3

Mounting Position

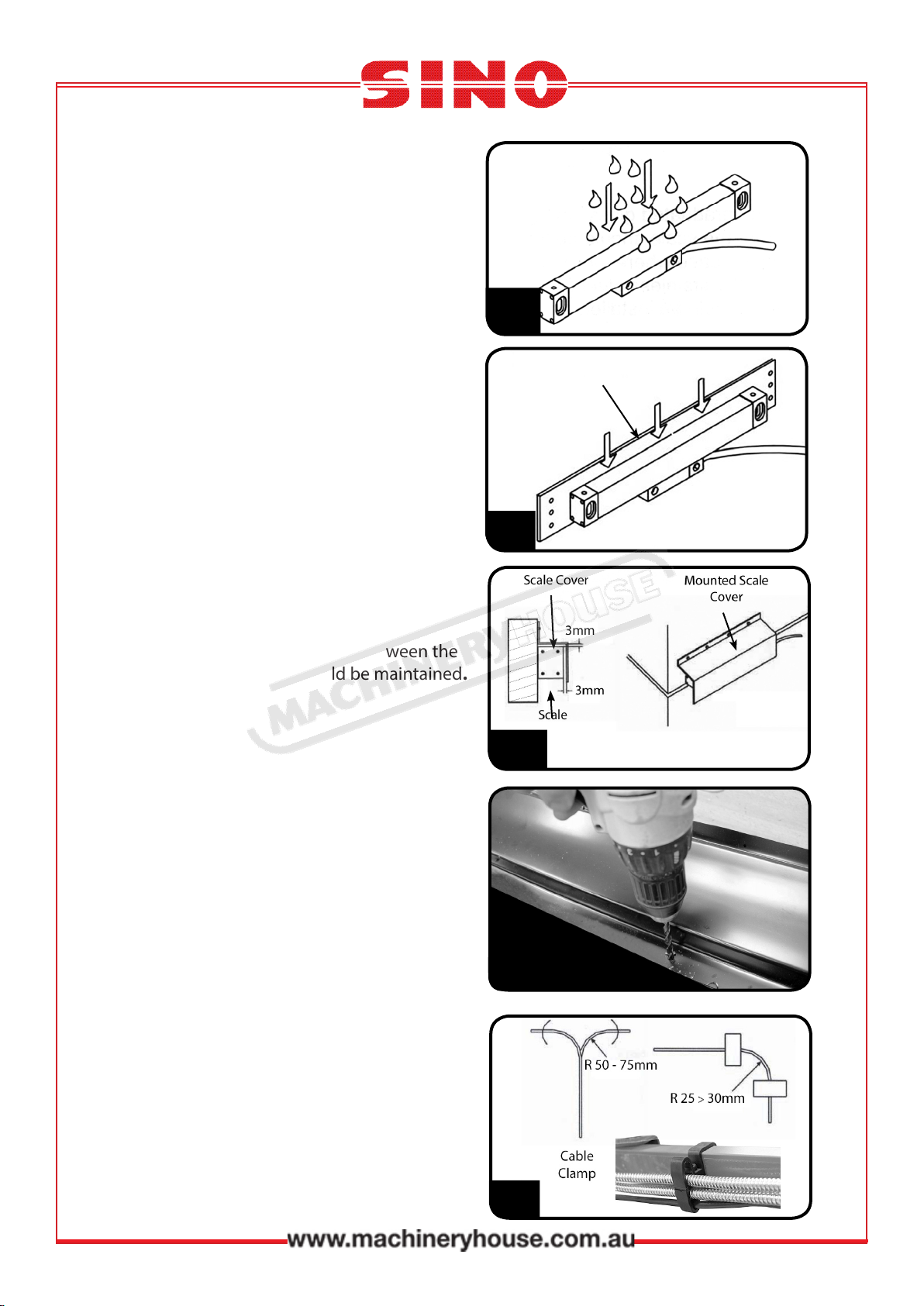

4. The opening of the scale must not be

installed as to be directly exposed to swarf,

oil, water, dust or other foreign products.

(Fig. 3)

Covers provided should be installed.

Fig . 3

Backing Plates

5. In cases where machined at surfaces are

not available, optional backing plates

should be used to provide a at datum for

the installation. (Fig. 4)

Fig. 4

Mounting Plate

Cover Clearance

6. A clearance of at least 3.0mm between the

scale and scale cover should be maintained.

(Fig. 5)

Drilling and Tapping Holes

7. When drilling and tapping the holes be sure

that the drill and tap are square to the cover.

(Fig. 6)

All tapped screw holes must have at least 6

threads to allow the screw to be rmly

secured into the holes. When the screw is

needed to secure a heavy load, the tapped

holes must have at least 8 threads. After

tapping, the holes must be deburred and

cleaned

Fig. 5.

Fig. 6

Securing Cable

8. All cables must be xed, but allow for the

maximum machine travel movements.

Diagram (Fig. 7) recommends the

minimum radius that should be used for

bending the scale cable. Use the cable

clamps supplied to secure the cables to

the display arm. Fig. 7

Instruction Manual for XH-2 (D5200)