TLV VFM-T2 User manual

172-65256M-00 (VFM-T2) 7 September 2001

Vortex Flowmeter Counter

VFM-T2

Copyright © 2001by TLV CO., LTD.

All rights reserved

ISO 9001/ ISO 14001

Manufacturer

Kakogawa, Japan

is approved by LRQA LTD. to ISO 9001/14001

172-65256M-00 (VFM-T2) 7 Sep 2001

1

Contents

Introduction.......................................................................2

Safety Considerations .......................................................3

Handling Precautions ........................................................4

Verifying the Nameplate..................................................................................4

Precautions When Transporting the Product..................................................4

Precautions When Storing the Product...........................................................4

General Description...........................................................5

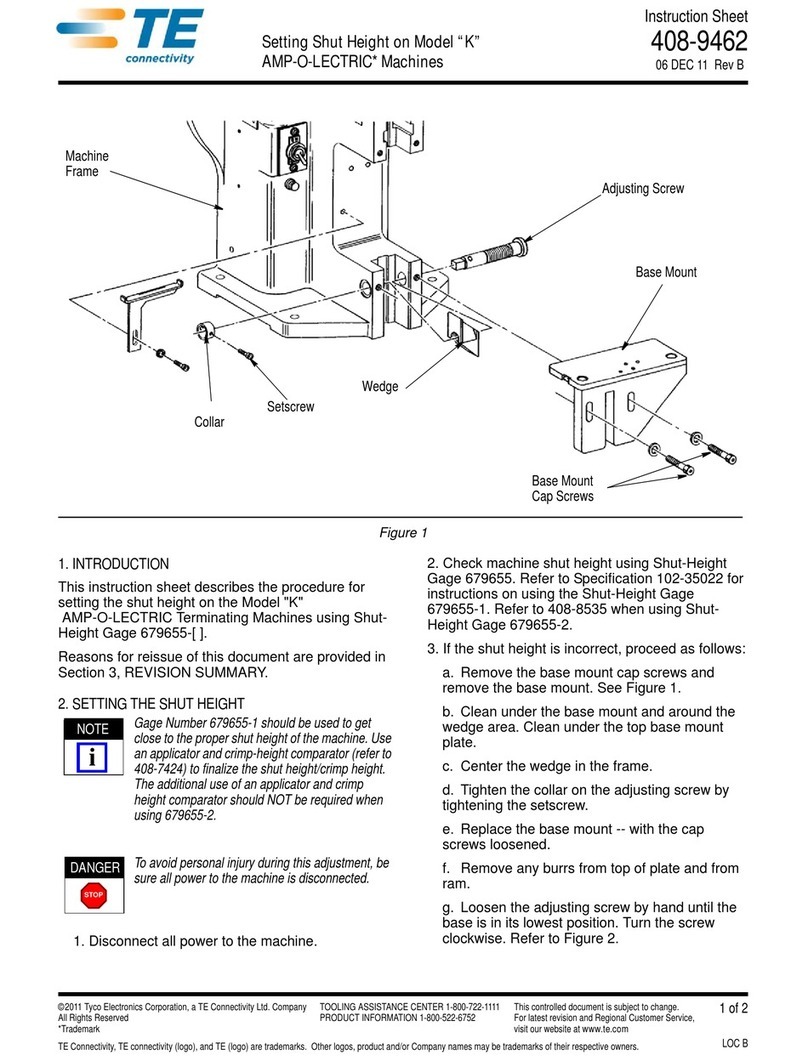

Part Names and Exterior Dimensions................................5

Instructions for Installation.................................................5

Installation Location........................................................................................5

Installation Method..........................................................................................6

Instructions for Wiring Connections...................................6

Wiring Cables .................................................................................................6

Wiring Method.................................................................................................6

Description of the Field Wiring Terminal Block ...............................................7

Input Signal Connection..................................................................................7

Configuration Block Diagram.............................................8

Functions and Operation...................................................9

The LCD Counter Display...............................................................................9

