TITEFLEX R105 Series Manual

PRINTED COPY - NOT UNDER REVISION CONTROL

TITEFLEX COMMERCIAL ASSEMBLY PROCEDURE

TITLE: R105/R115/R122/R144 SERIES MEDIUM PRESSURE HOSE AP-33

ASSEMBLIES UTILIZING TK2 FITTINGS (ABRASIVE WHEEL) Rev. G

PROPRIETARY DATA NOTICE TO ALL RECEIVING THIS DOCUMENT

The information contained in this document was developed at the private expense by Titeflex Commercial. The contents are deemed proprietary

and all patent rights are reserved. Any submission is in a spirit of confidence and acceptance is deemed to be an acknowledgment of the

confidential relationship. Information contained hereon not lawfully obtained from another source shall not be released, duplicated, used or

disclosed in whole or in part for any procurement of manufacturing purpose without the prior written permission of the president, Titeflex

Commercial. Page 1of 15

SPECIFICATION CHANGE HISTORY

REV LTR

REV DATE

DESCRIPTION-CHANGE

APPROVALS

REQ

ENG

QA

IR

6/24/04

Initial Release

RNK

6/23/04

RNK

6/23/04

HBG

6/23/04

A

10/12/04

Revised Tables 1 & 2 to reflect swage/crimp diameter

tolerance of ± .005 and added to size –16 data.

RNK

10/04/04

RNK

10/04/04

HBG

10/04/0

B

2/20/06

Updated Tables 4 and 5 ‘JIC Pusher’ to reflect change in

TK2 nuts.

AJB

2/14/06

AJB

2/14/06

HBG

2/17/06

C

10/11/10

Added note for McLube application to Swaging Procedure

TMS

10/8/10

AJB

10/11/10

JJM

10/11/10

D

3/6/12

Updated Tables 4 and 5: ‘MNPT Pusher’ part numbers for

step down fittings were corrected

TSJ

3/5/12

AJB

3/5/12

JJM

3/5/12

E

02/06/2013

Added warning labels and swaging information

TSJ

02/04/13

AJB

02/04/13

CGB

02/04/13

F

3/21/16

Added text to para 4.8.2

LS

3/16/16

GR

3/16/16

SG

3/16/16

G

8/28/18

IN-1224 Added swager safety to sect 4.4 and removed PT

Log reference from 4.8.1.h

GR

8/20/18

AP

8/27/18

LS

8/27/18

NOTE: This specification shall be modified from time to time, as required, by modifications to the products herein,

or as required by addition of new products, or deletion of old products. Holders of this specification

outside of the normal Titeflex Commercial change distribution list will not be kept up to date.

PRINTED COPY - NOT UNDER REVISION CONTROL

TITEFLEX COMMERCIAL ASSEMBLY PROCEDURE

TITLE: R105/R115/R122/R144 SERIES MEDIUM PRESSURE HOSE AP-33

ASSEMBLIES UTILIZING TK2 FITTINGS (ABRASIVE WHEEL) Rev. G

PROPRIETARY DATA NOTICE TO ALL RECEIVING THIS DOCUMENT

The information contained in this document was developed at the private expense by Titeflex Commercial. The contents are deemed proprietary

and all patent rights are reserved. Any submission is in a spirit of confidence and acceptance is deemed to be an acknowledgment of the

confidential relationship. Information contained hereon not lawfully obtained from another source shall not be released, duplicated, used or

disclosed in whole or in part for any procurement of manufacturing purpose without the prior written permission of the president, Titeflex

Commercial. Page 2of 15

WARNING: Failure to read, thoroughly understand, and follow all instructions can result in

serious personal injury, damage to equipment, or voiding of factory warranty! It is the assembler’s

responsibility to make sure all components are properly assembled and installed using the

instructions provided.

As you read this procedure and the instructions included within, you will see NOTICES,

CAUTIONS, WARNINGS and DANGER. Each message has a specific purpose.

NOTICES are additional information to help you complete a procedural task or add additional

useful information.

CAUTIONS are safety messages that indicate a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. A CAUTION may also be used to alert against

unsafe practice or possible equipment damage.

WARNINGS are safety messages that indicate a potentially hazardous situation, which, if not

avoided could result in moderate to serious injury.

