►www.tmgindustrial.com 1 / 20 TOLL FREE: 1-877-761-2819

CONTENTS

1. PREFACE..................................................................................................................................................3

2. SAFETY ALERTS.......................................................................................................................................3

3. DRIVING QUALIFICATION .........................................................................................................................3

4. SAFETY PRECAUTIONS ............................................................................................................................3

4.1 General precautions ........................................................................................................................3

4.2 Preparations for safety operation.....................................................................................................4

4.3 Attentions before starting up engine ................................................................................................4

4.4 Attentions after starting up engine...................................................................................................4

4.5 Attentions during working ...............................................................................................................4

4.6 Attention of loading and unloading the machine ...............................................................................4

4.7 Attention of the maintenance...........................................................................................................4

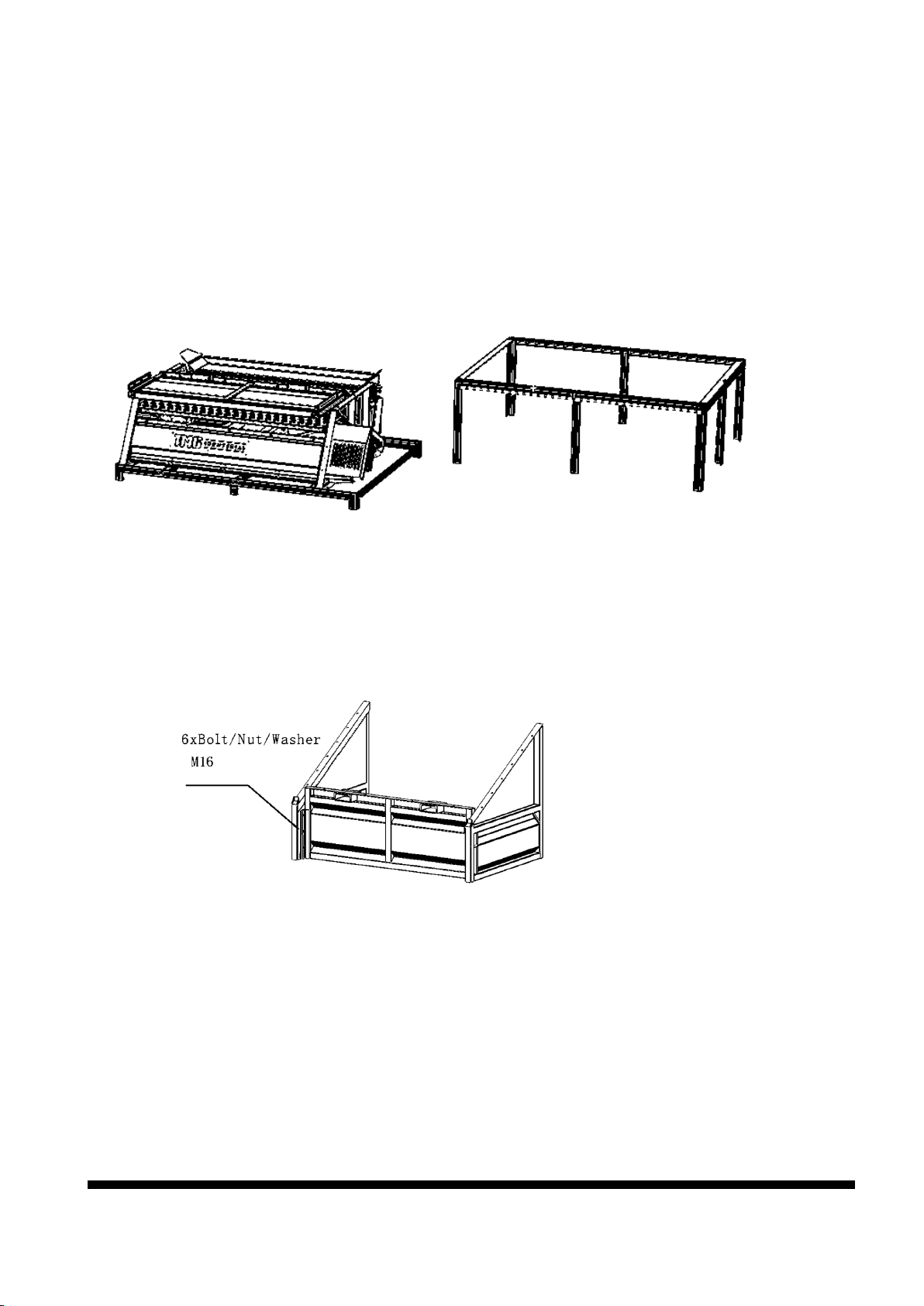

5. SET-UP FOR FIRST USE. ...........................................................................................................................5

