Onyx by Draper Page 2 of 2

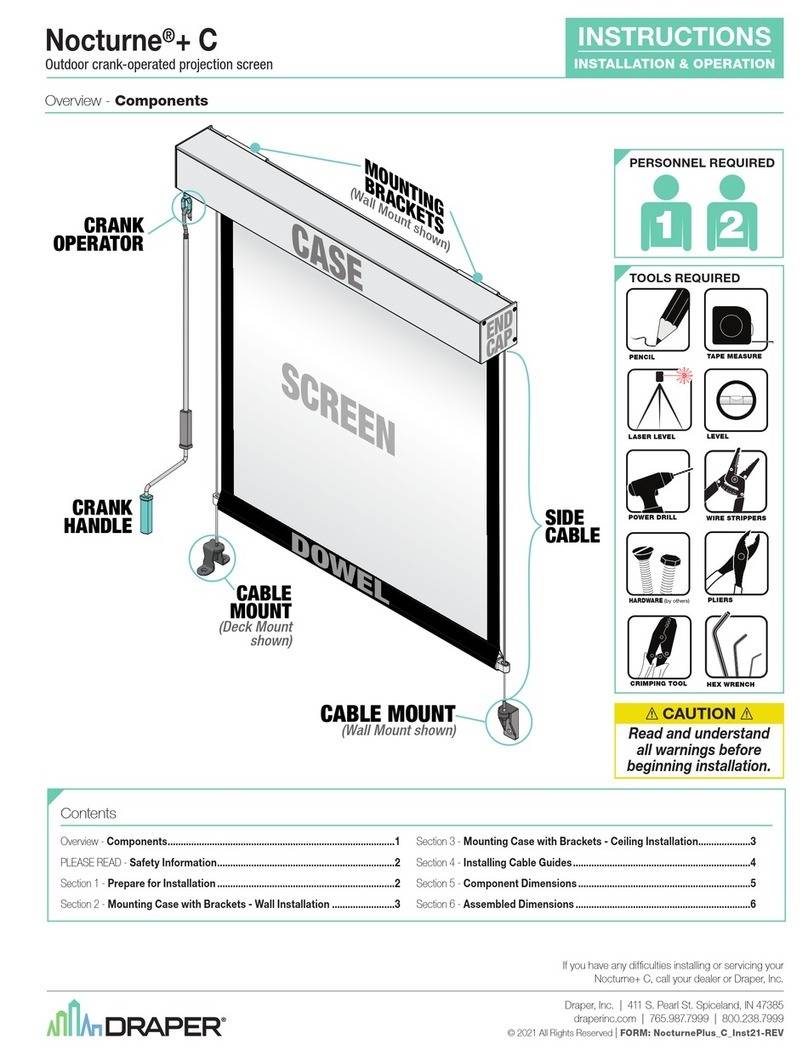

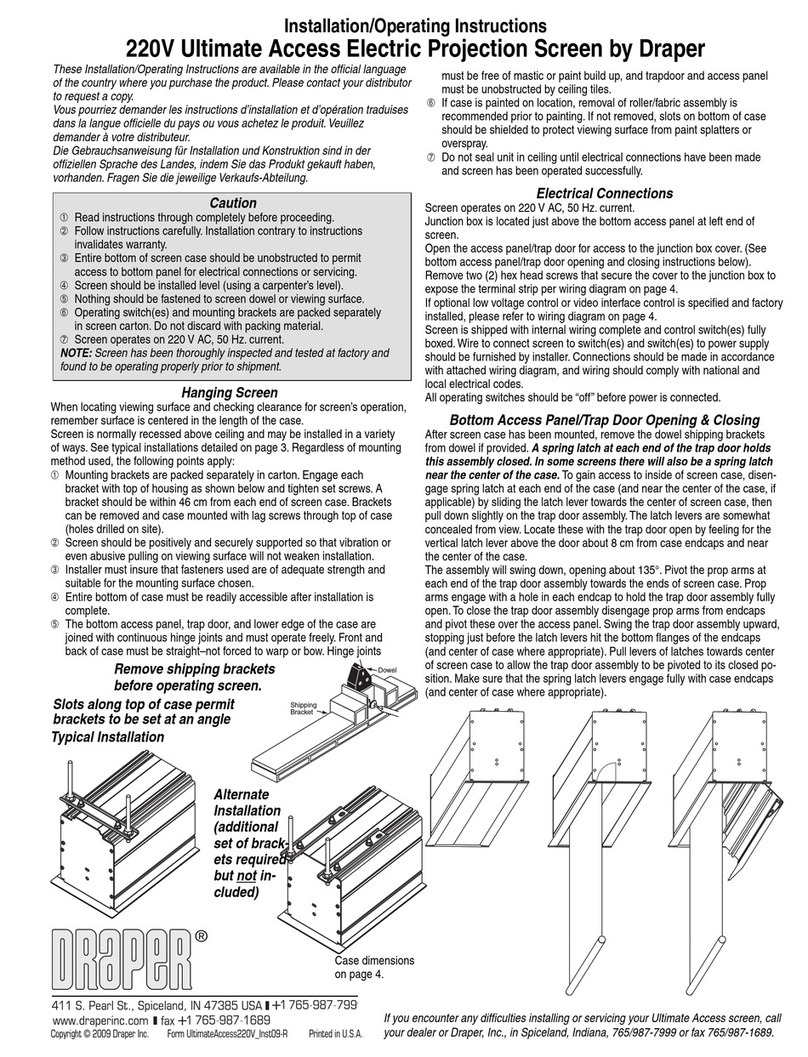

Figure 10

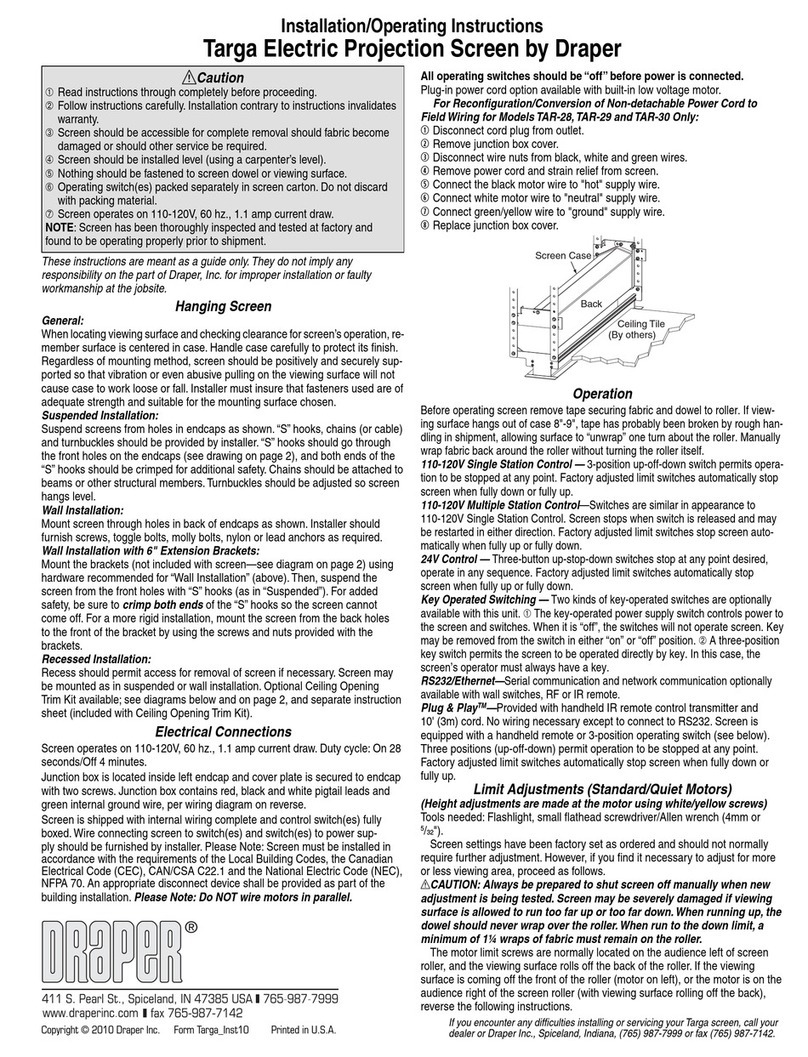

Mounting Screen to Wall

1Determine height at which screen is to be mounted.

Please Note: Top edge of screen frame will be located 1" above mounting

