Titus LSC Series User manual

Redefine your comfort zone. ™ | www.titus-hvac.com

LSC

LOW PROFILE SERIES FAN

POWERED TERMINAL UNIT WITH

SENSIBLE COOLING COIL

INSTALLATION &

OPERATION MANUAL

2IOM - LSC Redefine your comfort zone. ™ | www.titus-hvac.com

IOM LSC

Warnings, Cautions and Notices

Note that warnings, cautions and notices appear at appropriate intervals

throughout this manual. Warnings are provide to alert installing contractors

to potential hazards that could result in death or personal injury. Cautions

are designed to alert personnel to hazardous situations that could result

in personal injury, while notices indicate a situation that could result in

equipment or property-damage-only accidents. Your personal safety and

the proper operation of this machine depend upon the strict observance

of these precautions. Read this manual thoroughly before operating or

servicing this unit.

ATTENTION Warnings, Cautions and Notices appear at appropriate

sections throughout this literature. Read these carefully:

WARNING Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION Indicates a potentially hazardous situation which, if not

avoided, could result in minor or moderate injury. It could also be used to

alert against unsafe practices.

NOTICE Indicates a situation that could result in equipment or property-

damage only

WARNING

Only qualified personnel should install and service the equipment. The installation, starting up, and servicing of heating, ventilating, and air-

conditioning equipment can be hazardous and requires specific knowledge and training. Improperly installed, adjusted oraltered equipment by

an unqualified person could result in death or serious injury. When working on the equipment, observe all precautions in the literature and on

the tags, stickers, and labels that are attached to the equipment.

WARNING

Proper Field Wiring and Grounding Required!

All field wiring MUST be performed by qualified personnel.

Improperly installed and grounded field wiring poses FIRE and

ELECTROCUTION hazards. To avoid these hazards, you MUST

follow requirements for field wiring installation and grounding

as described in NEC and your local/state electrical codes. Failure

to follow code could result in death or serious injury.oraltered

equipment by an unqualified person could result in death or serious

injury. When working on the equipment, observe all precautions in

the literature and on the tags, stickers, and labels that are attached

to the equipment.

WARNING

Personal Protective Equipment (PPE) Required!

Installing/servicing this unit could result in exposure to electrical,

mechanical and chemical hazards.

Before installing/servicing this unit, technicians MUST put on all

Personal Protective Equipment (PPE) recommended for the work

being undertaken. ALWAYS refer to appropriate MSDS sheets and

OSHA guidelines for proper PPE.

When working with or around hazardous chemicals, ALWAYS

refer to the appropriate MSDS sheets and OSHA guidelines

for information on allowable personal exposure levels, proper

respiratory protection and handling recommendations.

If there is a risk of arc or flash, technicians MUST put on all Personal

Protective Equipment (PPE) in accordance with NFPA 70E or other

countryspecific requirements for arc flash protection, PRIOR to

servicing the unit.

Failure to follow recommendations could result in death or

serious injury.

3

IOM - LSC

Redefine your comfort zone. ™ | www.titus-hvac.com

Table of Contents

Warnings, Cautions and Notices ................................................................................................................................................ 2

Model Number Descriptions ....................................................................................................................................................... 4

General Information .................................................................................................................................................................... 6

Pre-Installation

Receiving and Handling ................................................................................................................................................... 7

Shipping Package ............................................................................................................................................................ 7

Receiving Check List ........................................................................................................................................................ 7

Jobsite Storage ................................................................................................................................................................ 7

Installation Preparation ....................................................................................................................................................7

Service Access ................................................................................................................................................................. 8

Pre-Installation Check List ............................................................................................................................................... 8

Components Data ....................................................................................................................................................................... 9

Unit Dimensions ........................................................................................................................................................................ 10

Coil Flange Connections ........................................................................................................................................................... 12

Weights ................................................................................................................................................................................12

Water Coil Pipe Connections .................................................................................................................................................... 14

Installation Mechanical

Duct Connections ........................................................................................................................................................... 15

uct Work Recommendations ......................................................................................................................................... 15

Hydronic Piping Consideration ...................................................................................................................................... 15

Condensate Drain Connection ....................................................................................................................................... 15

External Insulation Requirements ................................................................................................................................. 15

Installation General - Hanging the Unit ................................................................................................................................... 16

Installation Check List ............................................................................................................................................................... 18

Installation Electric

Unit Wiring Diagrams .................................................................................................................................................... 19

Supply Power Supply ..................................................................................................................................................... 19

Electric Heater Min-Max KW – Unit size 3 ................................................................................................................... 20

Electric Heater Min-Max KW – Unit size 4 ................................................................................................................... 21

ECM Motor Overview and Setup

Overview ........................................................................................................................................................................ 22

General Information ....................................................................................................................................................... 22

ECM Motor Fan Flow Adjustment ................................................................................................................................. 22

Manual PWM Signal Interface Board ........................................................................................................................... 23

Operation ............................................................................................................................................................. 23

Remote PWM Signal Interface Board ........................................................................................................................... 23

Jumper Setup ...................................................................................................................................................... 24

Input / Output Control Signals ............................................................................................................................ 24