DANGER: are safety messages that indicate a hazardous situation which, if not avoided, will

result in death or serious injury

CAUTIONS, WARNINGS and DANGER identify the hazard, indicate how to avoid the hazard,

and advise of the probable consequence of not avoiding the hazard.

PRINTED COPY - NOT UNDER REVISION CONTROL

TITEFLEX COMMERCIAL ASSEMBLY PROCEDURE

TITLE: R105/R115/R122/R144 SERIES MEDIUM PRESSURE HOSE AP-33

ASSEMBLIES UTILIZING TK2 FITTINGS (ABRASIVE WHEEL) Rev. G

PROPRIETARY DATA NOTICE TO ALL RECEIVING THIS DOCUMENT

The information contained in this document was developed at the private expense by Titeflex Commercial. The contents are deemed proprietary

and all patent rights are reserved. Any submission is in a spirit of confidence and acceptance is deemed to be an acknowledgment of the

confidential relationship. Information contained hereon not lawfully obtained from another source shall not be released, duplicated, used or

disclosed in whole or in part for any procurement of manufacturing purpose without the prior written permission of the president, Titeflex

Commercial. Page 3of 15

1.0 PURPOSE

To establish assembly instructions and inspection procedures for R105/R115/R122/R144

Series medium pressure extruded PTFE assemblies using TK2 fittings for assemblies cut

with an abrasive wheel.

2.0 DEFINITIONS

N/A

3.0 ASSOCIATED DOCUMENTS

CQP-830 Nonconforming Material Report and Control

CQP-833 Scrap Processing

CQP-835 Daily Scrap Reports

MES 246 McLUBE Dip Coating

4.0 PROCEDURE

4.1 General

4.1.1 Check the tooling for wear, cracks, and contamination.

4.2 Preparation of Hose

4.2.1 Select the appropriate R105, R115, R122 or R144 hose and calculate the

desired hose length by subtracting the fitting deduct length of both end

fittings.

4.2.2 Wrap the area of the hose to be cut with a single layer of reinforced

packing tape or masking tape. Note: This step may be omitted for sizes 4,

5 and 6 hose.

4.2.3 Measure with a tape measure or other suitable device and cut hose (See

Figure #1) to the predetermined length. Use a cutoff wheel or other

suitable device. Ends must be cut clean and approximately square.

PRINTED COPY - NOT UNDER REVISION CONTROL

TITEFLEX COMMERCIAL ASSEMBLY PROCEDURE

TITLE: R105/R115/R122/R144 SERIES MEDIUM PRESSURE HOSE AP-33

ASSEMBLIES UTILIZING TK2 FITTINGS (ABRASIVE WHEEL) Rev. G

PROPRIETARY DATA NOTICE TO ALL RECEIVING THIS DOCUMENT

The information contained in this document was developed at the private expense by Titeflex Commercial. The contents are deemed proprietary

and all patent rights are reserved. Any submission is in a spirit of confidence and acceptance is deemed to be an acknowledgment of the

confidential relationship. Information contained hereon not lawfully obtained from another source shall not be released, duplicated, used or

disclosed in whole or in part for any procurement of manufacturing purpose without the prior written permission of the president, Titeflex

Commercial. Page 4of 15

NOTE: When measuring hose length at this operation or at 4.7, it is permissible to

measure from the 1" mark on the tape to minimize wear on the tab.

4.2.4 Trim any burrs in the innercore using a sharp knife or chamfer tool and

blow out any grit from ID of hose using clean shop air.

4.2.5 Trim any excess braid wire using wire snips or the edge of the cutoff

wheel to achieve a consistent outside diameter. Excessive braid wire left

behind from the cutting operation can affect the assembly of the fitting to

the hose.

4.3 Hose/Fitting Insertion (One Piece Fitting)

4.3.1 Expand the hose ends per Figure #2 using the appropriate hose expander

T168658-X as shown in Table 4. The expander should be rotated inside

the hose 4 –6 revolutions using a hand held variable speed drill at slow

speed. Remove the tape from the ends of the hose.

4.3.2 Place the fitting with collar end up as shown in Figure #3 into appropriate

117483-X Fitting Installation Fixture and cap off with the split dies halves.