Verifying the Meter Factors.............................................................................9

Calculating Total and Instantaneous Flow Rates..........................................10

Setting and Adjusting Jumpers, Switches and Volumes...............................10

Internal Construction........................................................................................... 11

Removing the Internal Components.................................................................... 11

Waveform Shaping Function............................................................................... 11

Functions to Establish Factors............................................................................ 13

Modifying the Pulse Width Output Signal (Optional)............................................ 14

Operation and Adjustment for Setting and Modifying the Analog Output Circuit

(Optional)............................................................................................................ 15

Operation........................................................................17

Preparations Before Operation.....................................................................17

Operation......................................................................................................17

Troubleshooting ..............................................................17

Standard Specifications...................................................18

Product Warranty............................................................19

172-65256M-00 (VFM-T2) 7 Sep 2001

2

Introduction

Thank you for purchasing the vortex flowmeter counter.

This product has been thoroughly inspected before being shipped from the

factory. When the product is delivered, before doing anything else, check the

specifications and external appearance to make sure nothing is out of the

ordinary. Also be sure to read this manual carefully before use and follow the

instructions to be sure of using the product properly.

If detailed instructions for special order specifications or options not contained

in this manual are required, please contact for full details.

Please keep this manual in a safe place for future reference.

Please read this manual in conjunction with the VFM Vortex Flowmeter

Transmitter “Instruction Manual”.

172-65256M-00 (VFM-T2) 7 Sep 2001

3

Safety Considerations

•Read this section carefully before use and be sure to follow the instructions.

•Installation, inspection, maintenance, repairs, disassembly, adjustment and

valve opening/closing should be carried out only by trained maintenance

personnel.

•The precautions listed in this manual are designed to ensure safety and

prevent equipment damage and personal injury. For situations that may

occur as a result of erroneous handling, three different types of cautionary

items are used to indicate the degree of urgency and the scale of potential

damage and danger: DANGER, WARNING and CAUTION.

•The three types of cautionary items above are very important for safety: be

sure to observe all of them as they relate to installation, use, maintenance

and repair. Furthermore, TLV accepts no responsibility for any accidents or

damage occurring as a result of failure to observe these precautions.

Symbols

Indicates a DANGER, WARNING or CAUTION item.

DANGER Indicates an urgent situation which poses a threat of death or

serious injury

WARNING

Indicates that there is a potential threat of death or serious

injury

CAUTION Indicates that there is a possibility of injury or equipment /

product damage

CAUTION

Do not touch the terminals during transmission.

Failure to observe this precaution could result in such hazards as

damage to the product,malfunctions, electric shock or fire.

Make sure the power supply is OFF before carrying out work on

the wiring or inspections involving disassembly.

If such work is carried out with the power on, there is a danger that

equipment may malfunction or electric shock may occur, leading to

injury or other accidents.

Make sure that wiring work requiring a special license is carried

out only by qualified personnel.

If carried out by unqualified personnel, overheating or short circuits

leading to injury, fires, damage or other accidents may occur.

172-65256M-00 (VFM-T2) 7 Sep 2001

4

Handling Precautions

This product has been thoroughly inspected before being shipped from the factory.

When the product is delivered, check the exterior for any damage.

This section outlines precautions to be taken when handling the product.

Verifying the Nameplate

This product is assembled and adjusted to

meet each specification. The model and rated

specifications are found on the product

nameplate located on the outside of the case.

Verify the number starting with “VT” on the

sticker located on the display panel and the

number starting with “VFM” engraved in the

Tag. No. space on the nameplate of the VFM

transmitter to which the counter is connected.

Location of Nameplate

uu When making inquiries concerning the product, please be prepared to

provide details such as the product name, model, product number and

rated specifications.

Precautions When Transporting the Product

1) To prevent damage from accidents during transport, where at all possible, transport

the product to the installation site in the original packaging in which it was shipped

from TLV.

