6. Changing and Saving Temperature Set Value

Main Operation Screen

When SET button pressed ‘’S’’ led will

be active and temperature set value will

be displayed.

SET Value Screen

Temperature set value can

be changed with increment

and decrement buttons.

When SET button pressed

temperature set value can be saved.

‘’S’’ will be inactive and goes back to

main operation screen.

Main Operation Screen

Temperature set value parameter (Default=30) MODBUS ADDRESS:40001

Temperature set value, can be programmed between minimum temperature set value and

maximum temperature set value .

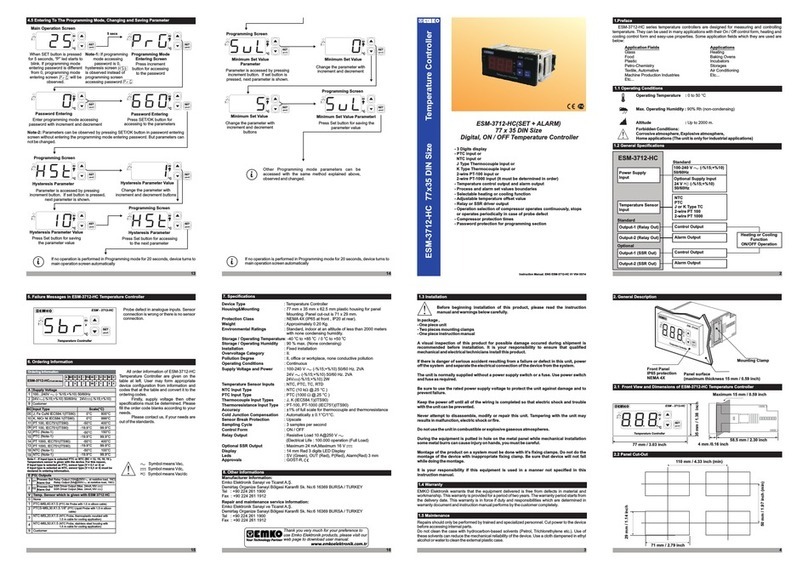

4.2 Device Label and Connection Diagram

4. Electrical Wiring Diagram

4.1 Supply Voltage Input Connection of the Device

Note-1 :External fuse is recommended.

Make sure that the power supply voltage is the same

indicated on the instrument.

Switch on the power supply only after that all the electrical

connections have been completed.

Supply voltage range must be determined in order. While

installing the unit, supply voltage range must be controlled

and appropriate supply voltage must be applied to the unit.

c

There is no power supply switch on the device. So a power

supply switch must be added to the supply voltage input.

Power switch must be two poled for seperating phase and

neutral, On/Off condition of power supply switch is very

important in electrical connection.

External fuse that on Vpower supply inputs must be on

phase connection.

External fuse that on Zpower supply inputs must be on (+)

connection.

