Contents

1.The General Introduction..................................................................................... 1

2.Proper usage............................................................................................................2

3.Introduction o the product..................................................................................4

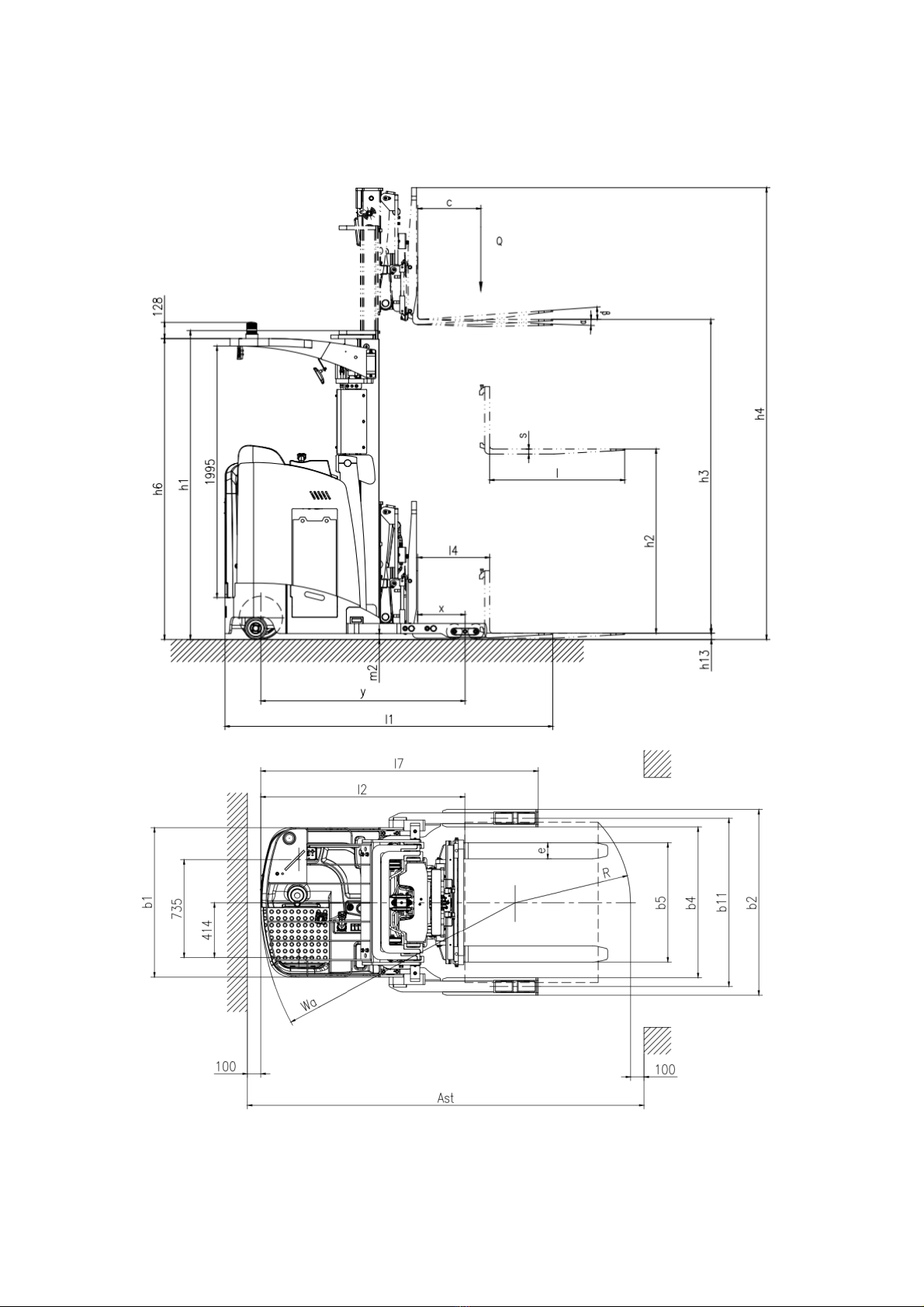

3.1Model O er iew...................................................................................................4

3.2Model parameters..............................................................................................5

3.3Safe operation and warning labels.....................................................................8

3.4Name plate ......................................................................................................... 8

4.Sa ety Caution..........................................................................................................9

5.Test run,Transportation,Outage....................................................................... 10

5.1Test run ............................................................................................................ 10

5.2Lifting & Transportation...................................................................................10

5.3Outage................................................................................................................ 11

6.Routine Inspection............................................................................................... 11

7.The Schematic diagram o Operating Mechanism......................................... 13

7.1Schematic diagram................................................................................................13

8Operating speci ication........................................................................................14

8.1Parking............................................................................................................... 14

8.2Loading capacity graph.....................................................................................14

8.3Lifting up............................................................................................................ 15

8.4Lowering down ................................................................................................15

8.5Fork mo e forward /backward/Left/Right .................................................. 15

8.6Fork Tilt forward /back ward ........................................................................ 15

8.7Tra eling ........................................................................................................ 16

8.8Steering ............................................................................................................ 17

8.9Braking ............................................................................................................. 18

8.10Brake structure &Brake Schematic............................................................... 18

8.11Trouble.............................................................................................................18

8.12Emergency situations..................................................................................... 19