has

been

corrected.

ELECTRIC MOTOR

Although

totally

enclosed, theelectric motorsused by TITAN are

not

explosion proof.Therefore,

it

is

essential to

keep the working

area

around thepump well ventilated.Additionally,

the

pump

itself

should be a

minimum

of

25'

from thespray area.

WARNING:

Always keep pumpoutside

of

anyenclosed spray area. Never clean

the

exteriorof

the pump

with

any flammable solvents, while the pump is plugged in

or

operating.

GAS ENGINE (Where Applicable)

Always

keep

pump

outside

of

any

enclosed spray area. Keep area

around

pump

well

ventlllated.

Keep all

solvents

away

from

engineexhaust. (Never

fill

the

fuel

tank

while

the

engine

is

running

or

hot.

Fuel

spilled

on

a

hot

surface

can Ignite and cause a

fire.)

Always

attach

ground

wire located

on

rear

of

engine

to

a

grounded

object,

i.e.

water

pipe. NOTE: Refer

to

engine

owners

manual

for

additional

safety

and

service

Information.

FLUID SECTION

Halogenated Hydrocarbon solvents can cause an explosion when used with aluminum or galvinized components

in a closed (pressurizable) fluid system (pumps, heaters, filters, valves, spray guns, tanks, etc.)

The explosion could cause serious injury, death, and/or substantial property damage.

Cleaning agents,

coat_!Dg.s,

paints, etc., may contain Halogenated Hydrocarbon solvents.

~~

\ I

Titan

Tool

Inc. spray equipment includes aluminum or galvinized components and will be affected by

Halogenated Hydrocarbon solvents.

(_)

EXPLANATION

OF

THE HAZARD

There are three key elements to the Halogenated Hydrocarbon (HHC) solvent hazard. These elements are:

1. The presence

of

HHC solvents.

2.

Aluminum

or

Galvanized Parts.

3.

Equipment

Capable

of

Withstanding Pressure.

When all three elements are present, the result can

be

an

extremely violent explosion. The reaction can be

sus-

tained with very little aluminum or galvanized metal: any amount of aluminum is too much.

The reaction is unpredictable. Prior use of

an

HHC solvent without incident (corrosion or explosion) does

NOT

mean that such use

is

safe.

PELIGRO

DE

INCENDIO 0 EXPLOSION

Laaltavelocidad delliquidodentrode

Ia

bombayIamangueraproduceelectricidad estatica.

Si

alguncomponente del

equipoderocio noestaconectadoatierracorrectamente pueden producirsechispasy

el

sistemase vuelvepeligroso.

Tambien

pueden producirse chispas

at

enchufar o desenchufar cables electricos o al poner

en

funcionamiento

el

molor. Las chispas pueden encender los vapores provenientes de los solventes o de los liquidos rociados. Siempre

conecte

el

rociador a

un

enchufe ubicado a no menos de 25 pies de distancia del rociador y

Ia

zona de rocio.

Si

ocurren chispas de electricidad estatica o si sufre

un

choque ligero mientras usa

el

equipo, deje de rociar

de

immediate. Verifique que

el

sistema

en

su

totalidad este conectado a tierra correctamente.

No

vuelva a usar

el

sistema hasta que

el

problema haya sido resuelto. ADVERTENCIA: Lavar siempreIa unidad

por

inundacion

en

un

recipientemetalicoseparado

con

Iaboca

del

rociadorremoviday

teniendo

Iapistola

firmemente

contrael

ladodel recipienteparaasegurarunapuesta atierracorrects y evitar

Ia

descargaestatica

que

podria

causar

lesi6n

corporal

grave.

MOTOR ELECTRICO:

Los motoreselectricos utilizadospor

TIT

AN

noson apruebadeexplosion. Por to tanto,esesencial mantener

el

area

de trabajo alrededor de

Ia

bomba bien ventilada. Ademas,

Ia

bomba misma debe estar a una distancia

minima

de

25 pies (7,5 m) del area de rociadura.

ADVERTENCIA:

Mantener siempre

Ia

bomba fuera decualquier

area

de rociadura cerrada. Nunca limpie

el

exterior

de

Ia

bomba con solventes inflamables mientras

Ia

bomba

este conectada o operando.

8