TOA-DKK CD-36D User manual

Please keep this instruction manual close at hand of the persons who are in charge of

the operation of this product.

Before operating this product, please read this instruction manual carefully for its

correct handling.

REAGENTLESS FREE

CHLORINE ANALYZER

MODEL CD-36D

(Including explanation on the sensor)

No. CD3-IB21928E

Model: CD-36D Table of Contents

-

1

-

Table of Contents

●Safety Information·······························································································3

(1) Notes on use of the instruction manual ⋅⋅⋅⋅ 3

(2) Meaning of markings ⋅⋅⋅⋅ 3

(3) Safety precautions ⋅⋅⋅⋅ 4

●Warranty·······················································································································5

1. General ·····················································································································6

(1) Outline of Start-up Procedure ⋅⋅⋅⋅ 6

(2) Configuration of the Transmitter for the Measuring System ⋅⋅⋅⋅ 6

(3) External View ⋅⋅⋅⋅ 8

2. Names of Major Parts··················································································9

3. Preparation for Operation······································································10

3.1 Filling of Beads ···································································································· 10

3.2 Filling of Sodium Chloride Tablets ········································································11

3.3 Introduction of Sample Water················································································12

4. Operation ··············································································································14

4.1 Start-up Procedure ··································································································14

4.2 Shutdown of Operation····························································································16

5. Calibration············································································································17

(1) Zero Calibration ⋅⋅⋅⋅ 17

(2) Span Calibration ⋅⋅⋅⋅ 18

6. Setting of Measuring Range and Output Signal···············20

6.1 Setting of Measuring Range··················································································20

6.2 Setting of Output Signal in “Maintenance”mode················································21

7. Maintenance·······································································································23

7.1 Maintenance Items·································································································23

7.2 Yearly Consumables and Spare Parts··································································24

7.3 Cleaning of Detector and Replacement of Sensing Electrode····························24

7.4 Replacement of Beads ··························································································26

7.5 Cleaning of Flow Cell·····························································································28

7.6 Adjustment of Output Signal of the Transmitter···················································29

7.7 Replacement of Fuse·····························································································32

7.8 Overhaul and Replacement of Detector·······························································33

(1) Overhaul of model CLR-21-A detector ⋅⋅⋅⋅ 33

(2) Replacement of CLV Series detector ⋅⋅⋅⋅ 33

Model: CD-36D Table of Contents

-

2

-

8. Installation············································································································34

8.1 Installation of Flow Cell and Detector···································································34

8.2 Installation of Transmitter······················································································35

(1) Selection of Installation Site for the Transmitter ⋅⋅⋅⋅ 35

(2) Installation Method ⋅⋅⋅⋅ 35

8.3 Wiring······················································································································36

(1) Wiring Diagram ⋅⋅⋅⋅ 36

(2) Wiring for the Transmitter ⋅⋅⋅⋅ 37

8.4 Piping······················································································································38

9. Option·······················································································································39

(1) Conductivity modifying column, Model: CLZ-2 ⋅⋅⋅⋅ 39

(2) Flow Cell, Model: CLZ-4 ⋅⋅⋅⋅ 41

(3) Pole Stand, Model: B150 ⋅⋅⋅⋅ 42

10. Specifications····································································································43

(1) Basic Specifications ⋅⋅⋅⋅ 43

(2) Performance ⋅⋅⋅⋅ 44

(Last page ⋅⋅⋅⋅ 44)

Model: CD-36D Safety Information

-

3

-

Safety Information

(1) Notes on use of the instruction manual

Important items for safety are described in this manual such as notations of warning and caution.

Please handle the instruction manual as follows:

(a)The instruction manual is required not only at the start of operation but also required when

maintenance is performed or in case a failure occurs. Please keep the manual at hand all the time.

(b)If the manual is lost or too smeared to read, please order a new copy through your local sales agent

or directly from our sales office.

(c)Some of the diagrams used in the manual or on warning labels (affixed to the product) may be

modified with part of its shapes or displays omitted or they may be described in abstract form. In

addition, numbers etc. shown on the display are examples for such cases.

(d)The contents of the manual may be changed without prior notice for reasons such as to improve

performance.

(e)Intellectual property right of the manual belongs to DKK-TOA. Do not disclose all or part of the

manual to third parties without prior notice.

(2) Meaning of markings

Meaning of symbols and markings used in notations of warning and caution in the instruction manual

and on warning labels are described below. In addition, the alert symbol ( ) of warning labels is

meant to notify the existence of hazard and it also means “See the Instruction Manual.”

:

Indicates a potentially hazardous situation which can lead to death or serious injury if you do not

follow instructions.

Serious injury means an injury such as loss of sight, burns (high temperature or low temperature),

electric shock, bone fracture and poisoning, and the aftereffects of the injury remains or the injury

requires hospitalization or long periods of outpatient treatment.

:

Indicates a potentially hazardous situation which can result in minor injury or property damage if you

do not follow instructions.

Minor injury means an injury not requiring hospitalization or long periods of outpatient treatment.

Property damage refers to damage that affects property around the product such as equipment and

buildings (wide-ranging damage).

【IMPORTANT】: Indicates important matters such as to prevent damage to the product main body,

prevent data destruction, prevent wasting time, and maintain performance.

〔NOTE〕 : Indicates comments, reasons, background information, a case example and other

items to help the reader understand the meaning.

: Indicates reference items.

①, ②, ③: Indicates item numbers such as the ones used in operations.

Model: CD-36D Safety Information

-

4

-

(3) Safety precautions

Power Supply

Do not connect power supply exceeding the specification limit. In addition, be careful

not to connect erroneously to other terminals.

Gasses

Do no use this instrument in a location where hazardous gas such as explosive gas,

corrosive gas or flammable gas exists. This kind of gas can cause explosion or fire.

Electric Shock

Do not touch internal as well as external connection terminals while power is applied.

Touching terminals can cause electric shock.

Make sure to install grounding wire. Otherwise, electric shock can result if a problem

occurs in the power supply system.

Replacement Parts

For replacement parts such as piping materials, use parts specified by DKK-TOA.

Using any other parts can result in a failure or damage.

No Modification

Do not modify the analyzer. In addition, do not disassemble the sections where not

described in this manual. Modifying the analyzer or disassembling the sections not

indicated can result in a failure or damage.

Warning Label Lost

If any warning label affixed to this instrument becomes too difficult to read or lost,

please order a new one through your local sales agent or our sales office and affix it

to its original position.

Disposal

In case you dispose of this instrument or any part of this product, handle it as

industrial waste as specified by law. However the items described above are

excluded.

Model: Warranty

-

5

-

Warranty

(1) Warranty Coverage

DKK-TOA Corporation (DKK-TOA) warrants its products against defective material or workmanship for the warranty

period.

(a) The warranty period is one year from the date of delivery to the original user. If the date of delivery cannot be

specified, the warranty period is 24 months from the month following the date of manufacture shown on the

product nameplate.

(b) Specific written agreements with DKK-TOA, if any, shall take precedence over this warranty.

(c) The limitation of warranty described herein may not apply where applicable laws do not allow such limitation.

(2) Limited Warranty

This warranty does not cover the cases listed below.

(a) Direct or indirect failure or damage caused by the use of the product for a purpose or in a manner not prescribed by

the specifications or the instruction manual for the product.

