Titus FFDE User manual

Redefine your comfort zone. ™ | www.titus-hvac.com

INSTALLATION &

OPERATION MANUAL

Fan Filter Unit

FFDE / FFDER / FFDERA

2IOM - FFDE Redefine your comfort zone. ™ | www.titus-hvac.com

IOM

FFDE / FFDER / FFDERA

Table of Contents

Critical Operations of the Fan Filter Unit .................................................................................................................3

Warnings.................................................................................................................................................................. 4

Installation............................................................................................................................ ....................................5

Unit Control Box........................................................................................................................................................6

Universal Control Card Set Up.................................................................................................. ...............................7

Troubleshooting.................................................................................................................... ..................................12

Infrared Speed Control.......................................................................................................... .................................13

Pre-filter Cleaning (foam) ................................................................................................. .....................................14

Service: Removal and Replacement of FFDE Filters............................................................... .. ............................15

Service: Removal and Replacement of Roomside Replaceable Filters ................................. .. ............................16

Service: FFDE and FFDER Motor Removal and Installation ................................................... ..............................17

Service: FFDERA Motor Removal and Installation .......................................................... .....................................18

Technical Note: TN1004 Changing Motors in the Field.........................................................................................19

Technical Note: TN1002 Design with VAV Boxes...................................................................................................21

Unit Wiring Diagrams ............................................................................................................................................22

Unit Replacement Parts List...................................................................................................................................25

Drawing - FFDE Filter ........................................................................................................... ..................................26

Drawing - FFDER & FFDERA Filter .......................................................................................... ...............................27

Testing.....................................................................................................................................................................28

3

IOM - FFDE

Redefine your comfort zone. ™ | www.titus-hvac.com

1. Touching of the HEPA filter will damage it, voiding the warranty

on the filter. The screen is only to protect against an accidental

‘touch’ of the filter. Never place a hand or tool on the filte . Never

lie filter face flat down on a surface alwa have filter on its side to

protect from damage.

2. Prior to powering the unit, verify voltage on label and that the unit

has been wired into the correct voltage. The serial number label on

the top of the unit has the required voltage.

3. To insure you order the proper replacement parts or complete

unit, record the part number and serial number. This information

is located on the serial number label, located adjacent to the

electrical box. If you can’t locate the Sales Order Number, please

contact Titus for this information. Once obtained, record the

information for reference.

WARNING

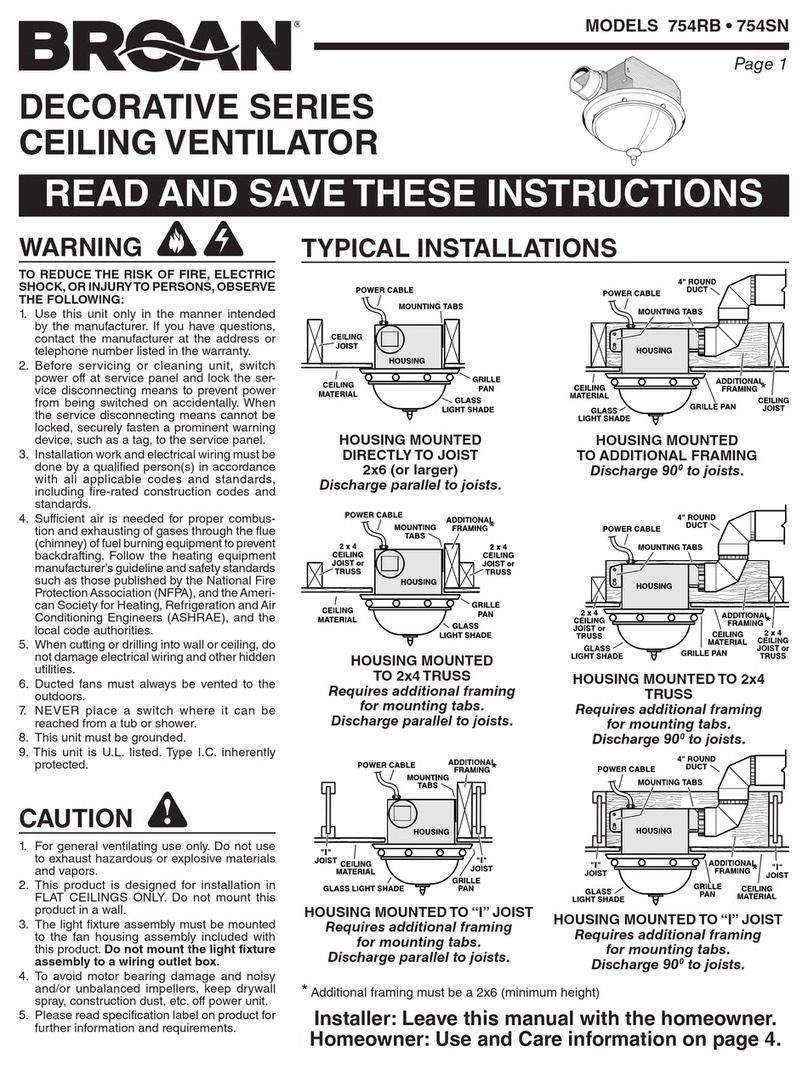

TO REDUCE THE RISK OF FIRE, ELECTRICAL SHOCK, OR INJURY TO

PERSONS, OBSERVE THE FOLLOWING:

A. Installation work and electrical wiring must be done by qualified

person(s) in accordance with all applicable codes and standards,

including fire-rated construction.

B. When cutting or drilling into wall or ceiling, do not damage

electrical wiring and other hidden utilities.

C. If this unit is to be installed over an area using liquid, such as water

or chemical cleaning solutions, it must be marked as appropriate

for the application.

D. Use this unit only in the manner intended by the manufacturer. If

you have any questions, contact the manufacturer.

E. Before servicing or cleaning the unit, switch power off at unit

service panel and lock service panel to prevent power from being

switched on accidentally. Units come set in manual mode from the factory. Please

review installation requirements and set up with your end

user (See page 8 for complete set up instructions).

Critical Operation Conditions of FFD, FFDR, & FFDRA models

4IOM - FFDE Redefine your comfort zone. ™ | www.titus-hvac.com

IOM

FFDE / FFDER / FFDERA

Step 3. Raise the unit and secure it into place using the chosen support

system method suspended from a structural support bracing.

Step 4. Have an electrician wire the unit to the appropriate voltage,

according to the wiring diagram (page 21-23), and all national and local

electrical codes. All units are equipped with a three position terminal

block for field onnection. Verify correct singlephase power, before

energizing units.

Step 5. Turn on the power using the two position rocker switch (ON/OFF)

located on the electrical box. For FFDR and FFDRA units, let the unit run for

a few hours to purge off particulate (if filters are shipped loose) that may

be adhered to the inside of the unit before installing the filters. Do not run

fan at full speed as this may cause overload condition.

Note: Your fan filter may have been shipped separate. Controls have been

shipped separately.

Installation

Note: Titus fan filter units are completely assembled at the factory with

the exception of the optional ¼”-20 eyebolts that are used when hanging

the unit from an engineered design support system and installation of the

HEPA/ULPA filters (eyebolts not included and can be ordered separately,

p/n 222449-001).