Push hose end firmly into the die halves per Figure #4 until hose bottoms

in collar. A slight twisting motion may be required. (Note: To insure the

hose is bottomed in the collar, mark the hose OD prior to installing fitting

where the collar ends. Push on the hose until the end of the collar now

meets the mark on the hose OD.)

4.3.3 Repeat for other end of hose.

4.4 Hose/Fitting Insertion (Two Piece Fitting)

4.4.1 Remove tape from cut ends of the hose. Place the collar into the

appropriate 117484-X Fitting Installation Fixture per Figure #7 and cap off

with the split dies halves. Push the hose end firmly into the die halves

until the hose bottoms in collar. A slight twisting motion may be required.

(Note: To insure the hose is bottomed in the collar, remove the collar from

the installation fixture and visually inspect the opposite end of the collar

for the hose.)

PRINTED COPY - NOT UNDER REVISION CONTROL

TITEFLEX COMMERCIAL ASSEMBLY PROCEDURE

TITLE: R105/R115/R122/R144 SERIES MEDIUM PRESSURE HOSE AP-33

ASSEMBLIES UTILIZING TK2 FITTINGS (ABRASIVE WHEEL) Rev. G

PROPRIETARY DATA NOTICE TO ALL RECEIVING THIS DOCUMENT

The information contained in this document was developed at the private expense by Titeflex Commercial. The contents are deemed proprietary

and all patent rights are reserved. Any submission is in a spirit of confidence and acceptance is deemed to be an acknowledgment of the

confidential relationship. Information contained hereon not lawfully obtained from another source shall not be released, duplicated, used or

disclosed in whole or in part for any procurement of manufacturing purpose without the prior written permission of the president, Titeflex

Commercial. Page 5of 15

4.4.2 Repeat for other end of hose.

4.4.3 Expand the hose end per Figure #8 using the appropriate hose expander as

shown in Table 4 by inserting the expander through the open end of the

collar. The expander should be rotated inside the hose 4 –6 revolutions

using a hand held variable speed drill at slow speed.

4.4.4 Repeat for other end of hose.

4.4.5 Assemble the insert into prepared hose end by hand and push the fitting

until it bottoms against the collar per Figure #9. Note: It may be necessary

to use the side of a bench or other suitable device to facilitate the fitting

insertion.

4.5 Crimping Procedure

Crimp the entire length of the retaining collar to the dimensions shown in Table 1 or

Table 2 for detailed crimping dimensions. Note: The entire length of the collar must be

crimped.

4.6 Swage Procedure

Swaging operation develops extreme pressure on the tooling. Misalignment, wear, or

damaged tooling could result in tooling failure and flying objects which could cause

serious personal injury.

For protection, safety glasses with a face shield must be worn while swaging. All

guarding around the swager should be inspected and in place prior to use.

Note: McLube 1700L must be used on collars prior to swaging. Dip all collars into

McLube 1700L then remove and allow to dry. If Aerosol version is used apply 2-3 coats

allowing each coat to dry thoroughly between each application.

PRINTED COPY - NOT UNDER REVISION CONTROL

TITEFLEX COMMERCIAL ASSEMBLY PROCEDURE

TITLE: R105/R115/R122/R144 SERIES MEDIUM PRESSURE HOSE AP-33

ASSEMBLIES UTILIZING TK2 FITTINGS (ABRASIVE WHEEL) Rev. G

PROPRIETARY DATA NOTICE TO ALL RECEIVING THIS DOCUMENT

The information contained in this document was developed at the private expense by Titeflex Commercial. The contents are deemed proprietary

and all patent rights are reserved. Any submission is in a spirit of confidence and acceptance is deemed to be an acknowledgment of the

confidential relationship. Information contained hereon not lawfully obtained from another source shall not be released, duplicated, used or

disclosed in whole or in part for any procurement of manufacturing purpose without the prior written permission of the president, Titeflex

Commercial. Page 6of 15

Select the appropriate swage die and pusher set from Table 4 for R115/R122 hose and

Table 5 for R105/R144 hose for the size assembled. Place the dies around the assembly

and into the swage machine paying close attention to not pinch the reinforcing braid of

the hose between swage die halves. Activate the swager and push the fitting into the die

set per Figures #6 or 10 until the hex of the fitting makes contact with the top of the die

set. Retract swage pusher and remove hose assembly from die halves. Repeat for other

end.