(b) Direct or indirect failure or damage caused by force majeure, including but not limited to an act of God, natural

disaster such as earthquake, storm and flood damage, and lightning, fire, accident, abnormal voltage, salt damage,

gas damage, labor unrest, acts of war (declared or undeclared), terrorism, .civil strife, or acts of any governmental

jurisdiction.

(c) Failure or damage caused by any repair or modification not authorized by DKK-TOA.

(d) Failure or damage caused by the transport, moving, or dropping of the product after the purchase that is not

attributable to DKK-TOA.

(e) Electrodes and consumables (The warranty period for each part has priority when the period is shorter than that for

the main unit of the product. If the customer requires any part after more than six months from the date of

manufacture, consult DKK-TOA or its distributor.)

(f ) Failure or damage caused by the use of consumables, parts, or software not supplied by DKK-TOA.

(g) Malfunctions or damage caused by the use of connecting equipment not supplied by DKK-TOA.

(h) Loss of data, settings, programs, or software stored on the product not attributable to DKK-TOA.

( i) Any product other than DKK-TOA’s, if specified by the purchaser or user, that incorporates, or is incorporated into

or combined with DKK-TOA’s products (*1). In such cases, this warranty covers DKK-TOA’s products only.

( j ) Any product not under proper maintenance in accordance with the instruction manual furnished by DKK-TOA.

(k) Products without a nameplate (excluding products proved to have been delivered by DKK-TOA).

EXCEPT AS EXPRESSLY SET FORTH IN THE PRECEDING SENTENCES, DKK-TOA MAKES NO

WARRANTY OF ANY KIND WHATSOEVER WITH RESPECT TO ANY PRODUCT. DKK-TOA EXPRESSLY

DISCLAIMS ANY WARANTY IMPLIED BY LAW, INCLUDING BUT NOT LIMITED TO ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

LIMITATION OF REMEDIES: In the event that a defect is discovered within the warranty period, DKK-TOA or its

authorized distributor will, at its option, repair or replace the defective product or its part, or will refund the purchase

price of the product. THIS IS THE EXCLUSIVE REMEDY FOR ANY BREACH OF WARRANTY.

LIMITATION OF DAMAGES: IN NO EVENT SHALL DKK-TOA BE LIABLE FOR ANY INCIDENTAL OR

CONSEQUENTIAL DAMAGES OF ANY KIND FOR BREACH OF ANY WARRANTY, NEGLIGENCE, ON THE

BASIS OF STRICT LIABILITY, OR OTHERWISE.

(3) Others

(a) Product parts for maintenance (*2) will normally be supplied for five years (*3) from the date manufacturing and

sales are discontinued.

(b) The cause of any malfunction or damage shall be determined by a DKK-TOA technician.

(c) For repairs, contact a local distributor in your country or state.

*1: Warranties for products from other companies must be maintained by the user.

*2: Maintenance parts refers to parts that are required to maintain operation of the product.

*3: This five-year period is subject to availability of parts or their replacement.

Model: CD-36D 1. General

-

6

-

1. General

This “Reagentless Free Chlorine Analyzer”, Model: CD-36D (hereinafter, referred to as the

“Transmitter” or “Product”), is designed and manufactured for the purpose of monitoring the residual

free chlorine in the city water and is applicable for your monitoring system to continuously monitor

the city water quality being distributed.

The measured value is delivered as an output signal of 4 to 20mA DC (or 1 to 5V DC depending on

the specifications fixed at the order).

The measuring ranges of the analyzer are shown below depending on the ordered specification.

Normally they cannot be changed once they are chosen.

Measuring range ⋅⋅⋅⋅⋅⋅ Choose one from 0 to 1, 0 to 2, and 0 to 3mg/L (or ppm)

(1) Outline of Start-up Procedure

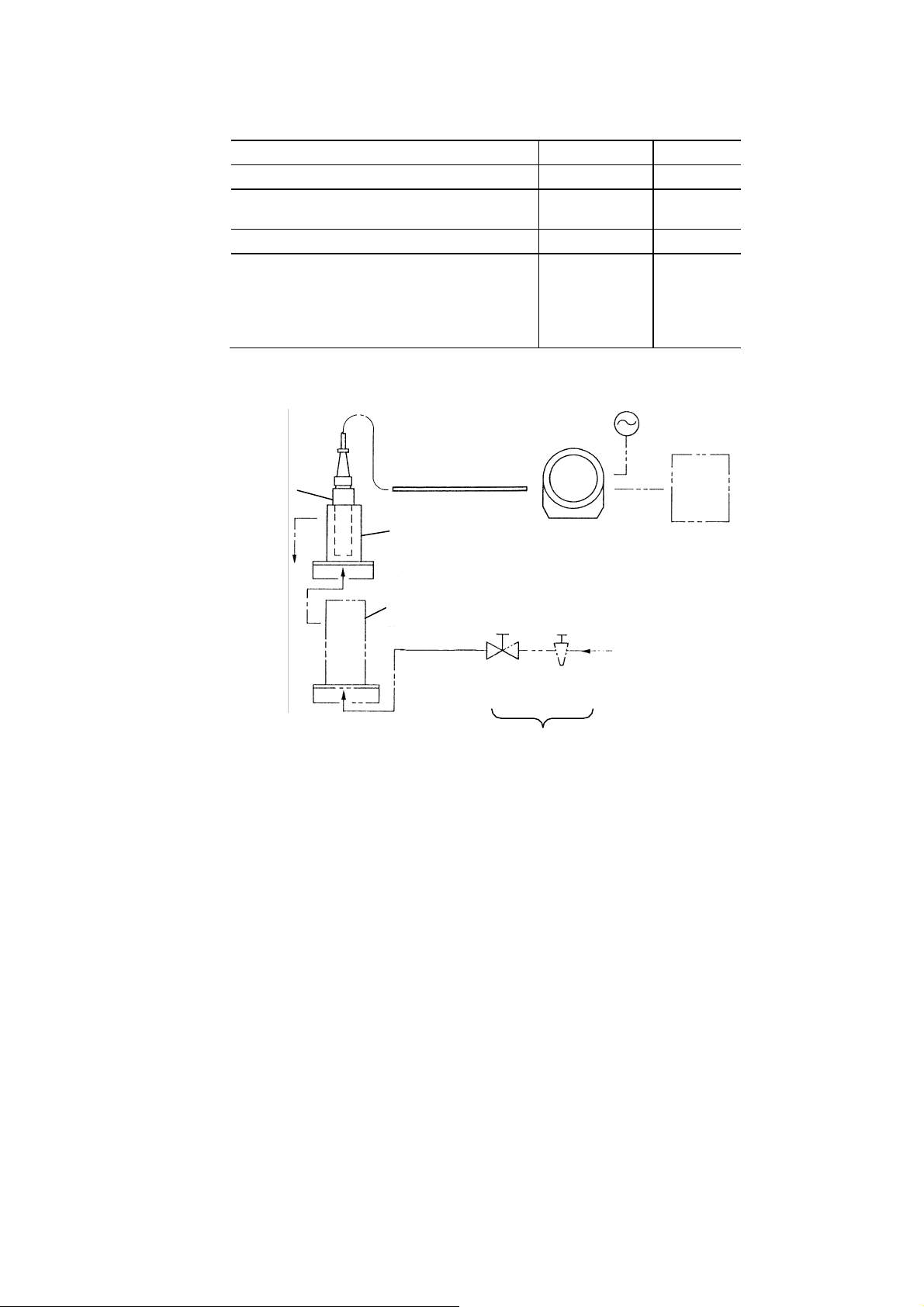

The following table shows the outline of start-up procedure.