Remote Control Air Balance ................................................................................................................................ 24

Manual Air Balance ............................................................................................................................................. 25

Pre-Startup Checklist ................................................................................................................................................................. 26

Maintenance

Maintenance Procedures ............................................................................................................................................... 27

Air Filter .......................................................................................................................................................................... 27

Inspecting and Cleaning Condensate Pans .................................................................................................................. 27

Coil Maintenance ........................................................................................................................................................... 27

Inspecting and Cleaning Coils ............................................................................................................................. 28

Hydronic Coil Cleaning Procedures ..................................................................................................................... 28

Winterizing the Coil ............................................................................................................................................. 28

Replacing Motors ................................................................................................................................................ 28

Periodic Maintenance Check List ........................................................................................................................ 29

4IOM - LSC Redefine your comfort zone. ™ | www.titus-hvac.com

IOM LSC

Model Number Description

LSC – Low Profile Series Fan Powered Terminal Unit with Cooling Coil

Following is a complete description of the LSC model number. Each digit

in the model has a corresponding code that identifies specific unit options.

Digit 1, 2, 3, 4 – Unit Type

LSC = Basic Unit

LSCX = Special Unit

Digit 5, 6 – Cabinet Size

03 = Unit size 3

04 = Unit size 4

XX = Special

Digit 7 – Cabinet Configuration

R = Right Hand Control Enclosure

L = Left Hand Control Enclosure

X = Special

Digit 8, 9 – Cabinet Material

2G = 20Ga Galvanized Steel Cabinet

XX = Special

Digit 10 – Cabinet Liner

J = EcoShield Matte faced ½”

L = EcoShield Foil Faced ½”

0 = Fiberglass Dual Density ½”

3 = fiberglass Foil Faced ½”

9 = FiberFree ½”

X = Special

Digit 11 – ECM Motor Power Supply

1 = ECM motor 120V/1Ph/60Hz

2 = ECM Motor 208V/1Ph/60Hz

3 = ECM Motor 277V/1Ph/60Hz

X = Special

Digit 12 – Motor Control

M = Manual Control Board

R = Remote PWM Control

X = Special

Digit 13 – Primary Inlet Size

4 = 4” Diameter

6 = 6” Diameter

8 = 8” Diameter

22 = 16” x 8” Rectangular

XX = Special

Digit 14,15,16,17 – Minimum Primary Airflow (cfm)

Digit 18,19,20,21 – Maximum Primary Airflow (cfm)

Digit 22,23,24,25 – Fan Airflow (cfm)

Digit 26 – Airflow Measuring Sensor

0 = None

3 = Aerocross

X = Special

Digit 27,28,29 – Cooling and Heating coils

200 = 2 Rows Cooling only coil

201 = 2 Rows Cool + 1 Row Heating coil

400 = 4 Rows Cooling only coil

401 = 4 Rows Cool + 1 Row Heating coil

XXX = Special

Digit 30, 31 – Filter (Optional Accessories)

00 = None

F1 = 1 x 1” Filter – NOT Ducted

F2 = 1 x 1” Filter + Spare Filter - NOT Ducted

F3 = 1 x 2” Filter – NOT Ducted

F4 = 1 x 2” Filter + Spare Filter - NOT Ducted

F5 = 1 x 1” Filter – Ducted

F6 = 1 x 1” Filter + Spare Filter - Ducted

F7 = 1 x 2” Filter – Ducted

F8 = 1 x 2” Filter + Spare Filter – Ducted

XX = Special

Digit 32,33 – Motor Fuses ( Optional Accessories)

00 = None

MF = Motor Fuses

XX = Special

Digit 34,35 –Unit Accessories (Optional Accessories)

0 = None

B = Hanger Brackets

Y = Slip & Drive Adaptor (Fan Discharge)

X = Special

Digit 36,37,38,39 – Controller (Optional Accessories)

0000 = None

XXXX = Special

Digit 40,41,42,43 – Damper Actuator (Optional Accessories)

0000 = None

DT01 = Electronic Damper Actuator – Titus

XXXX = Special

5

IOM - LSC

Redefine your comfort zone. ™ | www.titus-hvac.com

Model Number Description (continued)

Digit 44,45,46,47 – Controls Optional Accessories

0 = None

D = Disconnect Switch (Non Fused)