bracket hole centerline when mounted to wall.

2Mark hole centerline so that both wall brackets can be mounted parallel

and at equal height.

3Install wall brackets so that the outermost edges are safely within overall

length of the aluminum frame extrusion to allow for minor horizontal screen

adjustments. Installer is responsible for providing attachment hardware.

4Position screen slightly above Z-brackets on wall (see Fig. 11).

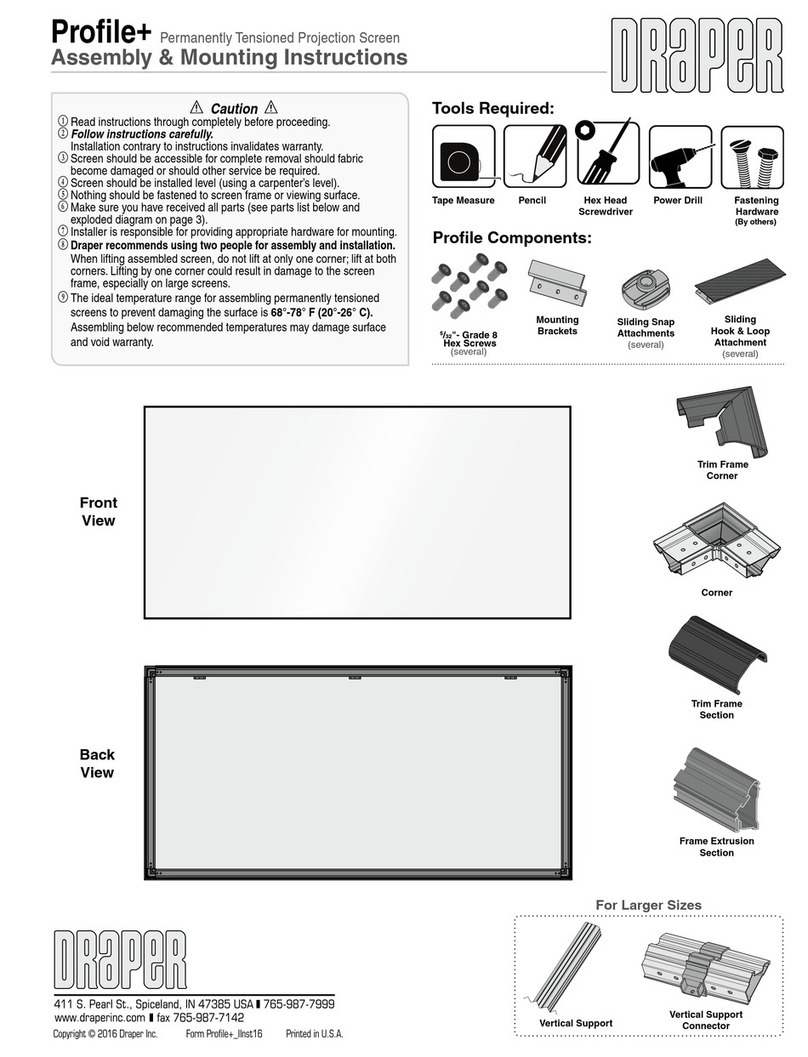

Surface to Frame Assembly

1Return frame onto clean surface, face down, and drape completed surface

assembly over completed frame profile with rounded edge of surface

retention extrusion visible.