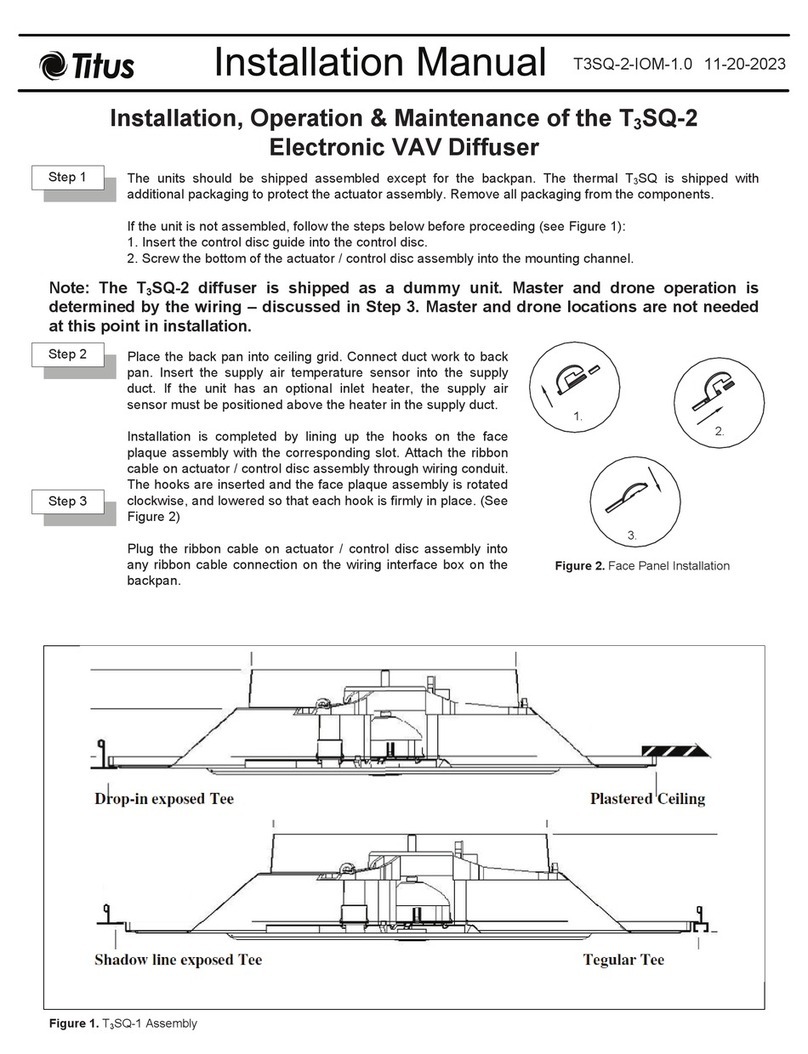

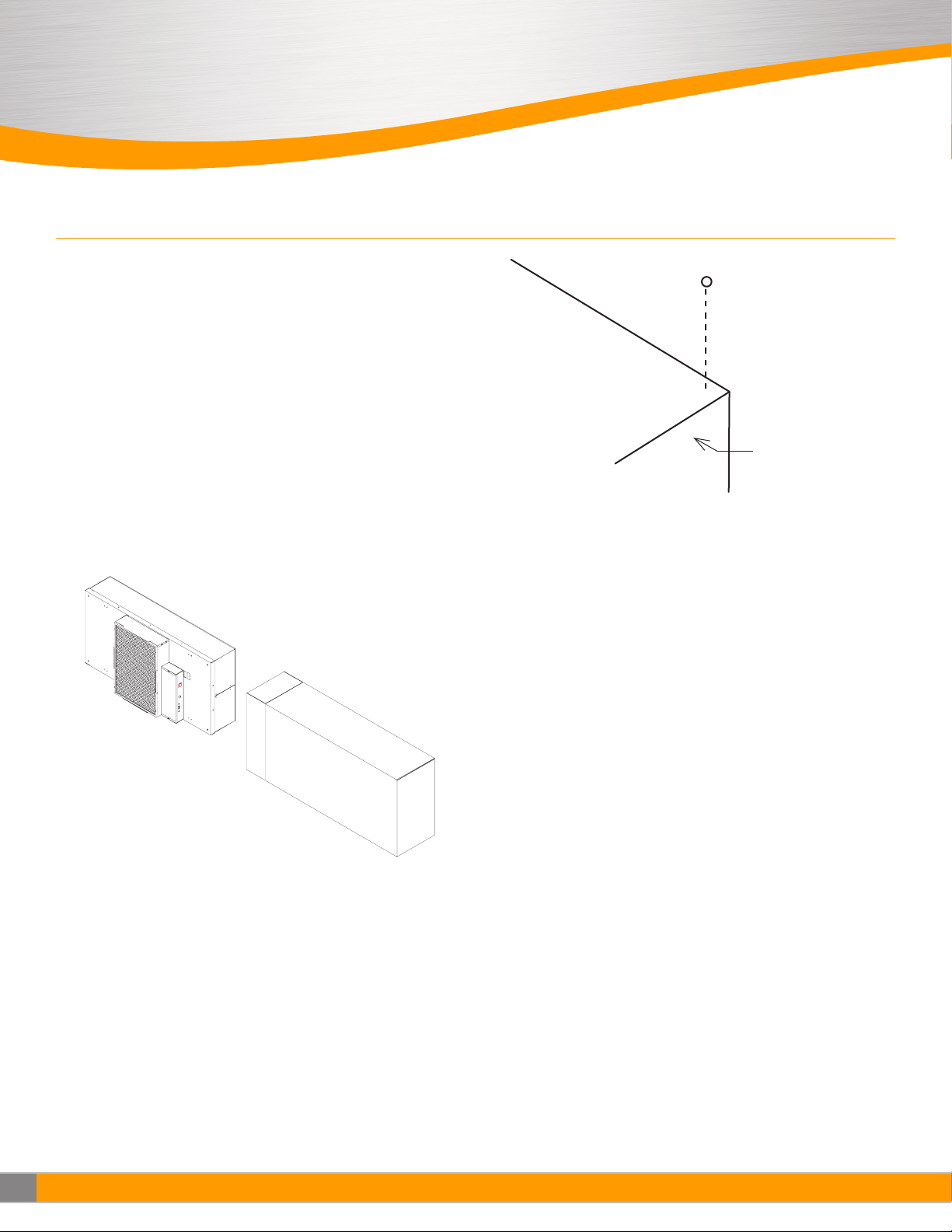

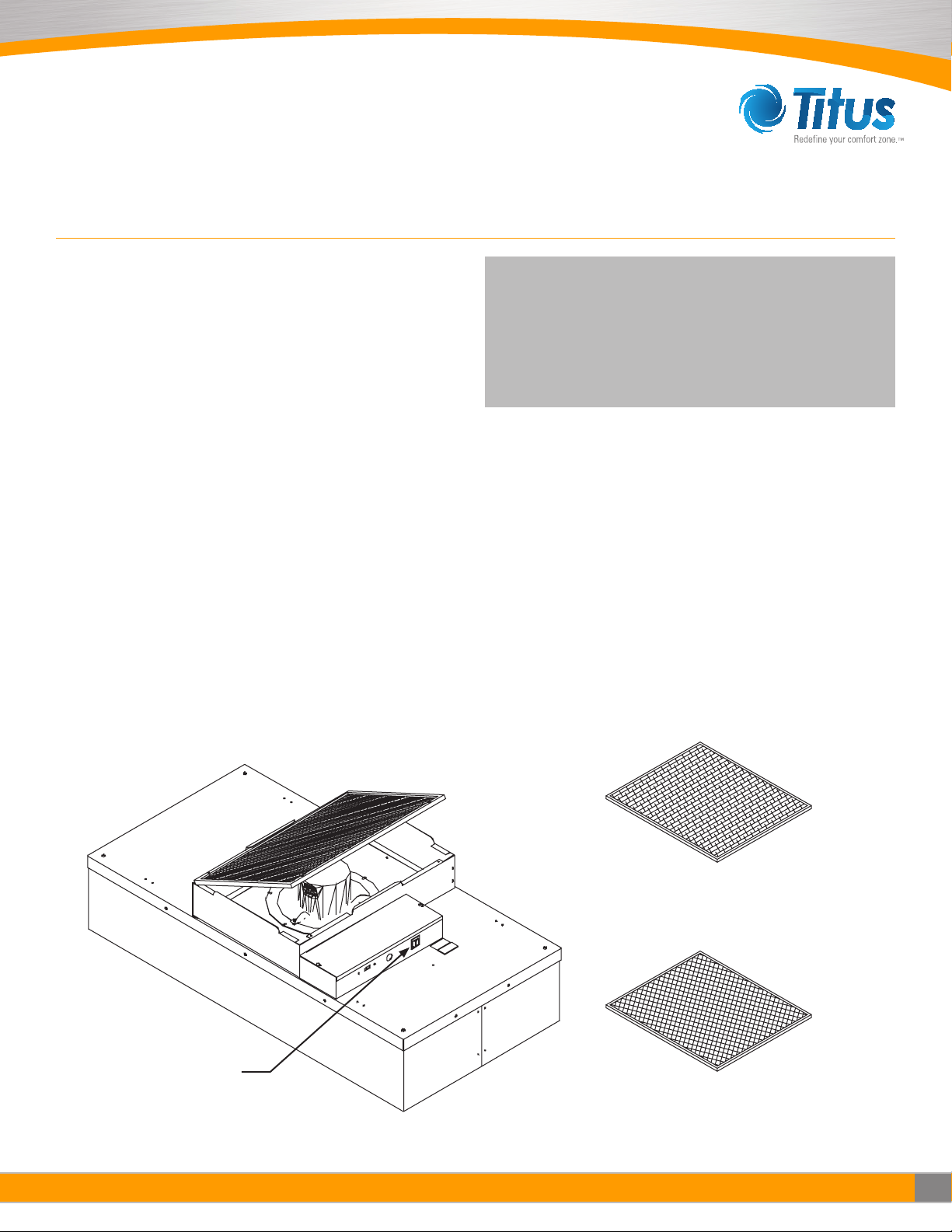

Step 1. Carefully remove the unit from the shipping carton and inspect for

any damage that may have occurred during transportation (See Figure 1).

Note: When ordering FFDR and FFDRA units, the HEPA filters may

be shipped separately to be installed into units after the fan box has

been installed.

Recommendation: Review mode settings at this time as specified for

installation (see page 6 for controls).

Step 2. If using rigidly supported grid (usually 2” (50 mm) or wider), raise

unit through ceiling and lower onto the gasketed grid. If using a flexible

grid (typically supported with wires), the unit must be secured to an

engineered design support system with s-hooks and chain. Screw the

four eyebolts into the nutserts on the lid assembly before lifting into an

overhead position (see Figure 2)

Note: Confirm fan dimensions to match T-grid dimensions.

Figure 1: Unboxing

Figure 2: Hanger Supports

EYEBOLT

FAN FILTER

UNIT

5

IOM - FFDE

Redefine your comfort zone. ™ | www.titus-hvac.com

CAT 5e

Network Cable Connection

(RJ45 Connector)

ON/OFF Switch

RPM Test Probe Jack Comm.

Filter Indicator Light

Pressure Switch Adjuster Manual Speed Potentiometer

Unit Control Box

ON/OFF SWITCH - SPEED/AIRFLOW ADJUSTMENT

All units are equipped with a two-position rocker switch (ON/OFF), which is located on the side of the electrical box, on top of

the unit. Unless specified otherwise units are furnished with a Universal Control Card to enable adjustment of airflow or set to

your means of communication. (see Page 6 for CON4 Universal Card Card Set Up).

Note: The CAT5e/RJ45 network ports are non-directional (i.e. in or out). Be sure to examine your cabling to insure that there is no cross-over wired cables.

FILTER INDICATOR LIGHT OPTION:

The pressure switch for the filter indicator light option is set at 0.60 in wc

from the factory. The set point for the pressure switch can be adjusted

between 0.50 in wc and 3.00 in wc by turning the set screw, accessible for

the front of the control enclosure. Counterclockwise rotation will increase

the set point differential for switching; clockwise rotation will reduce the

set point.

The process to adjust this for a specific application is detailed below:

Step 1. Adjust fan speed to highest setting

Step 2. Measure and note initial pressure differential between ceiling