Outline of Start-up Procedure

Step Description Reference Section

Installation, piping and wiring “8. Installation”

Filling of beads and introduction of

the city water “3. Preparation for Operation”

To start the operation of the

Transmitter, execute the calibration

according to the instructions. “4. Operation”

Installation

Preparation for Operation

Operation

Normal Operation

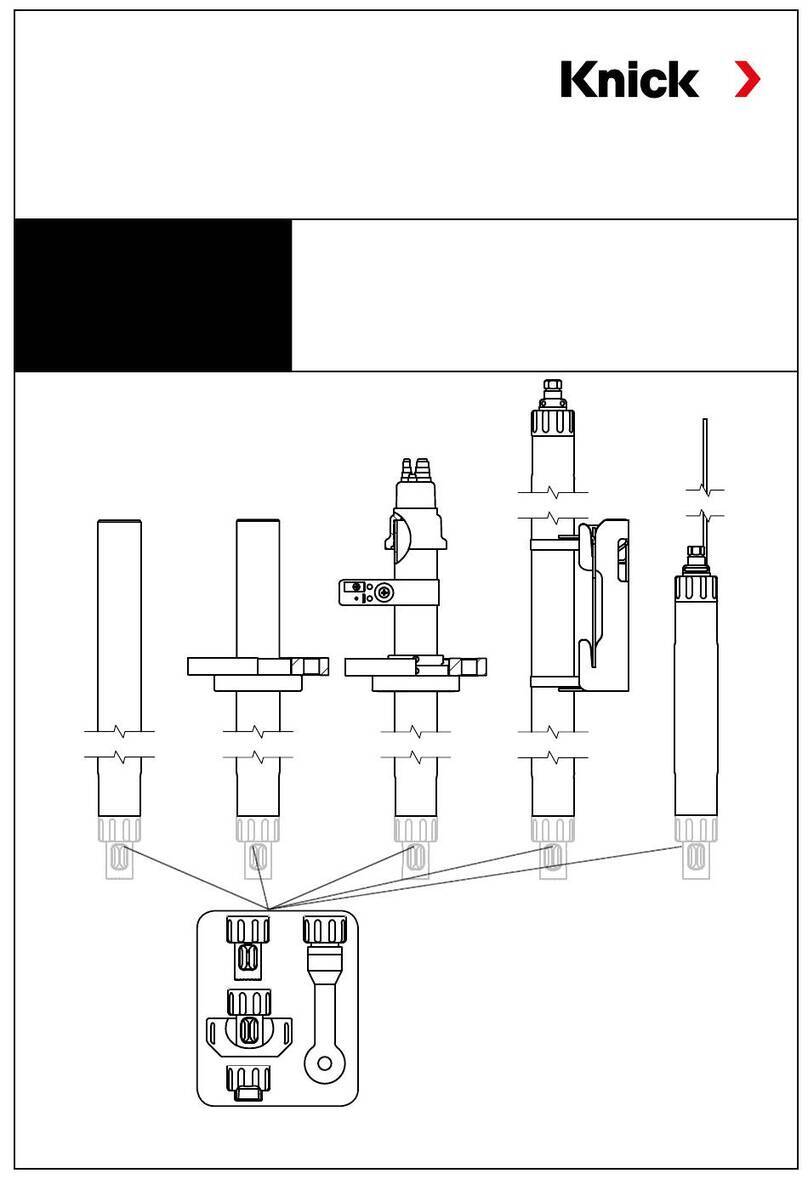

(2) Configuration of the Transmitter for the Measuring System

(a)The reagentless free chlorine analyzer, “Transmitter”, for the measuring system consists of several

elements as described and illustrated in the following table and figure.

(b)The vibrating type residual free chlorine detector, Model: CLV series, is an detector developed for

priority on “easy to handle” and “low cost”. On the other hand, the rotating type residual free

chlorine detector, Model: CLR-21-A, is an detector developed for stable measurement. Therefore,

please specify which detector to be incorporated with the Transmitter when placing order. Note

that the Transmitter needs to be returned to DKK-TOA to change its setting if it is requested to

change the type of the incorporated detector to the other one.

(c)The flow cell, Model: CLZ-4, is made of acrylic and provided with a sampling valve and a flow

regulating valve for laboratory analysis.

Model: CD-36D 1. General

-

7

-

Configuration of the Transmitter for the Measuring System

Item Model Remarks

Reagentless free chlorine analyzer Transmitter CD-36D Transmitter

Vibrating type residual free chlorine detector or

Rotating type residual free chlorine detector CLV series or

CLR-21-A Detector

Flow cell for residual free chlorine detector CLZ-1 Flow cell

[as option]

Column for measurement of pure water CLZ-2 Flow cell

Flow cell for residual free chlorine detector CLZ-4

Pole stand B150

Detector L e a d W i r e s

FlowCell

Model:CLZ-1 Transmitter

Model:CD-36D

Receiver

Columnformeasurement

ofpurewater(option)