2) During transport, avoid subjecting the product to strong impacts or shocks.

Precautions When Storing the Product

If the period of time between the when the product is delivered and when it reaches

the installation site is long, special consideration must be given to the possible

occurrence of unexpected accidents. When it is known in advance that the storage

period might be long, be sure to observe the following precautions.

<Caution> After the product has been stored for a long period of no use, it

is likely that an inspection of the internal components is necessary.

Please consult with TLV.

1) Where at all possible, store the product in the original packaging in which it was

shipped from TLV.

2) Select a location for storage that meets the conditions set forth below.

ŸA location in which it will not be exposed to rain or water.

ŸA location in which it is subjected to minimal vibration or impacts.

ŸA location in which it will experience only slight fluctuations in temperature

and humidity (approximately 25°Cand 65%).

Nameplate

172-65256M-00 (VFM-T2) 7 Sep 2001

5

General Description

Make sure the power supply is OFF before carrying out work on the wiring

or inspections involving disassembly. If such work is carried out with the

power on, there is a danger that equipment may malfunction or electric

shock may occur, leading to injury or other accidents.

Make sure that wiring work requiring a special license is carried out only

by qualified personnel. If carried out by unqualified personnel,

overheating or short circuits leading to injury, fires, damage or other

accidents may occur.

Do not touch the terminals during transmission. Failure to observe this

precaution could result in such hazards as damage to the product,

malfunctions, electric shock or fire.

This vortex flowmeter counter is built around a single-chip microprocessor and is

lightweight and compact in design. It offers four independent functions (cumulative

total flow, instantaneous flow rate, hourly and per-minute total flow and resettable

total) in a single unit. Optional 4 –20mA DC and 1 –5V DC flow rate outputs are

also available.

Part Names and Exterior Dimensions

Instructions for Installation

Installation Location

1) Select a location that has no or extremely slight amounts of mechanical vibration or

corrosive gas.

2) Select a location with low humidity, of typical room temperature and in which only

slight fluctuations in temperature are experienced.

NOTE: Though the acceptable operating temperature range is −10°C to

+50°C, whenever possible select a location that is of typical room

temperature.

3) Secure sufficient space to the rear of the counter for ease of wiring and

maintenance.

8-Digit LCD Display

Analog Output Terminal

Block (Option)

M3.5 ×4P

[RESET]

Button

Panel-mount

Exterior Terminal Block

(M3.5 ×8P)

Units: mm

Select

Switch

[MODE]

Button

172-65256M-00 (VFM-T2) 7 Sep 2001

6

Installation Method

1) The counter is designed for panel mounting.

2) To install the panel, follow the steps below.

ŸAfter removing the panel-mount fitting from the body, insert the body into

the front of the panel.

ŸUsing the panel-mount fitting, secure it to the panel from the interior of the

panel.

Instructions for Wiring Connections

Make sure the power supply is OFF before carrying out work on the wiring

or inspections involving disassembly. If such work is carried out with the

power on, there is a danger that equipment may malfunction or electric

shock may occur, leading to injury or other accidents.

Make sure that wiring work requiring a special license is carried out only

by qualified personnel. If carried out by unqualified personnel,

overheating or short circuits leading to injury, fires, damage or other

accidents may occur.

Do not touch the terminals during transmission. Failure to observe this

precaution could result in such hazards as damage to the product,

malfunctions, electric shock or fire.

Wiring Cables

Be sure to use electrostatically-

shielded, polyethylene-insulated, vinyl-

sheathed control cables (CEVS 0.75 to

2 mm2, 2-or 3-conductor) or the

equivalent as input and output signal

lines.

Wiring Method

1) It is recommended that cables be routed through conduits.

NOTE: Be sure to route the power cable independent of the input and output

control cables.

2) Keep the cables away from other power cables or power circuits to prevent

inductive interference. If inductive interference is suspected, use devices such as

capacitors or surge suppressors where necessary.

