Tohnichi T-BLE User manual

2016/06/14

Solar Powered Wireless Signal

Torque Wrench System

BLseries

Operation Manual

Tohnichi Mfg. Co., Ltd.

1

Safety Precautions

To customers: Before using this product, please read this operating instruction carefully to use it

properly. If you have any question, please contact your nearest distributor or TOHNICHI MFG. CO.,

LTD. This operating instruction should be stored in a safe place.

Signal Words

The signal words are the headers which indicate the level of hazard that should be known for

human safety and in handling devices. The signal words for safety are "Danger", "Warning" and

"Caution" depending on the level of hazard to human. The signal words are used with the safety

symbol to indicate the following situations.

The receiver can be operated only with the power voltage of DC18V to 36V specified in this

operating instruction.

Do not drop water or oil on this instrument. Do not use this instrument in an atmosphere of

flammable gas and steam. Use in such an atmosphere may result in fire.

Avoid shock or vibration to this instrument. It may cause a damage or failure.

Before use, make a pre-operation inspection and check the settings.

Be sure to conduct a periodic inspection of torque wrenches.

Use a torque wrench within the measurement range specified in the operating instruction.

Disconnect from power supply if the product needs to be stored for a long period of time.

Avoid using the instrument in a place where there are metal structures around it.

Avoid using the instrument near welding machines, electric discharge machines or machines

producing electromagnetic noise such as PC.

Before wiring, check power supply off.

Contact your nearest distributor or Tohnichi if any trouble.

Safety Symbol

This symbol is used for drawing attention to "safety precautions". If you see this

symbol in this operating instruction, attention should be paid to safety. Take

preventative actions according to the description and conduct "safety operations

and proper control".

“Danger" Indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury.

"Warning" Indicates a potentially hazardous situation which, if not avoided, could result

in death or serious injury.

"Caution" Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury.

Warning

2

INDEX

1 Outline 4

2 Feature 4

3 Components 4

4 Specifications 5

5 External View

5-1 BLE, European and China model 6

5-2 BLA, US model 7

5-3 BL, Japan model 8

5-4 Receiver Display and RS232C 9

5-5 Input and Output terminal 10

6 Preparation for Use

6-1 Solar Cell 11

6-2 Receiver 12

6-3 Antenna 15

6-4 Error on BL receiver 15

6-5 RS232C 16

7 Setting Receiver

7-1 Setting Procedure 17

7-2 Setting Procedure 18

8 Mounting Method of BL transmitter onto LS torque wrench 21

9 Trouble 23

10 Optional Item 23

11 Regulations 24

3

1 Outline

Tohnichi BL series torque wrenches send tightening completion signals by radio waves. The Solar

Panel eliminates need for battery maintenance and costs associated. R-BL receiver models capture

signals from BL wrenches and transfer to external equipment, such as a count checker CNA-4mk3,

Poka-Patrol. The receiver can transfer Completion signals and transmitter serial number to external

equipment. Miss-tightening prevention system can be established with PC or PLC.