plenum and unit plenum (downstream of the fan & upstream of the filter)

Step 3. Restrict discharge airflow incrementally to increase differential

pressure until measured value matches filter loading requirements for

the project

a. If no specific filter loading requirements are specified a general

recommendation is to use twice the pressure differential

measured in step 2

Step 4. With the unit discharge blocked, adjust the set point of the

pressure switch

a. If the indicator light is illuminated, increase the set point of the

pressure switch (CCW rotation) until the is unilluminated

i. Slowly decrease set point until light illuminates

b. If the indicator light is unilluminated, slowly decrease the set point

of the pressure switch (CW rotation) until the light illuminates

Step 5. Remove obstruction(s) from the unit discharge

Step 6. Adjust fan speed to operational set point

6IOM - FFDE Redefine your comfort zone. ™ | www.titus-hvac.com

IOM

FFDE / FFDER / FFDERA

CON4 Universal Control Card Set Up (Model ENV1028)

CON4 UNIVERSAL CONTROL CARD - PRODUCT OVERVIEW

Titus’s ENV1028 Universal Control Card provides MODBUS network and

analog control capabilities to a Titus Fan Filter Unit equipped with an

electrically commutated motor. Three different control modes provide

installation versatility by allowing the FFU to be controlled via MODBUS

RTU network, analog 0-10 VDC control signal, or by adjusting the onboard

potentiometer. The ENV1028 Universal Control Card is fully compatible

with all of Titus’s plug & play System Control Consoles using MODBUS

RTU. Additional details of the controls modes are provided on page 7.

FEATURES

• Networkable Via MODBUS RTU

• 0-10 VDC Analog Control

• Manual Control Via Onboard Potentiometer

• Simple Connections

• RJ45 For Networking Connection

• Screw Terminals For Analog Control

• Test Probe Jacks For DC mV Signal Output Of The Following:

• RPM

• Motor Control Set Point

• LED Diagnostics

• Support for external LED (10mA) remote status notification via 2

Pin MTA connector

• Onboard green LED for Board Status notification

• Onboard red LED for Network Traffic

• Powered from Network or Local Supply

CONTROL DIP SWITCH

ADDRESSING DIP SWITCH

DUAL RJ-45 JACKS FOR CAT 5 CABLE

RED LED FOR NET ACTIVITY

GREEN LED FOR SYSTEM/RPM STATUS

RPM TEST PROBE JACK "SIGNAL"

MANUAL SPEED POT

RPM TE

S

T PR

O

BE

J

A

C

K "

CO

M"

ANALOG INPUT "SIGNAL"

ANALOG INPUT "COM"