E = Control Enclosure

G = Dust Tight Control Enclosure

T = Dust Tight Disconnect Switch

X = Special

Digit 48,49,50 – Electric Heaters Type

0 = None

E21 = 208V/1Ph 1Stage

E22 = 208V/1Ph 2 Stages

E23 = 208V/1Ph 3 Stages

E31 = 240V/1Ph 1Stage

E32 = 240V/1Ph 2 Stages

E33 = 240V/1Ph 3 Stages

E41 = 277V/1Ph 1Stage

E42 = 277V/1Ph 2 Stages

E43 = 277V/1Ph 3 Stages

E61 = 208V/3Ph 1Stage

E62 = 208V/3Ph 2 Stages

E63 = 208V/3Ph 3 Stages

E91 = 480V/3Ph 1Stage

E92 = 480V/3Ph 2 Stages

E93 = 480V/3Ph 3 Stages

E21 = 208V/1Ph 1Stage

E22 = 208V/1Ph 2 Stages

E23 = 208V/1Ph 3 Stages

L21 = 208V/1Ph Lynergy PWM

L22 = 208V/1Ph Lynergy 2 Stage

L23 = 208V/1Ph Lynergy 0-10V or 0-20mA

L24 = 208V/1Ph Lynergy 2-10V or 4-20mA

L25 = 208V/1Ph Lynergy Incremental T-stat

L26 = 208V/1Ph Lynergy Binary

L27 = 208V/1Ph Lynergy 3 Point Floating

L31 = 240V/1Ph Lynergy PWM

L32 = 240V/1Ph Lynergy 2 Stage

L33 = 240V/1Ph Lynergy 0-10V or 0-20mA

L34 = 240V/1Ph Lynergy 2-10V or 4-20mA

L35 = 240V/1Ph Lynergy Incremental T-stat

L36 = 240V/1Ph Lynergy Binary

L37 = 240V/1Ph Lynergy 3 Point Floating

L41 = 277V/1Ph Lynergy PWM

L42 = 277V/1Ph Lynergy 2 Stage

L43 = 277V/1Ph Lynergy 0-10V or 0-20mA

L44 = 277V/1Ph Lynergy 2-10V or 4-20mA

L45 = 277V/1Ph Lynergy Incremental T-stat

L46 = 277V/1Ph Lynergy Binary

L47 = 277V/1Ph Lynergy 3 Point Floating

L61 = 208V/3Ph Lynergy PWM

L62 = 208V/3Ph Lynergy 2 Stage

L63 = 208V/3Ph Lynergy 0-10V or 0-20mA

L64 = 208V/3Ph Lynergy 2-10V or 4-20mA

L65 = 208V/3Ph Lynergy Incremental T-stat

L66 = 208V/3Ph Lynergy Binary

L67 = 208V/3Ph Lynergy 3 Point Floating

L91 = 480V/3Ph Lynergy PWM

L92 = 480V/3Ph Lynergy 2 Stage

L93 = 480V/3Ph Lynergy 0-10V or 0-20mA

L94 = 480V/3Ph Lynergy 2-10V or 4-20mA

L95 = 480V/3Ph Lynergy Incremental T-stat

L96 = 480V/3Ph Lynergy Binary

L97 = 480V/3Ph Lynergy 3 Point Floating

Digit 51,52,53 – Electric Heaters KW rating

1.0 = 1.0 KW

1.5 = 1.5 KW

(Refer to 19 & 20 for available KW rating for alternative

power supply voltages)