2 Feature

•World’s first solar power transmitter

•Create up to 4 contact-free outputs in one receiver

•DC24V power source

•Available AC100V - 240V with optional BA-8 AC adapter

•Upgrading LS type torque wrench to BL type is possible

•Quick communication setting with one click

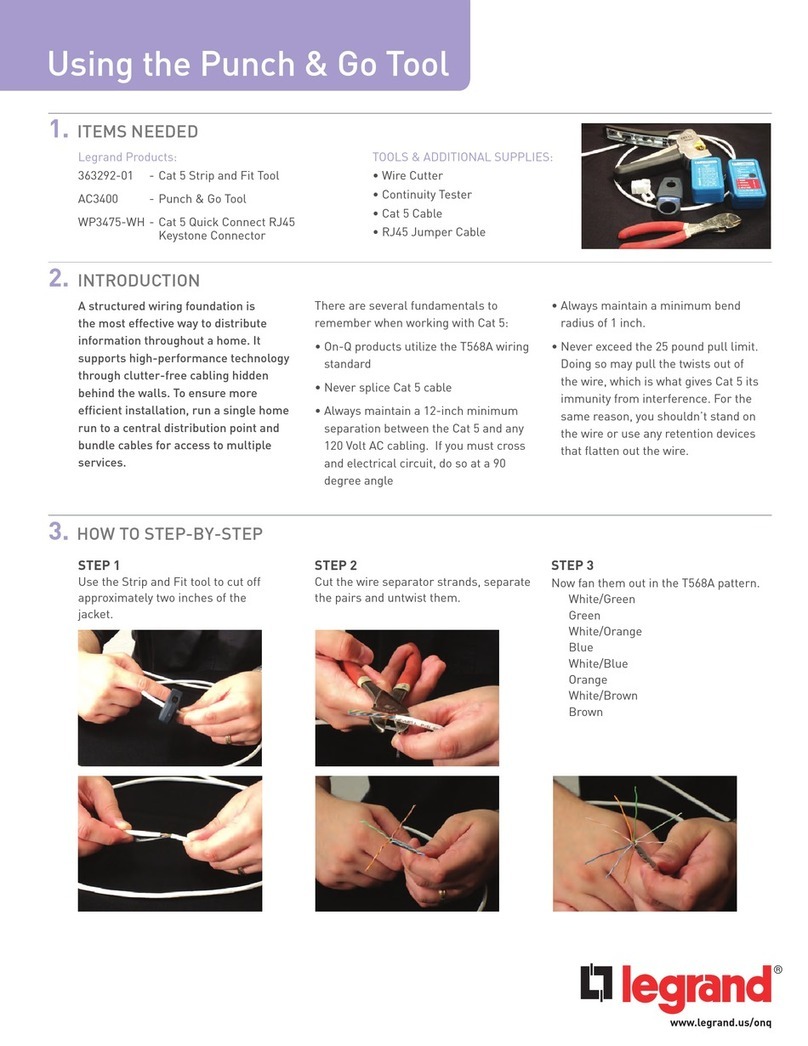

3 Components

Receiver

Wireless

Wired

PC / PLC

Option

・

RS232C

・

ID/8-digit

Up to 10 torque wrench

Wired

4

4 Specifications

Model T-BLE R-BLE T-BLA R-BLA T-BL R-BL

Description Transmitter Receiver Transmitter Receiver Transmitter Receiver

Frequency 868.3Mhz 902.875Mhz 928.35Mhz

Modulation

System FSK

Rate 125kbps

ID Fixed 8 digit

LED Light #1 LED Light #1 #1

Power Solar Cell DC24V #2 Solar Cell DC24V #2 Solar Cell DC24V #2

Antenna Helix Antenna Dipole

Antenna Whip Antenna Dipole

Antenna Helix Antenna Dipole

Antenna

Temperature 0 – 40 degree Celsius

Distance 10 – 20 m, 30 – 60 feet #3

Wireless

Certificate EU, China USA, Canada Japan

#1 4 Contact Signal Outputs and 6 RS232C Outputs, LAN Output by Request

#2 Connected directly to DC18-36V or with Optional, AC Adapter BA-8, 100 – 240V

#3 Radio frequency communication errors may be caused by electronic noise or a shield placed

between the transmitter and receiver. In addition, radio waves reflected by metal, concrete,

etc. may interfere with radio waves directly sent to the antenna of the receiver and dead

point occurs, resulting in communications errors.

