Contents

1. Introduction....................................................................................................................................................................................02

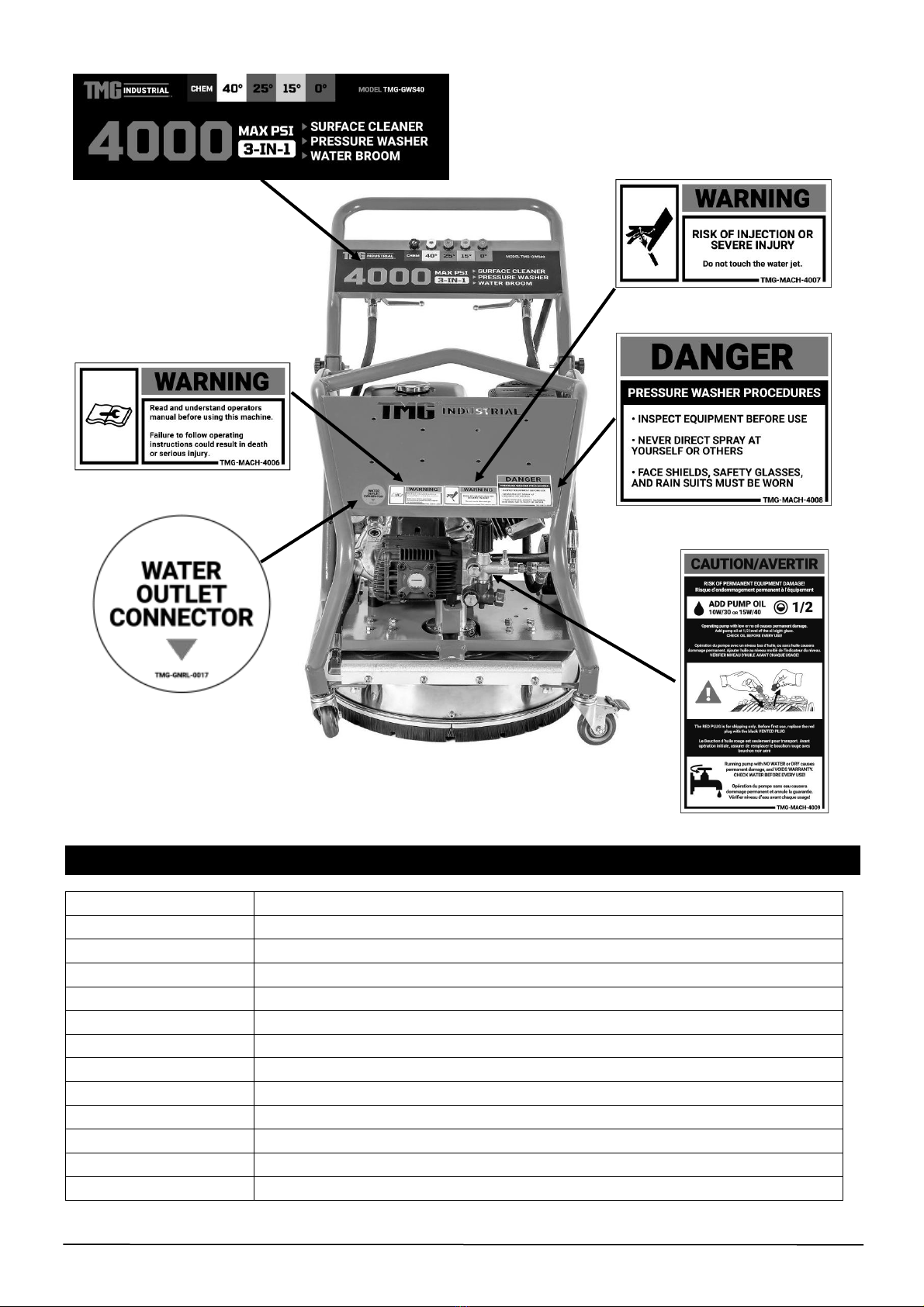

2. Products Identification...................................................................................................................................................................03

3. Safety Guidelines...........................................................................................................................................................................03

4. Products Specifications.................................................................................................................................................................07

