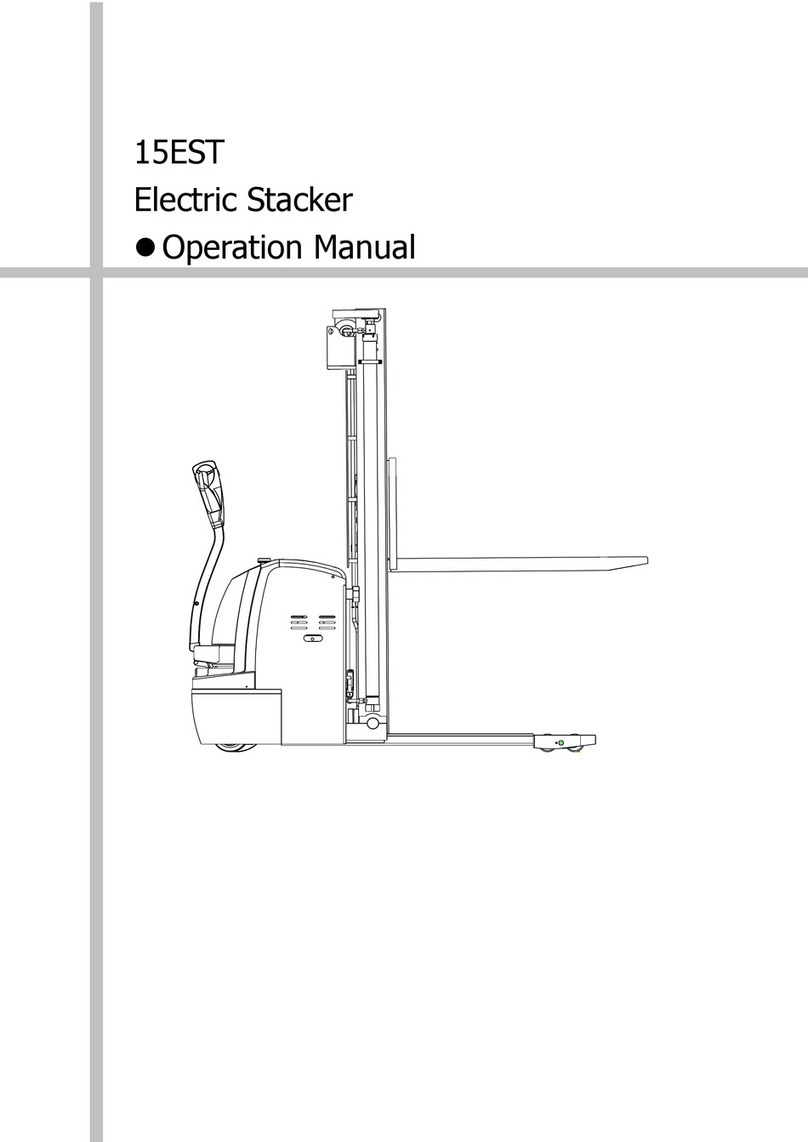

7

should be conducted as soon as the battery is discharged.。

- When the forklift is not in operation, the general power supply must be turned off, the

electric lock must be pulled out and one supplementary charging must be conducted every

five months during the period when the forklift is in storage.。

- It is strictly prohibited to open the storage battery air vent valve; otherwise, poor sealing

will be caused and the capacity and service life of the battery will be affected.。

5. Maintenance

5.1 If the forklift is able to operate satisfactorily depends on careful maintenance.

When maintenance is neglected, human safety may be endangered and property may be

damaged. When the truck is in operation, routine inspection should be conducted

frequently and abnormal should be removed in time. Do not operate forklift with trouble

to ensure safety and prolong the service life of the forklift.

