2

4 USAGE

1. Perform the startup procedure on the main unit (refer to the main unit

operation manual).

2. Once the system is on and the compressor is running, return to the spray

gun and open the air valve. Ensure that air is owing out of the nozzle.

Never trigger the spray gun without air supply on. Doing so

will signicantly reduce the life of the nozzle and spray gun.

3. Once the system has achieved the desired pressure and heat settings

(refer to the main unit operation manual and material manufacturer’s

temperature recommendations) the A and B side material inlet valves

can now be opened.

4. The system is now ready to spray. The gun will not spray until the trigger

and trigger safety are depressed at the same time. This can be achieved

by making sure the user’s hand is gripping the trigger while at the same

time setting the trigger safety within the user’s palm.

Damage to the spray gun may result when used with an air

pressure lower than 30 PSI.

The spray gun trigger will be locked (it will not spray) as long

as the trigger safety is not depressed.

It is recommended that the sprayer be tested on a scrap piece

of cardboard somewhere outside of the immediate intended

spray area.

4.1 CHANGING THE NOZZLE

Nozzle performance is something that can be felt and seen

very easily. A new nozzle should produce approximately 300

cycles per minute (CPM) spraying performance.

Once the Helix LP is linked and ready to spray, press #4 on

the A side control panel. This will display the cycle rate. This

range can vary with material and temperature.

When the cycle rate drops about 10%, a change in

performance should be noticeable, requiring a slower

spraying movement. The cycle rate will gradually decrease

as the nozzle usage increases.

At approximately 100-120 cycles per minute (CPM)

applicators may nd that spraying movement speed is too

slow and replace the nozzle.

The main unit will automatically manage the pressures and

ratio regardless of the cycle rate. It will not be necessary to

make any system adjustments.

If any leakage is noticeable at the spray gun, immediately

stop spraying, close all ball valves on the whip hoses, and

replace the spray gun.

5 PARTS LIST

Part No. Description Gun

Qty.

Round

Nozzle

Qty.

