INTRODUCTION..................................................................................................................................................................................4

Manual Accuracy............................................................................................................................................................4

Machine Description.........................................................................................................................................................4

Identification.....................................................................................................................................................................4

PRODUCTS SPECIFICATIONS.............................................................................................................................................................5

SECTION 1:SAFETY.............................................................................................................................................................................6

Safety Instructions for Machinery.....................................................................................................................................6

Additional Safety for Blast Cabinets.................................................................................................................................7

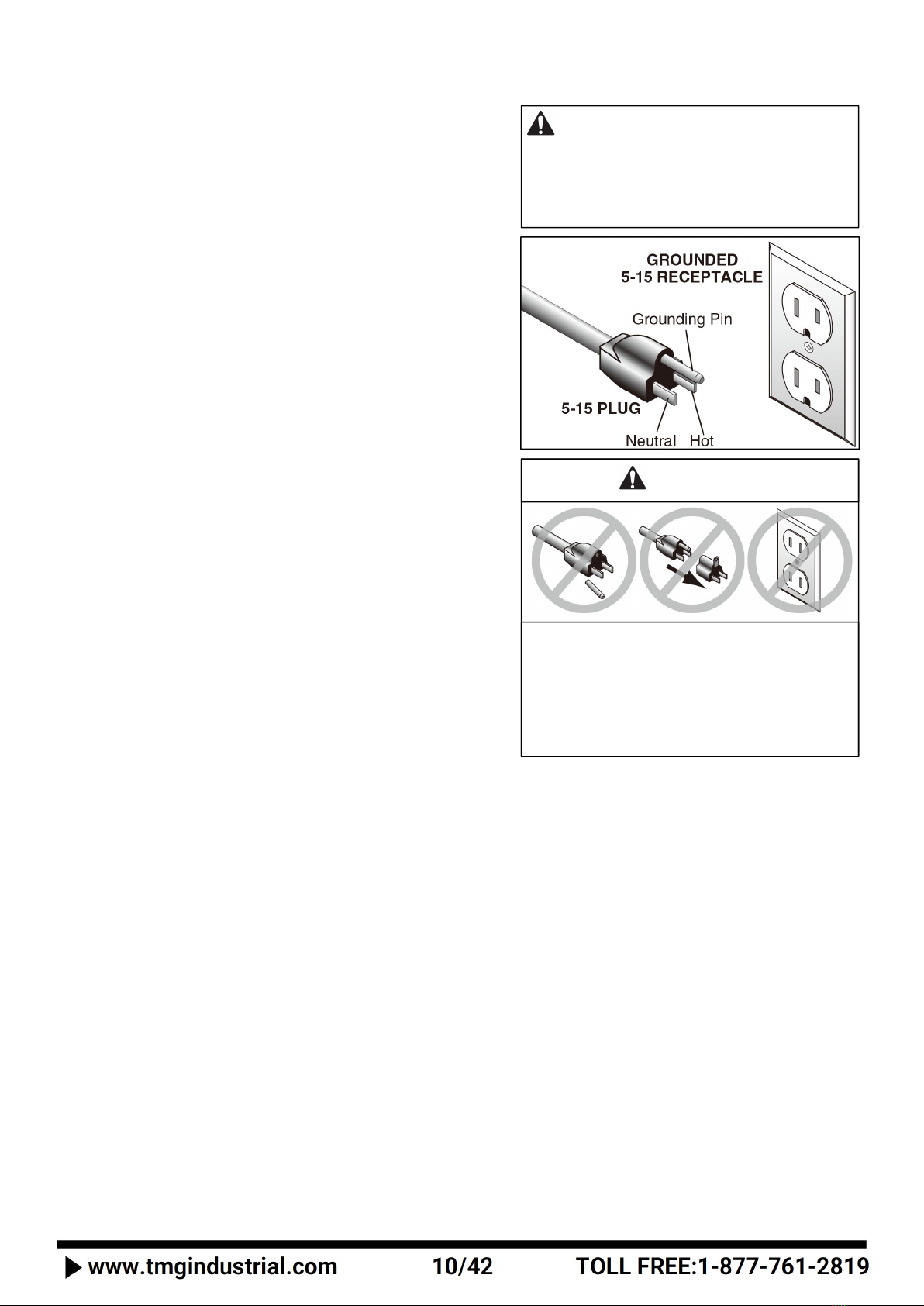

SECTION 2: POWER SUPPLY..............................................................................................................................................................9

SECTION 3:SETUP............................................................................................................................................................................11

Needed for Setup............................................................................................................................................................11

Unpacking.......................................................................................................................................................................11

Inventory.........................................................................................................................................................................11

Site Considerations........................................................................................................................................................12

Mounting........................................................................................................................................................................13

Air System Setup............................................................................................................................................................14

Pneumatic Diagram........................................................................................................................................................15

Assembly........................................................................................................................................................................16

Test Run..........................................................................................................................................................................20

SECTION 4: OPERATIONS.................................................................................................................................................................21

Preparation.....................................................................................................................................................................21

Basic Operation..............................................................................................................................................................21

Operation Tips................................................................................................................................................................23

Blasting Media................................................................................................................................................................25

SECTION 5: MAINTENANCE..............................................................................................................................................................27

Schedule ........................................................................................................................................................................27

Cleaning..........................................................................................................................................................................27

SECTION 6: SERVICE........................................................................................................................................................................28

Troubleshooting.............................................................................................................................................................28

Filter Replacement..........................................................................................................................................................29

Motor Brush Replacement..............................................................................................................................................29

LED Replacement............................................................................................................................................................32

SECTION 7: WIRING..........................................................................................................................................................................34

Wiring Safety Instructions..............................................................................................................................................34

Wiring Diagram...............................................................................................................................................................35

Wiring Components........................................................................................................................................................36

SECTION 8: SAFETY LABELS............................................................................................................................................................36

SECTION 9: EXPLODED VIEW & PARTS LIST....................................................................................................................................37

Master Exploded View....................................................................................................................................................37

Master Parts List ...........................................................................................................................................................38

Blast Cabinet Exploded View .........................................................................................................................................39

Blast Cabinet Parts List..................................................................................................................................................40

Dust Collector Assembly Parts List................................................................................................................................40

Dust Collector Assembly Exploded View........................................................................................................................41

LED Light Assembly Exploded View................................................................................................................................42

LED Light Assembly Parts List .......................................................................................................................................42

Electrical Box Assembly Exploded View.........................................................................................................................42

Electrical Box Assembly Parts List ................................................................................................................................42