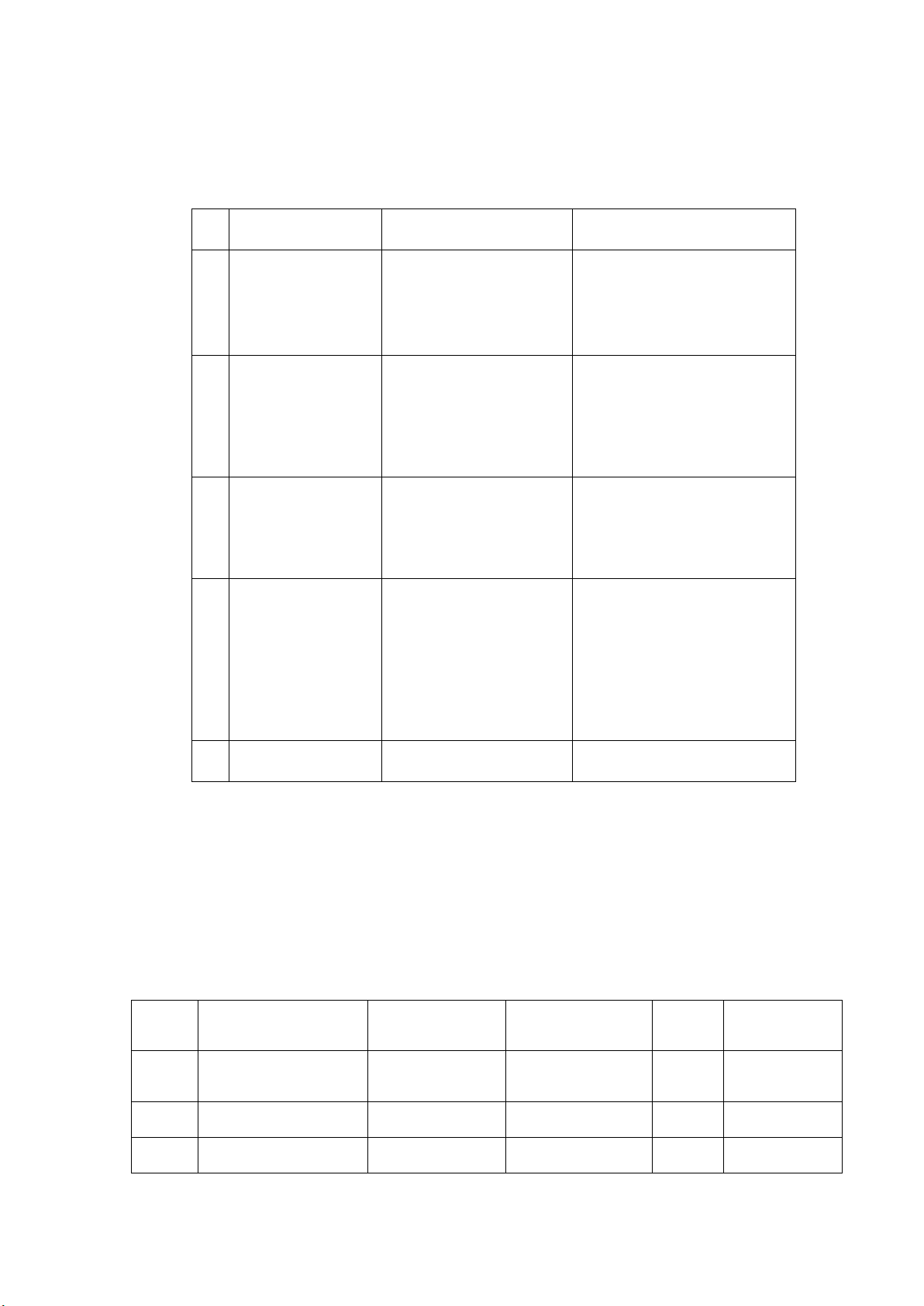

5.2 Maintenance: The maintenance of the forklift is usually divided into three levels, routine

maintenance, level 1 Maintenance and level 2 maintenance.

Routine maintenance: Once everyday and the main content is to keep the surface clean

and examine if the power supply cable is damaged.

Level 1 maintenance: Once every week. The maintenance contents, besides the contents

of routine maintenance, should focus on if the operation of the components is normal, if

the fastening items are loose, if there is any oil leakage, if there is any abnormal wearing

in mechanical components, if there are abnormal temperature rise or sparks in electric

equipment, etc. Adjustment and trouble shooting should be conducted if any abnormal

situation is discovered.

Level 2 Maintenance: It should be conducted periodically and overall inspection should be

conducted according to following requirements:

a. Mechanical maintenance should be conducted every half a year. The main contents are

to replace lubricating oil for the transmission gear and bearing of the drive wheel, apply

lubricant to various rotating joints, while examining if the fastening items are loose, if

the wheels are rotating flexibly, if the fork rises and declines normally. The operation

noise of the forklift after maintenance should be no greater than 70db.

b. Maintenance of hydraulic system: Once every 12 months. Examine if the oil cylinders

are in normal state, if there is any internal or external leakage and if the hydraulic oil is

clean. The hydraulic oil is usually replaced every 12 months. ISO oil standard is applied

to hydraulic oil. When the ambient temperature is -5 ~ 40 , HL℃-N32 is adopted and

when the ambient temperature is -35 ~ -5 , HV℃-N20 low temperature hydraulic oil is

used. The waste oil from the replacement should be treated according to the relevant

local regulation and law. Examine if the operation of the load limit valve is normal.

c. Electric equipment maintenance: It should be conducted every three months to examine

if the connectors of electric equipments are reliable, if the switches are normal and if the

insulation of the electric equipment is in normal condition (The insulation resistance of

electric equipment and the forklift body should be greater than 0.5MΩ).