WWW.TMGINDUSTRIAL.COM 1 / 22 Toll Free:1-877-761-2819

1. Preface

•Thank you very much that you have purchased the products.

•This operation manual will tell you how to correctly operate and maintain your

machine. Before using the machine, please read the operation manual

thoroughly to guarantee the correct operation. Following the operation

requirements in the operation manual will make that your machine is in the

best operation state so as to extend the life of the set. For you own safety and

protection injury, carefully read, understand and observe the safety

instructions described in this manual.

•Keep this manual or a copy of it with the machine. This machine is built with

user safety in mind; however, it can present hazards if improperly operate and

serviced. Follow operating instructions carefully!

•With the increasing improvement and enhance of the products made by the

company, there may be some differences between the contents described in

the operation manual and the practical products, it is our desire that the users

will pay attention to the differences.

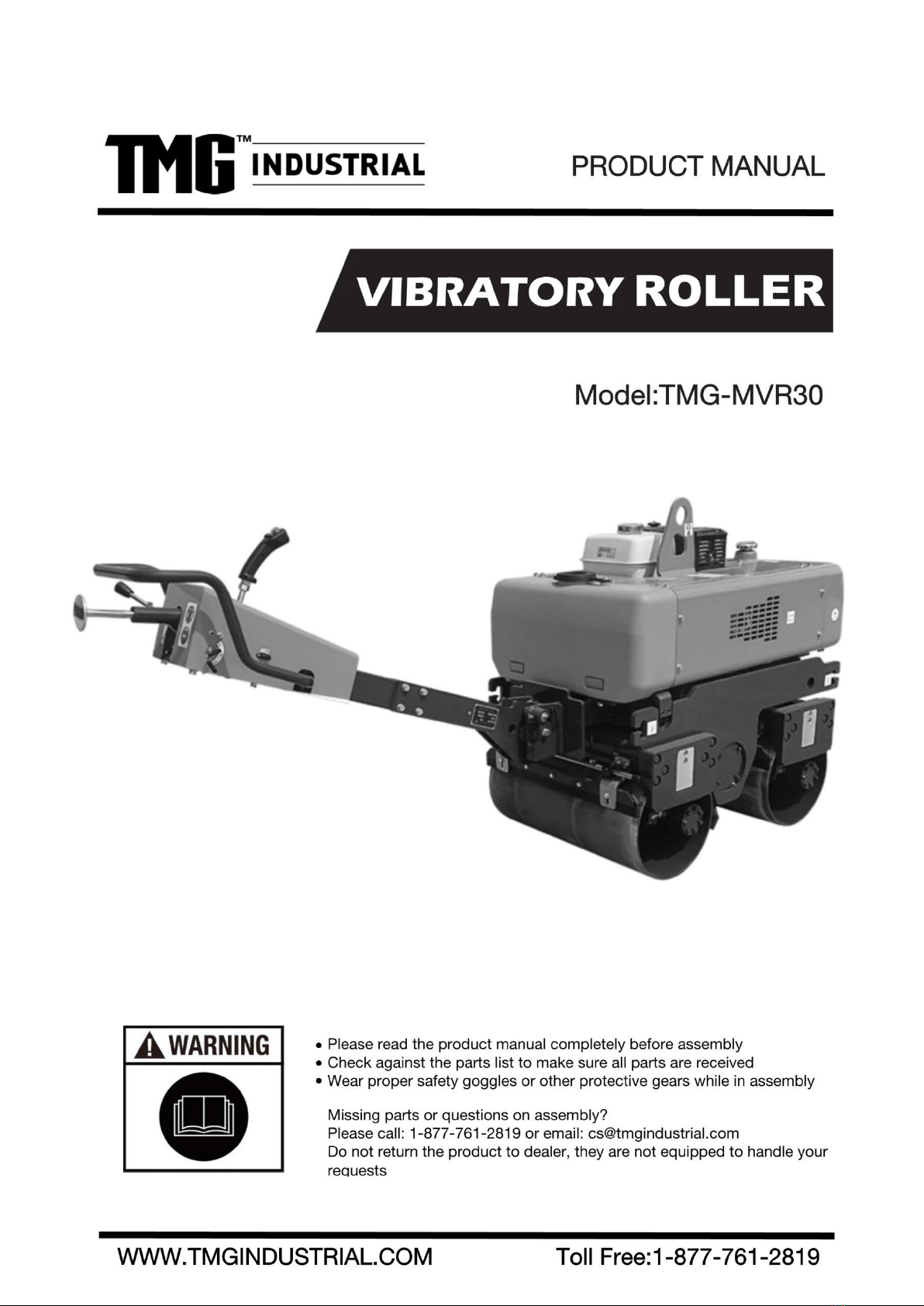

•The walk-behind double drums roller is light road roller. It is used to compress

on the asphalt, sand soil gravel and it is also used to planish the lawn and

playground.

•This machine is with hydraulic unit, variable plunger pump, and constant

displacement hydraulic motor, which make the machine has excellent

performance.

2. Safety alerts

•In order to operate the machine safely, it is very necessary to maintain the

machine regularly. Please read the Safety alerts carefully to master the skills of

maintenance and operation.

3. Driving qualification

•Qualified staffs are allowed to operate the machine

•Compaction task Operator should get training on the aspects of compaction

before operating the machine.