c

230VVCONNECTION DIAGRAM

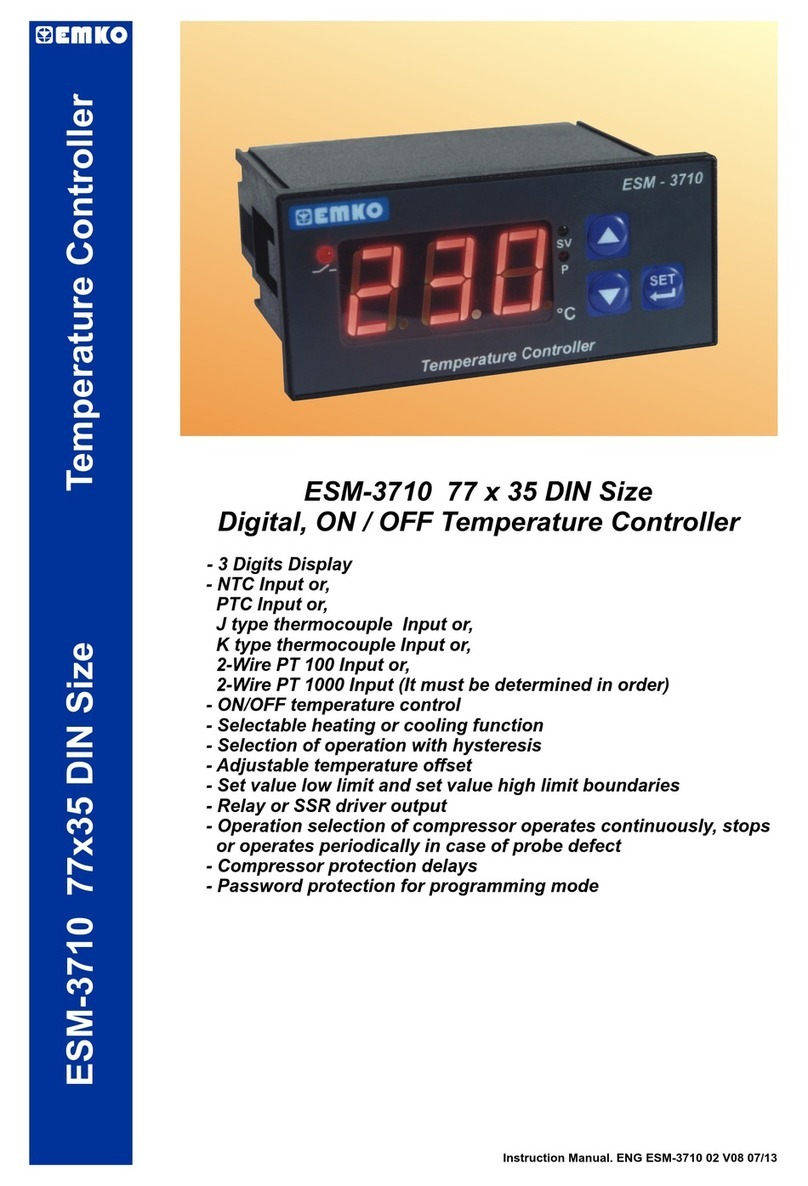

5.Front Panel Definition and Accessing to the Menus

BUTTON DEFINITIONS

1. Increment Button :

** It is used to increase the value in the Set screen and Programming mode.

2. Decrement, Silencing Buzzer and Downloading to Prokey Button :

** It is used to decrease the value in the Set screen and Programming mode.

** It is used to silence the buzzer.

** If Prc =0, it is used to download from device to prokey.

3. Set Button :

** In the main operation screen; if this button pressed, set value will be displayed. Value can be

changed using increment and decrement buttons. When Set button pressed again, value is

saved and returns back to main operating screen.

** To access the programming screen; in the main operation screen, press this button for 5

seconds.

** It is used to saving value in the Set screen and programming screen.

4. Alarm Set Button :

** In the main operation screen; if this button is pressed, Alarm set value will be displayed. Value

can be changed using increment and decrement buttons. When Set button is pressed again,

value is saved and returns back to main operating screen.

LED DEFINITIONS

5. Cooling led :

** This led indicates that cooling control is selected and process output relay is active. If any of

compressor protection time active, this led blinks.

6.Heating led :

** This led indicates that heating control is selected and process output relay is active.

7.Alarm led :

** It is active in all alarm status.

8.Celcius led :

o

** Indicates that device is in C mode.

9.Fahrenheit led :

o

** Indicates that device is in F mode.

10.Alarm Set led :

** It is active when alarm statuses.

11.Set led :

** Indicates that device is in Set value changing mode.

12.Program led :

**Blinks in programming mode .

Cooling

Heating

Sensor Offset Parameter ( Default = 0 ) MODBUS ADDRESS:40007

from -20 to 20 °C for NTC(-50°C, 100°C) or PTC(-50°C, 150°C),

from -36 to 36 °F for NTC(-58°F, 212°F) or PTC(-58°F, 302°F),

from -10.0 to 10.0°C for NTC(-50.0°C,100.0°C) or PTC(-50.0°C,150.0°C),

from -18.0 to 18.0°F for NTC(-58.0°F,212.0°F) or PTC(-58.0°F,302.0°F),

Compressor Start Delay at Power On Parameter ( Default = 0)

MODBUS ADDRESS:40009

When power is first applied to the device, compressor is on when this time delay is expired.