3) Use spade terminals to ensure good electrical connections. The terminals for

connections are located on the rear of the unit.

Terminal Block

(Optional Analog Output

Mounted Here)

Terminal Block

Units: mm

Panel-cut Dimensions

172-65256M-00 (VFM-T2) 7 Sep 2001

7

Description of the Field Wiring Terminal Block

Before connecting the cables, make sure that the

flowmeter transmitter is compatible with the

counter. Acceptable combinations of these units

can be determined by checking their model number

and instrument number. Connect the wiring

correctly.

NOTE: The upper terminal on the rear of the

counter is found only on models with analog

output.

Exterior Connection Terminal

Block Diagram

<Caution> As incorrect combinations could lead to serious damage to

these units, be sure to check again after connecting the cables.

Description of Field Wiring Terminals

Name Terminal No. Connection and Specifications

Power Supply 6

L1 7

L2 100V, 110/115V, 200V, 220/230V ±10%

50/60Hz

Ground 8Must be grounded

Pulse

Input Current Pulse 1, 21: +(+24 or 12V DC) 2: −

Pulse

OutputsOpen Collector 4, 54: +5: −

Optional Feature

<Caution> If not using

terminal 1 and 2, they

4 –20mA DC 1, 21: +

2: −

Analog

Output

1 –5V DC 3, 4 3: +

4: −

MUST be connected using a

wire link. If they are not linked,

analog voltage does not reach

terminals 3 and 4.

Input Signal Connection

Current Pulse

Empty

Terminal

172-65256M-00 (VFM-T2) 7 Sep 2001

8

Configuration Block Diagram

lExplanation of Various Circuits (By Block)

•Power Circuit: generates various internal voltages from the power supply

voltage (POWER)

•Doubler Circuit: converts low frequencies* into frequencies that can be

processed by the F/I circuit in the next step

* When the full scale frequency is in the range of 2 –4Hz and the waveform

ratio of the input pulse is 1:1: J1 CLOSE.

•F/I Circuit: converts an input frequency of 4 –20mA or 1 –5V to an analog

signal

Transmitter Power Source

Pulse Input

Schmitt

Voltage Drop

Optional

OPEN: Single

CLOSE: Double

Analog Output

Pulse Output

Power Circuit

Optional

Synchronizes

Input Frequency

Doubler

Filter Factor

Frequency

Category

F/I Circuit

1ms (Standard)

Scaled One

Shot

Frequency

Category

172-65256M-00 (VFM-T2) 7 Sep 2001

9

Functions and Operation

Make sure the power supply is OFF before carrying out work on the wiring

or inspections involving disassembly. If such work is carried out with the

power on, there is a danger that equipment may malfunction or electric

shock may occur, leading to injury or other accidents.

Make sure that wiring work requiring a special license is carried out only

by qualified personnel. If carried out by unqualified personnel,

overheating or short circuits leading to injury, fires, damage or other

accidents may occur.

The counter is designed to show the following functions on the display by using the

select switch or by pressing the [MODE] or [RESET] buttons.

The LCD Counter Display

If the [MODE] button is pushed when the

select switch is set to either “8” or “0”, the

LCD counter displays the following

sequence:

Verifying the Meter Factors

If the [MODE] button is pushed when the select switch is set to either “C” or “4”, the

meter factors are displayed in the following sequence:

NOTE: For items marked with an asterisk*,set points can be selected only within the ranges

shown.

[RESET]

Button

Select

Switch

[MODE]

Button

NOTE: The [RESET] button is activated only at this time, and

pushing [RESET] changes the counter back to “0”.

C 0

The [RESET] button is not enabled.

(Inoperable)

0: 1/1, 1: 1/10, 2: 1/100

0.0001 -1.9999

1-128

NO

TE: This is effective only when input pulses have

very small periodic variation.

For details, see “Calculating Total and

Instantaneous Flow Rates”.