5

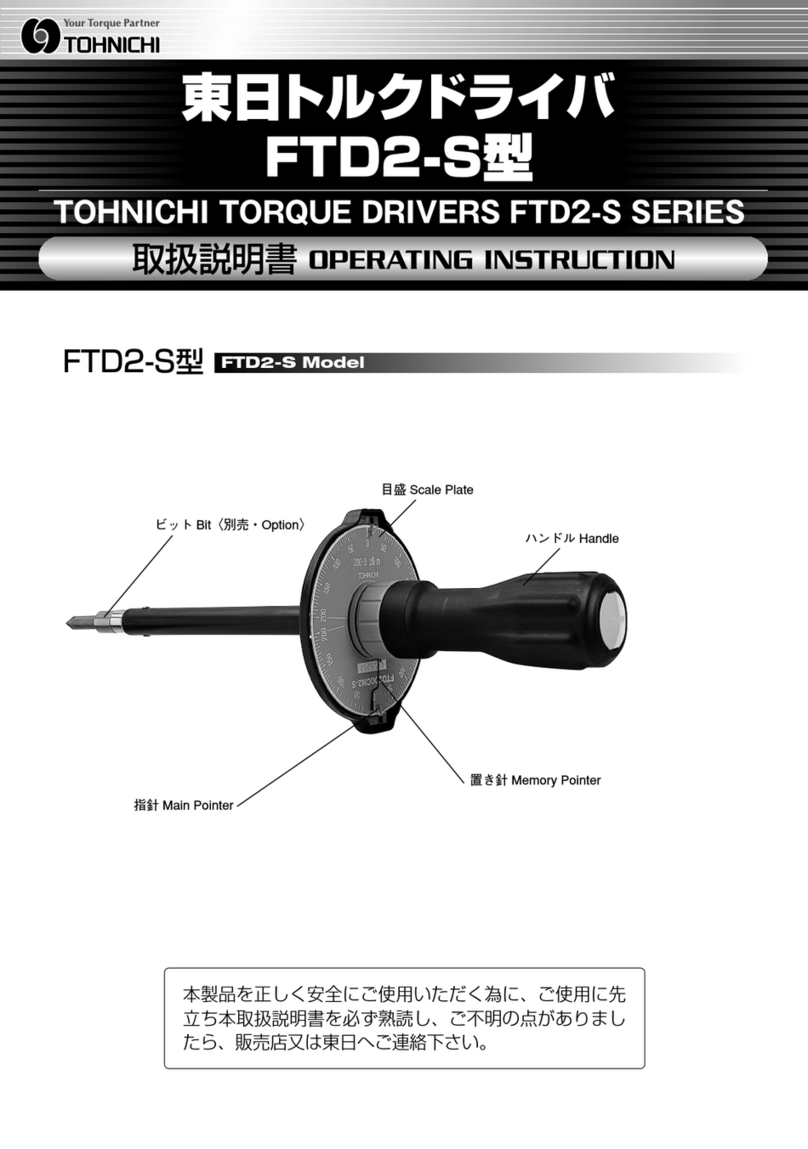

5 External View and Each Part Name

5-1 BLE, European and China model

6

5-2 BLA, US model

7

5-3 BL, Japan model

8

5-4 Receiver Display and RS232C

RS232C Pin Assignment

Pin Number Signal Description Direction

1

2 TXD Transmitted Data Signal

3

RXD

Received Data Signal

4

5

GND

Ground

6

7 CTS Clear to Send Signal

8 RTS Request to Send Signal

9

R-BL to PC/PLC

R-BL

PC/PLC D-Sub9S

Pin #

Signal

Description

Pin #

Signal

Description

1

1

DCD

N/A

2

TXD

Transmitted Data Signal

2

TXD

Transmitted Data Signal

3

RXD

Received Data Signal

3

RXD

Received Data Signal

4

4

DTR

N/A

5

GND

Ground

5

GND

Ground

6

6

DSR

N/A

7

CTS

Clear to Send Signal

7

CTS

Clear to Send Signal

8

RTS

Request to Send Signal

8

RTS

Request to Send Signal

9

9

NC

N/A

Frame

Shield

Frame

Shield

Indicating “ID”

Preference on mode setting

Indicating ID # when received signal

Status on mode setting

9

5-5 Input / Output Receiver

Terminal Block

Terminal # Description Features

1 OUT1 Output non-voltage contact signal and LED1 is lit When receiving

completion signal from BL transmitter #1. There is no polarity.

2

3 OUT2 Output non-voltage contact signal and LED2 is lit When receiving

completion signal from BL transmitter #2. There is no polarity.

4

5 RESET Contact terminal to reset “outputting non-voltage contact signal”

and “auto-reset”. Required to input pulse, more than 0.1 second.

6

7 OUT3 Output non-voltage contact signal and LED3 is lit When receiving

completion signal from BL transmitter #3. There is no polarity.

8

9 OUT4 Output non-voltage contact signal and LED4 is lit When receiving

completion signal from BL transmitter #4. There is no polarity.

10

11 LS IN When BL torque wrench is down, LS torque wrench can be wired

to LS-IN and COM for back-up.

12

LED light

LED light

10

6 Precautions for Use

6-1 Solar Cell

Charge the battery before first use and after long periods of nonuse.

BL has available 3000 uses within 8 hours under 500 lux illuminance and 9.6 sec.

communication cycle.

BL can perform 300 uses on a full charge under 0 lux illuminance, No Light Conditions.

A fully charged battery will lose power after approx. 4 days if under no light conditions, 0 lux.

It is recommended to have sufficient light on the line/station to continually recharge the

internal battery cell.

There is no battery level indicator.

Keep the solar panel clean. A dirty panel decreases power generation efficiency.

Do not use a solvent such as paint thinner when you clean up the solar panel.

Recharge to full within 1 and half years even if you do not use BL to prevent the battery from

dying.