It can be adjusted from 0 to 20 minutes.

Compressor Stop-Start Delay Parameter ( Default = 0) MODBUS ADRES:40010

When compressor is inactive, this time delay must be expired for activation of the

compressor. It can be adjusted from 0 to 20 minutes.

Compressor Start-Start Delay Parameter ( Default = 0) MODBUS ADRES:40011

This time delay must be expired between two activation of the compressor. It can be

adjusted from 0 to 20 minutes.

6.3 Modbus Adresses of Device Status Parameters (Read Input Register)

Operating Type Parameter ( Default = 0) MODBUS ADDRESS:40008

If parameter value is ‘0’ device skips to parameter

5 6 9 10

121187

1.Switch off the device.

2.Put in PROKEY then energize the device.

3.When the device is energized, the parameter values in PROKEY, start downloading to the device

automatically. At first, message is shown on the display, when loading has finished,

message is shown.

4.After 10 seconds device starts to operate with new parameter values.

5.Remove the PROKEY.

1-Before mounting the device in your panel,

make sure that the cut-out is of the right size.

2-Insert the device through the cut-out. If the

mounting clamps are on the unit, put out them

before inserting the unit to the panel.

3- Insert the mounting clamps to the fixing sockets

that located left and right sides of device and make

the unit completely immobile within the panel

3

1-Pull mounting clamps from left and right fixing

sockets.

2-Pull the unit through the front side of the panel

Before starting to remove the unit from

panel, power off the unit and the related

system.

c

2.3 Panel Mounting

2.4 Removing from the Panel

3. Using Prokey

DOWNLOADING FROM DEVICE TO PROKEY

1.The device is programmed by using the parameters.

2.Energize the device then put in PROKEY and press button. Message is shown on the

display. When the loading has finished, message is shown.

3.Press any button to turn back to main operation screen.

4.Remove the PROKEY.

DOWNLOADING FROM PROKEY TO DEVICE

NOTE: message is shown when an error occurs while programming. If you want to reload, put

in PROKEY and press button. If you want to quit, remove PROKEY and press button. The

device will turn back to main operation screen.

NOTE: message is shown when an error occurs while programming. If you want to reload,

switch off the device and put in PROKEY then energize the device. If you want to quit remove

PROKEY and press button. The device will turn back to main operation screen.

TO USE PROKEY, VALUE OF THE PrC PARAMETER MUST BE ‘0’.

IF PrC=1 AND BUTTON IS PRESSED MESSAGE WILL BE SHOWN. 10s. LATER

DEVICE TURNS BACK TO THE MAIN OPERATION SCREEN OR YOU CAN PRESS SET

BUTTON TO TURN BACK TO MAIN OPERATION SCREEN.

1

3

6.2 Programming Mode Parameter List

Hysteresis Parameter for Compressor Output ( Default = 1 )

MODBUS ADDRESS:40004

from 1 to 20°C for NTC (-50°C, 100°C) or PTC (-50°C, 150°C),

from 1 to 36°F for NTC (-58°F, 212°F) or PTC (-58°F, 302°F),

from 0.1 to 10.0°C for NTC(-50.0°C,100.0°C) or PTC (-50.0°C,150.0°C),

from 0.1 to 18.0°F for NTC (-58.0°F,212.0°F) or PTC (-58.0°F,302.0°F),

In ON/OFF control algorithm, temperature

value is tried to keep equal to set value by

opening or closing the last control element.

ON/OFF controlled system, temperature

value oscillates continuously. Temperature

value’s oscillation period or amplitude around

set value changes according to controlled

system. For reducing oscillation period of

temperature value, a threshold zone is formed

below or around set value and this zone is

named hysteresis.

ON

OFF

Temperature

Control

Output

Set

HSt

Time

HSt

Time

Minimum Temperature Set Value Parameter (Default = Minimum Value of Device

Scale ) MODBUS ADDRESS:40005

Temperature set value can not be lower than this value.

This parameter value can be adjusted from minimum value of device scale to maximum

temperature set value parameter

Maximum Temperature Set Value Parameter (Default = Maximum Value of Device

Scale )MODBUS ADDRESS:40006

Temperature set value can not be bigger than this value.