Display

Cumulative Total

Display

Meter Factor* ⇒

Number of Sampling Cycles* ⇒

Frequency Reduction*

Resettable Total

Cumulative Total

Instantaneous

Flow Rate ( / h)

Instantaneous

Flow Rate ( / min)

Resettable Total

⇒

NOTE: This is effective only when input pulses

have very small periodic variation.

For details, see “Calculating Total and

Instantaneous Flow Rates”.

Instantaneous

Flow Rate ( / h)

Instantaneous

Flow Rate ( / min)

172-65256M-00 (VFM-T2) 7 Sep 2001

10

Calculating Total and Instantaneous Flow Rates

(1) Total: both cumulative and resettable total

Input Pulses →Frequency →Meter Factor →Frequency →To Individual

(2) Instantaneous: used only when input pulses have very small periodic variation.

The period of sample cycles is measured down to the unit of 1 ms, calculated

using the following equation and the result shown on the display.

3600 ×A ×F

Flow rate per hour = b1 =

T (ms) ×10 NOTE: A: number of sampling cycles

F: meter factor

T: interval of input pulse

b1

Flow rate per minute = b2 =

60 ×100

NOTE: The number of sampling cycles is determined such that the accuracy of the

instantaneous flow rate in full scale is held within ±1% (100 ≤T≤200ms).

NOTE: It is designed so that when T ≥5000 (ms), the instantaneous flow rate on the

display will show “0”.

NOTE: Set it so that sampling cycles × input period ≤5000 (ms).

NOTE: Note that when “hard” dividing, the units for instantaneous flow rate are

modified.

Setting and Adjusting Jumpers, Switches and Volumes

lThe multifunction counter is preset to the customer specifications at the

factory before shipment. Unless it is necessary to change the preset

settings in the field, further adjustment should not be required.

NOTE: It is necessary to remove the internal components (motherboard) of the unit

when setting, modifying or adjusting jumpers, switches or volumes.

Hard

Soft

1/1,1/10 or 1/100

0.0001 -1.9999

(1.000 set for input

of unit pulse)

1/1,1/10 or 1/100

µ-CPU

Reduction

(Dividing)

Counter and

Output Unit

Reduction

(Dividing)

172-65256M-00 (VFM-T2) 7 Sep 2001

11

Internal Construction

For pulse type, the motherboard is of 2-board construction, containing a “display

board” and a “power board”. Analog type (optional) is of 3-board construction,

containing the addition of an “F/I board”. The power board and F/I board are

connected by individual connectors to the display board.

The external connection terminals are found on the rear of the counter.

Removing the Internal Components

<Caution> Be sure to perform this operation with the power supply turned

OFF.

NOTE: Disconnect all wiring from the counter unit.

1) Remove the panel-mount

fitting, and then pull the unit out

from the front of the panel.

2) Remove the screws from

the rear plate, and then take

the rear plate off.

3) Pull the internal unit

out to the rear.

Waveform Shaping Function

Specifications for Type of Pulse Input and Input Settings

Jumper Set PointsType of Pulse

Input J2 J5 J1 J3 J4 Power to

Transmitter Input

Impedance

Current Pulse 3 –C Uncoupled *1*2*324V DC 510Ω

NOTE: *1: Couple to increase the waveform shaping filter approximately 10 times.

*2: This jumper is used to select the pulse output specifications.

Synchronized input (1/1) : A –C

Scaled (display units) : B–C(STD.)

→→ See the next section.

*3: A microprocessor input speed with a maximum of 200Hz is required. It may

be necessary to set “hard” dividing prior to the processor input.Divide by

one of the following: 1/1, 1/10 or 1/100.

→→ See the next section.

F/I Board (Optional)

Terminal Blocks

Display Board

Power Board

Panel-mount Fitting

Rear Plate

Internal Unit

172-65256M-00 (VFM-T2) 7 Sep 2001

12

uu Solder jumpers to the locations on the power board indicated by the shaded

areas below in accordance with the individual specifications.