Digit 54 – Mercury Contactor

0 = None

B = Mercury Contactor

X = Special

Digit 55 – Electric Heater Disconnect Switch and Fuses

0 = None

C = Fuses

D = Disconnect Switch Door Interlock Fused

E = Disconnect Switch Door Interlock

X = Special

Digit 56, 57, 58 – Electric Heater Accessories

0 = None

F = Secondary Manual Reset Cutout

G = Dust Tight Enclosure

T = Lynergy Discharge Limit Temp Sensor

X = Special

6IOM - LSC Redefine your comfort zone. ™ | www.titus-hvac.com

IOM LSC

General Information

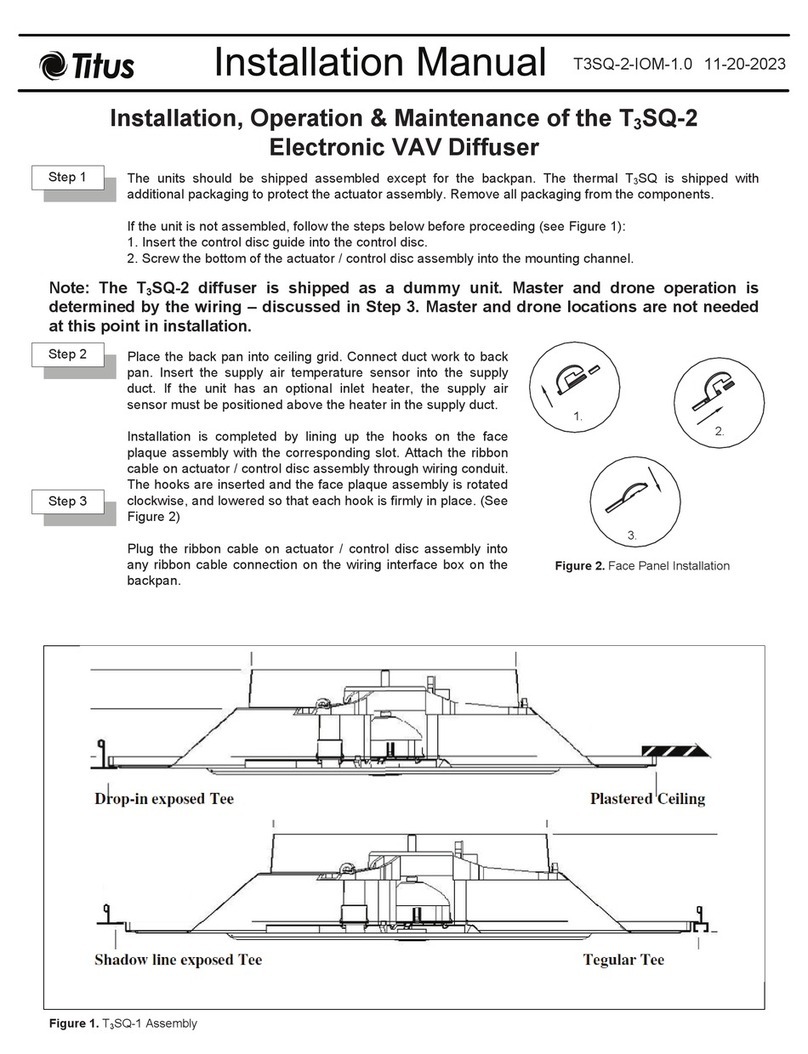

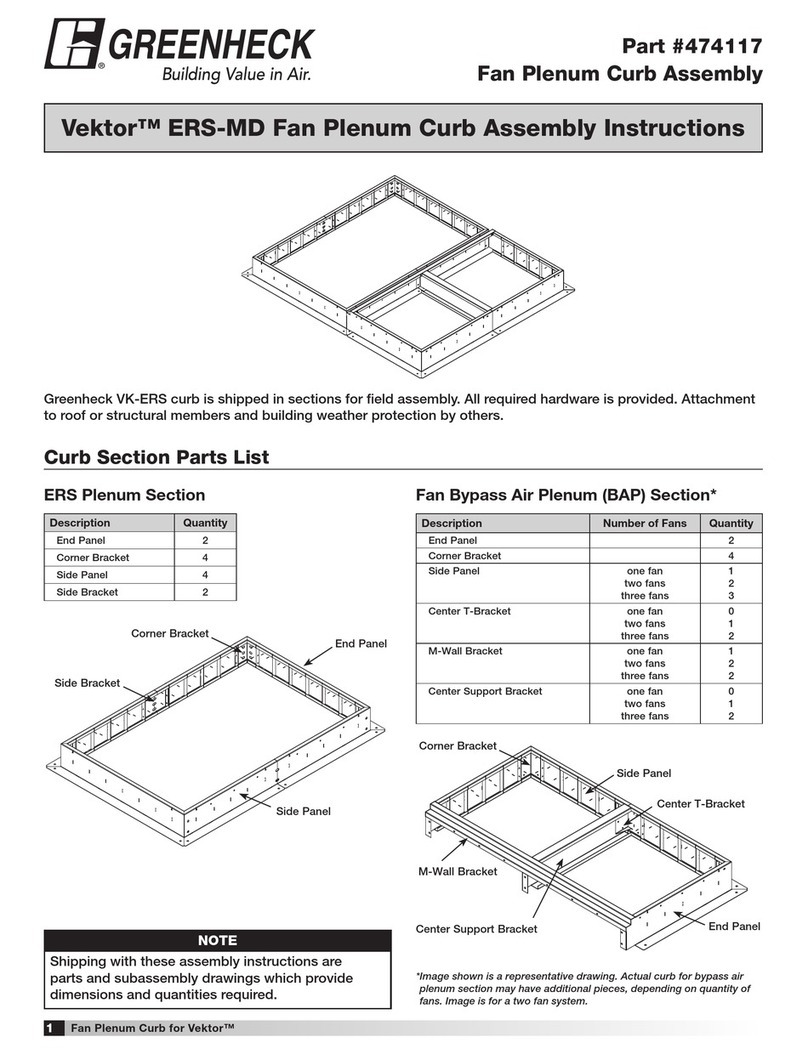

The LSC units are intended for single or multi zone applications with an airflow range of 400 to 1850 CFM. The LSC units incorporate as standard a

Primary Air damper which receives air from a Dedicated Outside Air system (DOAS), high efficiency ECM motor(s) and are available as two-pipe systems

with or without electric heat (one hydronic circuit), four-pipe system (two hydronic circuits) or four-pipe with standby electric heating. The unit mounted

low voltage 24 VAC, 50VA Class II transformer provides low voltage to the ECM motor controls and connections field mounted controller/damper

actuator. See Figure 1 for unit components.

Primary Air Inlet c/w:

Aerocross – Airflow measuring device

Damper Blade

Return Air:

Non Ducted (STD)

Ducted Flange (Optional)

Sensible Cooling Coil

and

Hot Water Coil

Condensate Pan

Electric Heater

(Optional)

DWDI Centrifugal

Blower

ECM Motor

Control Enclosure

EcoShield Liner

Filter MERV8 (Optional)

Figure 1: LSC Unit Major Components (Unit Size 3 shown)

7

IOM - LSC

Redefine your comfort zone. ™ | www.titus-hvac.com

Pre-Installation

Receiving and Handling: Upon delivery, inspect all components for

possible shipping damage. See “Receiving Checklist” (below) for

detailed instructions. Titus recommends leaving units and accessories in

their shipping packages/skids for protection and ease of handling until

installation.

Shipping Package: The LSC units are multi packed and ship in pallets for

handling and storage ease. Each Unit has tagging information such as

the model number, sales order number, serial number, unit size, piping

connections, and unit style to help properly locate the unit in the floor plan.