Model:CLZ-2

SampleWater

Valve Pressure

Reducer

Notsupplied

Configuration of the Transmitter for the Measuring System

Model: CD-36D 1. General

-

8

-

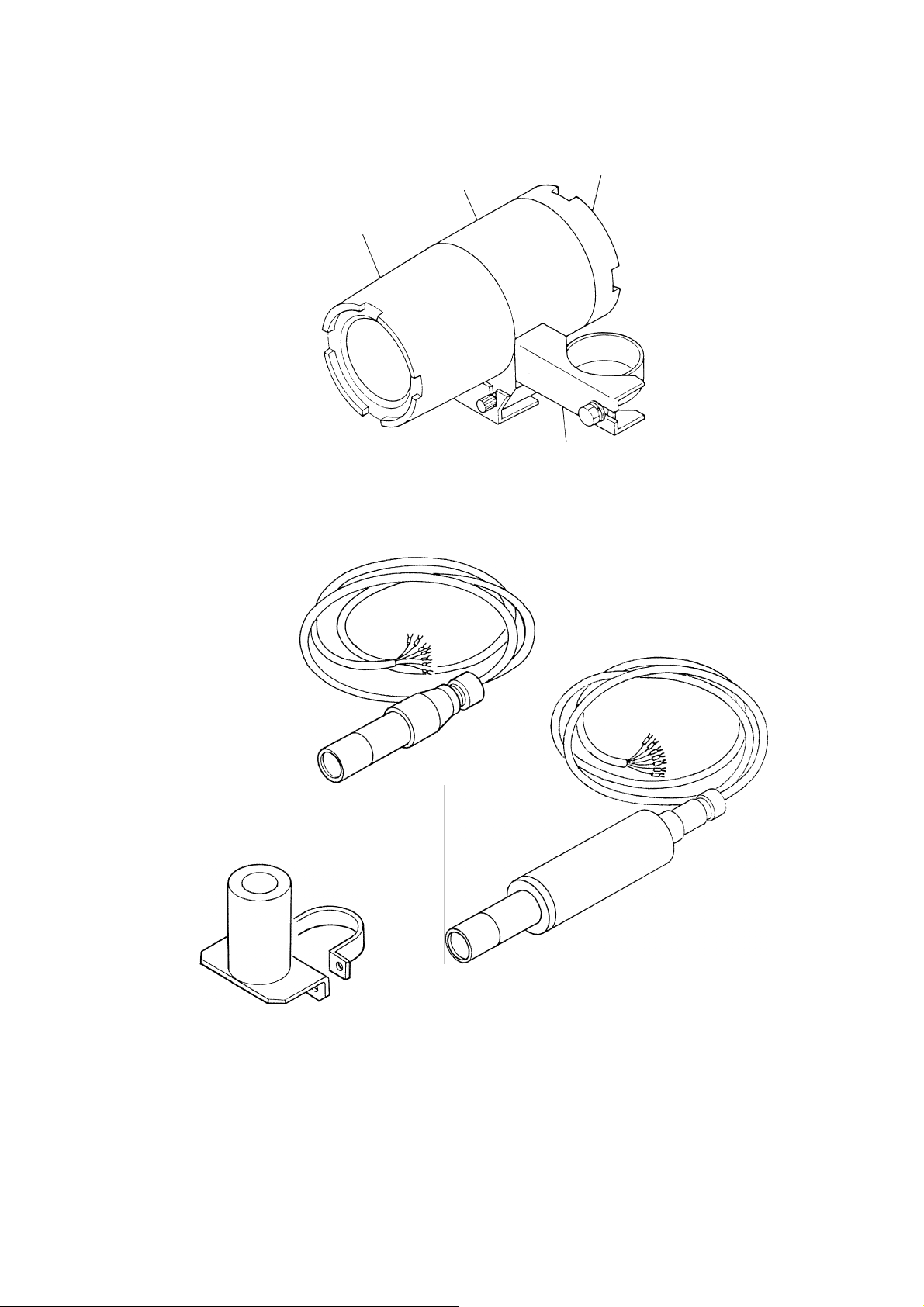

(3) External View

Front Cap

Rear Cap

Fittings for Installation

Casing

Reagentless Free Chlorine Analyzer, “Transmitter” Model: CD-36D

Vibrating Type Residual Free Chlorine Detector

Model: CLV Series Lead

Lead Wires: 1.5m (Standard)

Flow Cell for

Residual Free Chlorine Detector

Model: CLZ-1

Rotating Type Residual Free Chlorine Detector

Model: CLR-21-A

Lead Wires: 1.5m (Standard)

Model: CD-36D 2. Names of Major Parts

-

9

-

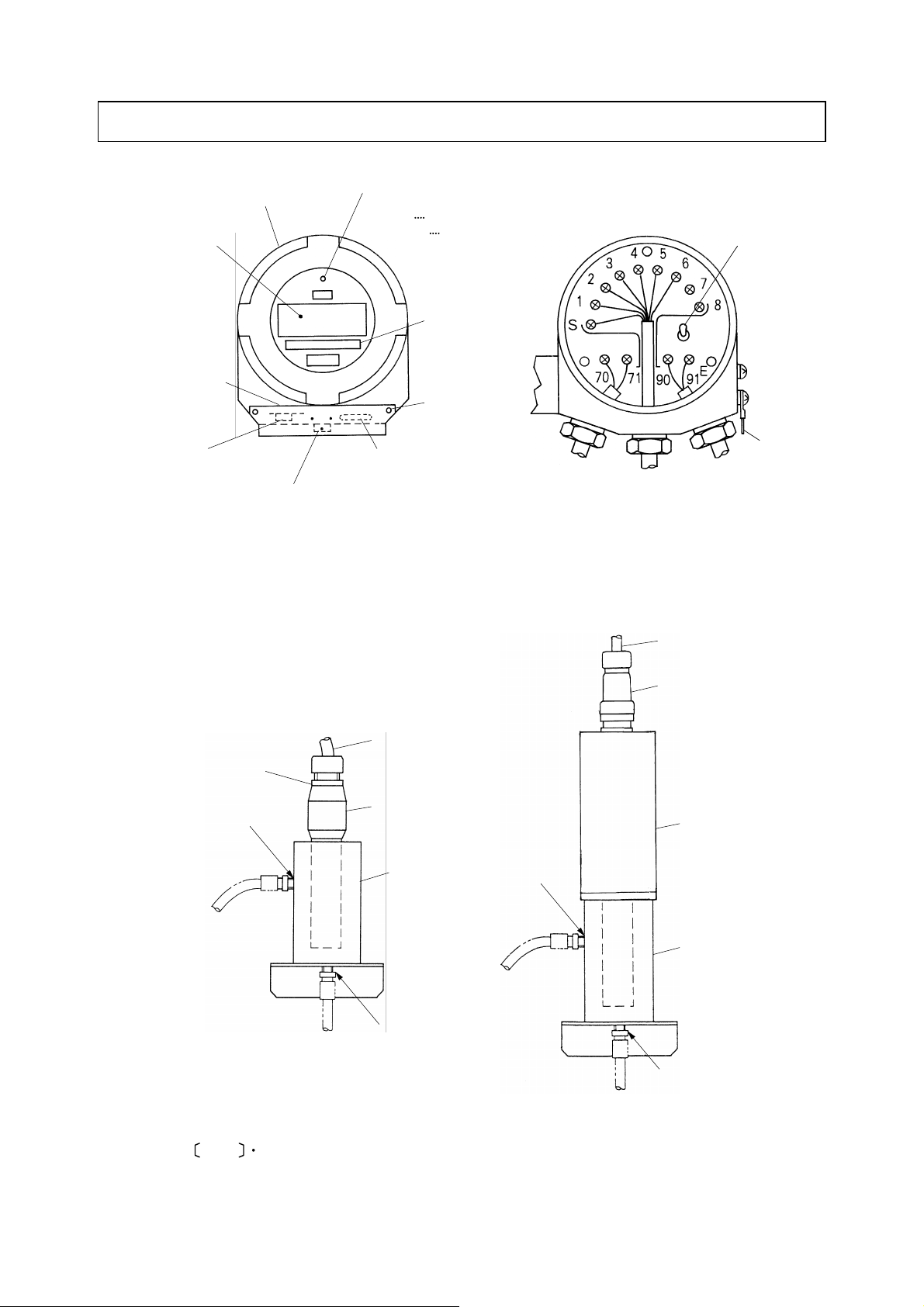

2. Names of Major Parts

Front Cap

Digital Display

Knob Cover:

To prevent knobs

for calibration from

inadvertent touch.

“ZERO Knob:”

For zero adjustment in

calibration

Display of

Measuring

Range

Fixing Screw

for Cover

“SPAN Knob:”

For span adjustment

in calibration

Mode Switch:

To switch the mode to

“MEAS” for “Measurement” mode and

“TEST” for “Maintenance” mode

Cable for

Output Signal Detector

Lead Wires

Cable for

Power supply

Power Switch

(POWER)

Earth Line

Pilot Lamp:

To display the mode presently set,

If “ON” cin “MEAS” mode

If blinking cin “TEST” mode

Transmitter

Connector

Sample Outlet

Lead Wires

Detector

Flow Cell

(Model: CLZ-1)

Sample Inlet

Sample Outlet

Lead Wires

Detector

Flow Cell

(Model: CLZ-1)