This parameter value can be adjusted from minimum temperature set value parameter

to maximum value of the device scale

Decimal Seperator Enabling Parameter ( Default = 0 ) MODBUS ADDRESS:40003

Disable.

Enable.

Temperature Unit Selection Parameter ( Default = 0 ) MODBUSADDRESS:40002

°C selected.

°F selected.

Sensor Defect Parameter ( Default = 0 ) MODBUS ADDRESS:40012

Compressor is active during this time period in case of probe defect (Default = 0)

MODBUS ADDRESS:40013

If probe defect parameter is 2, then this parameter is observed. It can be adjusted

from 0 to 99 minutes.

Compressor is OFF in case of sensor defect.

Compressor is ON in case of sensor defect.

Compressor operates periodically according to and Time periods in

case of sensor defect.

Compressor is inactive during this time period in case of probe defect

( Default = 0 )MODBUS ADDRESS:40014

If probe defect parameter is 2, then this parameter is observed. It can be adjusted

from 0 to 99 minutes.

Buzzer Function Selection Parameter ( Default = 0 ) MODBUS ADDRESS:40023

Buzzer is inactive.

Buzzer is active if an alarm occurs.

Buzzer is active during this time

When this parameter is 1, if decrement button is pressed, is observed. In this

condition buzzer is active till buzzer silence button is pressed.

( Default = ) MODBUS ADDRESS:40024

If buzzer function selection parameter value =0, this parameter can not be

observed. Buzzer stays active during this time. It can be adjusted from 1 to 99 minutes

Programming Section Accessing Password 27

.

( Default = 0 ) MODBUS ADDRESS:400

It is used for accessing to the programming section. It can be adjusted from 0 to 9999. If it is

selected 0, password will not be asked

PROKEY communication selected.

Communication Mode Selection Parameter 25( Default = 0 ) MODBUS ADDRESS:400

RS 485 communication selected.

Slave ID Parameter 26( Default = 1 ) MODBUS ADDRESS=400

Device communication address parameter (1 to 247).

Power Supply Connection

c

a

EXTERNAL

FUSE

(1A T)

Note-1

Supply

Switch

Supply Voltage

45

LN

2

Buzzer is active during sensor failures.

Buzzer is active during alarm or sensor failures.

6.1 Changing and Saving Alarm Set Value

230V ( %15) 50/60Hz ,

115V ( %15) 50/60Hz ,

Z

V±

V±

10...30 V -1.5 W

Must be determined in order.

, , , , and Parameters are observed if Operation type

is selected “Cooling”. If operation type is selected “Heating ” ,skip to the parameter.

i

Process and Alarm

Relay Outputs

Supply Voltage Input

Temperature Sensor

Input (NTC or PTC)

230V ( %15) 50/60Hz

115V ( %15) 50/60Hz

Z

V±

V±

10...30 V

Must be determined in order.

ü

OF

OCP

S

58

11

12

1

23

9

A

6

7 10

A

S

4

OF

OCP

S

ü

S

A

OF

OCP

S

ü

ü

S

A

OF

OCP

S

ü

S

A

OF

OCP

S

ü

S

A

21 4 5 6 7

P/N : ESM-3712-HCN

L

N

aa

3

Alarm Type Selection Parameter ( Default = 2 )MODBUS ADRESS:40015

Sensor Break Alarm

Process High Alarm

Process Low Alarm

Deviation High Alarm

Deviation Low Alarm

Deviation Band Alarm

Deviation Range Alarm

Alarm Set Value Low Limit Parameter ( Default = Minimum Value of Device Scale)

MODBUS ADDRESS:40016

Alarm set value can not be lower than this value.This parameter value can be adjusted

from minimum process set value parameter to alarm set value high limit parameter

value.

Alarm Set Value High Limit Parameter ( Default = Maximum Value of Device Scale)

MODBUS ADDRESS:40017

Alarm set value can not be greather than this value.This parameter value can be

adjusted from alarm set value low limit parameter value to maximum process set value

parameter.

Alarm On Delay Time Parameter( Default = 0 ) MODBUS ADDRESS:40018

It can be adjusted from 0 to 99 minutes.