Table 1. Measure of the solar cell charging time

Illuminance

lux

Activity Charging time

for available one use

Charging time for fully charge

200 - Approx. 3 min. Approx. 144 hours

500 Standard factory Approx. 1.5 min. Approx. 72 hours

1000 Under 60 to 70 cm

of fluorescent light, 30W Approx. 44 sec. Approx. 35 hours

2000 Under 40 cm

of fluorescent light, 30W Approx. 22 sec. Approx. 17 hours

1 Above table is an estimate only. It is when BL is being charged under continuous light conditions.

2 BL charges as you are using it, therefore it is not a requirement for to have a fully charged battery

before use.

Table 2. Measure of illuminance by the available uses

Illuminance

lux

No pre-charge 30 min. pre-charge 1 hour pre-charge

Available

Uses

Communication

Cycle /s

Available

Uses

Communication

Cycle/s

Available

Uses

Communication

Cycle/s

200 1500 19.2 1594 18.1 1688 17.1

500 3000 9.6 3188 9.0 3375 8.5

1000 6140 4.7 6524 4.4 6908 4.2

2000 12278 2.3 13045 2.2 13813 2.1

3 Available uses means when BLA is charged under continuous light under each level of illuminance, lux.

4 "No pre-charge" not include the time of available one use on Table 1.

5 "Communication cycle" means 8 hours, 28,800 sec. divided by available uses.

11

6-2 R-BL, Receiver

a Power Source

Use the Receiver R-BLA within the range of DC24V.

Make sure to connect DC24V and GND to respective terminal.

The tightening torque of the terminal block is T=50cN.m.

b Operating environment

Use the device in an environment where no metal structure exits nearby wherever possible.

Do not set the antenna for the receiver close to any metal pole, wire or iron pipe. The BL

receiver antenna is arranged parallel to pipes, the communication status may be worsened.

Do not use the device around welding machines, electric discharge machines or any machine

producing electromagnetic noise such as PC.

c Connection with other equipment

Before wiring, check that the power of the device to be connected with the receiver is in the

OFF position.

Use a solder-less terminal of the size as shown below.

The tightening torque of the terminal block screw is T=50cN.m.

5.8mm or less

5.8mm or less

R-BL, Receiver

GND

DC24V

12

d Connecting “RESET”and “LS IN”

If you would like to connect to the "RESET" and "LS IN" terminal please use a non-contact

voltage switch. Example, LS torque wrench, relay, etc.

Do not feed the external power to input circuit to prevent damage.

EMI filter

EMI filter

Internal circuit

RESET

Vcc

LS-IN

Photocouple

r

Photocoupler Non-voltage

contact switch

Non-voltage

contact switch

e Relay output from OUT1, OUT2, OUT3 and OUT4.

Relay

Relay

Internal circuit

OUT

1

OUT

4

Load

External power

Load

External power

・・・・

Set the load of the contact output within the rated load. Relay output rating: DC30V 1A, AC125V

0.5A. The above rated contact capacity is according to resistance load. Some kinds of loads have a

big difference between the steady-state current and the inrush current. Typical loads and inrush

currents are as follows:

Kind of Load Inrush Current

Resistive Load

1 time as large as the steady-state current

Solenoid Load

10 to 20 times as large as the steady-state current

Motor Load

5 to 10 times as large as the steady-state current

Incahdescent Lamp

10 to 15 times as large as the steady-state current

Mecury Vapor Lamp

About 3 times as large as the steady-state current

Sodium Vapor Lamp

1 to 3 times as large as the steady-state current

Capacitor Load

20 to 40 times as large as the steady-state current

Trans Load

5 to 15 times as large as the steady-state current

13

f Contact Protection Circuit

When the inductive load is opened or closed, a counter-electromotive voltage is generated

and causes a heavy damage to the contact, resulting in a significant shortening of operating

life. Therefore, a contact protection circuit is required. The examples of contact protection

circuits are as shown in the table below.

AC DC

If this circuit is used for timer

loads, leakage current flowing

through cr cause faulty operation.