2Insert any side of surface to notch #1 on corresponding side of frame

extrusion (see Fig. 10).

3Insert opposite side of surface to notch #1 of frame extrusion.

4Repeat steps 2-3 with remaining edges of surface.

5Ensure surface retention extrusions are centered lengthwise in tension

slots on all 4 edges of surface.

6If additional tension is desired or required over time, adjust surface one

edge at a time to tension notch #2.

Please Note: It is not necessary to adjust more than one edge at a time to

increase surface tension.

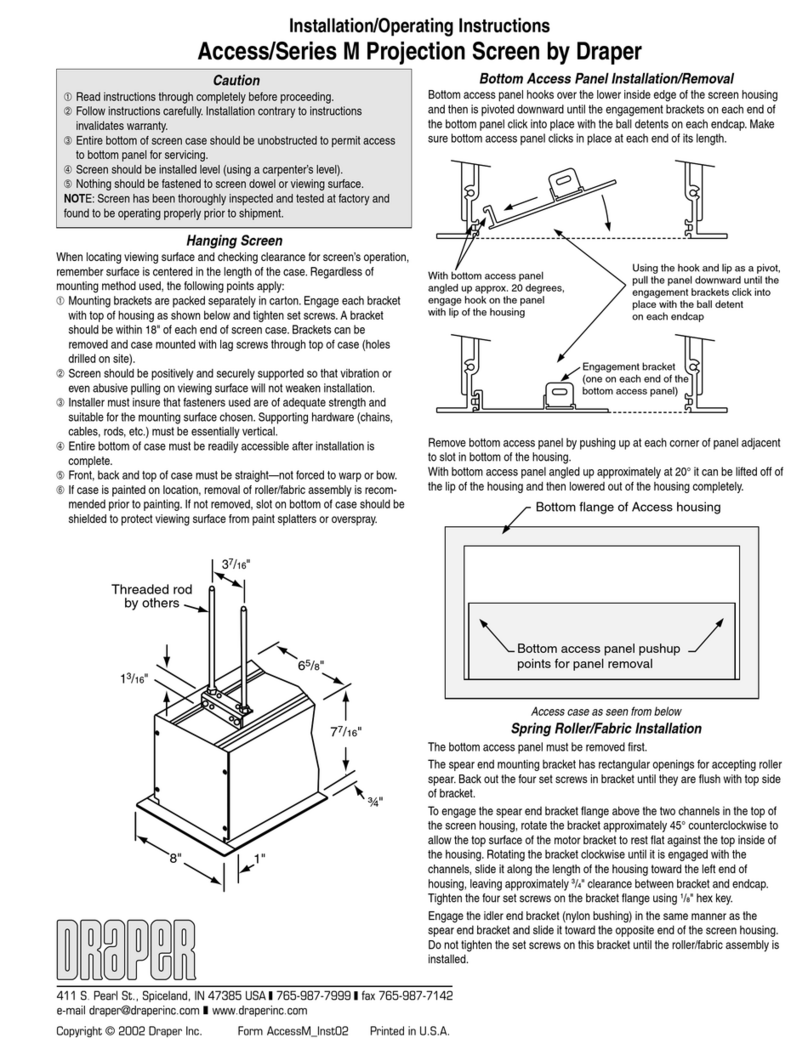

Figure 11

5Lower screen until it engages over wall brackets. Center screen horizontally

on brackets as necessary.

Please Note: Make sure screen is installed level.

