6 Performance Series 1650e

GB

Safety regulations

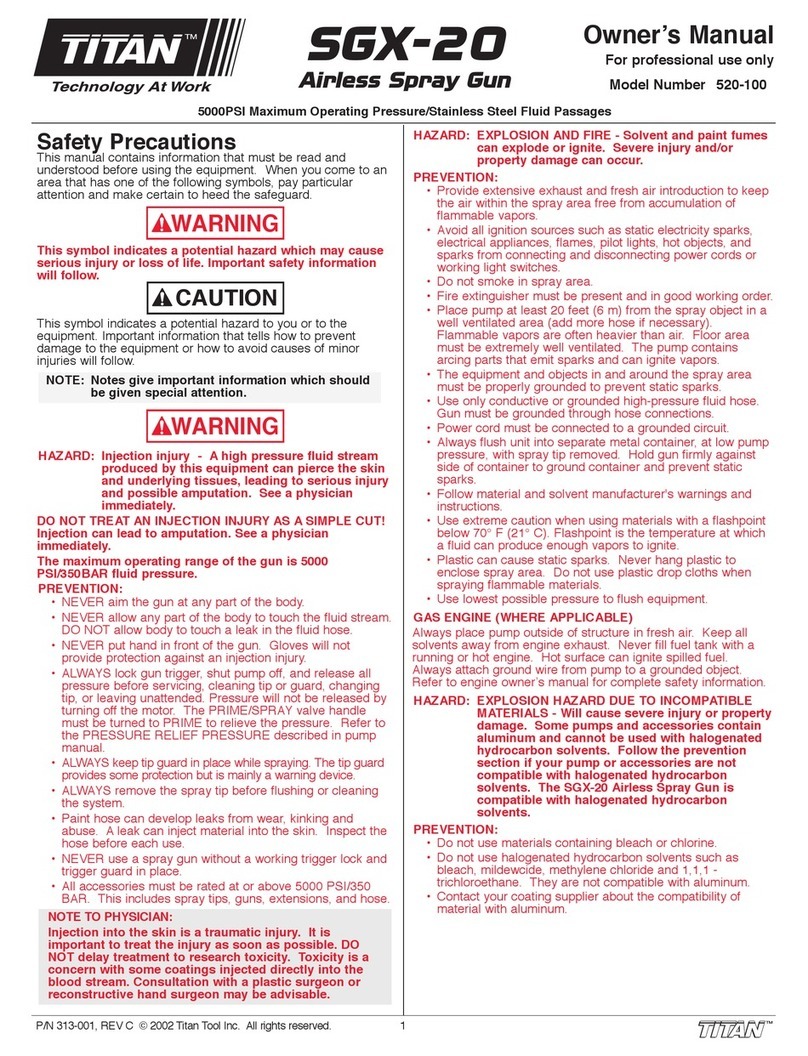

• Whencleaningtheunitwithsolvents,

the solvent should never be sprayed or

pumped back into a container with a small

opening (bunghole). An explosive gas/air

mixture can arise. The container must be

earthed.

• Donotuseapaintorsolventcontaining

halogenated hydrocarbons. Such as

chlorine, bleach, mildewcide, methylene

chloride and trichloroethane. They are not

compatible with aluminum. Contact the

coating supplier about compatibility of

material with aluminum.

HAZARD: HAZARDOUS VAPORS

Paints, solvents, and other materials

can be harmful if inhaled or come

in contact with body. Vapors can

cause severe nausea, fainting, or

poisoning.

PREVENTION:

• Wearrespiratoryprotectionwhen

spraying. Read all instructions supplied

with the mask to be sure it will provide the

necessary protection.

• Alllocalregulationsregardingprotection

against hazardous vapors must be

observed.

• Wearprotectiveeyewear.

• Protectiveclothing,glovesandpossibly

skin protection cream are necessary

for the protection of the skin. Observe

the regulations of the manufacturer

concerning coating materials, solvents and

cleaning agents in preparation, processing

and cleaning units.

HAZARD: GENERAL

This product can cause severe injury

or property damage.

PREVENTION:

• Followallappropriatelocal,state,and

national codes governing ventilation, re

prevention, and operation.