Setting the Pulse Output Specifications Selection Jumper: J3

(1) Synchronized input 1/1 (A –C)

(2) Scaled (display units): standard (B –C)

Power Board (underside)

Setting “Hard” Dividing: J4

(1)

(1) Dividing 1/1 (2) Dividing 1/10 (3) Dividing 1/100

Setting the Pulse Input Specifications Selection Jumper: J2

(1) 3 –C

Power Board (topside)

172-65256M-00 (VFM-T2) 7 Sep 2001

13

Functions to Establish Factors

It is possible to establish the following 4 factors:

1) Initial set point for the cumulative total

When replacing the battery or performing maintenance, it may be necessary to

establish previous readings before resuming cumulative totaling.

2) Frequency reduction: 1/1, 1/10 or 1000

When wanting to change the display units used in totalizing (pulse output unit).

3) Meter factor: 0.0001 -1.9999

Where readjustment of the meter factor is necessary to accommodate official meter

verification.

4) Number of sampling cycles: 1 –128

The counter shows the instantaneous flow rate at the particular point specified. For

example, in applicationswhere observing readings at increased accuracy is desired.

lOperation to Set and Modify the Factors

Since the four factors above are set in a similar

manner, only the procedure for the meter factor

is explained here to avoid duplication.

(Ex.) Changing the meter factor from 1.2345 to 0.9876.

1. Change the position of the select switch from the default position of “8” to “C”.

2. Push the [MODE] button to display the meter factor. In this case, .

3. Change the select switch from “C” to “D” and press the [MODE] button. The LCD

display changes from to and begins blinking (at 0.5 second

intervals).

4. Change the select switch from “D” to “E”.

In this position, press the [RESET] button to increment the number from “0” in the

order shown below.

Note that, as seen from the sequence above, the largest number possible is “9”. To

remedy this, with the display reading “0”, press the [MODE] button one time to move

the “0” one place to the left.

The LCD display changes to .

5. Press the [RESET] button 9 times to change the second digit to “9”.

The LCD display reads .

6. Push the [MODE] button one time to move the “09” one place to the left.

The LCD display now reads .

[RESET]

Button

Select

Switch

[MODE]

Button

F1.2345

F1.2345

F0.0090

F0.0009

F0.0000

F0.0000

172-65256M-00 (VFM-T2) 7 Sep 2001

14

7. Press the [RESET] button 8 times to change the third digit to “8”.

The LCD display now reads .

8. Press the [MODE] button one time.

The LCD display now reads .

9. Press the [RESET] button 7 times.

The LCD display now reads .

10. Press the [MODE] button one time.

The LCD display now reads .

11. Press the [RESET] button 6 times to change the smallest digit to “6”, which is

displayed at the far right-hand side of the LCD display of numerals.

The LCD display now reads .

All the numerals for the desired meter factor setting are now displayed.

Note that the number is still blinking at this point.

NOTE: The [RESET] button functions as the number-setting button, and the [MODE]

button functions as the place-shifting button.

12. After making sure that the blinking number is as desired, change the select switch

from "E" to "F" and press the [MODE] button. The LCD display stops blinking and

shows the newly set meter factor.

13. Verifying the New Meter Factor Setting

Change the select switch from "F" to "C" and press the [MODE] button to confirm

each individual digit. The new meter factor (Ex.) is displayed.

14. Change the select switch from “C” back to “8”.

This completes the setting of the factors.

Modifying the Pulse Width of the Output Signal (Optional)

When shipped from the factory, the pulse width is set to 1ms (standard

specification). However, if it is necessary, the product can be modified after it

arrives. It is possible to adjust the pulse width from 2 to 250ms by following the steps

below.

1. Turn the power OFF and pull the internal components out of the unit casing. (See

“Removing the Internal Components”.)

2. Set jumpers JP1 and JP2 on the display board to “2 –250ms”.

3. Turn ON the power.

4. Produce an output pulse from the flowmeter transmitter connected to the input or

connect a pulse generator and produce an input pulse.

