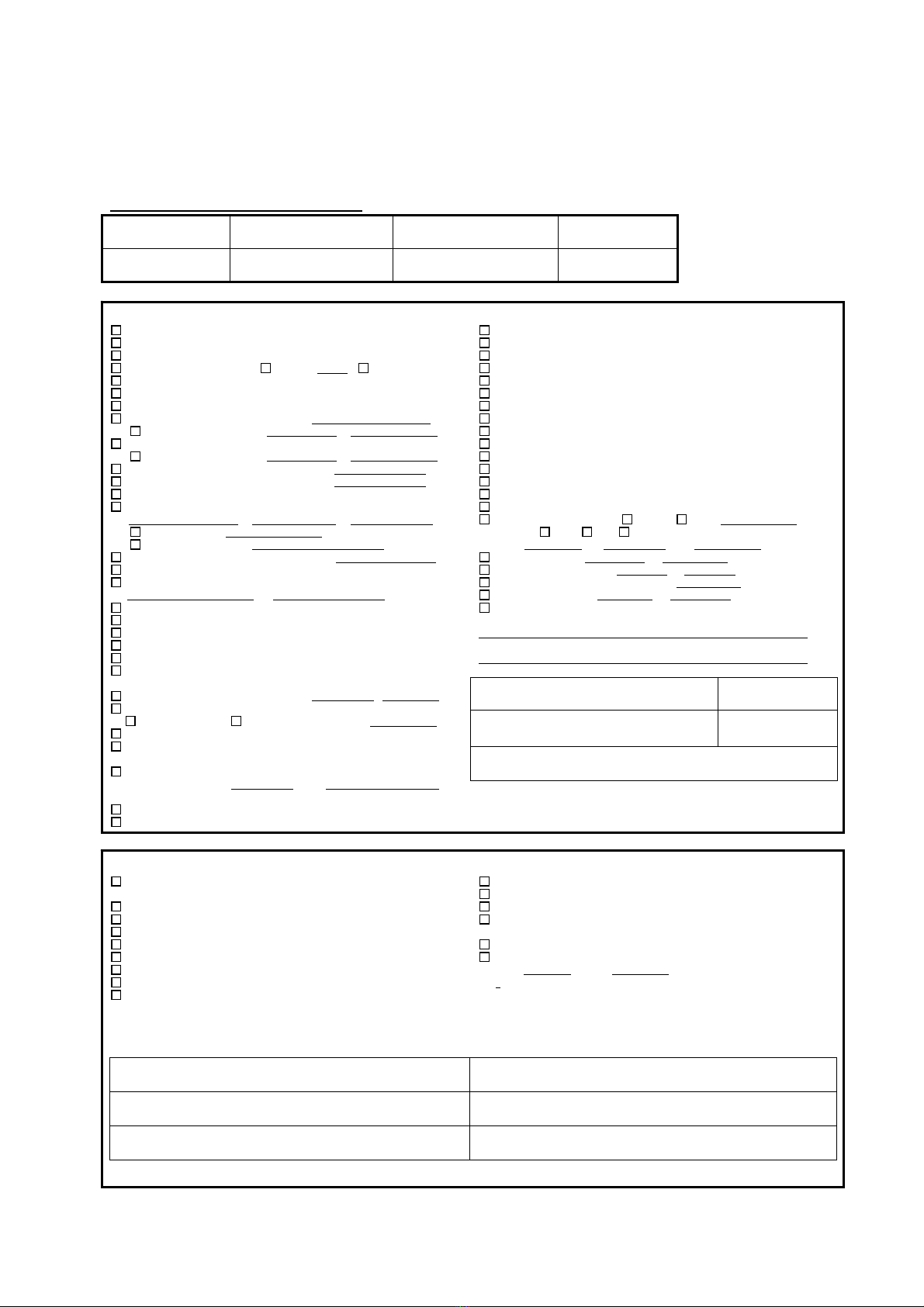

Trained personnel should check that the unit has been pre-delivered in accordance with the relevant To h a t s u

Outboard Manual. The following points must be confirmed at pre-delivery and during the water test.