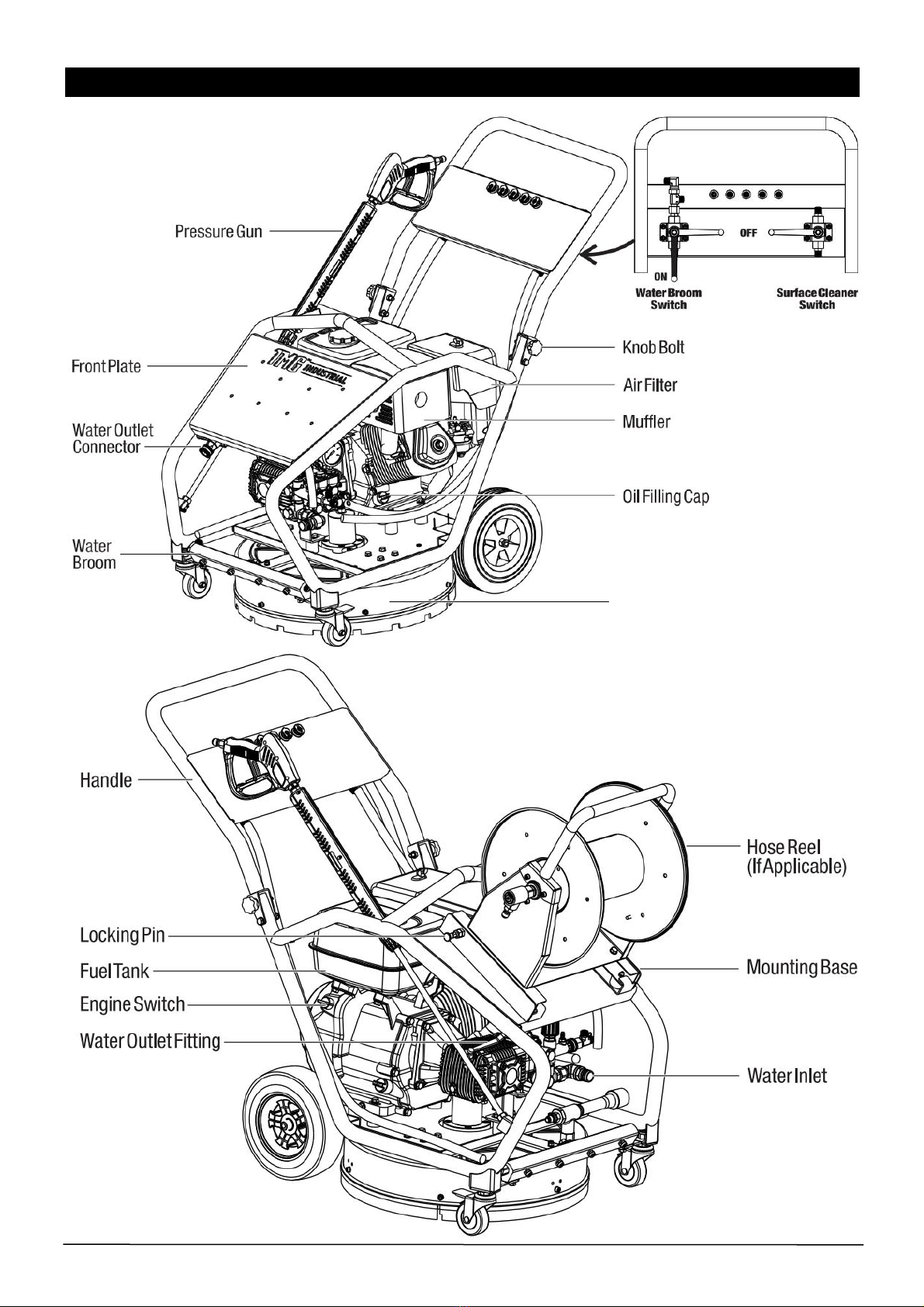

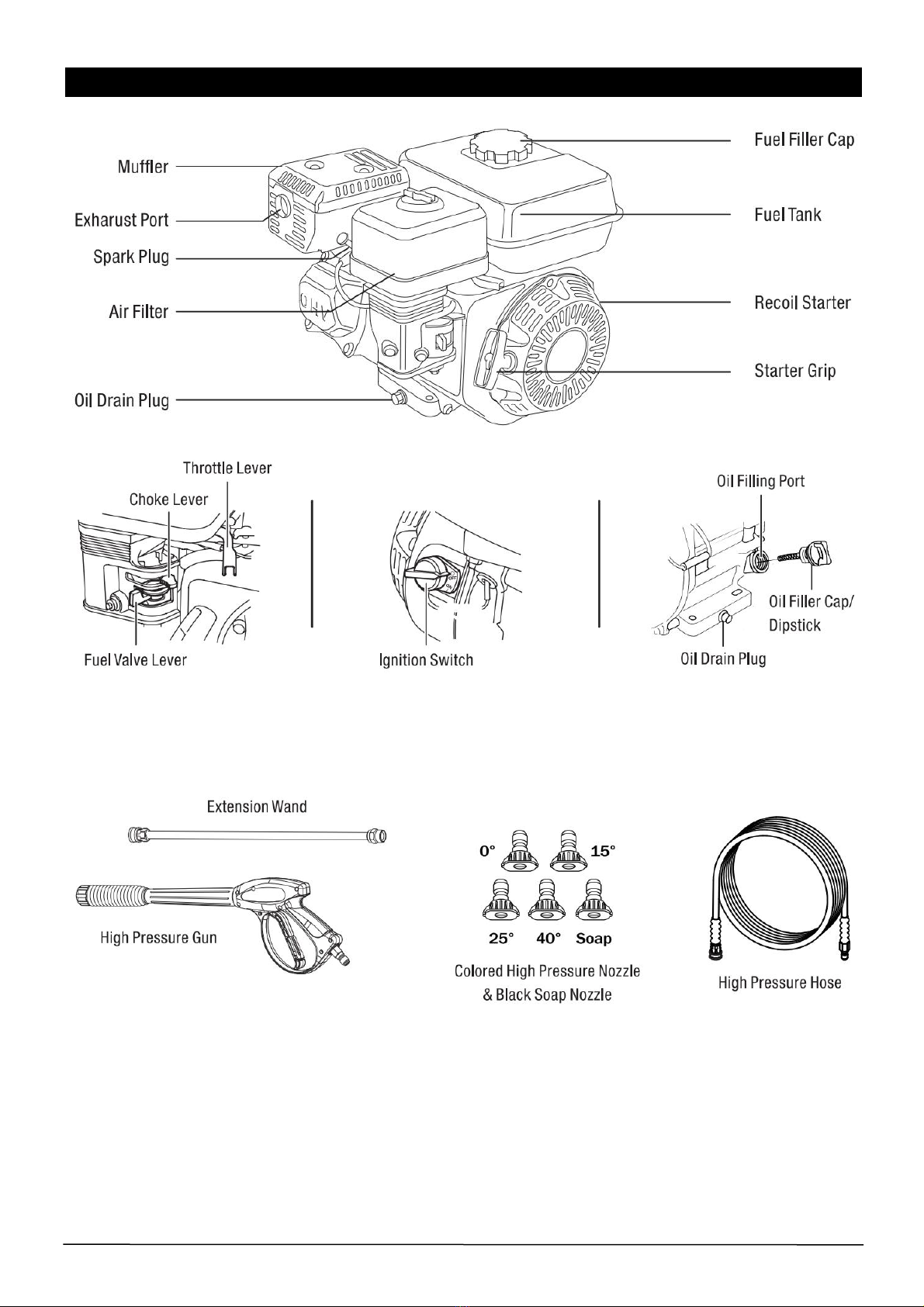

5. Parts Identification and Features...................................................................................................................................................08

6. Unpacking &Assembly...................................................................................................................................................................12

7. Setting Up the Before Use.............................................................................................................................................................12

8. Safe Working Environment............................................................................................................................................................15

9. Start up and Stopping Procedure..................................................................................................................................................16

10. Operation.......................................................................................................................................................................................17

11. Stopping the Pressure Washer......................................................................................................................................................18

12. Using Nozzles................................................................................................................................................................................18

13. Adjusting Spray Pressure..............................................................................................................................................................19

14. Using Chemicals & Detergents......................................................................................................................................................19

15. Maintenance..................................................................................................................................................................................20