2405674 PROPURGE™ gun and nozzle kit 1 15

0153951 PROPURGE™ gun kit 1 ------

0153952 Round Maze Nozzle™ kit ------ 25

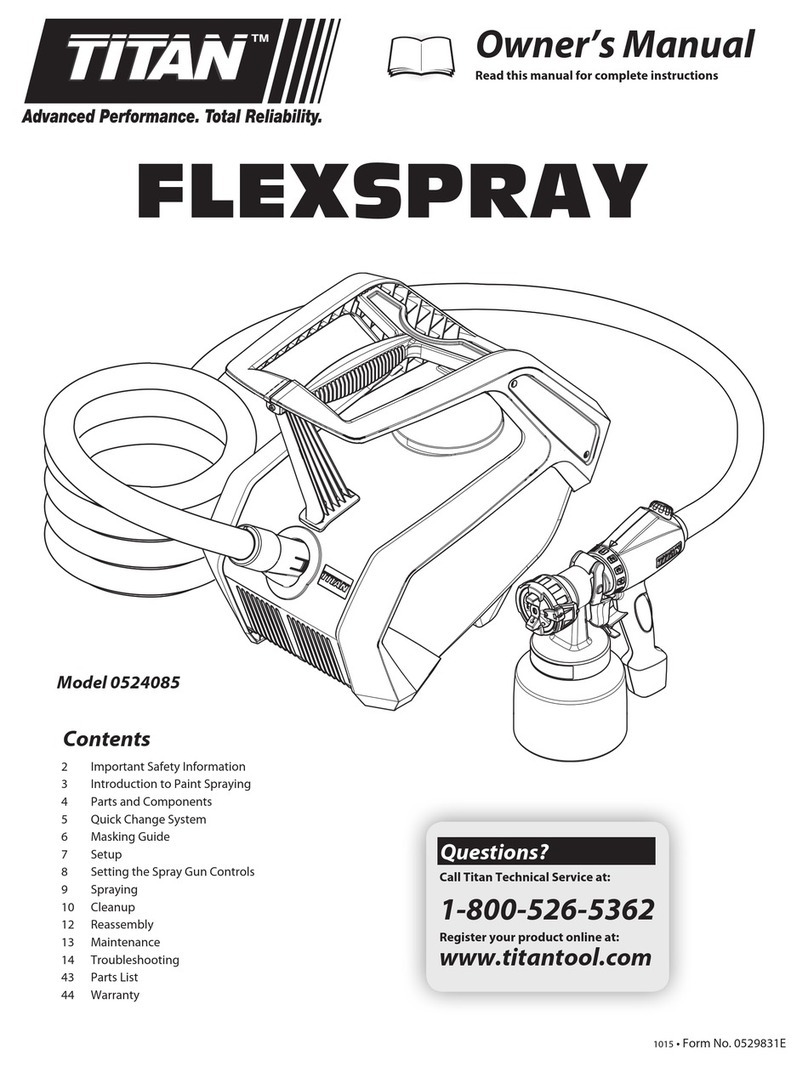

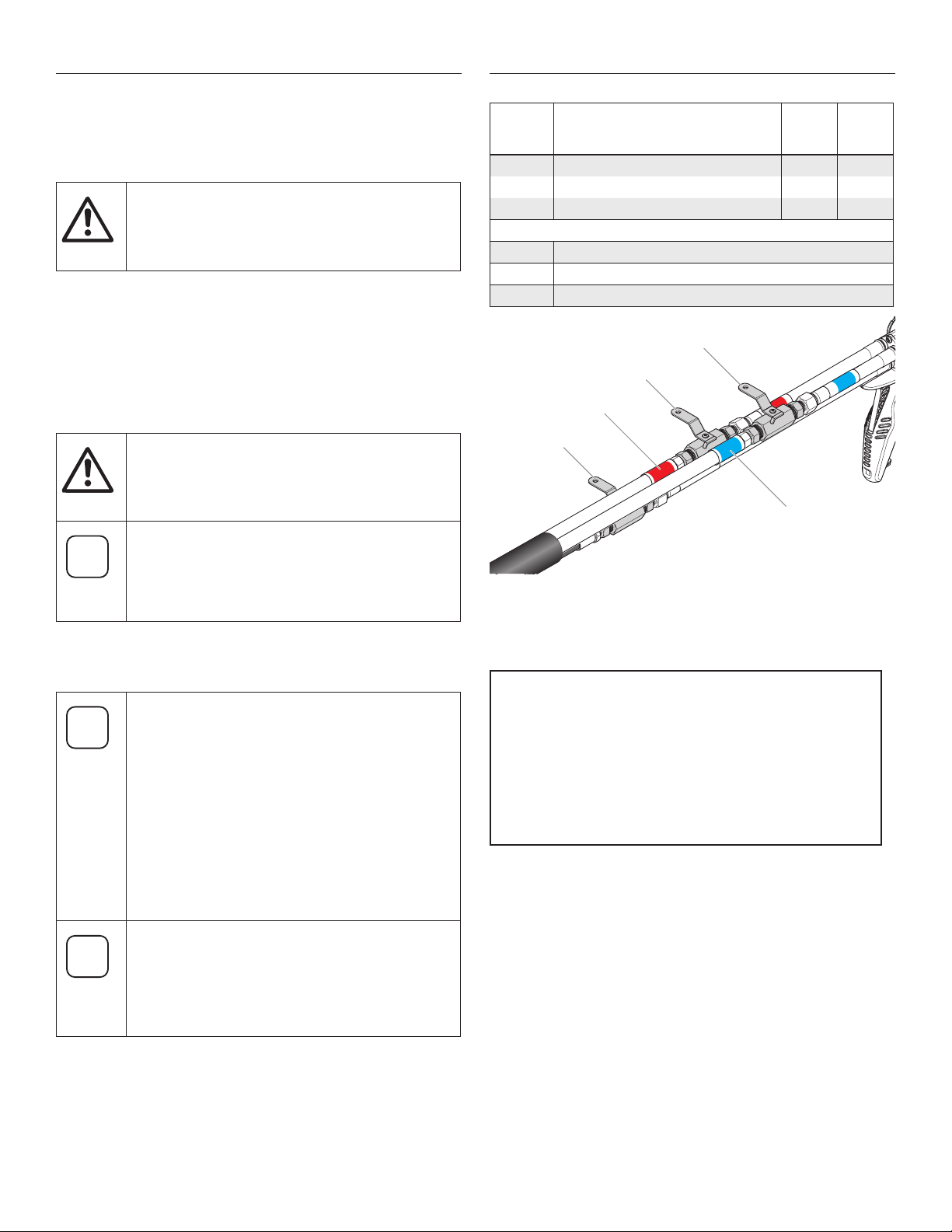

Not included, available for separate purchase (see graphic below):

0153979 Ball valve

0138982 Whip hose (blue)

0138983 Whip hose (red)

0138982

0153979

0153979

0153979

0138983

EU Declaration of conformity

We declare under sole responsibility that this product conforms

to the following relevant stipulations:

2006/42/EC, 2011/65/EU

Applied harmonised norms:

EN ISO 12100, EN 1953

The EU declaration of conformity is enclosed with the product.

If required, it can be re-ordered using order number 2399726.