4.7 Inspection

4.7.1 Perform a visual/dimensional inspection of the assembly per the

following:

A. Crimp/Swage Diameter - Measure first piece and visually

B. Overall Length - compare to remainder of order.

C. Swage Length -

Overall length tolerances are shown below and crimp/swage diameter and swage length

per Table 1 or Table 2.

Use a vernier or equivalent to measure crimp diameter and a tape measure to measure

overall length. The tape measure does not require calibration.

Overall length and dimensional tolerances are as follows:

Up to 18" +1/4"

- 1/8"

18" to 36" +1/2"

- 1/4"

36" to 50" +1"

-1/2"

Over 50" +2"

- 1"

PRINTED COPY - NOT UNDER REVISION CONTROL

TITEFLEX COMMERCIAL ASSEMBLY PROCEDURE

TITLE: R105/R115/R122/R144 SERIES MEDIUM PRESSURE HOSE AP-33

ASSEMBLIES UTILIZING TK2 FITTINGS (ABRASIVE WHEEL) Rev. G

PROPRIETARY DATA NOTICE TO ALL RECEIVING THIS DOCUMENT

The information contained in this document was developed at the private expense by Titeflex Commercial. The contents are deemed proprietary

and all patent rights are reserved. Any submission is in a spirit of confidence and acceptance is deemed to be an acknowledgment of the

confidential relationship. Information contained hereon not lawfully obtained from another source shall not be released, duplicated, used or

disclosed in whole or in part for any procurement of manufacturing purpose without the prior written permission of the president, Titeflex

Commercial. Page 7of 15

4.8 Pressure Test

WARNING: Proof pressure values exceed the working pressures of the hose, therefore

extreme care must be taken to protect from personnel injury and property damage.

There is potential risk of flying parts, sudden release of energy and high pressure

injection from test fluids among other dangers. Always test inside a protective cabinet

and direct hose ends away from personnel and in a safe direction.

4.8.1 Pressure test each assembly with water per following:

a. Connect assemblies to pressure manifold.

b. Run water through assemblies to remove air. Leave water on.

c. Place caps on assemblies.

d. Adjust pressure to proof value specified in for R115/R122 and Table 2 for

R105/R144 of this document.

e. With air hose, blow water from outside of hose assemblies and close safety cover.

f. Set timer for three minutes minimum. Longer assemblies may require longer than 3

minutes to visually inspect.

CAUTION: Never leave assemblies at proof pressure longer than necessary to evaluate,

proof pressure values exceed the working pressures of the hose.

g. Examine lines. Any evidence of leakage constitutes failure.

WARNING: Never touch pressurized lines to feel for wetness. Serious injury from high

pressure injection is possible. Proof testing must be done in a protective cabinet to protect

from personnel injury and property damage.

h. Complete Router as required.

PRINTED COPY - NOT UNDER REVISION CONTROL

TITEFLEX COMMERCIAL ASSEMBLY PROCEDURE

TITLE: R105/R115/R122/R144 SERIES MEDIUM PRESSURE HOSE AP-33

ASSEMBLIES UTILIZING TK2 FITTINGS (ABRASIVE WHEEL) Rev. G

PROPRIETARY DATA NOTICE TO ALL RECEIVING THIS DOCUMENT

The information contained in this document was developed at the private expense by Titeflex Commercial. The contents are deemed proprietary

and all patent rights are reserved. Any submission is in a spirit of confidence and acceptance is deemed to be an acknowledgment of the

confidential relationship. Information contained hereon not lawfully obtained from another source shall not be released, duplicated, used or

disclosed in whole or in part for any procurement of manufacturing purpose without the prior written permission of the president, Titeflex

Commercial. Page 8of 15

4.8.2 Sampling of pressure test is permitted in accordance with Table 3 except

as mentioned below. If any part is rejected, the entire lot is to be tested.

Acceptable parts shall be routed to packing/stores and shipping.

Rejectable parts shall be processed per CQP-830, CQP-833 and CQP-835.