If specified, the unit will ship with tagging designated by the customer.

Receiving Checklist: Complete the following checklist immediately after

receiving unit shipment to detect possible shipping damage.

•Inspect individual pallets before accepting. Check for rattles, bent

corners, or other visible indications of shipping damage.

•If a unit appears damaged, inspect it immediately before accepting

the shipment. Manually rotate the fan wheel to ensure it turns freely.

Make specific notations concerning the damage on the freight bill.

Do not refuse delivery.

•Inspect the unit for concealed damage before it is stored and as soon

as possible after delivery. Report concealed damage to the freight

line within the allotted time after delivery. Check with the carrier for

their allotted time to submit a claim.

•Do not move damaged material from the receiving location. It is

the receiver’s responsibility to provide reasonable evidence that

concealed damage did not occur after delivery.

•Do not continue unpacking the shipment if it appears damaged.

Retain all internal packing, cartons, and crate. Take photos of

damaged material.

•Notify the carrier’s terminal of the damage immediately by phone and

mail. Request an immediate joint inspection of the damage by the

carrier and consignee.

•Notify your Titus representative of the damage and arrange for repair.

Have the carrier inspect the damage before making any repairs to

the unit.

•Compare the electrical data on the unit nameplate with the ordering

and shipping information to verify the correct unit is received.

Jobsite Storage: This unit is intended for indoor use only. Store the unit

indoors to protect the unit from damage due to the elements. If indoor

storage is not possible, make the following provisions for outdoor storage:

1. Place the unit(s) on a dry surface or raised off the ground to assure

adequate air circulation beneath unit and to assure that no portion of

the unit contacts standing water at any time.

2. Cover the entire unit with a canvas tarp only. Do not use clear, black

or plastic tarps as they may cause excessive moisture condensation

and equipment damage.

Installation Preparation: Before installing the unit, consider the following

unit location recommendations to ensure proper unit operation.

1. Clearances: Allow adequate service and code clearances as

recommended in “Service Access” (the next section). Position the

unit and skid assembly in its final location.

2. Structural support: Ensure the structural support is strong enough to

adequately support the unit. The installer is responsible for supply

support rods for installation of ceiling units.

3. Level: To ensure proper unit operation, install the unit level (zero

tolerance) in both horizontal axes. Failure to level the unit properly

can result in condensate management problems, such as standing

water inside the unit.

4. Condensate line & piping: Consider coil piping and condensate drain

requirements. Verify condensate line is continuously pitched 1 inch

per 10 feet of condensate line run to adequately drain condensate.

5. Wall & ceiling openings: concealed units require wall/ ceiling

openings. Refer to submittal for specific dimensions before

attempting to install. Concealed units must meet the requirements of

the National Fire Protection Association (NFPA) Standard 90A or 90B

concerning the use of concealed ceiling spaces as return air plenums.

Refer to the submittal for specific dimensions of ceiling openings.

WARNING

Hazardous Voltage!

Disconnect all electric power, including remote disconnects and

discharge all motor start/run capacitors before servicing. Follow

proper lockout/ tagout procedures to ensure the power cannot

be inadvertently energized. For variable frequency drives or other

energy storing components provided by Titus or others, refer to the

appropriate manufacturer’s literature for allowable waiting periods

for discharge of capacitors. Verify with an appropriate voltmeter

that all capacitors have discharged. Failure to disconnect power

and discharge capacitors before servicing could result in death

or serious injury.

8IOM - LSC Redefine your comfort zone. ™ | www.titus-hvac.com

IOM LSC

Pre-Installation (continued)

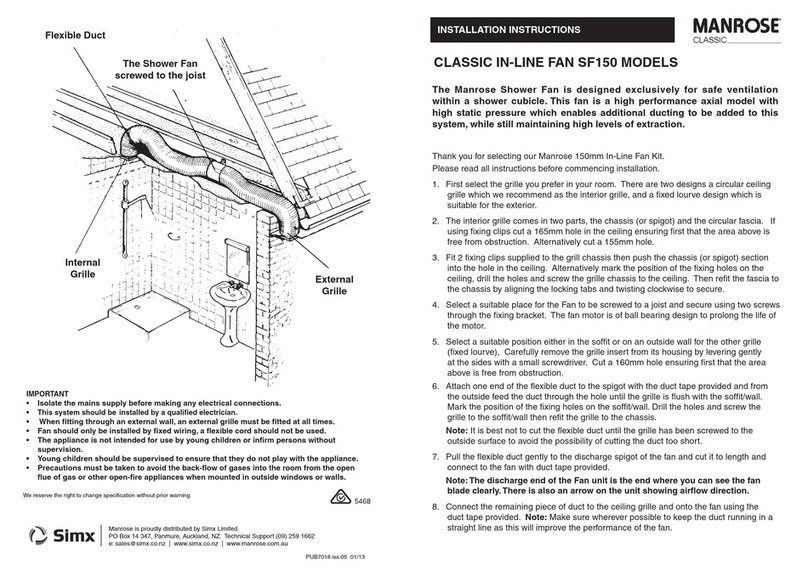

Service Access: Service access is available from the bottom and sides

of the units. Units have removable bottom and side panels to allow

access into the unit. See Figure 2 for recommended service and operating

clearances. Units have front or back piping connections. Reference piping

locations by facing the front of the unit (airflow discharges from the front).