Alarm Off Delay Time Parameter( Default = 0 ) MODBUS ADDRESS:40019

It can be adjusted from 0 to 99 minutes.When this parameter is 99, if increment button is

pressed, is observed and alarm latching output is selected. To make the alarm latching

output passive,decrement button must be pressed in main operation screen.

Alarm Delay Parameter After Power On

This parameter defines the delay for the alarm is being active after power on.It can be

adjusted from 0 to 99 minutes.

( Default = 0 )MODBUS ADDRESS:40020

Alarm Set Value Parameter ( Default = 20 )MODBUS ADDRESS:40021

Alarm output is controlled according to this value.For alarm type selection paramater

=1 or 2,this parameter value is can be adjusted from alarm set value low limit

parameter to alarm set value high limit parameter,for alarm type selection parameter

=3,4,5 or 6 this parameter value is can be adjusted from 0 to alarm set value high limit

parameter.

Alarm Hysteresis Parameter

Alarm hysteresis value.

( Default = 0 )MODBUS ADDRESS:40022

This parameter is can be adjusted 0 to %50 of the device scale.

MODBUS ADRES:30001 Temperature Value

o

MODBUS ADRES:30002 Led Status : 0.bit C Led,6.bit Compressor Led,

7.bit Alarm Led, 13.bit Program Led,

14.bit Set Led

MODBUS ADRES:30003 Device Status : 0.bit Alarm Status

2.bit Buzzer Status

3.bit Sensor Break Status

MODBUS ADRES:30004 Output Status 0.Bit Compressor Output,1.bit Alarm Output

MODBUS ADRES:30005 Device Type and Device Version

A

6.4 Operation Graphics of Alarm Output and Alarm Types

Power

Time

Alarm

Status

Alarm

Output

Active

Led

°C

Time

Time

Time

Alarm

Output

Power

Time

Alarm

Status

Alarm

Output

Active

Led

°C

Time

Time

Time

Alarm

Output

=

( Alarm Latching Output is Selected )

Decrement

Button must

be pressed

to make alarm

output is

passive.

6.4 Operation Graphics of Alarm Output and Alarm Types

ON

OFF

Alarm

Output

Process Value

Process Low Alarm

ON

OFF

Alarm

Output

Process Value

Deviation High Alarm

Deviation Low Alarm

ON

OFF

Alarm

Output

Process Value

( + )

ON

OFF

Alarm

Output

Process Value

( - )

Deviation Band Alarm

ON

OFF

Alarm

Output

Process Value

( - )

( + )

= Process Set Value

i= Alarm Set Value

Deviation Range Alarm

ON

OFF

Alarm

Output

Process Value

( - ) ( + )

Process High Alarm

Main Operation Screen

When ALARM SET button pressed ‘’A’’

led will be active and temperature set

value will be displayed.

ALARM SET Screen

Alarm set value can be

changed with increment and

decrement buttons.

OF

OCP

S

OF

OCP

S

ü

S

A

ü

S

A

AA

Main Operation Screen

OF

OCP

S

ü

S

A

A

ALARM SET Screen

When SET button pressed

Alarm set value can be

saved.

OF

OCP

S

ü

S

A

A

Alarm set Value saved,

’A’ will be inactive and goes back to

main operation screen.

ü

S

A

If no operation is performed in Alarm set value changing mode and process set value changing

mode for 20 seconds, device turns to main operation screen automatically.

i

1

2

PROKEY

RS-485

or

67

a

16(8)A

@250V 1HPV

LN

245

1

PTC

L

N

16A T Sigorta

NO

C

3

NO

COMP. ALARM

5A@250VV

230 VV± 15%

50/60Hz - 1.5VA

+-

230 VV± 15%

50/60Hz - 1.5VA

P/N : ESM-3712-HCN - 5.12.0.1/01.00/2.1.0.0

LINE

PROKEY

RS-485

or

C NO

COMP.

1 2 3 4 5 67

ALARM

NO

16(8)A @

250V 1HPV5A@250VV

LOAD

PTC

INPUT SCALE

(-50 ,150 ;°C °C °F °F-58 ,302 )