4.8.2.1 All assemblies for Nordson require 100% pressure test. Sampling

is not allowed

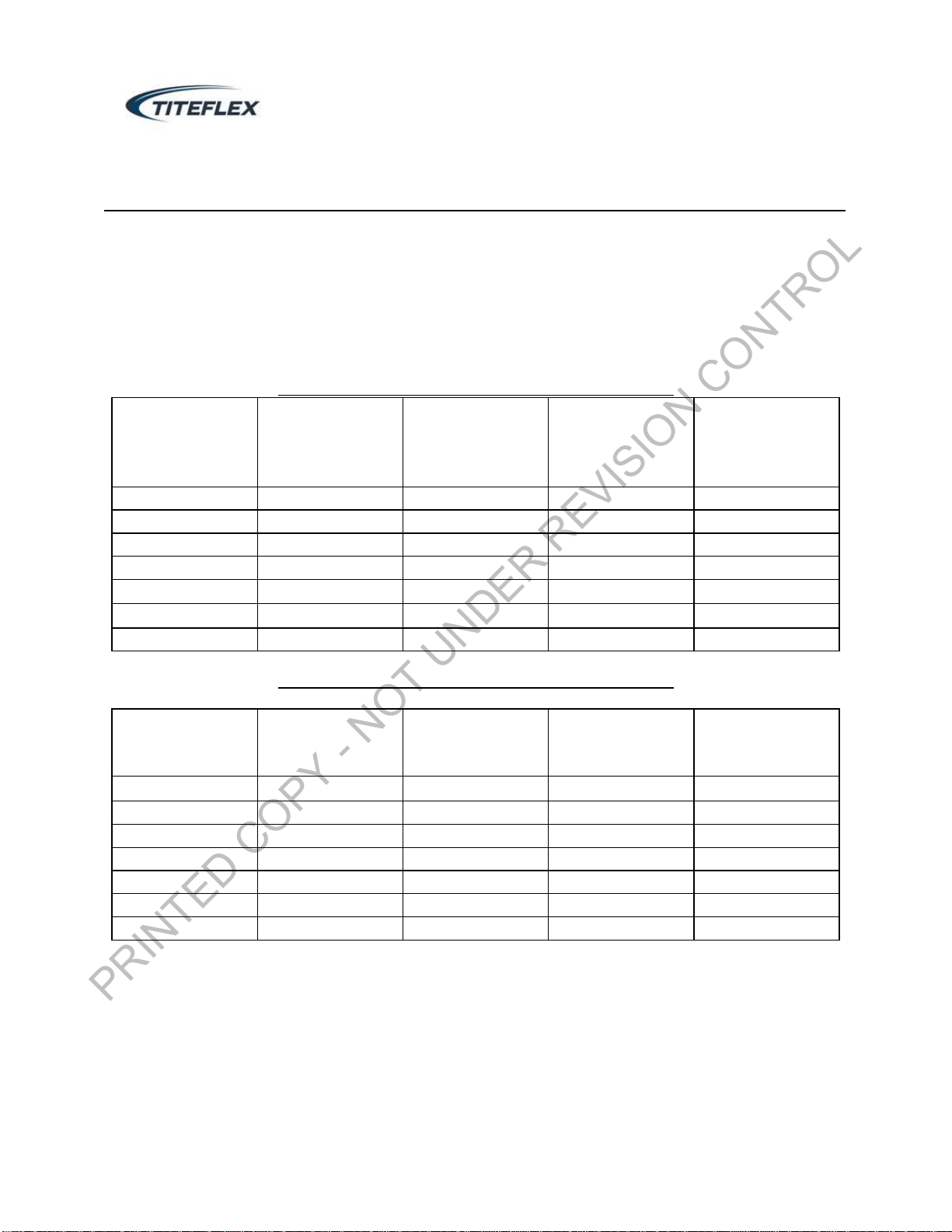

TABLE 1 R115/R122 Hose Crimp/Swage Diameters

Size

Crimp/Swage

Diameter

±.005

Swage Length

(Min)

Max Operating

Pressure, Room

Temp.

