2

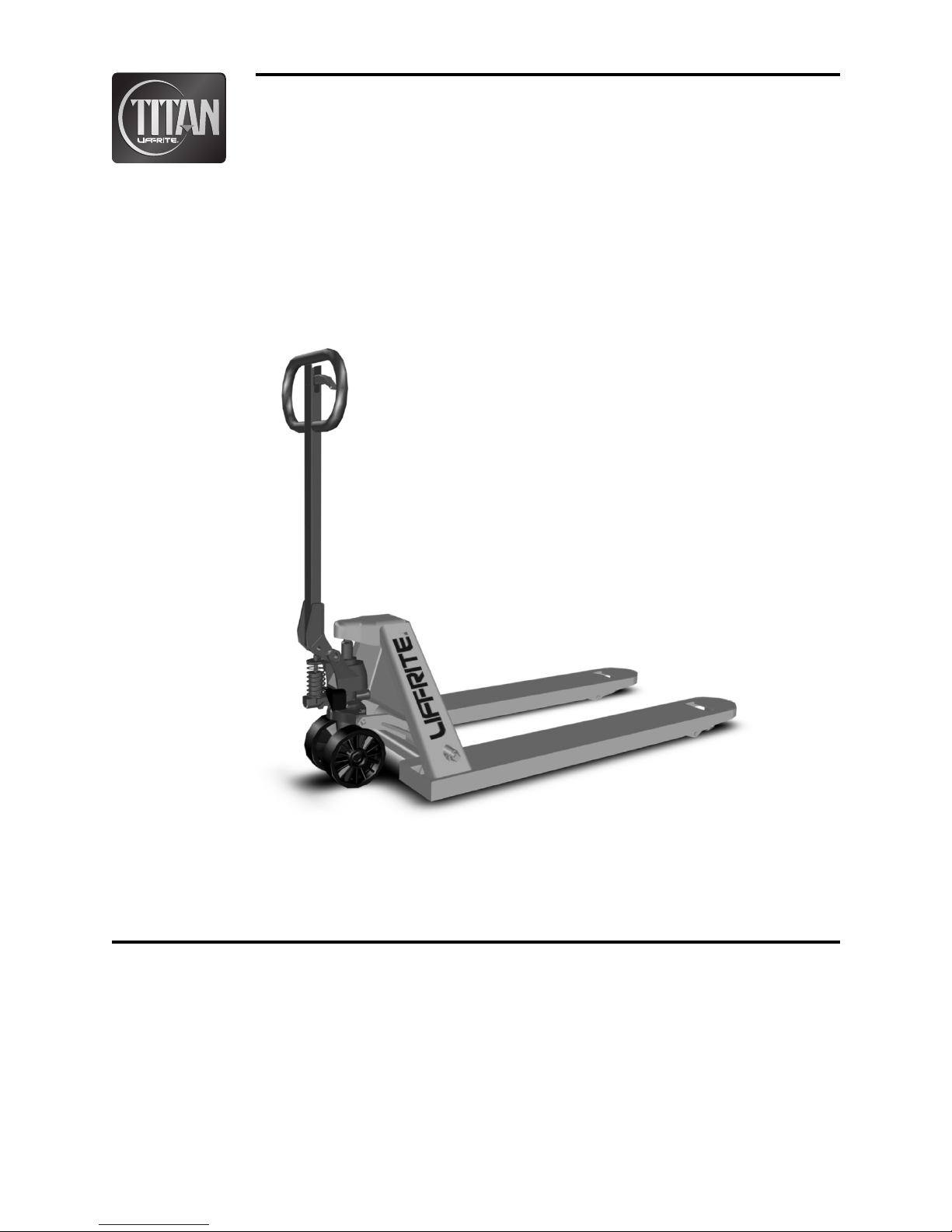

Lift-Rite, 5975 Falbourne Street, Mississauga, Ontario L5R3L8 Tel: Toll Free from USA: 1-800-558-6012; Tel: 1-905-456-2603 (Canada and International)

Fax: 1-905-456-1383 Owner’s Manual, Operating Instructions, and Replacement Parts Manual, Publication Number 1156118B ©2013 Dated 08 Oct 2013

Visually inspect hand pallet truck frame components and hydraulic unit for damage during

shipment by carrier. If damage is evident, notify delivering carrier immediately and file necessary

claims. Test the hand pallet truck pump for proper operation. If the hydraulic pump does not

respond to movement of the handle, an air lock may have developed during shipping. To

remedy this, go to the user friendly TROUBLESHOOTING guide in this manual.

