WARNING

Hands,feet,hair,clothing,oraccessoriescan

becomeentangledinrotatingparts.Contactwith

therotatingpartscancausetraumaticamputation

orseverelacerations.

•Donotoperatethemachinewithoutguards,

shields,andsafetydevicesinplaceandworking

properly.

•Keephands,feet,hair,jewelry,orclothingaway

fromrotatingparts.

•Donotoperatethemachineundertheinuenceof

alcoholordrugs.

•Keeppetsandbystandersawayfromanoperating

machine.

Stopthemachineifanyoneentersthearea.

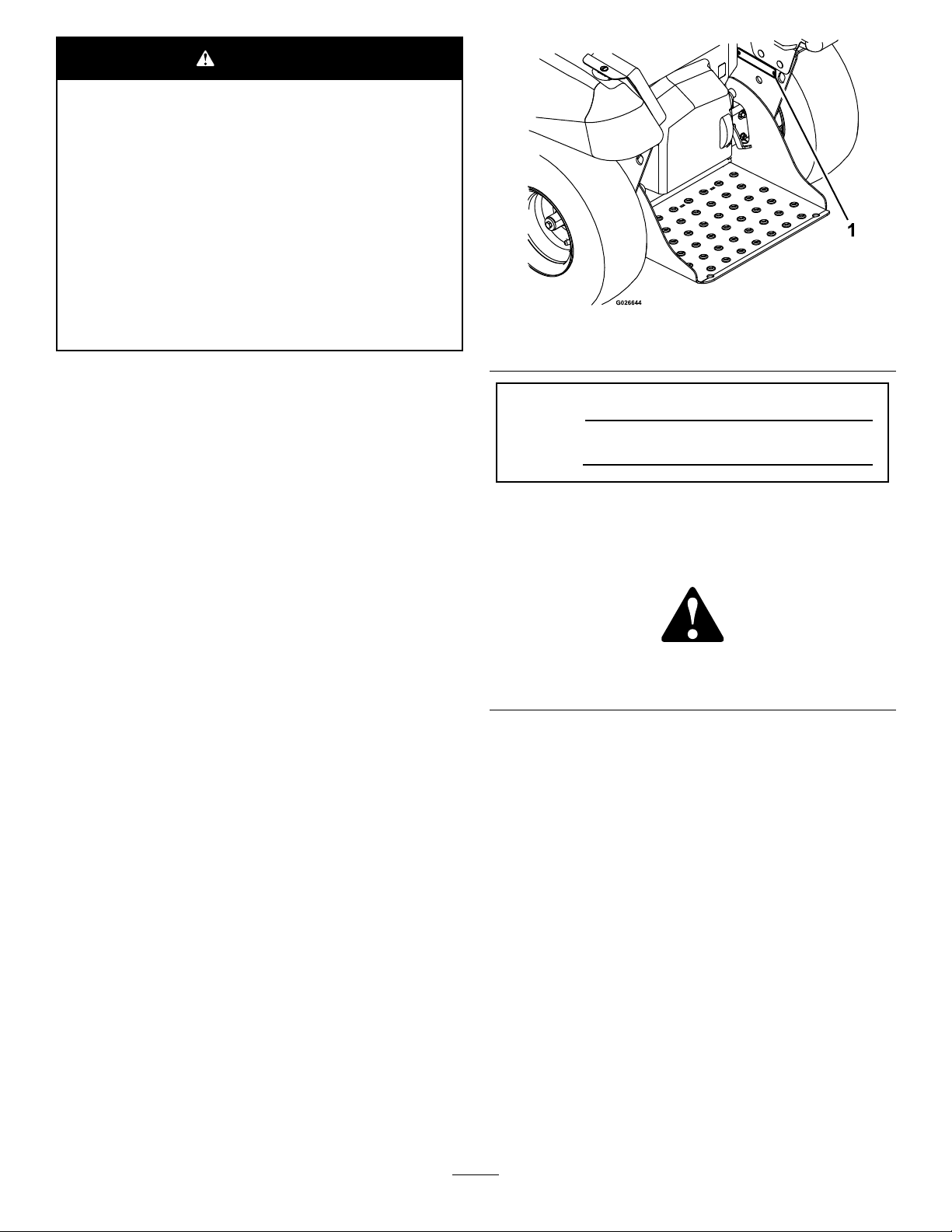

•Makesurethatyouhavegoodfootingwhileusingthis

machine,especiallywhenbackingup.

Note:Reducedfootingcouldcauseslipping.

•Stoponlevelground,disengagedrives,engagethe

parkingbrake(ifprovided),shutofftheenginebefore

leavingtheoperator'spositionforanyreason.

•Donotrunanengineinanenclosedarea.

•Lightningcancausesevereinjuryordeath.Iflightning

isseen,orthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Onlyoperateinwell-litareas,keepingawayfromholes

andhiddenhazards.

•Slowdownanduseextracareonhillsides.Besureto

travelsidetosideonhillsides.Turfconditionscanaffect

thestabilityofthemachine.Usecautionwhileoperating

neardrop-offs.

•Slowdownandusecautionwhenmakingturnsandwhen

changingdirectionsonslopes.

•Lookbehindanddownbeforebackinguptoensurea

clearpath.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

•Allowengineparts,especiallythemufer,tocoolbefore

touching.

•Removeaccumulateddebrisfrommuferandenginearea.

•EnsurethatmotioncontrolisintheNeutralpositionand

thattheparkingbrakeissetbeforestartingengine.Only

starttheenginefromtheoperator’sposition.

•Donotoperatethemachinewithouttheshieldsor

otherguardssecurelyinplace.Besureallinterlocksare

attached,adjustedproperly,andfunctioningproperly.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Stopthemachineafterstrikingobjectsorifanabnormal

vibrationoccurs.Makethenecessaryrepairsbefore

resumingoperations.

SafeHandlingofFuel

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporaddfuelwiththeengine

running.

•Allowtheenginetocoolbeforefueling.

•Donotfuelthemachineindoors.

•Donotstorethemachineorfuelcontainerwherethere

isanopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Donotllcontainersinsideavehicle,onatruck,orona

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandfuelit

ontheground.Ifthisisnotpossible,thenaddfuelwith

suchequipmentasaportablecontainer,ratherthanfrom

afueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeyourclothing

immediately.

•Donotoverllfueltank.Replacefuelcapandtighten

securely.

MaintenanceandStorage

•Donotallowuntrainedpersonneltoservicemachine.

•Donottouchequipmentorattachmentpartswhichmay

behotfromoperation.Allowallofthepartsofthe

machinetocoolbeforeattemptingtomaintain,adjust,or

servicethemachine.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•MovethemotioncontrollevertotheNeutralposition,

settheparkingbrake,stopengine,andremovekeyor

disconnectspark-plugwire.Waitforallmovementto

stopbeforeadjusting,cleaningorrepairing.

•Disconnectthebatteryorremovethespark-plugwire

beforemakinganyrepairs.Disconnectthenegative

terminalrstandthepositiveterminallast.Reconnect

thepositiverstandnegativelast.

•Cleangrass,dirt,anddebrisfromthedrives,mufers,and

enginetohelppreventres.

6