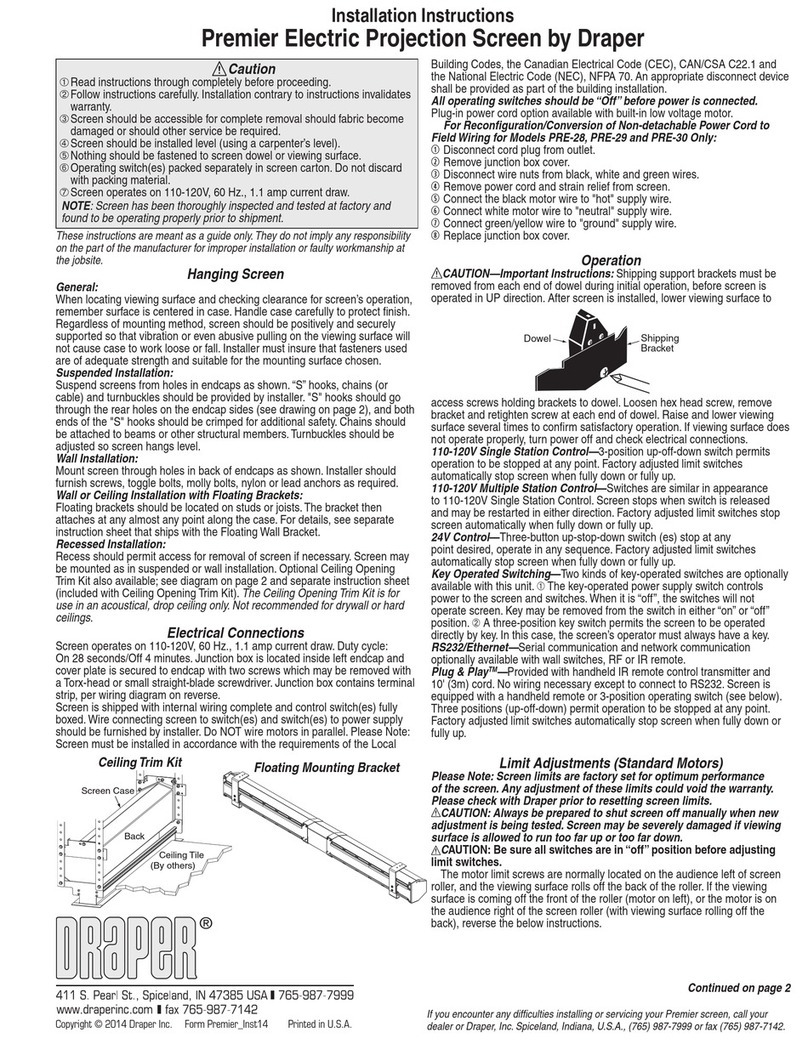

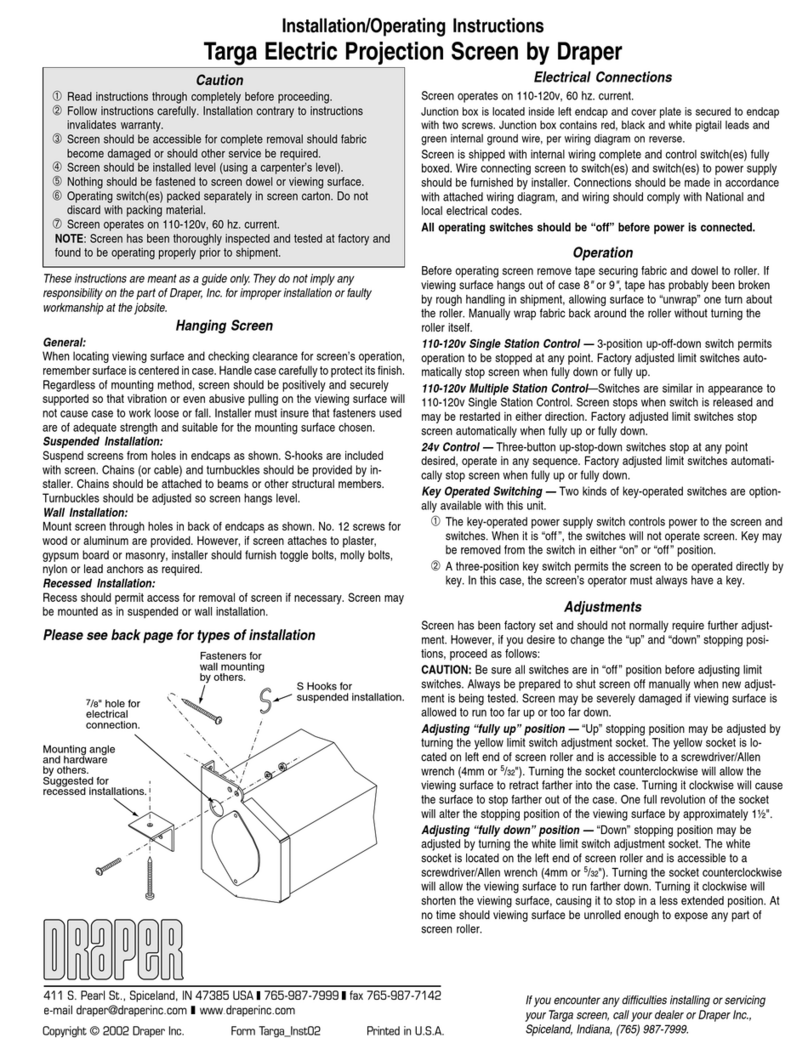

Figure 8

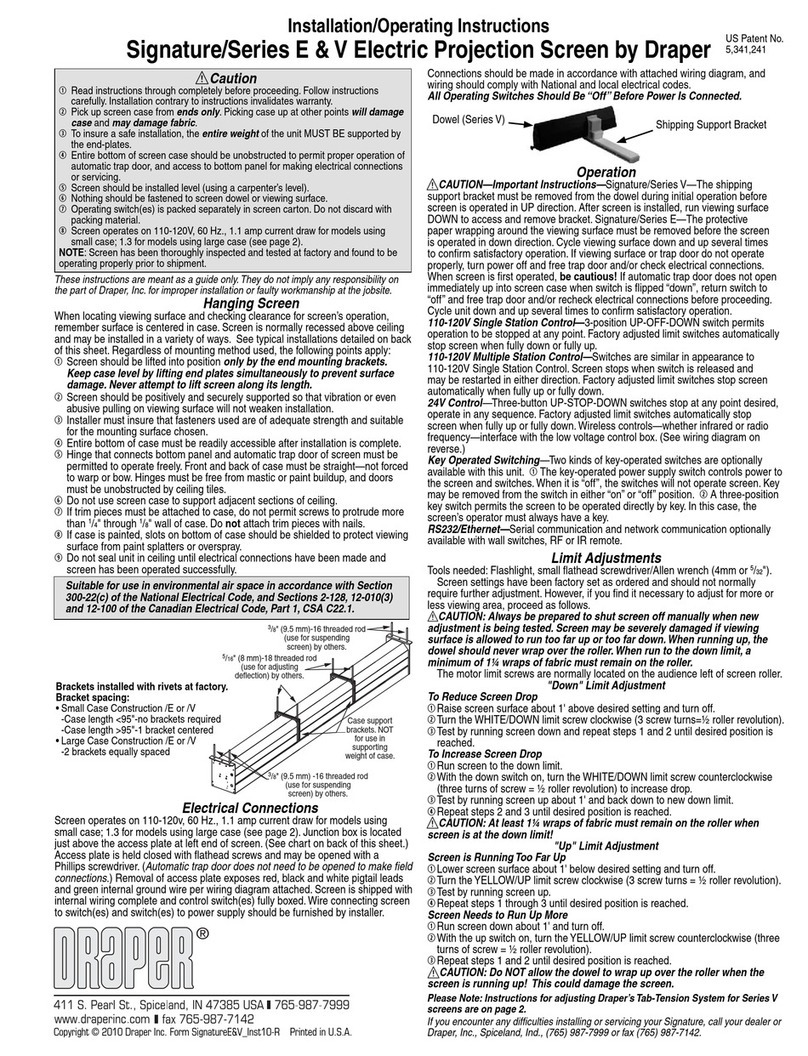

Surface Preparation

1Move frame assembly out of the way, unroll viewing surface and place on

smooth/clean surface. Orient viewing surface so that folded side of hem is

visible.