RefNo:

MODEL PRIMARY ID (Port) PRIMARY ID (Starboard) HULL ID NUMBER (HIN)

BOAT MAKER/MODEL IGNITION KEY NUMBER (Port) IGNITION KEY NUMBER (Starboard) TRAILER NUMBER

CHECKBEFOREOPERATION CHECKDURINGOPERATION

All Standard Items Supplied (Defect, Breakage, Missing parts)

Engine Mounting (High, Width, Proper hardware, Secured)

Harness and hoses installation (Secured and Properly Dressed)

Main Wire Harness installation Extended ft No Extended

Multifunction Gage Dip Switch Setting for Application

Instrument Operation/Connections

Tiller Handle Installation/Secure

RemoteControlOperation/Adjustments Type:

CableStrokeandRouting Length: m Min.radius: cm

Shift Throttle Operation

CableStrokeandRouting Length: m Min.radius: cm

MechanicalSteeringOperation/Installation Maker:

HydraulicSteeringOperation/Bleed Maker:

Primer Pump Installed Properly (Arrow pointing up)

Fuel Line/Tank Installation/Connections Routing Sealed/Secured

InnerDiameter: m

Length: m Height: m

BoatFuelFilter Type

FuelVacuumTestResult: kPa@WOT rpm(over 50ps)

BatteryMeets/ExceedsEngineSpecifications Type:

Battery Charged/Secured/Connections Tight

Battery Cable Installation and Routing

BatteryCableType: CableLength:

Battery S/W installation (Secured, Properly Connections)

Manual Tilt Operation

Power Trim/Tilt Operation

Lower Unit Oil Level

Overheat Warning System (Ground sensor lead on applicable models)

Visual Inspection of Engine

<2-Stroke Fuel and Oil Setup>

Break-InPremixRatio(ExceptTLDImodels) 25 : 1

Oil in Remote and Marine Engine Tank

To h a t s u TCW3 EquivalentQualityOilBrand:

Breed Oil Injection Pump / No air oil Injection Lines

Electric Oil Pump Function

<4-Stroke Oil Setup>

Check Engine Oil Level (Ensure unit is not overfilled)

Engine Oil Classification: Brand:

<Carburetion: 2 and 4-Stroke models>

Manual/Electric Choke Operation

Electric Starter Operation (Start in gear protection functions)

Manual/Electric Choke Operation

Neutral Switch function

Stop Switch/Emergency Switch Operation

Steering Operation

Throttle Operation/Friction Adjustment Neutral/Cruising

Proper Shift Cable Adjustment/Operation (F-N-R)

Cooling System Water Flow

Fuel/Oil/Water/Exhaust leaks

Oil Warning system Check (Equipped models)

Indicator Lamp and Buzzer

Oil and Temperature Warning functions (Equipped models)

Engine reaches operating temperature

Power Trim/Tilt Operation

Instrument Operation

Trim Tab Adjustment (retorque after operation)

Propeller Selection: Brand: To h a t s u Other:

Material: SUS AL Plastic

Model: Dia: Pitch:

IdleRPM Single/P: rpm S: rpm

IngearidleRPM Single/P: rpm S: rpm

Factory-recommendedW.O.T.RPMRange: rpm

W.O.T.RPM Single/P: rpm S: rpm

No Cavitations/Ventilation

Remarks:

Inspector’s signature Date

Dealer name Phone number

Dealership address

CUSTOMER DELIVERY CHECKLIST

Operation of Equipment/Boat Accessories Explained

(Proper Trim and Tilt operation demonstrated)

Operation/Orientation Ride with Dealership Personnel

Warranty/Owner’s Manual and Keys Given to Customer by Dealer.

Customer Introduced to Service Manager/Writer

Return-to-Port Operations (Oil System, RPM Reduction)

Gauge Operation/Warning Symbols Explained

2-Stroke: Use of To h a t s u 2 stroke/TC-W3 or Equivalent Rated Oil

4-Stroke: Use of To h a t s u 4 stroke or Equivalent Rated Oil

4-Stroke: Show Customer Proper Checking Procedures and Proper Level of

Engine Oil

Engine Break-in Procedure Explained

Maintenance/Care Schedule Explained

Advised of First Scheduled Maintenance

Warranty Coverage Explained to Customer’s Satisfaction,

Including Customer Responsibilities

Customer questions answered by Dealership Personnel

Break-in Time Placed on Engine by Dealership Personnel

hours: Minutes:

Customer name Phone number

Customer address

Customer signature Date

Date of Issue : / /2007 ORIGINAL TO BE HELD BY DEALER/COPY TO CUSTOMER

TOHATSU OUTBOARD MOTOR

Pre-Delivery Inspection Check List 2 and 4-Stroke Models

The above

materia

has been explained and/or provided to me by dealership

ersonne

.

My questions were answered and explained to my satisfaction.