INCOMING POWER 24VAC

COMMON

CONTROL HARNESS CONECTOR

LED CONNECTOR

11 23 45 67 82

7

IOM - FFDE

Redefine your comfort zone. ™ | www.titus-hvac.com

Control Modes

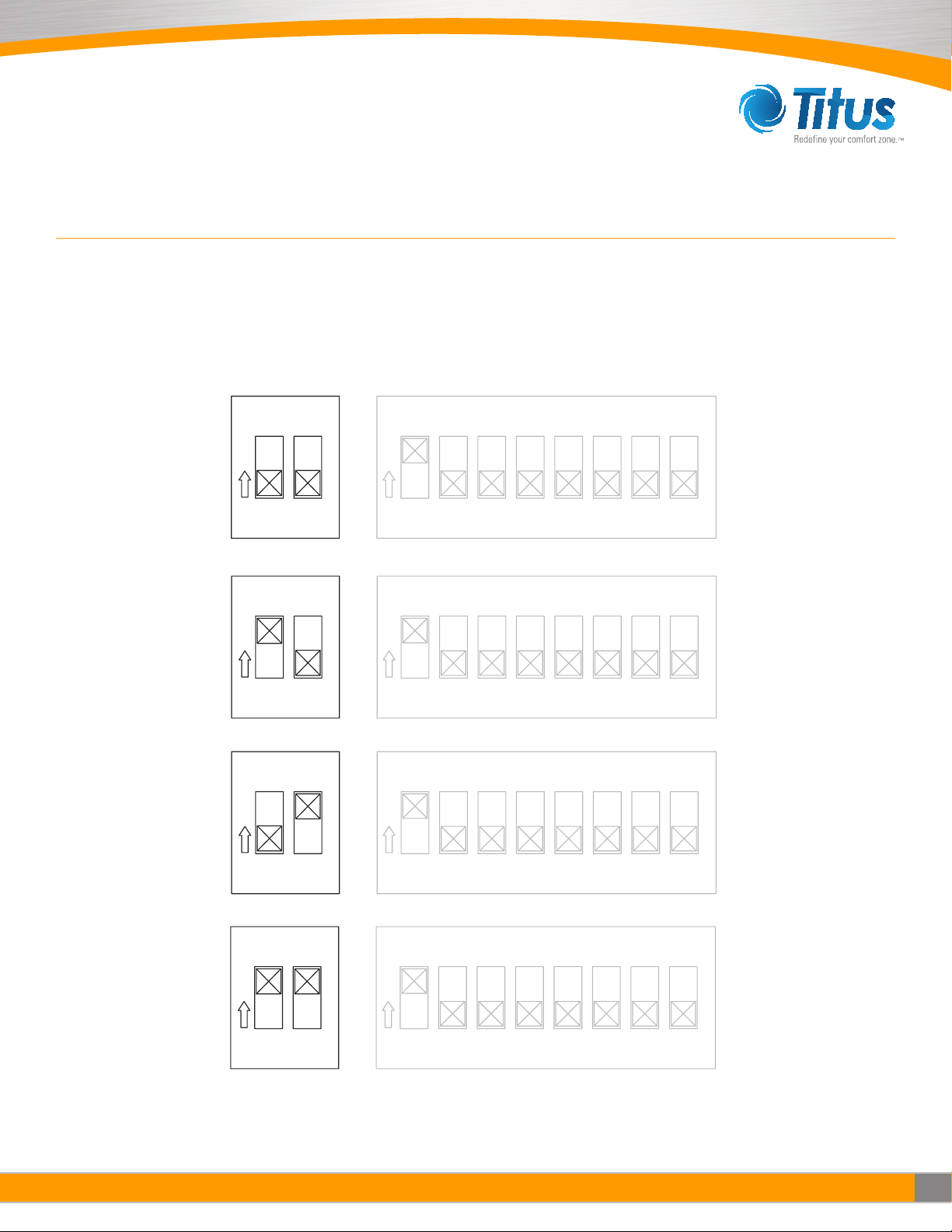

The ENV1028 operates in one of three selectable modes. The Mode is selected using DIP Switch S1.

• MANUAL control, on-board potentiometer

• ANALOG control, Remote 0-10 VDC

• NETWORK control, MODBUS RTU

Note: Network mode can be configured using either DIP switch setting shown above.

DIP switch pictorials are for reference and may be labeled differently by the manufacturer.

1

2

ON ADE02 1 3 4 5 6 7 8

O

N

2

1

2

ON ADE02 1 3 4 5 6 7 8

O

N

2

1

2

ON ADE02 1 3 4 5 6 7 8

O

N

2

Manual Mode = 1 OFF 2 OFF

Analog Mode = 1 ON 2 OFF

Network Mode = 1 OFF 2 ON

1

2

ON ADE02 1 3 4 5 6 7 8

O

N

2

Network Mode = 1 ON 2 ON

8IOM - FFDE Redefine your comfort zone. ™ | www.titus-hvac.com

IOM

FFDE / FFDER / FFDERA

Control Modes (continued)

1

2

ON ADE02 1 3 4 5 6 7 8

O

N

2

Control Mode

DIP Switches

Addess DIP Switches

Manual Control Mode:

In Manual control mode, the motor speed is set using the onboard

potentiometer. Onboard potentiometer rotation is CW to increase the

motor output.

Analog Control Mode:

In ANALOG control mode, the motor output is set using an external 0-10

VDC demand signal.

Note: Network mode can be configured using either DIP switch setting

shown above. DIP switch pictorials are for reference and may be labeled

differently by the manufacturer.

Network Control Mode:

In NETWORK control mode, the motor output is set using MODBUS

Register 2. Motor output is specified as a value from 0 to 100 representing

a percentage of motor torque output. Each ENV1028 in a MODBUS

network must be set to a unique address. The address value is set in

binary using the eight DIP switches of switch bank (S2). A maximum of

200 ENV1028 devices is recommended per local area network(LAN). If an

Titus ACC Control Console is the MODBUS master, then addresses should

be assigned within the address range supported by the Control Console.

Address zero should not be used as it is reserved for global commands.

Address switch settings are only checked by the ENV1028 at power-up.

Power must be cycled (OFF/ON) before affected changes take place.

Registers relevant to this mode:

• Register 1 “Start/Stop” (R/W)

– To enable motor, write a value of 1; To disable motor, write a

value of 0

• Register 2 “Motor Set Speed” (R/W)

– Motor Target speed value. Values may be written from 0 to 100

• Register 6 “RPM” (R)

– Motor RPM. Read from the motor

• Register 12 “Actual Motor Speed Instruction” (R)

– Speed control signal applied to the motor by the ENV1028. (R/W)