The control panel is always on the opposite the piping.

Note:

1. Right Hand unit shown. Control enclosure dictates the handing of

the unit.

2. Condensate Pan may be removed from the front or rear of the unit.

3. All LSC units are installed with removable bottom access panels.

PRE-INSTALLATION CHECKLIST

Complete the following before beginning unit installation.

•Verify the unit size and tagging with the unit nameplate.

•Make certain the ceiling is solid, and sufficient to support the unit

and accessory weights. See “Dimensions and Weights” section.

•Allow minimum recommended clearances for routine maintenance

and service. Refer to unit submittals for dimensions.

•Allow 4’ of straight duct before the first takeoff or before the discharge

ductwork makes any turns.

Figure 2

9

IOM - LSC

Redefine your comfort zone. ™ | www.titus-hvac.com

Components Data

Unit 03 04

Cooling Coil Data Face Area (ft2) 2.1875 2.1875

L x D x H (in)

2 Row 36 x 9 5/8 x 8 3/4 36 x 9 5/8 x 8 3/4

4 Row 36 x 9 5/8 x 8 3/4 36 x 9 5/8 x 8 3/4

Volume (US Gal)

2 Row 1.75 1.75

4 Row 3.5 3.5

Fin Per Inch 10 FPI 10 FPI

Heating Coil Data Face Area – ft2 2.1875 2.1875

1 Row 36 x 9 5/8 x 8 3/4 36 x 9 5/8 x 8 3/4

Volume – US Gal

1 Row 0.875 0.875

Fan / Motor Data Fan Quantity 1 2

Size – Dia(in) x Width (in) 10 5/8 x 8 7/8 10 5/8 x 8 7/8

Motor Quantity 1 2

Motor Power (HP) 1 x 1/3 HP 1 x 1/3 HP

Filter Data Quantity 2 2

Size L x H (Nominal in) 20 x 10 (each) 20 x 10 (each)

Type Pleated Pleated

Filtration Efficiency MERV 8 MERV 8

Note: Filter dimensions are nominal dimensions

10 IOM - LSC Redefine your comfort zone. ™ | www.titus-hvac.com

IOM LSC

Dimensions

11

IOM - LSC

Redefine your comfort zone. ™ | www.titus-hvac.com

Dimensions (continued)

12 IOM - LSC Redefine your comfort zone. ™ | www.titus-hvac.com

IOM LSC

Coil Flange Connections

Weights

13

IOM - LSC

Redefine your comfort zone. ™ | www.titus-hvac.com

Unit Labels

Each unit will have two main labels attached to the casing.

The FAN UNIT label lists:

Model Number

Model Number Description

Unit Power Supply requirements

Motor Horsepower

Full Load Amps

Electric Heater Power Supply requirements

Power – KW

Amperage consumption

Minimum Circuit Amps

Max Recommended Fuse

The AIR FLOW label lists:

Model Number

Unit Size

Factory Order Number

TAG / Location - indicates the engineer’s planned location for the unit

to be installed.

There may be other labels attached to the unit, as options or codes

may require.

If you have any questions, please contact the local TITUS Representative

for clarification. Have the key points from the Air Flow label available for

reference before calling.

NOTICE

Read all labels on a typical unit, before beginning installation.

14 IOM - LSC Redefine your comfort zone. ™ | www.titus-hvac.com

IOM LSC

Water Coil Connections

15

IOM - LSC

Redefine your comfort zone. ™ | www.titus-hvac.com

Installation - Mechanical

DUCT CONNECTIONS

Install all air ducts according to National Fire Protection Association

standards for the Installation of Air Conditioning and Ventilating Systems

(NFPA 90A and 90B). Install all air ducts according to the National Fire

Protection Association standards for the “Installation of Air Conditioning

and Ventilation Systems other than Residence Type (NFPA 90A) and

Residence Type Warm Air Heating and Air Conditioning Systems

(NFPA 90B).

The unit’s duct connections varies dependent on options ordered. Titus

recommends using galvanized sheet metal ductwork with the LSC units.

All duct connections should be sealed and fasten with sheetmetal screws.

Note: Do not run screws through the removable front panels.

DUCTWORK RECOMMENDATIONS

Follow the general recommendations listed below when installing

ductwork for the unit.

1. Discharge ductwork should run in a straight line, unchanged in size or

direction, for a minimum of 4’.

2. When making duct turns, placing takeoffs and transitions avoid

sharp turns and use proportional splits, turning vanes, and air scoops

when necessary.

3. When possible, construct, and orient supply ductwork turns in the

same direction as the fan rotation.

PIPING CONSIDERATIONS HYDRONIC COIL PIPING

Before installing field piping to the coil, consider the following:

•Coil connections can be 5/8-inch O.D. (or 1/2-inch nominal) or 7/8-

inch O.D. (or ¾-inch nominal) sweat copper connections.