Sample Inlet

Connector

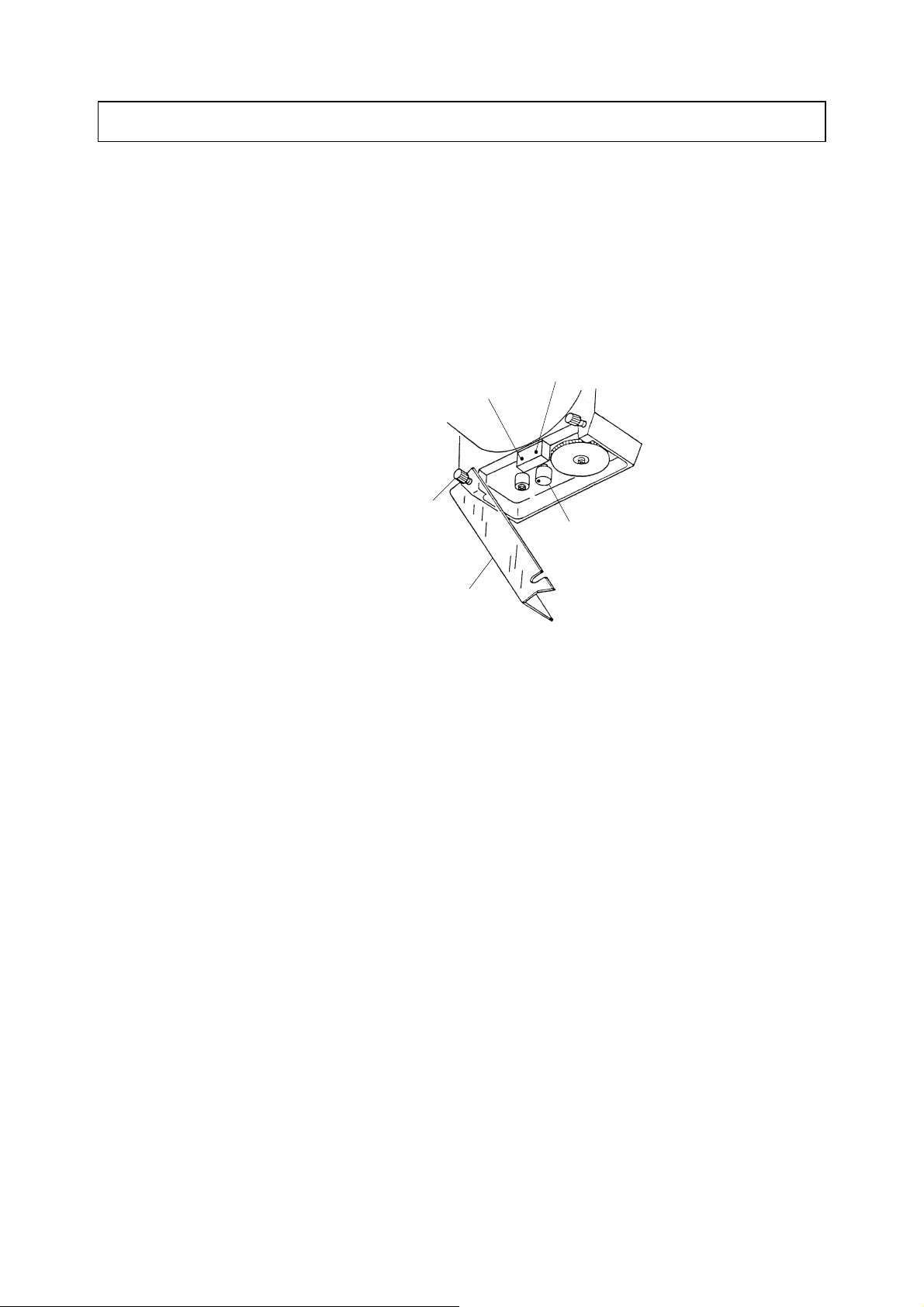

Vibration type residual chlorine detector

CLV Series

Rotation type residual chlorine detector

Model CLR-21-A

NOTE Flow cell incorporated with an detector is called “Sensor” in this instruction manual.

Sensor

Model: CD-36D 3.1 Filling of Beads

-

10

-

3. Preparation for Operation

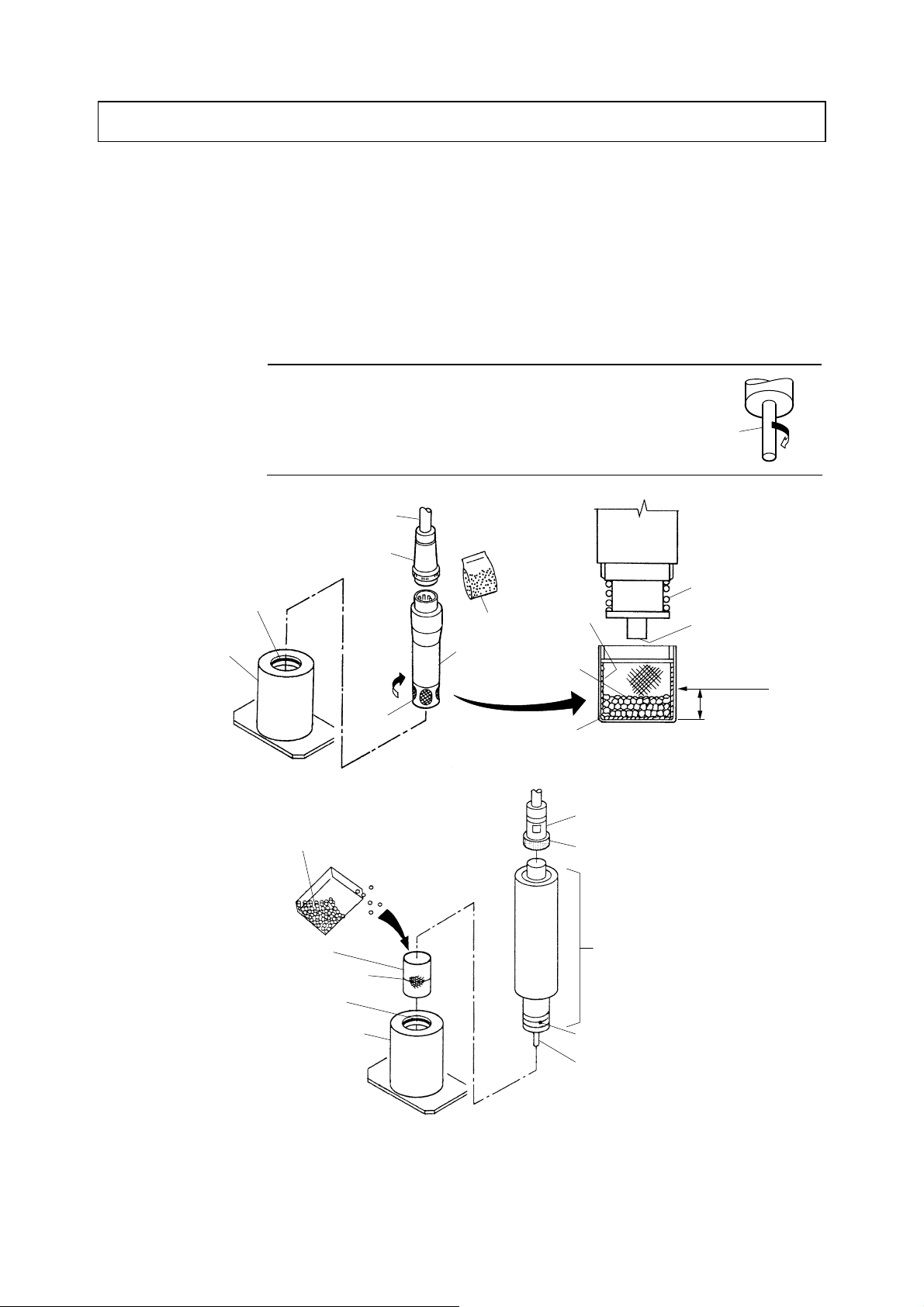

3.1 Filling of Beads

①Remove the detector. ⋅⋅⋅⋅⋅⋅ Prepare the beads supplied with the detector, and withdraw the

detector vertically from the flow cell.