(PSI)

Proof Pressure

(PSI)

±100 psi

-4

.350

.426

3000

4500

-5

.404

.426

3000

4500

-6

.478

.545

2500

3750

-8

.568

.572

2000

3000

-10

.705

.668

1500

2250

-12

.800

.733

1200

1800

-16

1.057

.854

1000

1500

TABLE 2 R105/R144 Hose Crimp/Swage Diameters

Size

Crimp/Swage

Diameter

±.005

Swage Length

(Min)

Max Operating

Pressure, Room

Temp. (PSI)

Proof Pressure

(PSI)

±100 psi

-4

.375

.426

3000

4500

-5

.432

.426

3000

4500

-6

.492

.545

2500

3750

-8

.585

.572

2000

3000

-10

.724

.668

1500

2250

-12

.818

.733

1200

1800

-16

1.066

.854

800

1200

PRINTED COPY - NOT UNDER REVISION CONTROL

TITEFLEX COMMERCIAL ASSEMBLY PROCEDURE

TITLE: R105/R115/R122/R144 SERIES MEDIUM PRESSURE HOSE AP-33

ASSEMBLIES UTILIZING TK2 FITTINGS (ABRASIVE WHEEL) Rev. G

PROPRIETARY DATA NOTICE TO ALL RECEIVING THIS DOCUMENT

The information contained in this document was developed at the private expense by Titeflex Commercial. The contents are deemed proprietary

and all patent rights are reserved. Any submission is in a spirit of confidence and acceptance is deemed to be an acknowledgment of the

confidential relationship. Information contained hereon not lawfully obtained from another source shall not be released, duplicated, used or

disclosed in whole or in part for any procurement of manufacturing purpose without the prior written permission of the president, Titeflex

Commercial. Page 9of 15

TABLE 3

Lot Size*

Sample Size

2 to 8

All

9 to 15

9

16 to 25

13

26 to 50

13

51 to 90

13

91 to 150

13

151 to 280

50

281 to 500

50

For lot sizes above 500 contact Quality Engineering for sample size.

TABLE 4 R115/R122 Swage Tools

Size

Swage Dies

Hose Expander

JIC Pusher

MNPT Pusher

4

117455-4

T168658-4

117512-04

106576-4-2 (1/8”)

106576-4 (1/4”)

5

117455-5

T168658-5

117512-05

106576-4 (1/4”)

6

117455-6

T168658-6

117512-06

106576-6-4 (1/4”)

106576-6 (3/8”)

8

117455-8

T168658-8

117512-08

106576-8-6 (3/8”)

106576-8 (1/2”)

10

117455-10

T168658-10

117512-10

106576-8

12

117455-12

T168658-12

117512-12

106576-12

16

117455-16

T168658-16

117512-16

106576-16

TABLE 5 R105/R144 Swage Tools

PRINTED COPY - NOT UNDER REVISION CONTROL

TITEFLEX COMMERCIAL ASSEMBLY PROCEDURE

TITLE: R105/R115/R122/R144 SERIES MEDIUM PRESSURE HOSE AP-33

ASSEMBLIES UTILIZING TK2 FITTINGS (ABRASIVE WHEEL) Rev. G

PROPRIETARY DATA NOTICE TO ALL RECEIVING THIS DOCUMENT

The information contained in this document was developed at the private expense by Titeflex Commercial. The contents are deemed proprietary

and all patent rights are reserved. Any submission is in a spirit of confidence and acceptance is deemed to be an acknowledgment of the

confidential relationship. Information contained hereon not lawfully obtained from another source shall not be released, duplicated, used or

disclosed in whole or in part for any procurement of manufacturing purpose without the prior written permission of the president, Titeflex

Commercial. Page 10 of 15

Size

Swage Dies

Hose Expander

JIC Pusher

MNPT Pusher

4

117455-4A

T168658-4

117512-04

106576-4-2 (1/8”)

106576-4 (1/4”)

5

117455-5A

T168658-5

117512-05

106576-4 (1/4”)

6

117455-6A

T168658-6

117512-06

106576-6-4 (1/4”)

106576-6 (3/8”)

8

117455-8A

T168658-8

117512-08

106576-8-6 (3/8”)

106576-8 (1/2”)