2Insert plastic tubing inside pocket formed by hem on all 4 edges of viewing

surface (see Fig. 8).

3Carefully slide surface retention extrusion (rounded edge visible) along

hem and onto surface on all 4 edges of fabric (see Fig. 9). Caution: Do

not allow fabric to snag on end of extrusion. If the screen

fabric is not parallel with the surface retention extrusion, then

it may slit and tear during installation.

Please Note: To make this step easier, pinch the end of the pocket closed

before sliding it into the surface retention extrusion.

Figure 9

4Surface retention extrusion should extend beyond edge of viewing surface

equally at both ends.

5Verify that all surface retention extrusions are installed with rounded edge

visible and are centered on surface material.

Plastic Tubing

Surface Retention

Extrusion

Back of

Viewing Surface

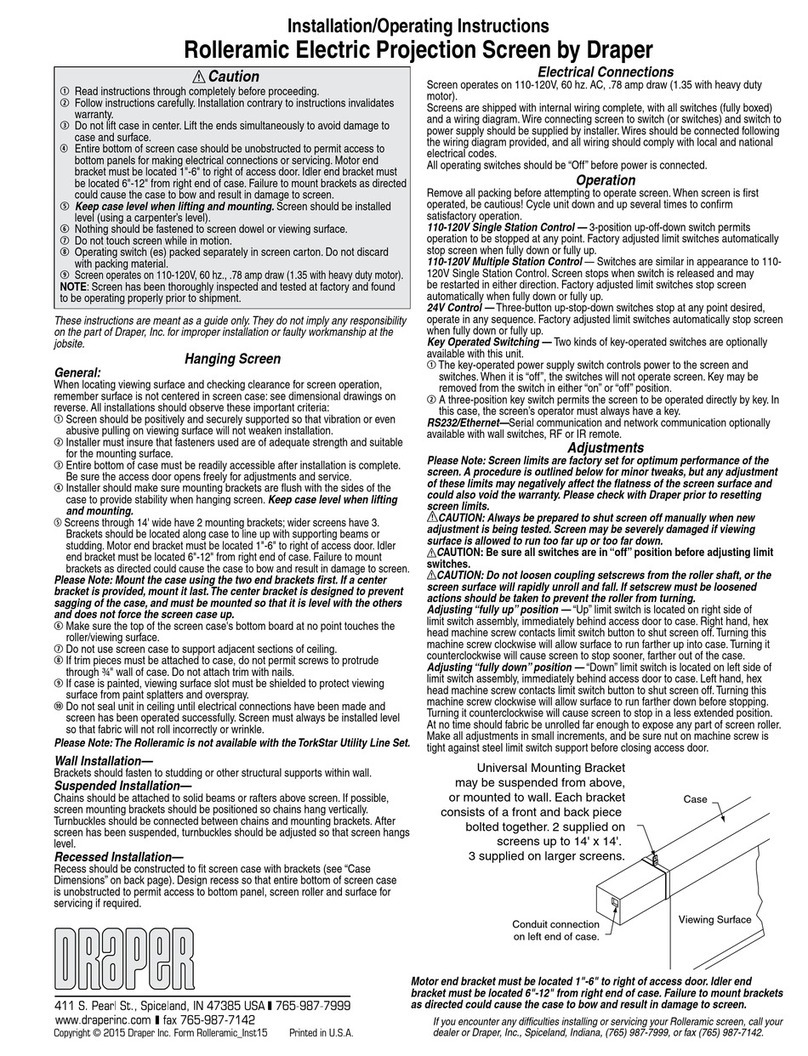

Onyx (Exploded Rear View)Onyx Frame

—Side Detail*

*Viewing surface is approximately ¼" from wall.