= Read/Write, (R) = Read Only

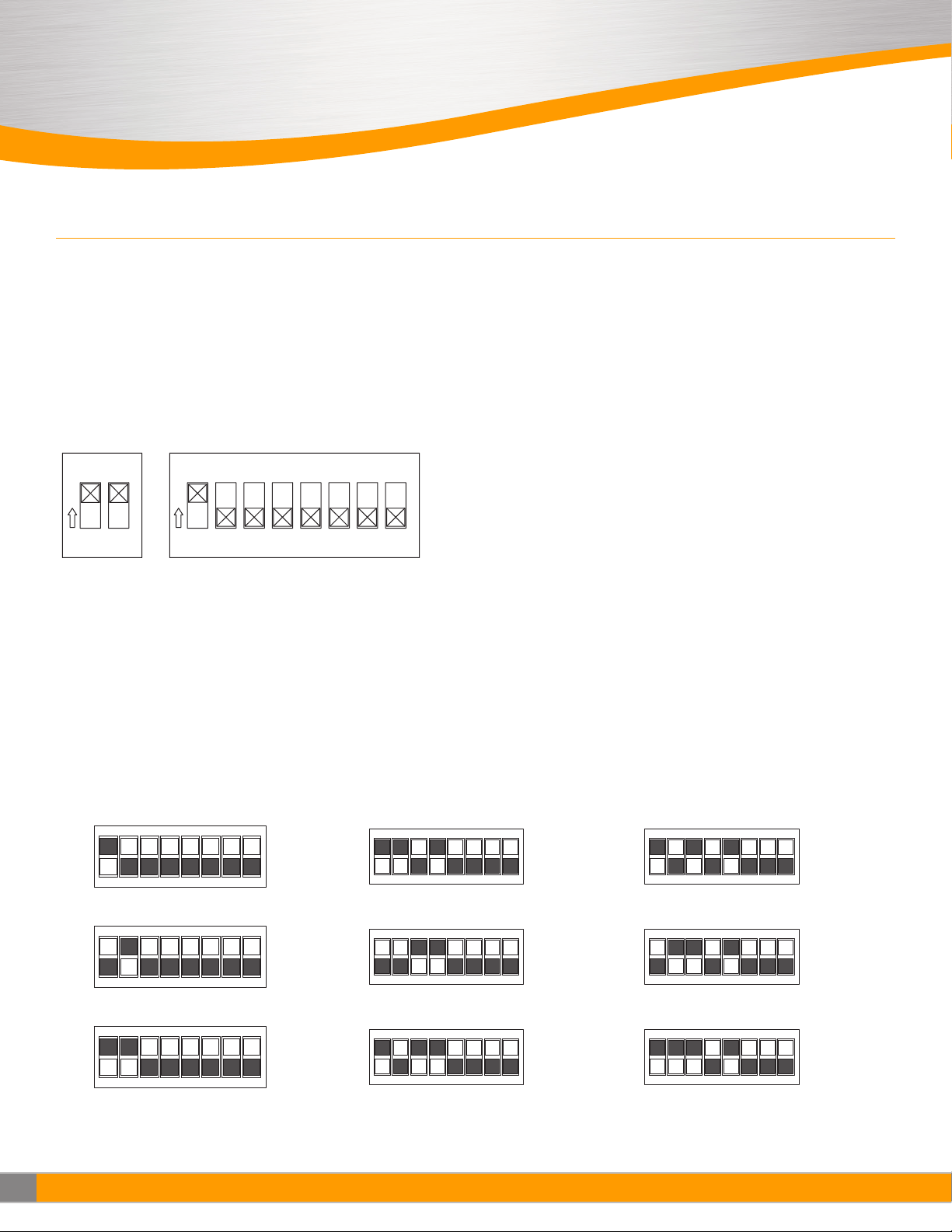

Example of binary S2 switch settings

1 2 3 4 5 6 7 8

ON DIP

1

1 2 3 4 5 6 7 8

ON

DIP

11

1 2 3 4 5 6 7 8

ON

DIP

21

1 2 3 4 5 6 7 8

ON DIP

2

1 2 3 4 5 6 7 8

ON

DIP

12

1 2 3 4 5 6 7 8

ON

DIP

22

1 2 3 4 5 6 7 8

ON DIP

3

1 2 3 4 5 6 7 8

ON

DIP

13

1 2 3 4 5 6 7 8

ON

DIP

23

9

IOM - FFDE

Redefine your comfort zone. ™ | www.titus-hvac.com

Electrical Specifications

Control and Interface Signals:

1. External Speed 0-10V Input

• Input impedance 20k Ohms.

• MIN ON-to-OFF threshold: 190mV*

• MAX OFF-to-ON threshold: 240mV*

• ON (~215mV) to 9.89V linearly scales 1 to 99% speed.

• 9.89V or more deadbands to 100% speed.

Test Probe JacksPoints:

The test probe jacks may be used to measure the motor rpm or the PWM

signal that is being output to the motor.

• In Manual or Analog Control Mode with an Address setting of 1 or

greater, the test probe jacks output 0-2000 mVDC representing motor

RPM. By changing the address DIP switches to 0, the test probe jacks

will output 0-1000 mVDC representing 0-100% demand signal to the

motor. The address may be changed without interrupting power to

the control card.

• In Network Control Mode, 0-2000 mVDC always represents RPM.

2. External LED Output

• 10mA regulated

• LED forward voltages up to 5V

3. RPM Signal

• Signal Value: mVDC = RPM

• Ex: 900mV = 900RPM

• RPM Output Range: ~ 0, 5 to 2000 RPM (0, 5mV to 2000 mV DC)

• RPM Output Resolution: 5RPM (Zero, 400 steps from 5 to 2000

RPM inclusive)

LED Indicators:

• Onboard Status LED:

The Onboard Status LED is software controlled by the unit

microcontroller. The Status LED is solid ON when RPM reported by

the motor is greater than zero and OFF when RPM reported by the

motor is zero.

• External Status LED:

Support for an external Status LED (10mA current-controlled driver),

via a 2-pin MTA connector, for remote system status notification. The

external Status LED operates in the same manner as the Onboard

Status LED.

• Onboard Net LED:

The Onboard Net LED is driven directly by the receive data signal.

The NET LED shows all network traffic on a 2-wire network. The NET

LED is intended to confirm low-level network connectivity,

independent of microcontroller or firmware functionality. If A/B

network wires are swapped, the NET LED will be normally on,

providing quick diagnostics of this common condition.

RJ45 Network Cable Connections:

Bus Power

Pass Through

0V (GND) RS-485 0V (GND) Bus Power

Pass Through

Power Lost or No Communications

Network Data Traffic In Progress

A/B network wires are swapped

Net LED Status Definition

LED OFF

LED ON

LED Flickering

Specification Min Max UnitsTypical

22

50

na

0

24

na

25

50/60 60

50

42

0.5

C

VA

Hz

VAC

Input Voltage

Supply Frequency

Input Power Consumption

Ambient Operating Temperature

Electrical and Environmental Specifications

10 IOM - FFDE Redefine your comfort zone. ™ | www.titus-hvac.com

IOM

FFDE / FFDER / FFDERA

Communication Specifications

Overview:

• MODBUS RTU protocol over RS485 (serial)

• 9600 baud rate, word length is 8, parity is none(n), stop bits=1

• 255 unique address values selectable by DIP switch settings

• (recommended network node capacity 200 nodes)

• Slew rate limited transceivers for improved network performance MODBUS Register Summary Table

DO NOT USE CROSSOVER CABLES. THIS MAY DAMAGE THE CONTROL CARD OR RENDER IT NON-OPERATIONAL.

To reset non-volatile registers to factory default values, write 170 (AA hex) to Register 14, and then cycle power.

Note: Register 24 may be read in network mode to determine the value of 0-10VDC signal that may be connected. For example, a pressure transducer

may be connected to indicate unit interal static pressure.

1

2

6

9

10

12

14

1

1

RUN/STOP

DEMAND

SPEED

STATUS

DEFAULT SPEED

CURRENT SPEED

DEFAULT RUN/STOP

RW

RW

RW

RW

R

R

R

0-100

0-100

0-100

0,1

0,1

0,5-2000

see detail

%

RPM

50

-

-

RAM

RAM

LIVE

LIVE

LIVE

EEPROM

EEPROM

power up from REG 14

power up from REG 10

applies to network only

applies in network mode only

Register Name R/W Values & Defaults Units Origin Comments

24

70-1000 LIVE

-

ANA1 Onboard Pot 0-1000=0-100%

0-1000 LIVE

-

ANA2 0-10V input 0-1000=0-10VDC

R

R

11

IOM - FFDE

Redefine your comfort zone. ™ | www.titus-hvac.com

Troubleshooting

Mode Choice:

Verify mode setting choice to DIP switch S1 (Control Mode), which is manual mode and then retry.

Motor Issues in Manual Mode:

(If you are in a network or analog mode, contact your controls contractor

for troubleshooting assistance; if you continue to

need assistance, contact the factory.)

Unit is not adjustable:

Step 1. Verify that rotation of the manual speed potentiometer does

not change the RPM. If rotating does nothing, remove the electrical box

cover, then remove the 4-pin motor connector from the control board and

reinstall 180 degrees rotated. Also insure that the 4-pin connection wires

are pushed down securely onto connector pins. Again adjust the knob to

verify proper fan operation. Note: The 4 pin connector is on the 1/8” white

cable from motor.

Low Air Velocity:

Step 1. Check to be sure that the manual speed potentiometer is set

correctly.

Step 2. Check incoming power supply for proper voltage (120,208-

240,277/24).

Step 3. Examine the HEPA filter.

High Air Velocity:

Step 1. Check to be sure that the air flow settings are correct

Net LED Status Definition

Green LED OFF Power Lost or No Communications

Green LED Flickering Network Data Traffic In Progres

Green LED ON A/B network wires are swapped

Filter Issues:

Non-Laminar Flow and/or Excessive Contamination:

Step 1. Insure that no large obstructions are upstream of airflow pattern

Step 2. Determine that no other air-moving devices are operating in or

around clean room which disrupt room’s airflow pattern

Step 3. Check air velocity and if low, conduct the “Low Air Velocity”

procedure outlined above.

Step 4. Conduct smoke and photometer test on HEPA/ULPA filter. Seal or

replace HEPA filter as necessary.

12 IOM - FFDE Redefine your comfort zone. ™ | www.titus-hvac.com

IOM

FFDE / FFDER / FFDERA

Infrared Speed Control (Optional)

The Flow-Set is a handheld infrared remote control configured to adjust

the fan filter unit.

An EVO/ECM-IRC control sends the motors a FLOW INDEX and a GO signal.

The motor sends back a status signal that is connected to a red lamp. The

control includes an infrared remote receiver.

The Flow-Set handheld remote sends infrared remote commands to the

EVO/ECM-IRC control, allowing remote adjustment of the Motor. (See

Figure 10). Using the Flow-Set, you can turn the motor on/off, adjust the

flow index from 1-100 and read the current settings.