•The supply and return piping should not interfere with the auxiliary

drain pan or condensate line connection.

•Supply connection should always be at the bottom of the coil and

return at the top.

•An Air Vent valve must be installed at the highest point of the water

coil to allow removal of “air pockets” inside the coil.

•The installer must provide adequate piping system filtration and

water treatment.

•Solder the joints using bridgit lead-free solder (ASTM B32-89) to

provide a watertight connection. Avoid overheating factory soldered

joints when soldering field connections to the coil to prevent leakage

from occurring.

•Insulate all piping to coil connections as necessary after connections

and pressure test are complete.

Note: When installing a field piping package in a LSC unit, allow sufficient

room to remove the auxiliary drain pan.

CONDENSATE DRAIN CONNECTION (IF INSTALLED)

1. De-burr the pipe end before making the connection to the drain pan.

2. Connect a 7/8-inch O.D. copper pipe or tube, with a 0.20 inch wall

thickness, to the auxiliary drain pan. This should be a mechanical

connection that allows easy removal of the auxiliary drain pan when

servicing the piping end pocket.

3. Slide the copper pipe over the drain pan nipple and tighten the collar

on the pipe with a hose clamp (installer supplied).

Maintain a continuous drain line pitch of one inch per ten feet of drain

line run to provide adequate condensate drainage. Extend the drain line

straight from the drain pan a minimum distance of six inches before

making any turns. The installer must provide proper support for the drain

line to prevent undue stress on the auxiliary drain pan.

Note: The installer is responsible for adequately insulating field piping.

See the “External Insulating Requirements” section for more information.

WARNING

Hazardous Voltage!

Disconnect all electric power, including remote disconnects and

discharge all motor start/run capacitors before servicing. Follow

proper lockout/ tagout procedures to ensure the power cannot

be inadvertently energized. For variable frequency drives or other

energy storing components provided by Titus or others, refer to the

appropriate manufacturer’s literature for allowable waiting periods

for discharge of capacitors. Verify with an appropriate voltmeter

that all capacitors have discharged. Failure to disconnect power

and discharge capacitors before servicing could result in death

or serious injury.

16 IOM - LSC Redefine your comfort zone. ™ | www.titus-hvac.com

IOM LSC

Installation - Mechanical (continued)

Installation - General

EXTERNAL INSULATING REQUIREMENTS

Insulate and vapor seal surfaces colder than surrounding air dew-point to

prevent unplanned condensation. Titus recommends field-insulation of the

following areas to prevent potential condensate problems:

1. Supply and return water piping connections

2. Condensate drain lines and connections

3. Fresh air intake duct connections

4. Discharge duct connections

INSTALLING THE UNIT

Follow the procedures below to install the unit properly. Refer to

“Dimensions and Weights,” Section for specific unit dimensions and

mounting hole locations.

Install horizontal units suspended from the ceiling using metal straps or

the optional Hanging Brackets located on the top of the unit. The hanger

holes allow a maximum shank size of 1/2-inch diameter threaded rods or

lag screws (installer provided).

NOTICE

Electrical Wiring!

Do not allow electrical wire to fall between the unit and installation

surface. Failure to comply may result in electrical shorts or difficulty

accessing wires.

NOTICE

Motor Overload!

All unit panels and filters must be in place prior to unit startup.

Failure to have panels and filters in place may cause motor overload.

17

IOM - LSC

Redefine your comfort zone. ™ | www.titus-hvac.com

Installation - General (continued)

Note: Follow the requirements of National Fire Protection Association

(NFPA) Standard 90A or 90B, concerning the use of concealed ceiling

spaces as return air plenums.

Follow the installation procedure below.

1. Prepare the ceiling opening for recessed units. Reference the unit

submittals for dimensions.

2. Position and install the suspension rods or a suspension device

(supplied by installer) according to the unit model and size in

“Dimensions and Weights,”

3. Level the unit by referencing the chassis end panels. Adjust the

suspension device.

4. Complete piping and wiring connections, in addition to any necessary

ductwork as instructed in the following sections.

5. Install the bottom panel before starting the unit.

6. If installed ensure condensate drain line is pitched one inch per ten

feet of pipe away from the LSC unit

18 IOM - LSC Redefine your comfort zone. ™ | www.titus-hvac.com

IOM LSC

Installation Checklist

The following checklist is only an abbreviated guide to the detailed

installation procedures given in this manual. Use this list to ensure all

necessary procedures are complete. For more detailed information, refer

to the appropriate sections in this manual.

1. Inspect the unit for shipping damage.

2. Level installation location to support the unit weight adequately.

Make all necessary ceiling openings to allow adequate air flow and

service clearances.

3. Ensure the unit chassis is installed level.

4. Verify that wall and ceiling openings are properly cut per the unit

submittals.

5. Verify that installation of units meets the national Fire Protection

Association (N.F.P.A.) Standard 90A or 90B concerning the use of

concealed ceiling spaces as return air plenums. Verify correct ceiling

opening dimensions on unit submittals. Secure the unit and any

accessory items properly to the ceiling support rods.

6. Complete all piping connections correctly.

7. Check field sweat connections for leaks and tighten the valve stem

packing, and piping package unions if necessary.