.draperinc.com (765) 987-799

Wall brackets

supplied with

screen. Installer is

responsible for

ensuring appropriate

screws/bolts are used.

Wall

Retention

Extrusion

Fabric Attachment Extrusions

Viewing

Surface

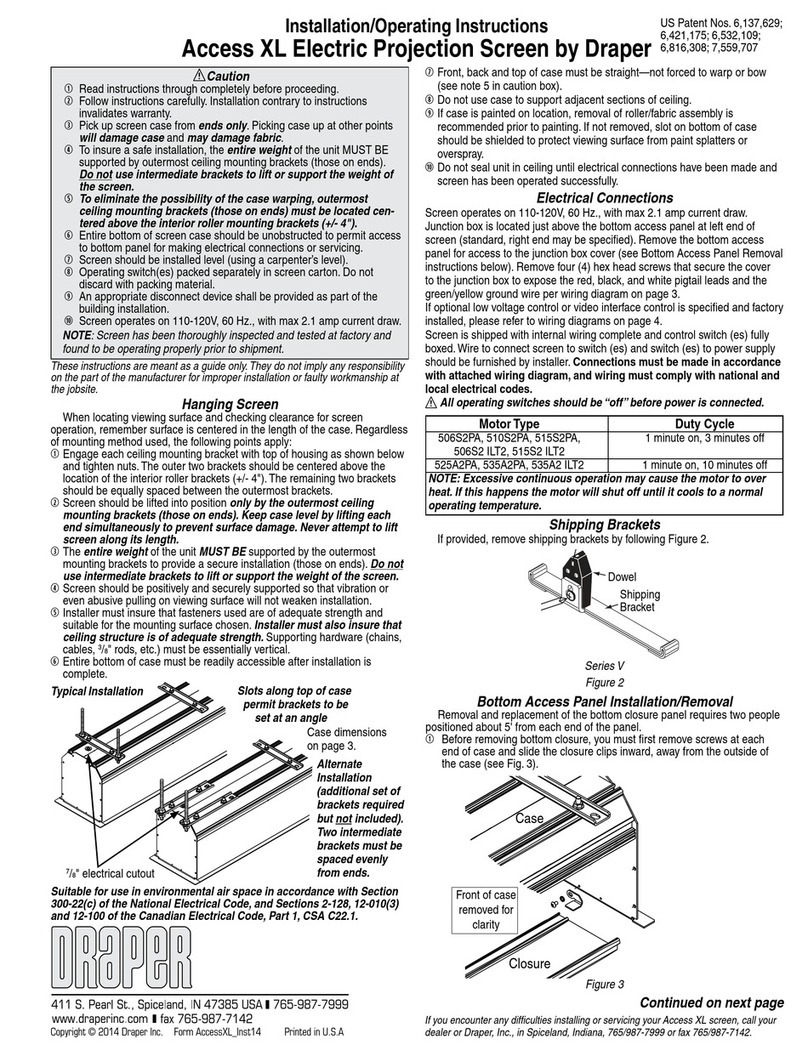

Corner Reinforcement Kit

A Corner Reinforcement kit is required for flown screens. Corner gussets

may only be installed after screen is otherwise completely assembled

(including surface).

1Install frame per Onyx instructions.

2Align corner gusset plate to frame.

3Install the supplied #10-24 x .250" fastener (A) into tapped hole in corner

bracket.

4 Align corner gusset plate parallel with the outer edges of the frame.

5 Drill one hole through frame (using holes in gusset plate as a guide) with

1

/

8

" or #30 drill bit.

6 Install one of the #8 x .750" self-threading fasteners (B) into the hole, and

tighten completely to set the plate in position.

7 Drill the remaining three holes using the gusset plate as a guide.

8 Install the remaining three #8 x .750" self-threading fasteners (B) and

tighten completely to set the plate in position.

Repeat the above steps on the remaining three corners of the screen.

Figure 12

A

B

B

B