Tolomatic TC05 User manual

Parts Sheet

1001-4009_06_TC05ps

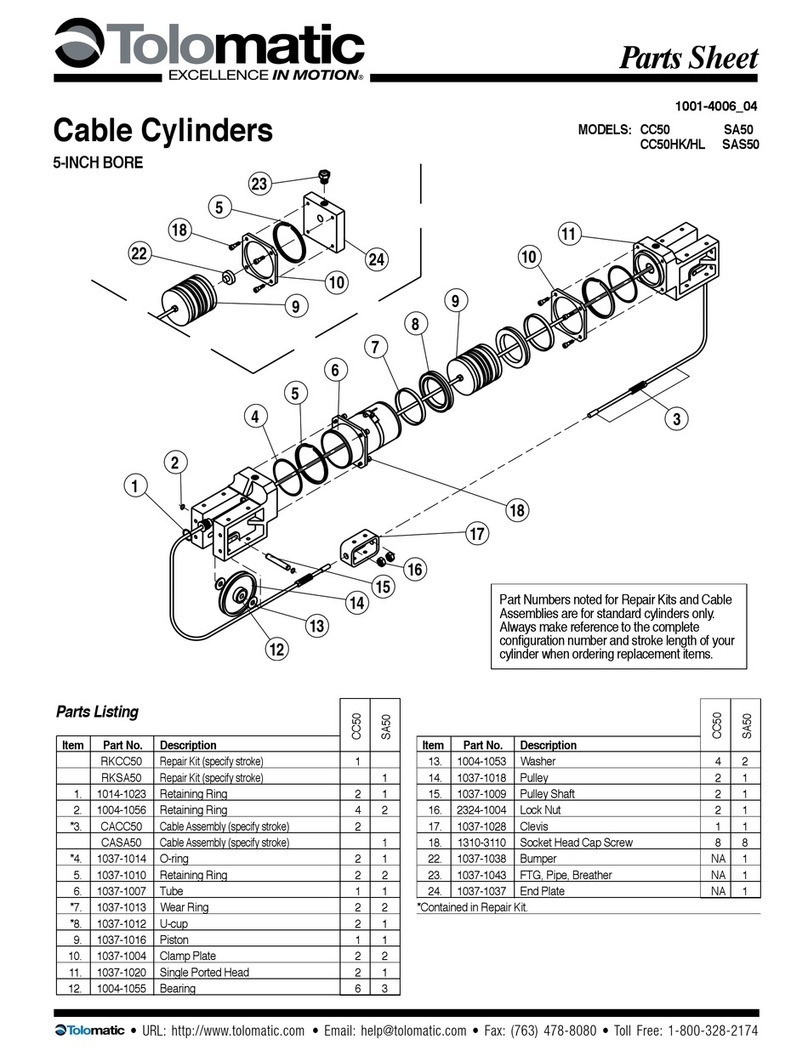

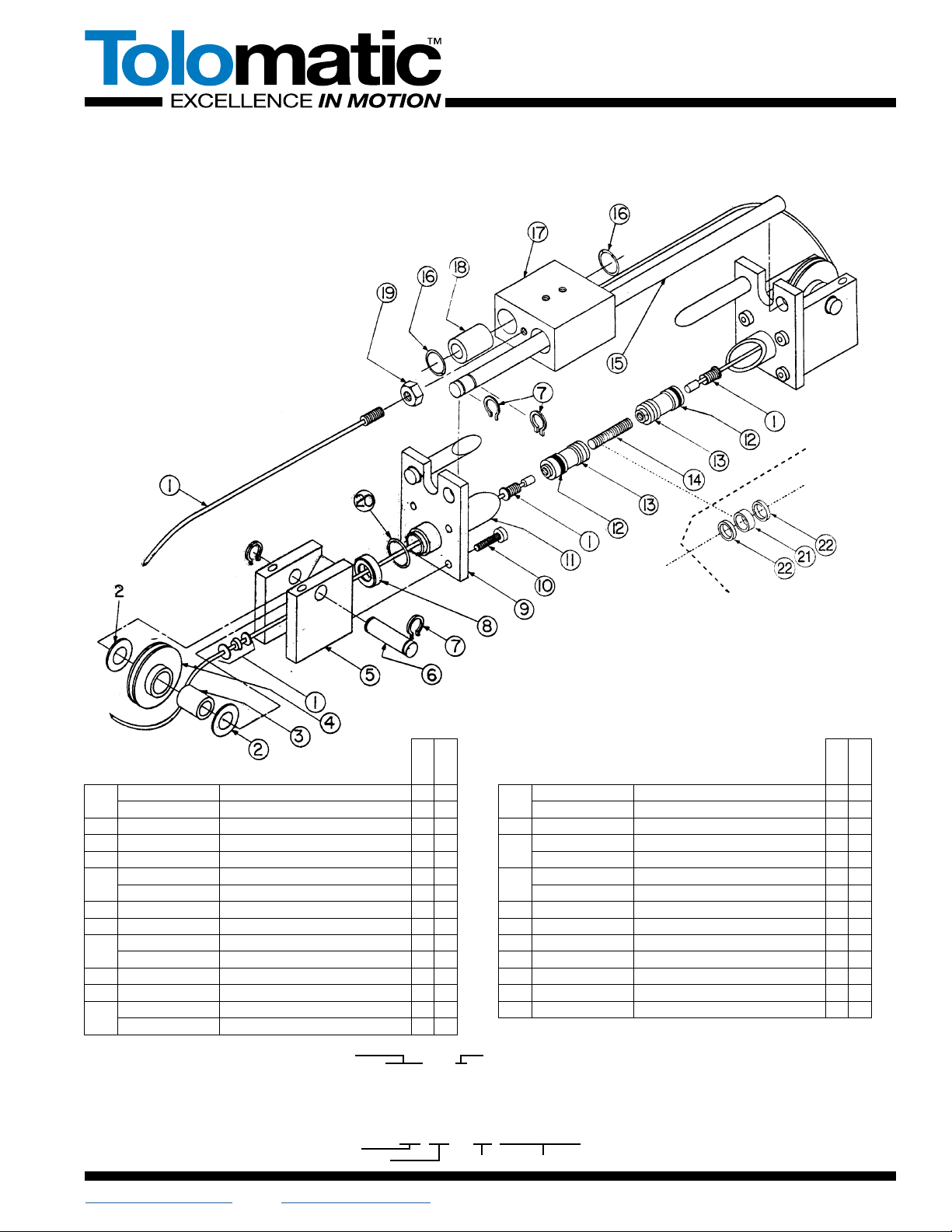

ITEM

PART NO. OR

CONFIG. CODE DESCRIPTION

TC05

TCM05

2,31. CATC05SK_ CABLE ASSEMBLY 2

CATCM05SK_ CABLE ASSEMBLY W/ MAGNET 2

2. 0100-1306 THRUST RACE 4 4

3. 1001-1055 NEEDLE BEARING 2 2

4. 1050-9005 PULLEY ASSEMBLY 2 2

5. 1085-1005 CYLINDER HEAD, SINGLE PORT 2 2

1001-1109 GLAND INSERT 2 2

6. 1001-1052 PULLEY SHAFT 2 2

7. 1001-1056 EXTERNAL RETAINING RING 8 8

38. 1085-1025 TUBE SEAL, BUNA-N MATERIAL 2 2

1085-1025 TUBE SEAL, VITON®MATERIAL 2 2

9. 1085-1050 CLAMP PLATE 2 2

10. 1085-1075 SOCKET HEAD CAP SCREW 8 8

111. RTBTC05SK_ ALUMINUM TUBE 1

RTBTCM05SK_ ALUMINUM TUBE W/ MAGNET 1

ITEM

PART NO. OR

CONFIG. CODE DESCRIPTION

TC05

TCM05

312. 1080-1020 PISTON U-CUP, BUNA-N MATERIAL 2 2

1080-1020 PISTON U-CUP, VITON®MATERIAL 2 2

13. 1085-1040 PISTON 2 2

14. 1001-1194 PISTON SPACER 1

1001-1231 PISTON SPACER WITH MAGNET 1

115. NGSTC05SK_ GUIDE SHAFT 2

NGSTCM05SK_ GUIDE SHAFT W/ MAGNET 2

16. 1001-1199 INTERNAL RETAINING RING 4 4

17. 1001-1197 BEARING BLOCK 1 1

18. 1001-1192 LINEAR BEARING 3 3

19. 1004-1188 JAM NUT 2 2

20. 1085-1018 EXTERNAL RETAINING RING 2 2

21. 1080-1012 MAGNET RING 1

22. 1085-1042 ROD, SPACER, PISTON 2

Track Cable Cylinder

TC05 1/2" Bore MODELS: TC05

TCM05

Replaced #1001-0230 & #1001-0234

Part Numbers noted for Repair Kits

and Cable Assemblies are for standard

cylinders only. Always make reference

to the complete configuration number

and stroke length of your cylinder

when ordering replacement items.