Point the Flow-Set at the Flow-Set target (red lamp if the motor is on)

on the equipment. Operate the on/off button or any of the four buttons.

The green lamp near the Flow-Set target lights, indicating you are in an

adjustment session. Continue to operate the on/off button or any of the

four buttons to achieve the desired settings.

Press the Enter button to save your new settings and exit the adjustment

session. Press the Clear button to delete your new settings, revert to the

IQ settings and exit the adjustment session. If you enter an adjustment

session and do not make any adjustments for 15 minutes, the adjustment

session automatically clears.

Use the Clear button to read the current settings. Point the Flow-Set at

the Flow-Set target and press the Clear button. A green lamp begins to

flash indicating the signal was received. The flash sequence indicates the

current flow index. The sequence occurs in two sets. The tens (1st) set

uses long flashes to indicate the tens digit. The units (2nd) set uses short

flashes to indicate the units digit. An extra long flash in the tens set or the

units set indicates the value of the corresponding digit is zero

•A flow index of 24 flashes two longs, then 4 short

•A flow index of 89 flashes 8 longs, then 9 short

•A flow index of 30 flashes 3 longs, then an extra long

•A flow index of 04 flashes an extra long, then 4 short

•A flow index of 100 flashes 10 longs, then an extra long

Use the On/Off button to turn the motor on or off. Point the Flow-Set at the

Flow-Set target on the equipment and press the on/off button. If you press

Enter while the motor is off, the motor stays off, even through a power on/

off cycle.

Adjust the flow index using the buttons. The button pair on the

left adjusts the index 10. The button pair on the right adjusts the

flow index 1. Using the 10 pair, you can quickly move the index

up and down. Using the 1 pair, you can precisely set the index to

achieve the desired flo . During an adjustment session, the green lamp

blinks each time you make a valid entry. If the flow index is already 100,

and you try to increase the flow index, the green lamp does not blink,

and the increase does not occur. If the flow index is at 91 and you press

the 10 buttons, the green lamp does not blink and the increase does

not occur because your entry would take the index above 100. When the

flow index is greater than 90, use the 1 button to increase the index.

The 1 and 10 keys respond in a like manner when you try to set the

flow index below 1. (Zero is not a valid flow index)

Batteries:

Two AA batteries power the EVO/IRC-Handheld Controller. (See Figure 10).

Remove the sliding door on the back of the unit to expose the battery

compartment. Remove the old batteries. Insert the new batteries in the

position indicated by the battery pictures molded into the bottom of the

battery compartment. The battery spring clips are difficult, so you may

need to use a small screwdriver to “shoehorn” the batteries into place.

For maximum battery life, store the EVO/IRC- Handheld Controller so the

buttons are not pressed. While current drain is minimum when the unit is

not sending infrared signals, some battery current is drawn to sense the

pressed key.

13

IOM - FFDE

Redefine your comfort zone. ™ | www.titus-hvac.com

Cleaning the Pre-filter (foam)

Tools Required: None.

Note: To keep the filter in top operating condition, washing the foam

prefilter is recommended every three to six months.

Step 1. To gain access to the prefilter, remove the ceiling panel next to the

unit, if applicable.

Step 2. Switch the ON-OFF switch to the off position.

Step 3. Remove the 16”x23” prefilter from the snap-in frame. (See

figure below)

Step 4. Clean the prefilter by hand washing in water with a mild

detergent or by using a vacuum cleaner. Allow prefilter to dry completely

before replacing.

Step 5. Reassemble by reversing the above steps.

WARNING

DISCONNECT THE UNIT FROM THE ELECTRICAL

POWER SOURCE BEFORE ATTEMPTING

ANY SERVICE

PREFILTER SURFACE ON TOP SIDE

SUPPORT SCREEN ON BOTTOM SIDE

ON/OFF SWITCH

14 IOM - FFDE Redefine your comfort zone. ™ | www.titus-hvac.com

IOM

FFDE / FFDER / FFDERA

Service: Removal and Replacement of FFDE HEPA/ULPA Filters

WARNING

DISCONNECT THE UNIT FROM THE ELECTRICAL

POWER SOURCE BEFORE ATTEMPTING

ANY SERVICE

WARNING

THE STANDARD FILTER IS PROTECTED WITH AN

EXTENDED METAL FACE SCEEN. THIS IS NEVER TO

BE USED TO HANDLE THE FILTER. IT IS ONLY FOR

PROTECTION AGAINST AN ACCIDENTAL TOUCH OF THE

FILTER. ONLY HANDLE THE FILTER BY THE FRAME

Note: All filters should be visually inspected for freight damage before

installation. It is necessary to use two workers when removing the filter

and for installation to avoid twisting or separation of the media seals.

Handle the filter only by the frame and never place anything on the

upstream filter side of the filter. Additionally, it is important to keep the

filter level to prevent any shearing force on the media itself.

FOR STANDARD FILTERS:

Tools Required: Phillips Head Driver, Battery Operated Drill with 5/32 drill

bit, Rivet Hand Tool, Ø5/32 aluminum rivet grip range.126-.187

Step 1. Remove unit from ceiling.

Step 2. Remove the 10 screws holding the HEPA/ULPA filter to the

lid assembly.

Step 3. Lift the lid assembly off the HEPA/ULPA filter (see figure). Remove

filter deflectors using 5/32 drill bit. Keep filter deflectors to install in

new filter. Discard the used filter as per requirements of the applicable

regulations. Carefully install the filter deflectors into the new filter using

the 5/32 rivets. Do not touch or place the filter deflectors on the HEPA/

ULPA media pack. This could cause tears in the filter pack.

Step 4. Before replacing with the new filter, carefully inspect the new

filter for any visible damage. Also inspect the gasket and the T-Bar to

insure a tight seal. Replace if necessary.

Step 5. To replace a filter, raise the filter and rotate into position in

the ceiling grid (with power off), then lower the plenum housing into

place. Reconnect wiring and hardware from previous steps that have

been removed.

Step 6. Restore power and verify proper operation of FFU.