*If used with AC voltage,

impedance of the load should be

○ ○

D

i

o

d

e

t

y

p

e

×

○

Energy stored in the coil is

discharged to the coil by flow of

current by the diode connected in

parallel to the load and is

consumed by joule heat of the

resistance of the inductive

Use a diode with a peak inverse

voltage 10 times higher than the

circuit voltage and a forward current

as high as or higher than the load

current. In an electronic circuit

where the circuit voltage is not so

high, a diode with a peak inverse

voltage about 2 to 3 times higher

Selection of element

Circuit example

C

R

t

y

p

e

※

△

○

The standard c and r are as follows:

c:0.5 to 1 (μF) per contact current

(1A)

r:0.5 to 1(Ω) per contact vaolage

(1V)

The above values vary depending on

the property of load or variations in

relay characteristic. Considering that

the capacitor "c" has the effect of

controlling the discharge when the

contactes are open and the resistor

"r" plays the role fo controlling the

current at the next power-on, check

through experiments is required.

Normally, use a capacitor with a

If the load is a relay or solenoid, the

reset time is delayed. It is effective

to connect between the loads when

the power supply voltage is 24 or

48V and to connect between the

contacts when the power supply

voltage is 100 to 200V

Applicability

Features/others

rc

Relay contact

I

n

d

u

c

t

i

v

e

l

o

a

d

r

c

Relay contact

I

n

d

u

c

t

i

v

e

l

o

a

d

Relay contact

Diode

In

d

u

c

tiv

e

lo

a

d

14

6-3 BL Antenna

Refer to below drawing when mounting or dismounting an antenna on R-BL receiver. Do not

turn antenna itself. Hold the antenna and turn the notched end of the antenna.

6-4 Error on R-BL receiver

When following Error codes are indicated on R-BL receiver, cancel each error condition.

Code Description Solution

ERR6 Flow Control Error

CTS, Clear to Send signal is undetected.

Make sure CTS/RTS flow control.

Check if the connector cable is properly connected.

ERR8 Memory Abnormality Memory data is defected. Reset all.

Contact Tohnichi for repairing.

ERR13 Overlapping The ID has been registered to a different output already.

Remove it and register again.

Hold the antenna not to rotate

Rotate the jagged part

15

6-5 RS232C

Description

Factory Default

Baud Rate

Selectable 2400/4800/9600/19200/38400/115200bps

115200bps

Parity

Selectable None/Even/Odd

None

Data Length

Selectable 7 or 8 bit

8bit

Stop Bit Selectable 1 or 2 bit 1bit

Flow Control

Selectable ON/OFF, CTS-RTS

off

Output Format, non registered ID

R E , * * * * * * * * CR LF

Output Format, registered OUT1 to 4

R E , * * * * * * * * , O U T * CR LF

Output Format, registered RS1 to 6

R E , * * * * * * * * , R S * CR LF

Output Format when input LS-IN

R E CR LF

Reset Command Format

A T 1 3 0 CR LF

Input Contact terminal to reset “outputting non-voltage contact signal” and “auto-reset”.

16

7 Setting Receiver

7-1 Setting Receiver

As a default setting, BL Receiver receives all signals of BL Transmitter, T-BLA to R-BLA, T-BLE to

R-BLE and T-BL to R-BL. Refer to 7-2, Setting Procedure. ID registered receiver does not receive any

other ID signal. Up to 10 Transmitters can be registered to one receiver. Total 4 IDs output as

non-voltage contact signal and RS232C output. Other 6 IDs output through RS232C only.

OUT1 to OUT4 Register IDs on OUT1 to OUT4

OUT1 to OUT4 outputs ID through contact output and RS232C.

RS1 to RS6 Register IDs on RS1 to RS6

RS1 to RS6 outputs ID through RS232C

Flow Control Select ON/OFF of CTS, RTS control

Baud Rate Select one from 2400, 4800, 9600, 19200, 38400, and 115200bps

Parity Select one from NONE, ODD, and EVEN

Data Length Select one between 7 and 8bit

Stop Bit Select one between 1 and 2bit

Buzzer Sound Select ON/OFF of buzzer sound

Auto Reset Timer Select between 0.0~9.9 seconds

Since R-BL does not receive any signal during the auto reset process, this

function also can be used as double count prevention

Auto reset function will be disabled if set as 0.0 second. In this case, reset can be done only

through reset input or through reset command.

Factory Default

Item

OUT1

to

OUT4

RS1

To

RS6

Flow

Control Baud Rate Parity Data

Length Stop Bit Buzzer

Auto

Reset

Timer

Status Off 115200bps NONE 8bit 1bit ON 0.1 Sec

17

7-2 Setting Procedure

Turn on the power switch while pressing SET key to start mode setting.

Status lamp flashes red and blue when you are in Mode Setting.

In Mode Setting, select BL preference by press “SET” key, from OUT1 to the End.