5.1 Unpack the package. .......................................................................................................................5

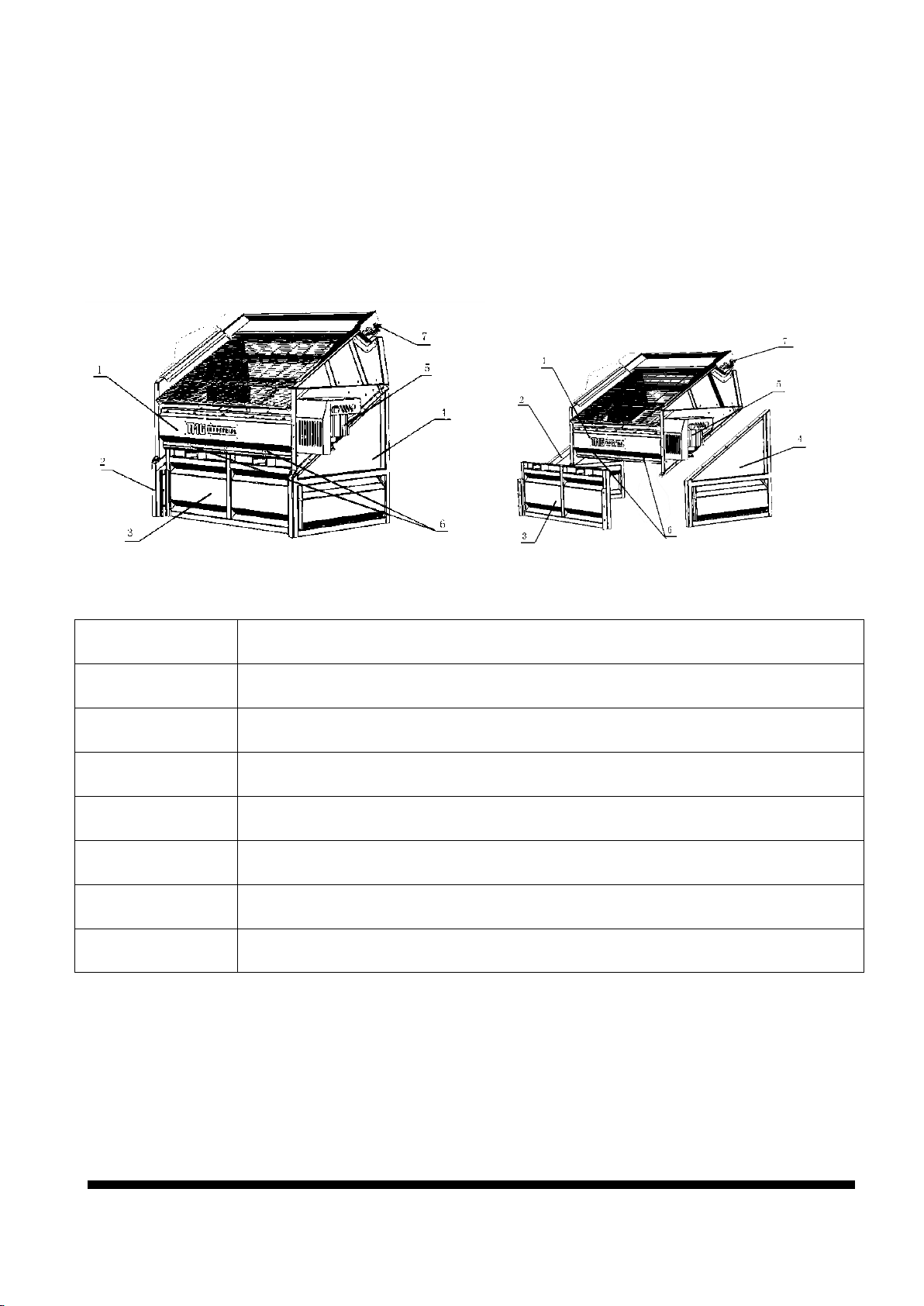

5.2 Assemble the three lower side panels(2,3,4) ....................................................................................5

5.3 Assemble the main body. ..............................................................................................................5

5.4 Tighten all bolts. .............................................................................................................................5

5.5 Check and trial run ..........................................................................................................................5

6. OPERATION. ............................................................................................................................................6

6.1 Inspection before operation.............................................................................................................6

6.2 Start up the engine..........................................................................................................................7

6.3 Machine running .............................................................................................................................7

6.4 Machine stopping............................................................................................................................7

6.6 Machine movement.........................................................................................................................8

6.6 Operation under the low temperature. ..............................................................................................8