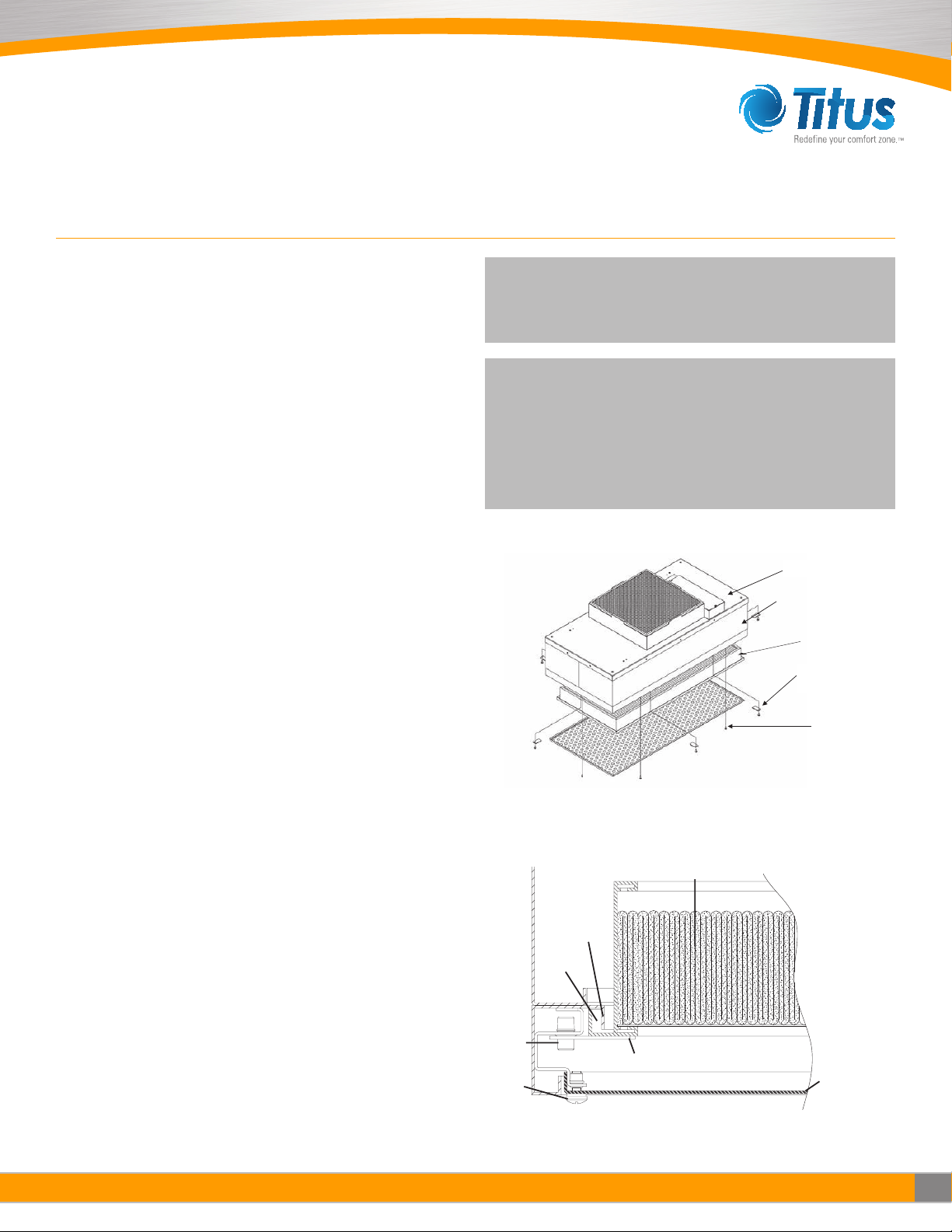

Standard Filter Change

On/Off Switch

Lid Assembly

#8 Screws (10x)

Ø5/32 Rivet (6x)

HEPA/ULPA Filter

Filter Deflector

Electrical Knock Out

15

IOM - FFDE

Redefine your comfort zone. ™ | www.titus-hvac.com

Service: Removal and Replacement of FFDER & FFDERA Filters

WARNING

DISCONNECT THE UNIT FROM THE ELECTRICAL POWER

SOURCE BEFORE ATTEMPTING ANY SERVICE

WARNING

THE STANDARD FILTER IS PROTECTED WITH AN

EXTENDED METAL FACE SCEEN. THIS IS NEVER TO

BE USED TO HANDLE THE FILTER. IT IS ONLY FOR

PROTECTION AGAINST AN ACCIDENTAL TOUCH OF THE

FILTER. ONLY HANDLE THE FILTER BY THE FRAME

Note: All filters should be visually inspected for freight damage before

installation. It is necessary to use two workers when removing the filter

and for installation to avoid twisting or separation of the media seals.

Handle the filter only by the frame and never place anything on the

upstream filter side of the filter. Additionally, it is important to keep the

filter level to prevent any shearing force on the media itself.

FOR FFDER & FFDERA FILTERS:

Tools Required: Phillips Head Driver, Battery Operated Drill, 3/16” hex

head ball driver (2ea)

Step 1. With the power off, remove the diffuser screen by removing the 6

each 10-32x1/2 screws, then carefully place in a safe location.

Step 2. Loosen the six 1/4x12 socket head screws far enough to rotate

the eight filter clips 90°. The filter may be loose enough to drop during

this operation. If not, slowly pull the filter away from the knife-edge seal,

taking care not to touch the filter face during this operation. It is important

to pull the filter slowly away from the seal, so that the gel remains in the

filter gel track.

Step 3. Carefully clean plenum assembly knife edge surface of residual

gel material.

Step 4. Inspect filter for visible damage, if damaged set aside for

replacement or repair.

Step 5. Inspect the gel seal, if reinstalling the removed filter. Determine

if the gel has lost its ability to seal (i.e. the gel should reform to cover the

track without voids or openings), if so repair the gel material or consider

replacement of filter.

Step 6. Place the filter evenly against the filter-sealing surface of the unit.

Reposition filter clips and screws. The clips should be rotated and angled

into place. It is recommended that four workers work on each corner of the

filter simultaneously, holding the filter seated into the track. Hand tighten

clips from opposite corners evenly until all clamps are tightened.

Step 7. Reinstall diffuser screen by hand-tightening the screws.

Step 8. Determine if recertification or testing of replacement is required.

Step 9. Restore power to FFU and verify proper operation of FFU.

FFDR & FFDRA Filter Change

Fan Filter Unit

Filter

2-Piece Welded

Plenum Housing

Filter Clip and

Screw (typ 6)

Diffuser Screen

Screws (typ 6)

FFDR & FFDRA Filter Replacement

Filter

Filter Clip

Gel Track

Knife- Edge

Seal

Diffuser

Screen

10-32

PHP

Screws

¼ -20

Cap

Screw

16 IOM - FFDE Redefine your comfort zone. ™ | www.titus-hvac.com

IOM

FFDE / FFDER / FFDERA

Service: FFDE and FFDER Motor Removal and Installation

Tools Required: Phillips Head Driver, Battery Operated Drill, (2) 8”

adjustable wrenches, 10 mm hex head wrench, #2 screwdriver, and slip

joint pliers.

Step 1. To gain access to the motor, remove the ceiling panel next to the

unit, if applicable.

Step 2. Switch the ON-OFF switch to the off position.

Step 3. Loosen the electrical box cover screws (2), and slide/lift off cover.

Step 4. Make note of all wire routing and locations for later reinstallation.

Step 5. Disconnect 5-pin and 16-pin wire harnesses from the electrical

box housing and remove the tubing for test port, if installed.

Step 6. Remove the eight mounting screws to free the motor/blower

assembly from the lid assembly. If using power drivers, set the unit to a

low torque setting to avoid stripping the sheet metal screws. Carefully

remove housing assembly, paying attention to wire routing.

Step 7. Using an adjustable wrench loosen the two set screws that attach

the blower wheel to the motor shaft.

Step 8. Mark the location of the motor support bracket (belly band), then

loosen the bolt just enough to allow the motor support bracket to slid off

the motor.

Step 9. Using the removed motor, mark the new motor with the location of

the motor support bracket.

Step 10. Replace with the new motor and reassemble by reversing the

above steps 1-8. Set the spacing at 0.25” (6.35 mm) clearance between

the blower and the upper motor plate/prefilter frame. This will give a 0.11”

overlap between the venturi ring and the blower.

WARNING

DISCONNECT THE UNIT FROM THE ELECTRICAL

POWER SOURCE BEFORE ATTEMPTING

ANY SERVICE

WARNING

ELECTRICAL SERVICE SHOULD ONLY BE PERFORMED

BY A LICENSED OR QUALIFIED ELECTRICIAN

Motor/Electrical Removal

Prefilter

Motor

Venturi Ring

Blower Wheel

ON/OFF Switch

Power Entrance

17

IOM - FFDE

Redefine your comfort zone. ™ | www.titus-hvac.com

WARNING

DISCONNECT THE UNIT FROM THE ELECTRICAL

POWER SOURCE BEFORE ATTEMPTING

ANY SERVICE

WARNING

ELECTRICAL SERVICE SHOULD ONLY BE PERFORMED

BY A LICENSED OR QUALIFIED ELECTRICIAN

Service: FFDERA Motor Removal and Installation

Motor/Electrical Removal

Plenum

Electrical connectors

located in inner

prefilter wall

Motor/Blower

Assy

Gel Seal Filter

Screen

Motor Assembly

Blower

Wheel

Wellnut

Venturi

Ring

Motor

Machine Screw

and washer

Grommet

Note: Minimum 2 person project.

Tools Required: 3/16 Ball Driver, Phillips screw bit, Head Driver, Battery

Operated Drill, (2) 8” adjustable wrenches, 10 mm

hex head wrench, #2 standard screwdriver, and slip joint pliers.

