3.0 Functions

3.1 Keys

ON/OFF

SPAN

(m)

MASS

(kg/m)

UP

(Hz/N)

DOWN

(Lbs)

MEM 1

MEM 2

MEM 3

This key switches the meter on or off. If the meter is on and sits idle for more

than 3 minutes, it automatically switches off to preserve battery life. When the

meter is rst switched on a battery check is made see Section 3.4 for a description

of the visual and audible low battery signal.

This key is used to enter the belt span length. The span key is held down while

the UP or DOWN keys are used to set the belt span in metres. Releasing the

SPAN key results in an audible beep to indicate the setting has been accepted.

Pressing the SPAN key alone, shows the current setting.

This key is used to enter the belt mass. The mass key is held down while the

UP or DOWN keys are used to set the belt mass in kg/m. Releasing the MASS

key results in an audible beep to indicate the setting has been accepted. Pressing

the MASS key alone shows the current setting.

Important Note:

Belt span and belt mass are required entries if tension results in force units (N or lbf)

are desired. Entries must be in SI units (m and kg/m)

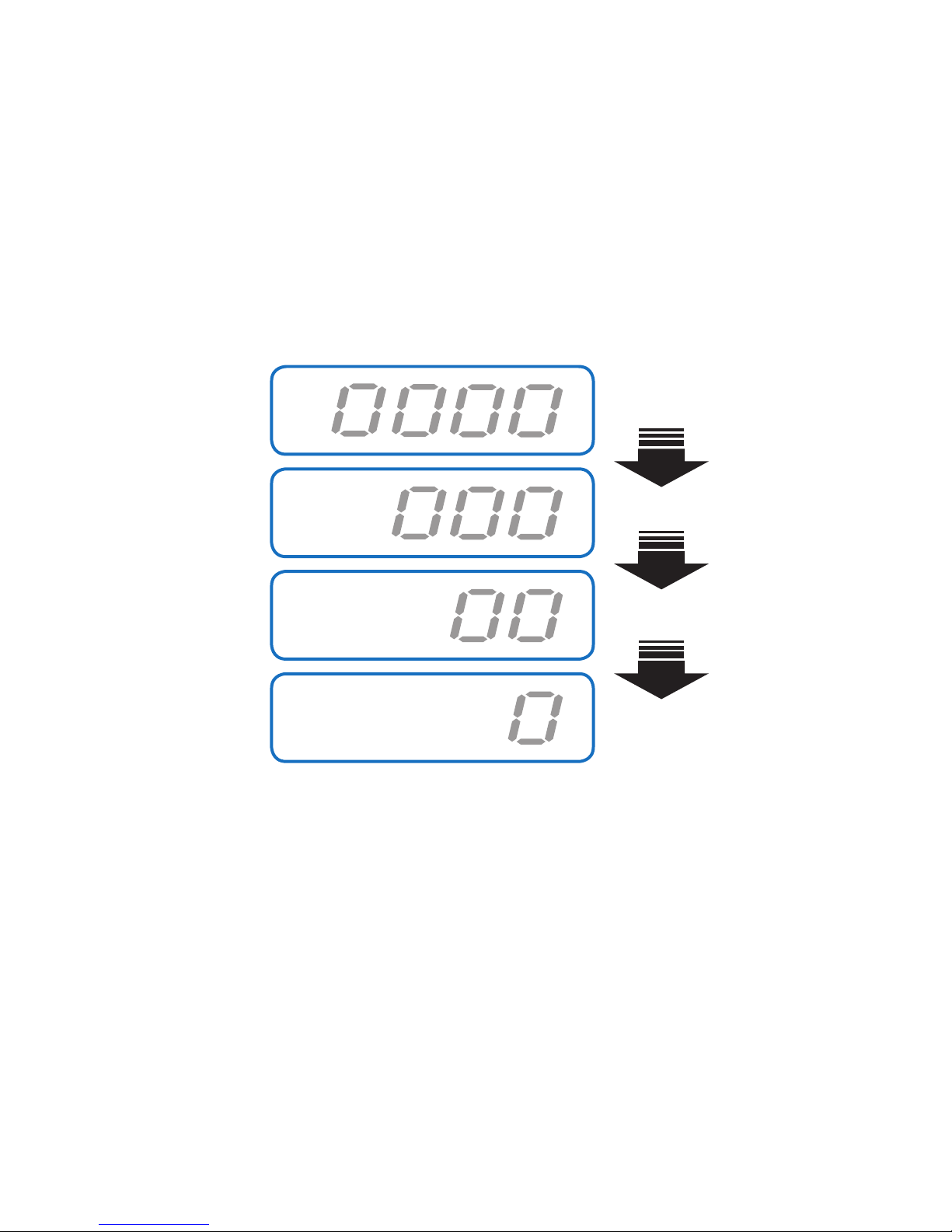

This key has two functions. The rst is to increase either the SPAN or MASS

parameters when used in conjunction with these keys. The second use is to

toggle between the Hz and the newton measurement modes.

This key has two functions. The rst is to decrease either the SPAN or MASS

parameters when used in conjunction with those keys. The second use is to

toggle between the Hz and the pound measurement modes.

The memory keys allow up to 3 sets of belt parameters to be stored in the

meter registry. Pressing the MEM 1 key recalls the rst set of belt parameters

and likewise for MEM 2 and MEM 3.

To store the belt parameters to a key, the belt span and mass parameters must

rst be entered and then immediately after release of either the SPAN or MASS

keys the appropriate MEM key should be pressed. Two beeps indicate that the

parameters have been successfully assigned to the key.