②Fill beads. ⋅⋅⋅⋅⋅⋅ Loosen the detector cap and remove it. Then, fill the cap with beads to the level

notch as shown in the following figure.

• For CLV series ⋅⋅⋅⋅⋅⋅ Ceramic or glass beads

•For Model: CLR-21-A ⋅⋅⋅⋅⋅⋅ Ceramic beads

【IMPORTANT】•Turn the sensing electrode clockwise and make sure

the electrode is fixed firmly. Loosening of the

electrode may cause a failure of the product. Sensing

electrode Fix

Beads Wire Mesh.

Ceramic

Beads

Cap

Counter

electrode

Sensing

Electrode

Beads Level

Notch

Beads to

be filled

Lead Wires

Connector

Detector

Rotate to

remove.

Cap

O-ring

Flow Cell

<In case of CLV series>

<In case of Model: CLR-21-A>

Beads

Cap

Level Line

O-ring

Flow Cell

Connector

Closing Ring

Detector

Counter Electrode

Sensing Electrode

Filling of Beads

Model: CD-36D 3.2 Filling of Sodium Chloride Tablets

-

11

-

③Clean the threads of the cap. ⋅⋅⋅⋅⋅⋅ Immerse the cap in water to make beads attached on threads

settle in cap and to clean the threads so that no beads remain on the threads.

④Put the cap back. ⋅⋅⋅⋅⋅⋅ Reinstall the cap on the top of the detector paying attention not to spill

beads from the cap.

⑤Return the detector to the original state. ⋅⋅⋅⋅⋅⋅ Insert the detector slowly and vertically into the

flow cell until it touches the bottom of the flow cell, and connect the connector of the detector lead

wires like before if it was disconnected to remove the detector.

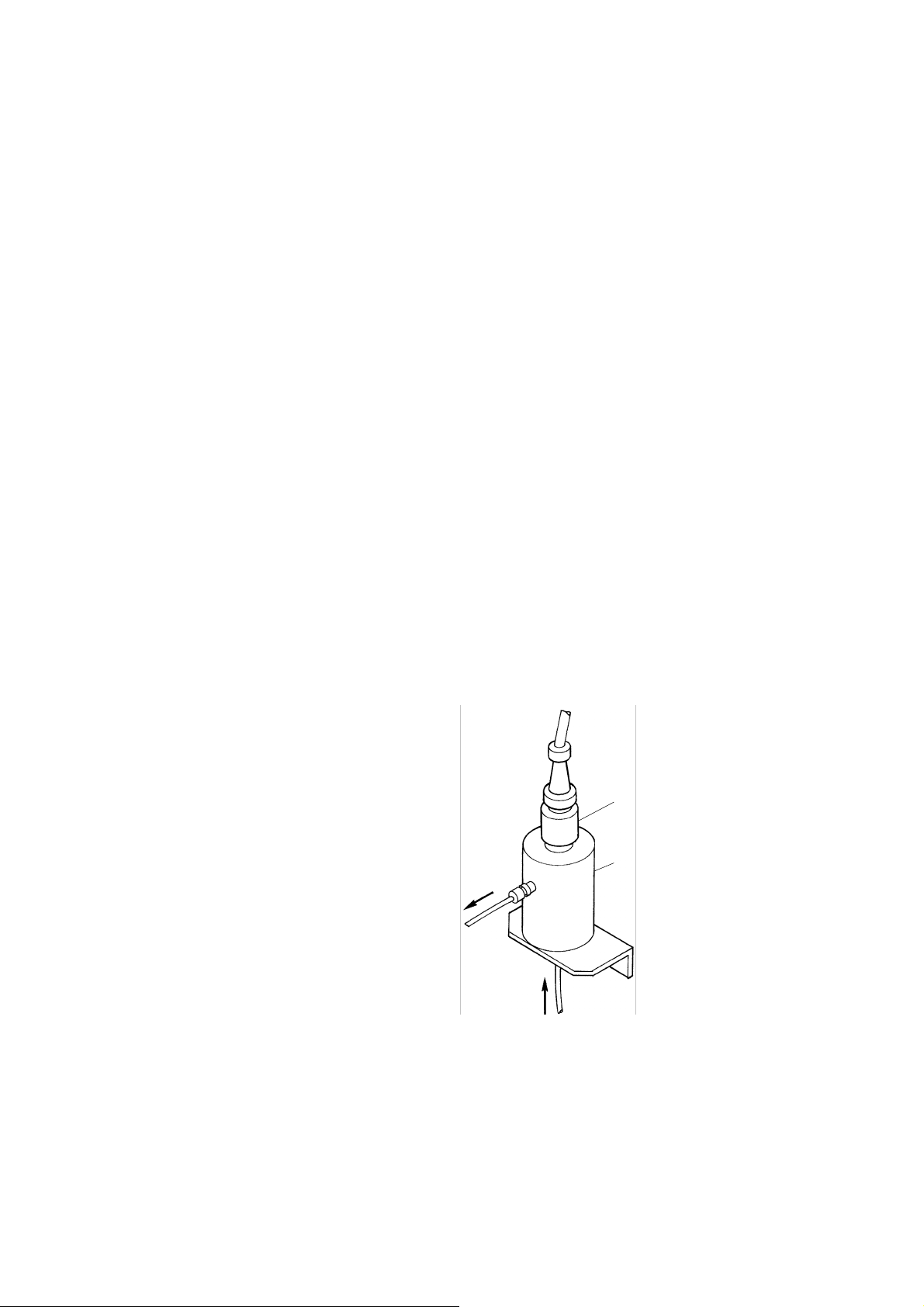

3.2 Filling of Sodium Chloride Tablets

(For specifications with a conductivity modifying column (option))

In order to achieve stable measurement when the conductivity of a sample is in the neighborhood of 3

8 mS/m or less, a conductivity modifying column (Model: CLZ-2) is provided to be combined as

option. In this case, fill sodium chloride tablets as shown below.

Lid

Container

Cell

Filter

Sample Outlet

Sample Inlet

Sodium Chloride Tablets

Code No.: 143A203

(Supplied as option)

Filling of Sodium Chloride Tablets

Model: CD-36D 3.3 Introduction of Sample Water

-

12

-

①Fill the container with sodium chloride tablets. ⋅⋅⋅⋅⋅⋅ Open the lid of the container and fill it with

sodium chloride tablets to its level of ca. 80%.

②Close the lid. ⋅⋅⋅⋅⋅⋅ Close the lid tight.

• The lid must be closed securely when introducing the sample water.

3.3 Introduction of Sample Water

Detector

Flow Cell

Sample Inlet

Sample Outlet

(Flow Rate: ca. 100mL/min)

Introduction of Sample Water to the Sensor

①Confirm that the sensor is ready for introduction of the sample water. ⋅⋅⋅⋅⋅⋅ Confirm that the

sample line is correctly connected the sample inlet and the detector is fixed properly.