8. Install condensate drain line connections if required.

9. Pitch condensate drain line away from LSC unit one-inch drop per

ten feet of pipe.

10. Complete all necessary duct connections.

11. Install the filed supplied controls.

12. Complete all interconnection wiring.

13. Connect electrical supply power according to the NEC and unit wiring

diagrams.

14. Remove any miscellaneous debris, such as sheetrock dust, that may

have infiltrated the unit during construction.

15. Replace the air filter (if installed) as required.

WARNING

Hazardous Voltage w/Capacitors!

Disconnect all electric power, including remote disconnects and

discharge all motor start/run capacitors before servicing. Follow

proper lockout/tagout procedures to ensure the power cannot

be inadvertently energized. For variable frequency drives or other

energy storing components provided by Trane or others, refer to the

appropriate manufacturer’s literature for allowable waiting periods

for discharge of capacitors. Verify with an appropriate voltmeter

that all capacitors have discharged. Failure to disconnect power

and discharge capacitors before servicing could result in death

or serious injury.

NOTICE

Unit Leveling!

The unit must be installed level (zero tolerance) in both horizontal

axis for proper operation.

19

IOM - LSC

Redefine your comfort zone. ™ | www.titus-hvac.com

Installation - Electrical

NOTICE

Use Copper Conductors Only!

Unit terminals are not designed to accept other types of conductors.

Failure to use copper conductors may result in equipment damage.

NOTICE

Equipment Damage!

Unit transformer provides power to the LSC unit only. Field

connections directly to the transformer may create immediate or

premature unit component failure.

UNIT WIRING DIAGRAMS

Specific unit wiring diagrams, based on unit options ordered, are

provided inside each unit and can be easily removed for reference. Use

these diagrams for connections or trouble analysis. Wiring diagrams are

attached on the inside of the Control enclosure

SUPPLY POWER WIRING

Refer to the unit nameplate to obtain the minimum circuit ampacity

(MCA) and maximum fuse size (MFS) or maximum circuit breaker (MCB) to

properly size field supply wiring and fuses or circuit breakers.

Refer to the unit operating voltage listed on the unit wiring schematic,

submittal, or nameplate. Reference the wiring schematic for specific

wiring connections.

Note: All field wiring should conform to NEC and all applicable state

and local code requirements. The control enclosure is always on the end

opposite the piping connections. Access the control box by removing the

two screws that secure the front cover. This will allow the panel to be

removed, to provide access to the electrical components.

Recommendation: Do not bundle or run interconnection wiring in parallel

with or in the same conduit with any highvoltage wires (110 V or greater).

Exposure of interconnection wiring to high voltage wiring, inductive loads,

or RF transmitters may cause radio frequency interference (RFI). In addition,

improper separation may cause electrical noise problems. Therefore, use

shielded wire (Belden 83559/83562 or equivalent) in applications that

require a high degree of noise immunity. Connect the shield to the chassis

ground and tape at the other end.

Note: Do not connect any sensor or input circuit to an external

ground connection.

All fan motors are single phase, same voltage as electric coil (when

supplied), with exception that 277 V motors are used with 480V, 3 phase

coils (4 wire wye).

FLA = Full Load Amperage, as tested in accordance with UL 1995

Minimum Circuit Ampacity (MCA) and Maximum Fuse Size (MFS)

Calculations for Fan-Coils with Single Phase Electric Heat

Heater amps = (heater kW x 1000)/heater voltage

MCA = 1.25 x (heater amps + all motor FLAs)

MFS type circuit breaker = (2.25 x largest motor FLA) + second motor FLA

+ heater amps (if applicable)

Select a standard fuse size or circuit breaker equal to the MCA. Use the

next larger standard size if the MCA does not equal a standard size.

Standard fuse sizes are: 15, 20, 25, 30, 35, 40, 45, 50, 60 amps.

LSC Unit electric heat MBh = (heater kW)*(3.413)

If the unit does not have a disconnect switch, the power leads and ground

terminal are situated inside the high voltage compartment in the control

enclosure. If the unit has a disconnect switch, power connections are done

directly to the disconnect switch located in the control enclosure.

20 IOM - LSC Redefine your comfort zone. ™ | www.titus-hvac.com

IOM LSC

Installation - Electrical (continued)

Note:

1. All KW’s must remain within Minimum and Maximum range shown for each unit size and step.

2. Electric Coils are attached to the unit discharge and wired to a control panel for “ Single Point” electric connections.

3. Electric Coils only include:

• Automatic reset thermal cutout (one per step)

• Positive Pressure airflow switch

• Magnetic Contactor per step for Analog and Digital controls and PE switch for each step for pneumatic units.

Table of contents

Other Titus Fan manuals

Popular Fan manuals by other brands

NOVENCO

NOVENCO ZERAX AZL-AZN-AZW Installation and Maintenance

NuTone

NuTone GF900N installation instructions

Orbegozo

Orbegozo CL 02105 M instruction manual

Bastilipo

Bastilipo Roche instruction manual

Casablanca

Casablanca 59081 Assembly instructions

Minka-Aire

Minka-Aire JAVA F753 Instruction manual warranty certificate