• Pullingthetriggercausesarecoilforce

to the hand that is holding the spray

gun. The recoil force of the spray gun

is particularly powerful when the tip

has been removed and a high pressure

has been set on the airless pump. When

cleaning without a spray tip, set the

pressure control knob to the lowest

pressure.

• Useonlymanufacturerauthorizedparts.

User assumes all risks and liabilities when

using parts that do not meet the minimum

specications and safety devices of the

pump manufacturer.

• ALWAYSfollowthematerial

manufacturer’sinstructionsforsafe

handling of paint and solvents.

• Cleanupallmaterialandsolventspills

immediately to prevent slip hazard.

• Wearearprotection.Thisunitcanproduce

noise levels above 85 dB(A).

• Neverleavethisequipmentunattended.

Keep away from children or anyone not

familiar with the operation of airless

equipment.

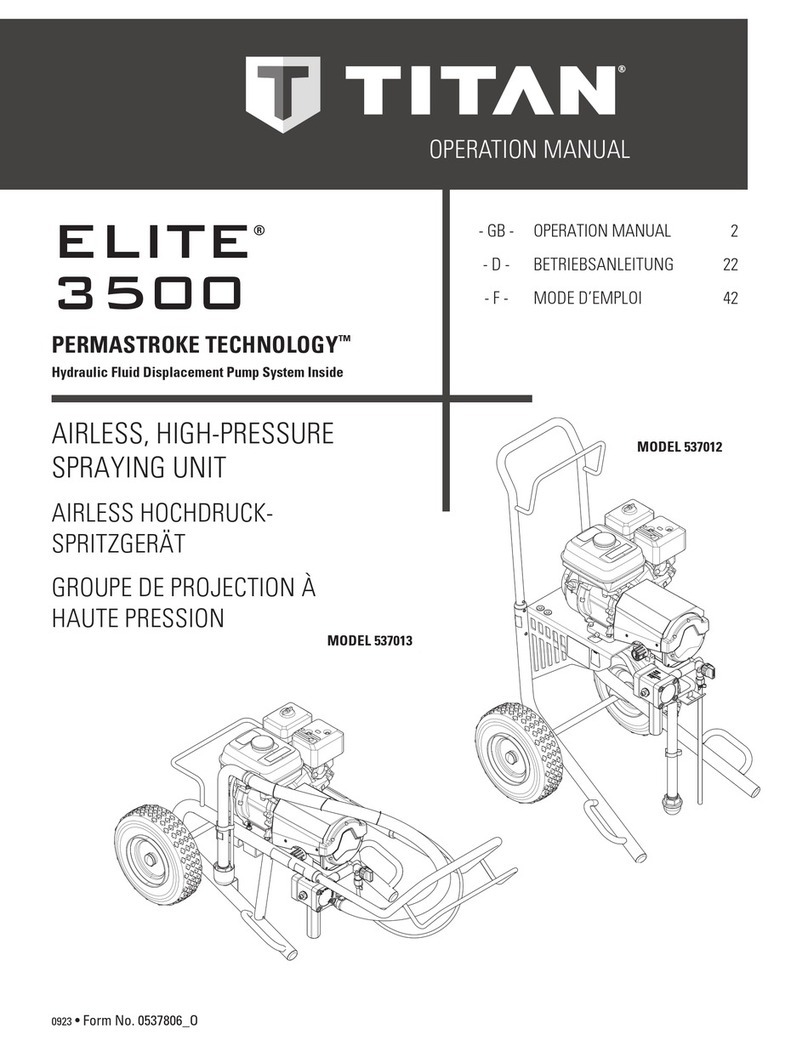

• Deviceweighsinexcessof36kg.Three-

person lift is required.

• Donotsprayonwindydays.

• Thedeviceandallrelatedliquids(i.e.

hydraulic oil) must be disposed of in an

environmentally friendly way.

• Thisapplianceisnotintendedforuseby

persons (including children) with reduced

physical, sensory or mental capabilities,

or lack of experience and knowledge,

unless they have been given supervision

or instruction concerning use of the

appliance by a person responsible for their

safety. Children should be supervised

to ensure that they do not play with the

applicance.