10

117455-10A

T168658-10

117512-10

106576-8

12

117455-12A

T168658-12

117512-12

106576-12

16

117455-16A

T168658-16

117512-16

106576-16

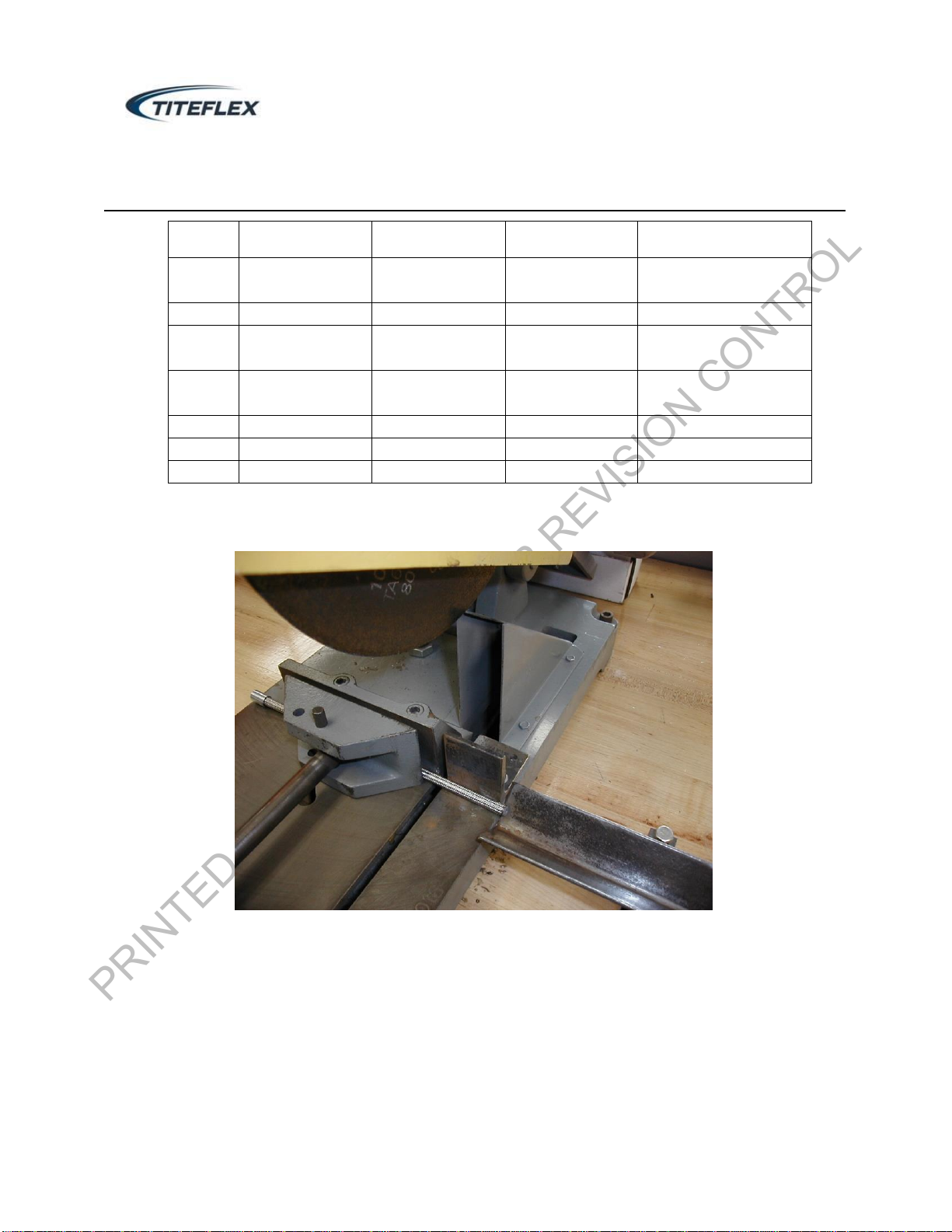

Figure #1: Hose Cut-off –Abrasive Wheel

Figure #2: Hose Expanding –One Piece Fitting

PRINTED COPY - NOT UNDER REVISION CONTROL

TITEFLEX COMMERCIAL ASSEMBLY PROCEDURE

TITLE: R105/R115/R122/R144 SERIES MEDIUM PRESSURE HOSE AP-33

ASSEMBLIES UTILIZING TK2 FITTINGS (ABRASIVE WHEEL) Rev. G

PROPRIETARY DATA NOTICE TO ALL RECEIVING THIS DOCUMENT

The information contained in this document was developed at the private expense by Titeflex Commercial. The contents are deemed proprietary

and all patent rights are reserved. Any submission is in a spirit of confidence and acceptance is deemed to be an acknowledgment of the

confidential relationship. Information contained hereon not lawfully obtained from another source shall not be released, duplicated, used or

disclosed in whole or in part for any procurement of manufacturing purpose without the prior written permission of the president, Titeflex