OUT1-OUT2-OUT3-OUT4-RS1-RS2-RS3-RS4-RS5-RS6-Flow-Baud-Parity-Length-Stop-Buzz-Auto-End

Setting OUT1 to OUT4

“ - - - - -“ is displayed on status screen when no tool is

registered.

Registered 8 digit number of Transmitter ID is displayed.

Select Switch

Set Switch

Power Switch

18

Press The “SELECT” key to choose between “ENTRY”or

“CLEAR”. Select “ENTRY” by pressing the “SET” key.

“READY” appears on screen. Status lamp blinks in red.

Operate BL transmitter and the receiver receives ID. The

registered ID number is displayed on status screen.

To cancel any registered ID, press SELECT key and choose

“CLEAR” and press the SET key.

Setting RS1 to S6

Press “SET” key to register the next tool.

After making a selection, press the “SET” key to go to the

next screen.

Setting Flow Control

Press SELECT key to select ON/OFF of Flow Control.

Setting Baud Rate

Press SELECT key to select a Baud Rate from 2400, 4800,

9600, 19200, 38400, and 115200bps.

This manual suits for next models

5

Table of contents

Other Tohnichi Tools manuals

Popular Tools manuals by other brands

Humboldt

Humboldt H-4137 instruction manual

Sears

Sears CRAFTSMAN WOODWORKERS VISE 391.5195 owner's manual

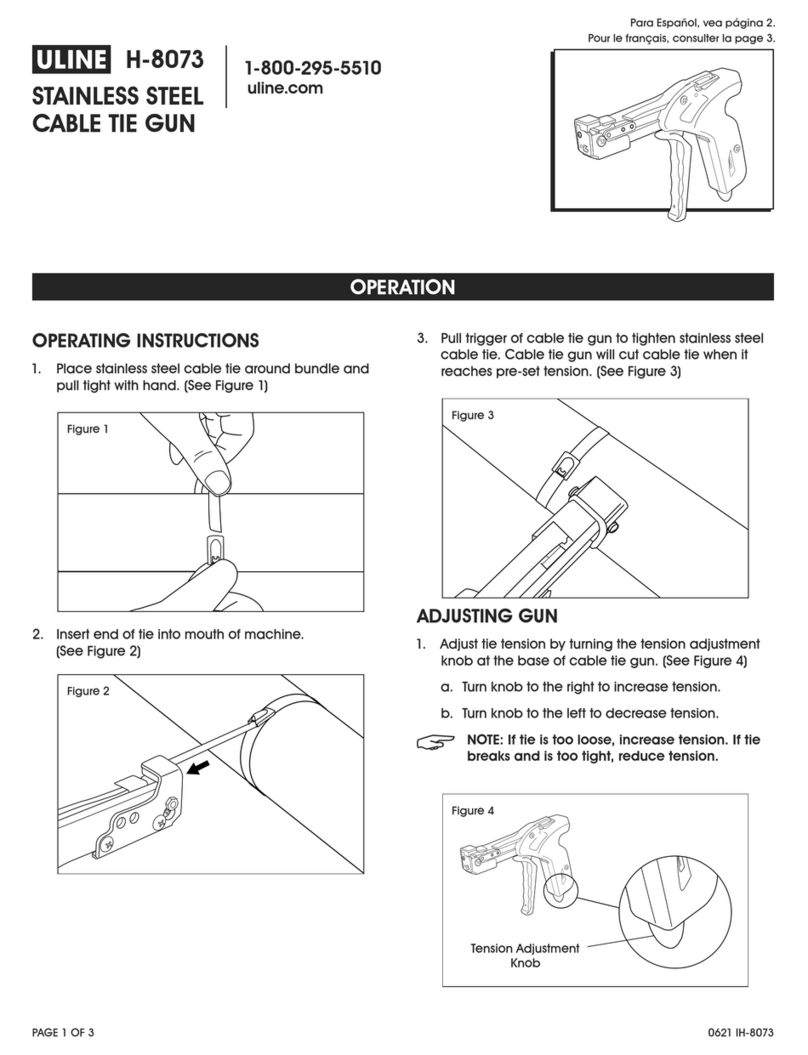

U-Line

U-Line H-8073 quick start guide

SKF

SKF TMHP 15 Series Instructions for use

DR Power Equipment

DR Power Equipment PTO POST HOLE DIGGER Safety & Operating Instructions

Launch

Launch Creader Elite GM troubleshooting guide