DELIVERY INSPECTION

OPERATING INSTRUCTIONS

(Read and understand prior to using this product)

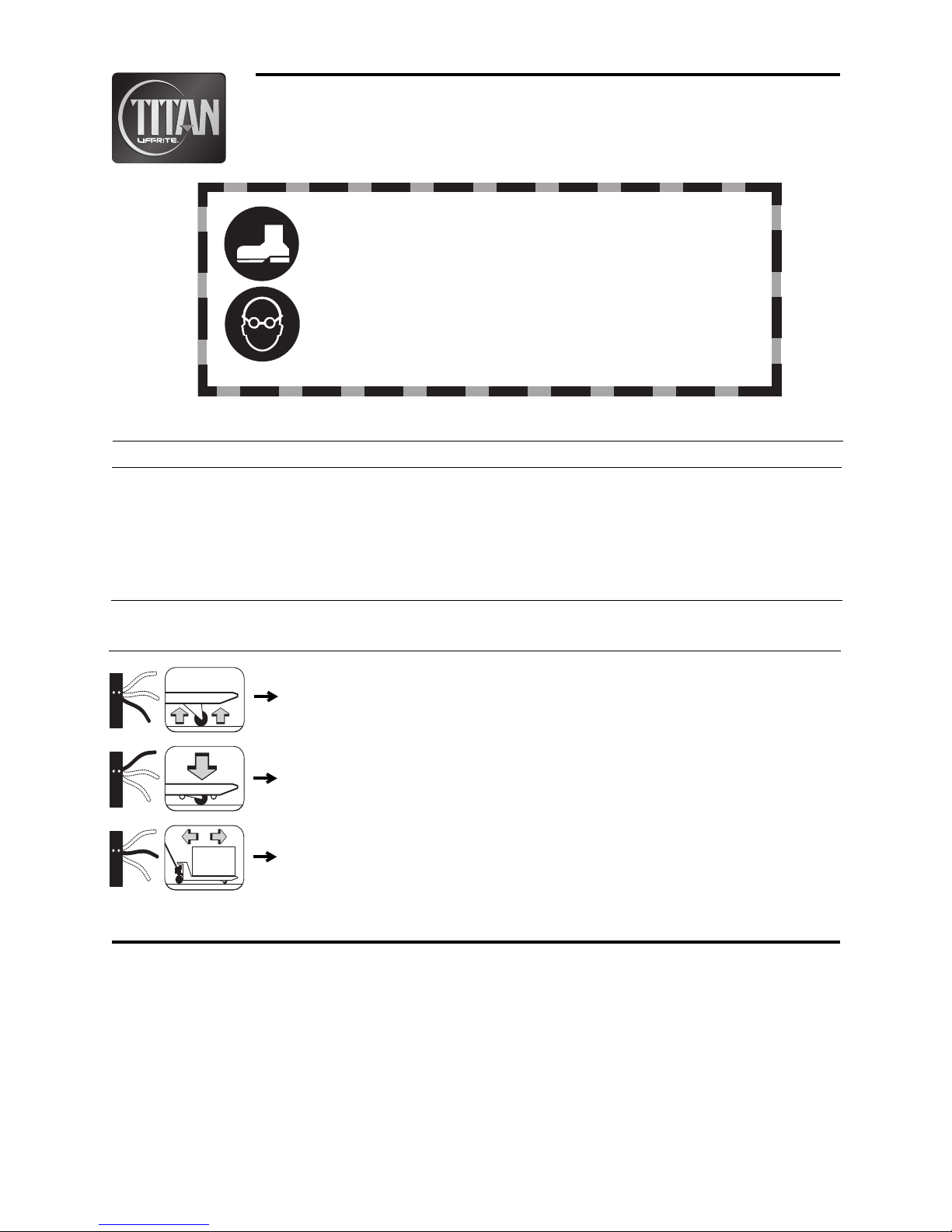

To raise the load, push down on

the fingertip control. Pump the

handle to raise the load from the

floor.

To lower the load, pull up on the

fingertip control.

For free handle movement, place

the fingertip control in the neutral

position.

NOTE:

The neutral position disengages

the pump from the lifting

mechanism. This frees the handle,

which makes pulling loads easier.

In addition, the pump is not

subject to shock pressures while

the truck is in motion.

SAFETY SHOES

Alwayswear safety shoes when working with hand pallet trucks.

PROTECTIVE GLASSES

When assembling or dismantling a hand pallet truck, protective

glasses must be worn to avoid personal injury.

OPERATOR’S RESPONSIBILITY

While operating a hand pallet truck, alwayswear safety equipment

and operate in a responsible manner to ensure a safe work area.