Commercial. Page 11 of 15

Figure #3: One Piece Fitting Installation Fixture

Figure #4: One Piece Fitting Assembly onto Hose

PRINTED COPY - NOT UNDER REVISION CONTROL

TITEFLEX COMMERCIAL ASSEMBLY PROCEDURE

TITLE: R105/R115/R122/R144 SERIES MEDIUM PRESSURE HOSE AP-33

ASSEMBLIES UTILIZING TK2 FITTINGS (ABRASIVE WHEEL) Rev. G

PROPRIETARY DATA NOTICE TO ALL RECEIVING THIS DOCUMENT

The information contained in this document was developed at the private expense by Titeflex Commercial. The contents are deemed proprietary

and all patent rights are reserved. Any submission is in a spirit of confidence and acceptance is deemed to be an acknowledgment of the

confidential relationship. Information contained hereon not lawfully obtained from another source shall not be released, duplicated, used or

disclosed in whole or in part for any procurement of manufacturing purpose without the prior written permission of the president, Titeflex

Commercial. Page 12 of 15

Figure #5: Assembled One Piece Fitting

Figure #6: Swaging of One Piece Fitting

PRINTED COPY - NOT UNDER REVISION CONTROL

TITEFLEX COMMERCIAL ASSEMBLY PROCEDURE

TITLE: R105/R115/R122/R144 SERIES MEDIUM PRESSURE HOSE AP-33

ASSEMBLIES UTILIZING TK2 FITTINGS (ABRASIVE WHEEL) Rev. G

PROPRIETARY DATA NOTICE TO ALL RECEIVING THIS DOCUMENT

The information contained in this document was developed at the private expense by Titeflex Commercial. The contents are deemed proprietary

and all patent rights are reserved. Any submission is in a spirit of confidence and acceptance is deemed to be an acknowledgment of the

confidential relationship. Information contained hereon not lawfully obtained from another source shall not be released, duplicated, used or

disclosed in whole or in part for any procurement of manufacturing purpose without the prior written permission of the president, Titeflex

Commercial. Page 13 of 15

Figure #7: Collar Assembly –Two Piece Fitting

Figure #8: Hose Expansion –Two Piece Fitting

PRINTED COPY - NOT UNDER REVISION CONTROL

TITEFLEX COMMERCIAL ASSEMBLY PROCEDURE

TITLE: R105/R115/R122/R144 SERIES MEDIUM PRESSURE HOSE AP-33

ASSEMBLIES UTILIZING TK2 FITTINGS (ABRASIVE WHEEL) Rev. G

PROPRIETARY DATA NOTICE TO ALL RECEIVING THIS DOCUMENT

The information contained in this document was developed at the private expense by Titeflex Commercial. The contents are deemed proprietary

and all patent rights are reserved. Any submission is in a spirit of confidence and acceptance is deemed to be an acknowledgment of the

confidential relationship. Information contained hereon not lawfully obtained from another source shall not be released, duplicated, used or

disclosed in whole or in part for any procurement of manufacturing purpose without the prior written permission of the president, Titeflex

Commercial. Page 14 of 15

Figure #9: Assembled Two Piece Fitting

PRINTED COPY - NOT UNDER REVISION CONTROL

TITEFLEX COMMERCIAL ASSEMBLY PROCEDURE

TITLE: R105/R115/R122/R144 SERIES MEDIUM PRESSURE HOSE AP-33

ASSEMBLIES UTILIZING TK2 FITTINGS (ABRASIVE WHEEL) Rev. G

PROPRIETARY DATA NOTICE TO ALL RECEIVING THIS DOCUMENT

The information contained in this document was developed at the private expense by Titeflex Commercial. The contents are deemed proprietary

and all patent rights are reserved. Any submission is in a spirit of confidence and acceptance is deemed to be an acknowledgment of the

confidential relationship. Information contained hereon not lawfully obtained from another source shall not be released, duplicated, used or

disclosed in whole or in part for any procurement of manufacturing purpose without the prior written permission of the president, Titeflex

Commercial. Page 15 of 15

Figure #10: Swaging of Two Piece Fitting

Figure #11: Swaged Two Piece Fitting

This manual suits for next models

3

Table of contents