16. Storage.......................................................................................................................................................................................... 22

17. Troubleshooting.............................................................................................................................................................................23

18. Pressure Washer Exploded View & Parts List................................................................................................................................26

Disclaimer:

The information in this document is to the best of our knowledge true and accurate, but all

recommendations or suggestions are made without guarantee. Since the conditions of use are beyond

their control, the factory disclaim any liability for loss or damage suffered from the use of this data or

suggestions. Furthermore, no liability is accepted if use of any product in accordance with this data or

suggestions infringes any patent. The factory reserve the right to change product specifications and

warranty statements without further notification. All images are for illustration purposes only.

1. Introduction

Thank you for purchasing this Professional Power Equipment Product.

Please read the following instructions carefully to help to ensure your personal safety and the correct assembly, use and

maintenance of this equipment. Please ensure that you have read and understand the information contained in the manual before

attempting to use the equipment. This equipment should only be used by trained and fully competent individuals, in a safe working

environment. Please ensure that the appropriate safety equipment is worn at all times and that the product is not adapted or

modified in anyway.

Please note that the contents of this instruction manual are based on the latest product information available at the time of

publication and that the manufacturer reserves the right to make changes at any time without notice.

W W W . T M G I N D U S T R I A L . C O M P 0 2 / 3 1 T o l l F r e e : 1 - 8 7 7 - 7 6 1 - 2 8 1 9