②Introduce the sample water. ⋅⋅⋅⋅⋅⋅ Introduce the sample water to the sensor and confirm that the

sample is flowing under the following conditions.

Model: CD-36D 3.3 Introduction of Sample Water

-

13

-

[Conditions of Sample Water]

• pH··································6.5 to 7.5pH

• Electrical conductivity····Equal to or higher than 8 mS/m

• Temperature ···················0 to 40°C (without freezing)

• Pressure ························· 0.01to 0.15MPa

• Consumption··················50 to 200mL/min

• Flow Rate·······················ca. 100mL/min (Roughly speaking, a flow rate of about half of a glass

in a minute)

• Setting Range·················50 to 200mL/min,

If a conductivity modifying column is adopted as option ⋅⋅⋅⋅⋅ 50 to

70mL/min “9. Option”

【IMPORTANT】•Maintain the electrical conductivity of the sample water constant since the

up or down of the electrical conductivity affects the indication.

•Set the flow rate of the sample water to ca. 100mL/min and maintain it

constant since the up or down of the flow rate also affects the indication.

[If a conductivity modifying column is adopted as option]

• If a conductivity modifying column (Model: CLZ-2) is adopted as option, confirm that the lid of

the container of the column is closed tight before starting introduction of the sample water.

Upon introducing the sample water, gradually loosen the lid of the container and the sample level

begins to rise in the container. Then, wait until the sample level in the container reaches ca. 20%

from its bottom.

When the level reaches ca. 20% in the container, close the lid tight.

【IMPORTANT】•If the sample is introduced when the lid is loose, the container will be

completely filled with sample. Make sure to close the lid tight at the

sample level of ca. 20%.

If it is found that the level has risen over ca. 20%, close the sample flow

regulating valve first, and loosen the lid. Then, when the level decreases

to ca. 20%, close the lid tight and open the sample flow regulating valve.

•If the Transmitter is left without sample flow for a long period, the sodium

chloride solution flowing out of the container may be dried up on the

surface of the filter and the filter may be clogged with dried sodium

chloride. Therefore, always keep the sample flowing. When the operation

is to be resumed after a long-term shutdown, start the measurement after

confirming that the crystal of sodium chloride on the filter has completely

been dissolved with the sample water.

③Adjust the flow rate. ⋅⋅⋅⋅⋅⋅ Adjust the sample flow rate with the sample flow regulating valve

provided in the sample line so that a small amount of the sample water overflows in the flow cell.

④Check for any leak. ⋅⋅⋅⋅⋅⋅ Check the entire unit of the sensor to see if there is any leak of the

sample water.

Model: CD-36D 4.1 Start-up Procedure

-

14

-

4. Operation

4.1 Start-up Procedure

①Confirm that the installation work and preparation are all finished. ⋅⋅⋅⋅⋅⋅ Confirm that “8.

Installation” (Installation, Piping, Wiring) and “3. Preparation for Operation” (Filling of Beads,

Introduction of Sample Water, etc.) are finished.

②Change to “Maintenance” mode. ⋅⋅⋅⋅⋅⋅ Loosen a little 2 fixing screws for cover and open its right

hand side. Then, turn the mode switch to “Maintenance” (TEST).

“Maintenance mode”

(TEST)

“Measurement mode”

(MEAS)

Mode Switch

Fixing Screw for Cover

Knob Cover

Position of the mode switch

〔NOTE〕•If the mode switch is turned to “Maintenance” mode (TEST), the output signal

automatically changes to a constant value near the median of the measuring range

regardless of the actual indicated value.

•If mode switch is turned to “Measurement” mode(MEAS), output signals for not only the

measured value of the sample water but also other indicated value are delivered giving

influence to the related controlling systems. Therefore, it is advised that the mode should

be set to “Maintenance” mode (TEST) when the measurement is not normal.

③Supply the power. ⋅⋅⋅⋅⋅⋅ Supply the power to the Transmitter.

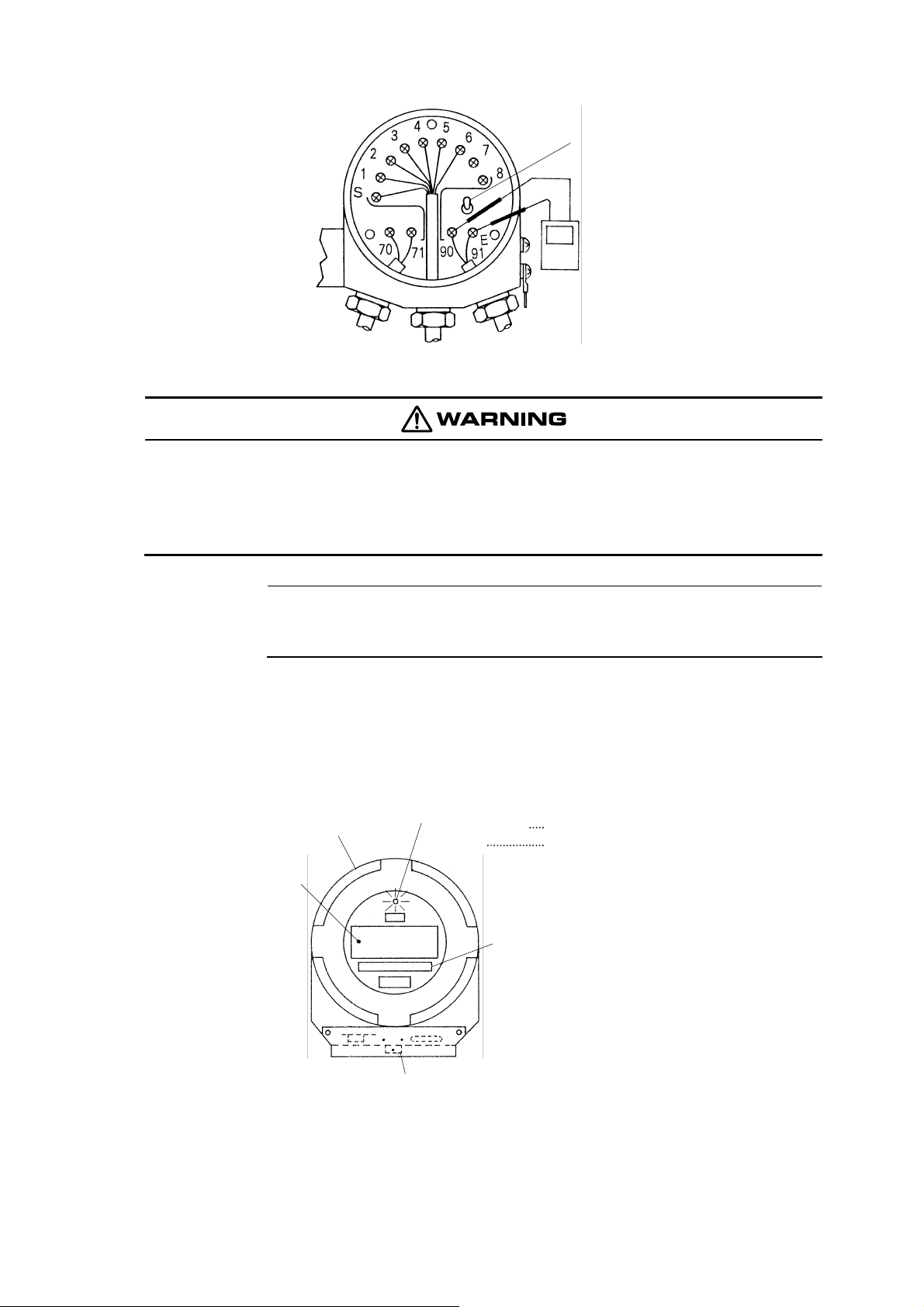

④Confirm the line voltage. ⋅⋅⋅⋅⋅⋅ Open the rear cap and connect a voltmeter to terminals “90, 91”.