5. Connect an instrument capable of measuring pulse width, such as an oscilloscope,

between terminal blocks 4 and 5 (PULSE OUT).

6. The pulse width is adjusted by turning the P1 volume.

F0.9876

F0.9876

F0.9870

F0.0987

F0.0980

F0.0098

172-65256M-00 (VFM-T2) 7 Sep 2001

15

NOTE: The waveform indicates

the connected status of the

transmitter.

<Caution>

ll Avoid turning P1 with excessive force as it could result in damage.

ll When JP1 and JP2 are set to “1ms”, the pulse width becomes 1ms (fixed).

ll Set the pulse width to a suitable flow rate range to ensure that the pulse

does not become too heavy.

Operation and Adjustment for Setting and Modifying the Analog Output

Circuit (Optional)

The items in the following section can be set and modified by switching the jumper

J1, SW1 and SW2 on the F/I board.

The analog output signal is adjusted by controlling the P1 (SPAN) and P2 (ZERO)

volume.

P1 (SPAN) Volume

P2 (ZERO) Volume

F/I Board

Pulse Width

172-65256M-00 (VFM-T2) 7 Sep 2001

16

lF/I Frequency Categories and Filter Constant Settings

Set the frequency category and filter constant that correspond to the input

frequency. SW2

SW1 123456Full Scale Frequency

Category [HZ]

0ON OFF ON ON ON ON 2.00 −3.99

0ON OFF ON ON ON ON 4.00 −9.99

1OFF ON ON 10.00 −19.99

2ON OFF OFF 20.00 −29.99

330.00 −39.99

440.00 −49.99

550.0 −59.9

660.0 −69.9

770.0 −79.9

880.0 −89.9

990.0 −99.9

A100.0 −109.9

B110.0 −119.9

C120.0 −129.9

D130.0 −139.9

E140.0 −149.9

FON ON ON ON 150.0 −199.9

2OFF OFF OFF OFF 200.0 −299.9

3OFF 300.0 −399.9

4ON 400.0 −499.9

5500 −599

6600 −699

7700 −799

8800 −899

9900 −999

A1000 −1099

B1100 −1199

C1200 −1299

D1300 −1399

E1400 −1499

FOFF ON OFF OFF OFF OFF 1500 −2000

lAdjusting the Analog Output Signal

Adjusting the ZERO and SPAN of the Analog Signal

Volume Adjustment Method

P1 (SPAN) Adjust the analog signal to the maximum value (20mA or 5V)

corresponding to the input frequency maximum value.

P2 (ZERO) Adjust the analog signal to the minimum value (4mA or 1V)

corresponding to the input frequency minimum value.

172-65256M-00 (VFM-T2) 7 Sep 2001

17

Operation

Preparations Before Operation

Inspect the counter and associated instruments to ensure that they are correctly

installed and wired and that nothing has been overlooked.

<Warning> Use of a power source of an incorrect voltage may result in

burnout of the counter. Make certain to use a power source of the rated

voltage.

(Pre-operational Check)

Supply power to the counter. Press the [MODE] button to test function and check for

irregularities.

<Caution> Avoid repeatedly turning the power ON and OFF, as this may

cause the counter to begin counting.

Next, supply a simulated pulse train of the appropriate type to confirm that the counter

counts and displays a correct totalized flow and instantaneous flow rate in response.

Operation

After pre-operational preparations are completed, turn on the power.

Troubleshooting

uIMPORTANT u

When internal trouble is suspected, contact TLV after inspecting the

counter by following the steps below.

Symptom Check Item Possible Causes

Is power being supplied?

(1) Check the voltage

(2) Inspect the fuse

(1) The supply voltage is incorrect

(2) The fuse is blown (internal)

(3) The power supply unit is

faulty

The display

indicates neither

total flow nor

instantaneous flow

rate

Is a pulse input train

being supplied?