Step 1. To gain access to the motor, remove the gel seal filter.

Step 2. Prior to removing motor/blower assembly, remove blower wheel to

expose motor connectors on motor. Using an adjustable wrench loosen the

two set screws that attach the blower wheel to the motor shaft. Disconnect

the two brown wires from the capacitor, using a pair of pliers. Disconnect

5-pin and 16-pin wire harnesses from the electrical box housing and

remove the tubing for test port, if installed.

Step 3. While supporting the motor blower assembly from below, remove

the six screws on the underside of the venturi ring and lower the assembly.

(See figure). Note the baffle does not have to be removed to remove the

motor/blower assembly.

Step 4. Before removal of the motor mount bracket, measure the precise

location of the bracket on the motor. Remove the bracket.

Step 5. Replace with the new motor and reassemble by reversing the

above steps. Set the location of the motor mount bracket as measured

(see above Step 6). Set the spacing at 0.25” (6.35 mm) clearance between

the blower and the upper motor plate/prefilter frame creating a 0. 1” (2.80

mm) overlap between the wheel and the venturi ring. When reinstalling

the assembly, align the plate to insure that the leads will reach the

electrical box.

18 IOM - FFDE Redefine your comfort zone. ™ | www.titus-hvac.com

IOM

FFDE / FFDER / FFDERA

Old Cable Style

Old Cable Style

New Cable Style

Technical Notes

Changing out from GE 2.3 to Nidec PerfectSpeed DC Motors in the field

The Titus family of Fan Filter Units has previously used the GE 2.3 motor

that was purchased by Regal Beloit. The older models have GE 2.3 motors

that have become obsolete and are replaced with the new Regal Beloit

model EON. The EON motor is currently being evaluated and you will be

receiving a new manufactured motor named Nidec PerfectSpeed.

When you order a replacement motor they will be a form and fit

replacement, except for the cable that connects to the control board and

the motor. The new Nidec motor will require you to replace the cable. The

old cable was a sixteen pin connector while the new motor cable will have

a four pin connector as shown in the photo to the right.

Please use the new cable with the new four pin connector to connect

your new motor. The cable number will be determined by the build style

of your unit.

Nidec Part References

•18 in Standard Build 63751-015

•12 in FFDERA Build 63751-016

•15 ft Whip 63751-017

Old Cable References

The power cable, has remained the same for the new motor and will be

reused. The rest of the fit and function will be a direct replacement. Follow

the procedure in the IOM for motor swap for your particular FFU.

Contact Us

Contact Titus sales or technical team for any assistance needed.

Note: GE 2.3 motors are obsolete.

19

IOM - FFDE

Redefine your comfort zone. ™ | www.titus-hvac.com

Motor Cable Configurations

20 IOM - FFDE Redefine your comfort zone. ™ | www.titus-hvac.com

IOM

FFDE / FFDER / FFDERA

Technical Notes (continued)

Designs with Duct Collar, VAV or constant air box and fan coils

For applications requiring powered fan filter units and a ducted connection

our recommendation would be to use FFD, FFDR, or FFDRA units equipped

with PSC motors.

Caution

FFDE, FFDER, and FFDERA units are not recommend for use with ducted

systems, and cannot operate with inlet static pressure exceeding 0.30

in wg.

For applications when you use a VAV box or Constant Airflow Terminal,

Duct Collars or Fan coils. The design engineer must advise the contractor or

air balancer that the air supply needs to be balanced. If you do not balance

the air supply properly you have the potential to starve or over feed the

fan with air causing the motor to stall which can damage the fan motor.

This also can be minimized by notifying Titus beforehand for assistance.

The ECM motors used in the FFDE, FFDER, and FFDERA designs are a

Microprocessor controlled motor and are designed to maintain a constant

air volume. When two controllers are compensating the air volume at the

same time, the motor microprocessor is unable to stabilize the airflow and

will shut itself down if it cannot find a stable operating point.

In addition to properly balancing the airflow to the Fan: you should

prepare a sequence of operations turning on FFU’s prior to energizing the

Air Handler to prevent potential backward rotation of the blower wheel

which can prevent motor rotating in the proper direction and will reduce

airflow and cause eventual shutdown. The drive components inside the

ECM motors are self-testing and sized for the motor being used inside the

unit they can’t compete with the airflows from a duct blower motor.

This manual suits for next models

2

Table of contents

Other Titus Fan manuals

Popular Fan manuals by other brands

AC Infinity

AC Infinity CLOUDLINE S4 user manual

M&G

M&G DuraVent PolyPro 4PPS-ADL installation instructions

Westinghouse

Westinghouse Contempra Trio owner's manual

EUROLAMP

EUROLAMP FS-10-360A instructions

Home Decorators Collection

Home Decorators Collection TOLEDO 52-PLM Use and care guide

Maico

Maico ECA 150 ipro VZC Mounting and operating instructions

Elkay

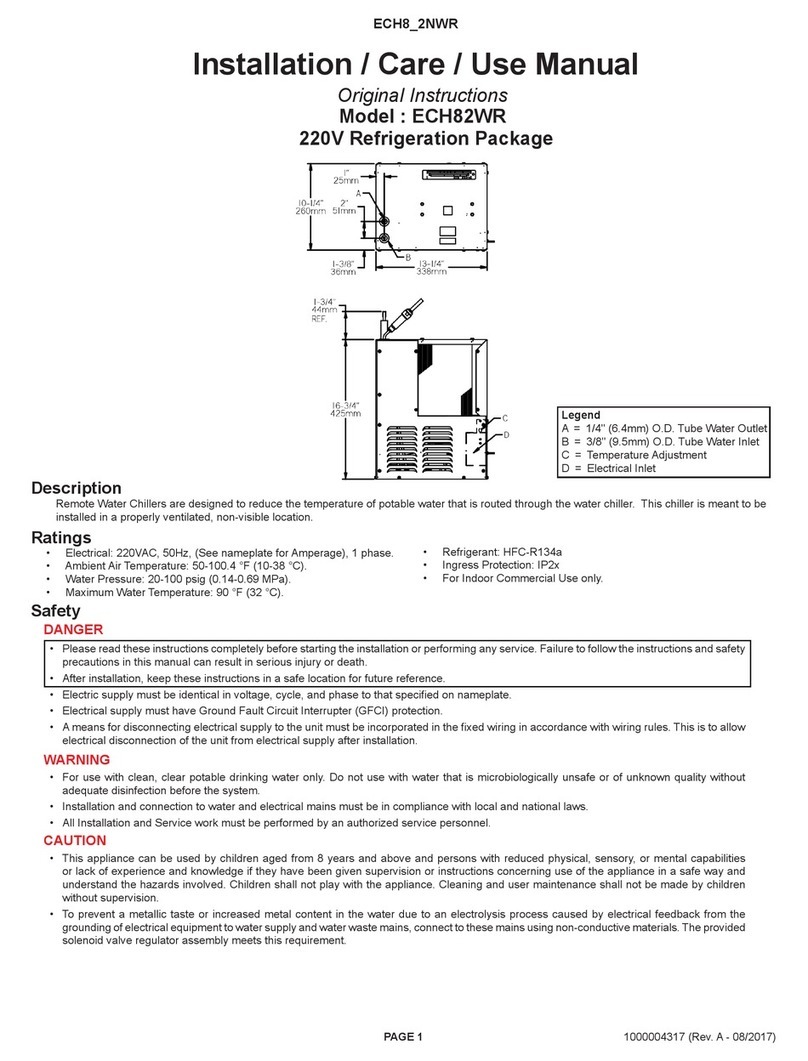

Elkay ECH82WR Installation, care & use manual

Dundas Jafine

Dundas Jafine Soffit Exhaust Vent Use and care guide

JONATHAN Y

JONATHAN Y Aldrin JYL9715A Use and care guide

Sonnenkonig

Sonnenkonig VIND 2 instruction manual

S&P

S&P ARTIC-255N GR manual

Inspire

Inspire Aruba plus Assembly, Use, Maintenance Manual