Employer/Controller Responsibilities

OH&S legislation places obligations on the employer, or the controller of the Slasher, to identify the hazards and control the risks

associated with the use of the Slasher in their workplace and to do so in accordance with the manufacturer's instructions.

When purchasing a Slasher:

· Ensure the manufacturer's instructions are provided at the point of purchase.

· Ensure the Slasher conforms to industry safety standards.

· Discuss your needs with the supplier, to ensure the Slasher is compatible with the power of your tractor and is appropriate for

The intended application-consider the speed of your tractor's PTO and its compatibility with the Slasher's gearbox.

· Seek practical advice and instruction from the supplier on the use and limitations of the Slasher. If you are hiring, leasing or

borrowing a Slasher on a temporary basis, get safe use instructions from the person supplying it.

· The employer must provide safety instructions to all those involved in using a Slasher.

· A copy of safety instructions must be kept in good condition with the Slasher.

· Generally, the safety instructions should be the manufacturer's instructions. Any variations from the manufacturer's

instructions must be based on a risk assessment and must not remove any of the safety features nor expose anyone to risks.

Supervision, Instruction and Training

The employer must provide safe systems of work, adequate supervision, instruction and training to all those involved in using a

Slasher. They must be instructed in the safe operation of the Slasher, including hazards specific to the workplace, including the

terrain, stability of the tractor, working environment and the like. The employer should ensure that everyone achieves a level of

understanding that enables them to safely and competently operate the Slasher.

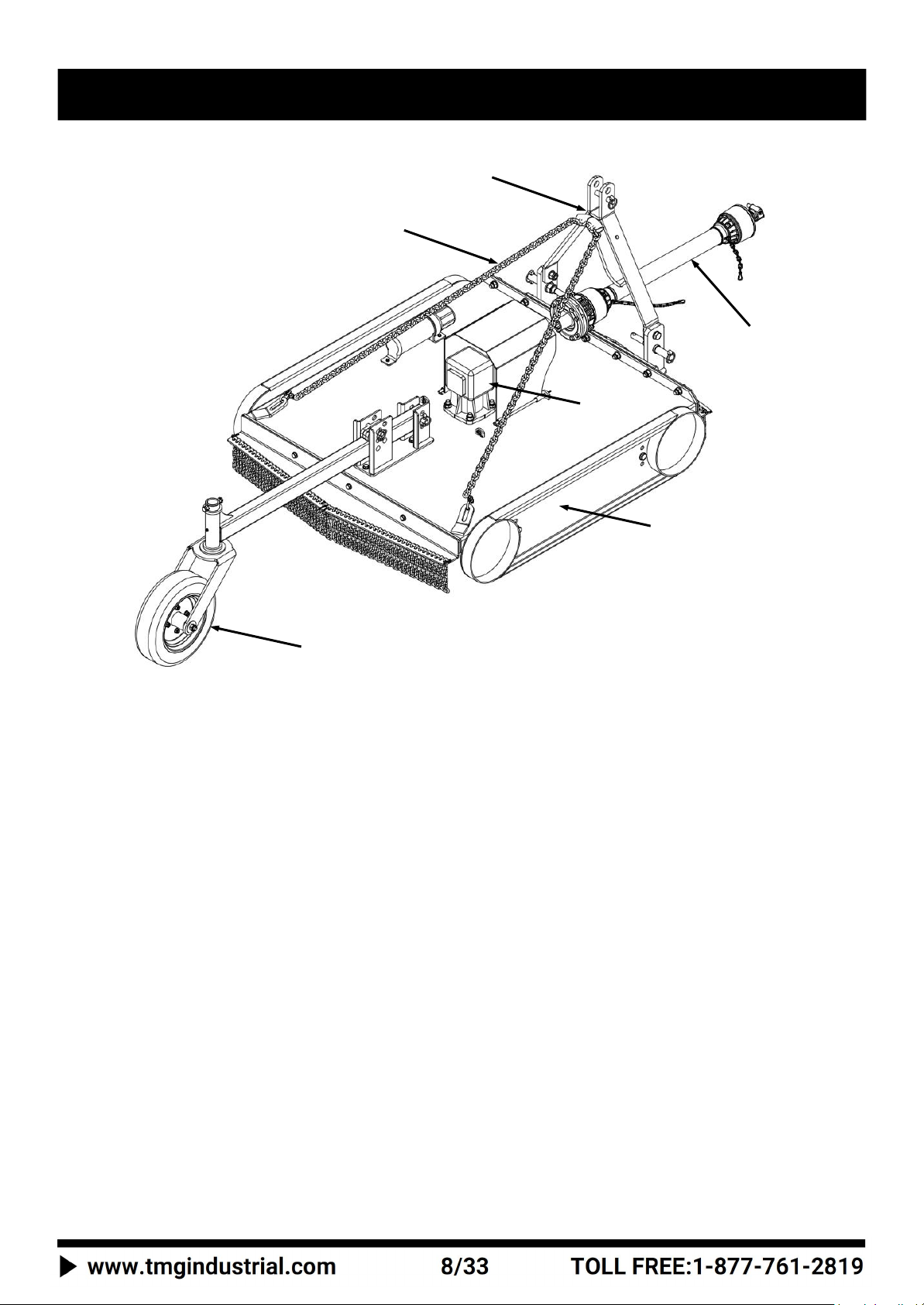

Inspection,Maintenance and Repair

· The Slasher must be inspected according to the manufacturer's instructions, prior to use. See page 25 for Maintenance

Instructions.

· All problems identified must be rectified,prior to use.

· The Slasher must be maintained according to the manufacturer's instructions.

· Replacement parts must be to the original manufacturer's specifications or their equivalent.

· Safety signs and decals should be legible,maintained and where necessary replaced. ·Repairs should be carried out by a

competent person.

· When suspending the Slasher for maintenance or repair, whether attached to the tractor or suspended in another way, adequate

safety stands must be used to prevent inadvertent lowering of the Slasher.

Service and Maintenance Safety

· Stop engine, set brake, remove ignition key and wait for all moving parts to stop before servicing, adjusting, repairing or

unplugging.

· Support the equipment with blocks or safety stands before working beneath it.

· Follow good shop practices including:

-keep service area clean and dry

-be sure electrical outlets and tools are properly grounded

-use adequate light for the job.

· Use only tools, jacks and hoists of sufficient capacity for the job.

· Replace and secure all shields removed during servicing before operating.

· Use heavy leather gloves to handle sharp objects.