Then, confirm that the line voltage aggress to the one indicated in the name plate attached on the

upper side of the Transmitter.

Model: CD-36D 4.1 Start-up Procedure

-

15

-

Power Switch

(POWER)

Voltmeter

Confirm the line voltage.

Electric Shock

● Since AC power supply is connected to terminals “90, 91”, make sure to turn off the

power supply to the Transmitter on the power supply side in case some work is

needed near the terminal board.

【IMPORTANT】•Do not turn on the power switch when the flow cell is not filled with sample

water since the sensing electrode may be damaged if it is kept vibrating or

rotating in the air for a long period.

⑤Confirm that the pilot lamp is blinking. ⋅⋅⋅⋅⋅⋅ Turn on the power switch located on the upper part

of the terminal board, and confirm that the pilot lamp is blinking, which indicates the present mode

is in “Maintenance” mode.

⑥Change to “Measurement” mode. ⋅⋅⋅⋅⋅⋅ When the indication is stabilized, turn the mode switch to

“Measurement” mode (MEAS), and confirm that the pilot lamp is lit continuously without blinking.

Front Cap

Digital Display

Pilot Lamp:

Display of

Measuring Range

Mode Switch

If continuously lit

If blinking in “Measurement” mode (MEAS)

in “Maintenance” mode (TEST)

Confirm that the pilot lamp is blinking.

Model: CD-36D 4.2 Shutdown of Operation

-

16

-

⑦Confirm the measuring range. ⋅⋅⋅⋅⋅⋅ The measuring range is preset to “0 to 2mg/L” by DKK-TOA

before shipping. If alteration of the measuring range is needed, refer to “6.1 Setting of Measuring

Range”.

⑧Close the rear cap. ⋅⋅⋅⋅⋅⋅ Close the rear cap tight.

⑨Execute calibrations. ⋅⋅⋅⋅⋅⋅ According to “5. Calibration”, execute “Zero” and “Span” calibrations.

⑩Confirmation. ⋅⋅⋅⋅⋅⋅ Confirm the following.

• The mode switch is in the position of “Measurement” (MEAS) and the pilot lamp is continuously

lit.

• Sample water is being fed to the flow cell in accordance with the intended conditions.

• The knob cover and the rear cap are correctly back in the original position.

Now, at this point, the Transmitter is in the normal state for measurement.

4.2 Shutdown of Operation

(a)Take the following steps to stop the operation of the Transmitter.

• Stop the supply of the sample water.

• Turn off the power switch. (Power: OFF)

(b)If the operation is to be resumed after shutdown of the operation, execute the span calibration.

Model: CD-36D 5. Calibration

-

17

-

5. Calibration

(a)When starting the operation of the Transmitter, it is necessary to execute the calibration in order to

adjust the characteristics between the detector and the Transmitter. Additionally, make sure to

execute the calibration on a regular basis during operation in order to maintain accurate

measurement.

(b)If the position of the “ZERO” knob seems to have moved from the original position set at the time

of starting the operation, execute both of the zero and span calibrations. In other cases, only the

span calibration will be sufficient.

(1) Zero Calibration

①Change to “Maintenance” mode. ⋅⋅⋅⋅⋅⋅ Loosen a little 2 fixing screws for cover and open its right

hand side. Then, turn the mode switch to “Maintenance” (TEST).

“Maintenance mode”

(TEST)

“Measurement mode”

(MEAS)

Mode Switch

Fixing Screw for Cover

Knob Cover

“SPAN” Knob

“ZERO” Knob

Position of the mode switch

〔NOTE〕•The calibration can also be executed in “Measurement” mode (MEAS). However, in this

case, the related controlling system will be disturbed since the output signal changes up

and down during the said calibration.

②Disconnect the lead wire “1”. ⋅⋅⋅⋅⋅⋅ Open the rear cap and disconnect the lead wire “1” from its

terminal.

Electric Shock

● Since AC power supply is connected to terminals “90, 91”, make sure to turn off the

power supply to the Transmitter on the power supply side in case some work is

needed near the terminal board.

〔NOTE〕•By disconnecting the lead wire “1” from its terminal, the output signal of the detector to

the Transmitter or the input signal to the Transmitter becomes equal to 0mg/L.

Model: CD-36D 5. Calibration

-

18

-

Disconnect the lead wire

“1” from its terminal.

Disconnect the lead wire “1”.

③Adjust the zero point. ⋅⋅⋅⋅⋅⋅ Wait until the indication stabilizes (for ca. 1 to 2min), and then, adjust

the indication to “0.00”mg/L by turning the “ZERO” knob.

④Connect the lead wire “1”. ⋅⋅⋅⋅⋅⋅ Connect the lead wire “1” back to the terminal “1” like before.

⑤Close the rear cap. ⋅⋅⋅⋅⋅⋅ Close the rear cap tight.

⑥Change to “Measurement” mode. ⋅⋅⋅⋅⋅⋅ Turn the mode switch to “”Measurement mode (MEAS)

and confirm that the pilot lamp is lit continuously.

At this point, the zero calibration is finished. Now, proceed to the span calibration.

(2) Span Calibration

The span calibration is an operation to adjust the indication of the Transmitter to an analyzed value

obtained with “DPD method”, “Amperometric titration method”, etc. for the residual chlorine in the

sample being measured.

①Aging. ⋅⋅⋅⋅⋅⋅ Under the conditions for measurement, let the sample flow through the flow cell for

more than 30 minutes as aging before starting the span calibration.

②Analyze the residual chlorine in the sample with another method. ⋅⋅⋅⋅⋅⋅ Collect a portion of the

sample water out of the flow being supplied to the flow cell when the concentration of the residual

chlorine in it is stable for analysis with “DPD method”, “Amperometric titration method”, etc.

③Adjust the span value. ⋅⋅⋅⋅⋅⋅ By turning the “SPAN” knob, adjust the indication of the Transmitter

to the analyzed value obtained in the previous step ②.

Model: CD-36D 5. Calibration

-

19

-

“Maintenance mode”

(TEST)

“Measurement mode”

(MEAS)

Mode Switch

Fixing Screw for Cover

Knob Cover

“SPAN” Knob

“ZERO” Knob

Position of the “SPAN” Knob

④Fix the knob cover in place. ⋅⋅⋅⋅⋅⋅ Put the knob cover back in place and tighten 2 fixing screws for

the knob cover.

【IMPORTANT】•When the calibration is finished, do not touch the “ZERO” and “SPAN”

knobs. If it seems to have been touched and moved inadvertently, repeat

the calibration from the beginning.

Table of contents

Other TOA-DKK Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Vaisala

Vaisala HUMICAP HMP5 quick guide

SIGLENT

SIGLENT SDS2352X-E user manual

PCB Piezotronics

PCB Piezotronics 353B34 Installation and operating manual

CCS

CCS WattNode WNC-3Y-208-MB Installation and operation manual

Würth

Würth MULTI-TESTER PRO II LCD Translation of the original operating instructions

SpiroHome

SpiroHome Lite user manual