(1) Is the wiring correct?

(2) Is the pulse input train

reaching the counter?

(1) The input lines are wired incorrectly

(2) The transmitter is faulty

(3) The waveform shaping circuit is

faulty

(4) The custom (µCPU) is defective

uIMPORTANT u

If the problem is suspected to be other than one listed above, contact the

TLV service network. When contacting TLV, be prepared to provide details

such as the product name, model and symptoms of the problem.

172-65256M-00 (VFM-T2) 7 Sep 2001

18

Standard Specifications

Item Description

Display Type LCD Character height: 12.7 mm

Items Displayed

Sequential display by pressing [MODE] Button

8-digit nonresettable Total flow readout

4-digit hourly Flow rate readout

4-digit per minute Flow rate readout

7-digit nonresettable Total flow readout

Scaler 0.0001 to 1.9999 (adjustable in steps of 0.0001)

Display

Program

Frequency

Reduction

Select the display units: 1/1 (standard), 1/10, 1/100

Backup Function The counter display values and settings are saved by an

internal E2PROM.

Transmitter Power Source 24V DC 50mA with overcurrent protection

Trigger Level 3V DC hysteresis 0.8V DC

Input Signal

Pulse Response 200Hz (contact input 50Hz): standard

Note: Can follow up to 2kHz when input frequencies are

reduced to 1/10 or 1/100.

When scaler value exceeds 1 150Hz maximum

Selection Scaled (same unit as displayed) = standard

or synchronized input (unscaled)

Output Signal Open collector after optical isolation.

Capacity 30V DC 50mA max.

Voltage When Power ON 1.5V DC max.

Pulse Output

Pulse Width

1ms: standard

Output Signal 4 –20mA DC and 1 –5V DC

Current Output: 350Ωmax.

Voltage Output Cutoff: 600Ωmax.

Load Resistance

Voltage Output: 1MΩmin.

Accuracy ±0.1% of full scale (temp. factor 0.015%/°C)

Ripple 1% of full scale (at 10% of full scale flow rate)

Output Signal

Analog Output

Time Constant 4(2) –19.99Hz: 6.5 seconds

20 –199.99Hz: 2.1 seconds

200 –2000Hz: 1.5 seconds

Figuresin brackets ( ) with frequency doubler

Ambient Temperature -10° to +50°C

Insulation Resistance Between power terminals and ground

10MΩor greater at 500V DC

Withstand Voltage Between power terminals and ground

1500V AC for 1 minute

Power Consumption 7VA max.

Weight Approximately 0.6 kg

Case Molded resin and aluminum

Frame Color Munsell N1.5 or equivalent

172-65256M-00 (VFM-T2) 7 Sep 2001

19

Product Warranty

1. Warranty Period

One year following product delivery.

2. Warranty Coverage

TLV CO., LTD. warrants this product to the original purchaser to be free

from defective materials and workmanship. Under this warranty, the product

will be repaired or replaced at our option, without charge for parts or labor.

3. This product warranty will not apply to cosmetic defects, nor to any product

whose exterior has been damaged or defaced; nor does it apply in the

following cases:

•Malfunctions due to improper installation, use, handling, etc., by

other than TLV CO., LTD. authorized service representatives.

•Malfunctions due to dirt, scale, rust, etc.

•Malfunctions due to improper disassembly and reassembly, or

inadequate inspection and maintenance by other TLV CO., LTD.

authorized service representatives.

•Malfunctions due to disasters or forces of nature.

•Accidents or malfunctions due to any other cause beyond the

control of TLV CO., LTD.

Under no circumstances will TLV CO., LTD. be liable for consequential

economic loss damage or consequential damage to property.

* * * * * * *

For Service or Technical Assistance:

Contact your representative or your regional office.

Manufacturer

CO., LTD.

881 Nagasuna, Noguchi

Kakogawa, Hyogo 675-8511 JAPAN

Tel: 81–(0)794–27–1800

Table of contents