3 Repair Kit (RK) includes: Piston U-Cups, Quad Rings,

O-Rings, Cable Assembly

4 Mis for optional switch magnet, which is required for

switches to function. Since the Magnet Option adds

length to the piston and the tube length, it must be

included when ordering.

Model

Repair Kit

Magnet

4

Stroke Length

Size

___ TC M 05 SK_____

RTB TC M 05 SK21.25

__ TC M 05 SK_____

RK TC M 05 SK21.25

Tube

1 Replacement Tube (RTB) & Guide Shaft (NGS) ordering method:

EXAMPLE:

2 Repair Kit (RK) & Cable Assembly (CA) ordering method:

EXAMPLE:

Parts Sheet #1001-4009_06_TC05ps TC05 Instructions – 2

Installation

When unpacking a track cable cylinder, BE EXTRA CAREFUL NOT TO

SCRATCH OR MAR THE NYLON COVERING ON THE CABLE. The cylin-

der may be mounted by use of the bolt holes in head. When attaching

the bearing block to a driven mechanism, be sure it is in perfect align-

ment and that the load does not exceed the specifications listed in the

catalog.

Pretensioning and proof-loading instructions: All track cable cylinders

are shipped without being pretensioned. They must be tensioned after

mounting to insure the maximum service life of the unit. There are two

types of stretch in cable— constructional and elastic. The construc-

tional stretch is removed by proof-loading of the cable. The elastic

stretch is removed by proper pretensioning of the cable.

Proof-loading of cables(for cylinders without Auto Tensioners)

1. Tighten the bracket terminal lock nuts equally with a torque wrench

to torque requirements listed in Table A.

2. Let set for 30 seconds.

3. Loosen lock nuts to remove tension.(But leave them tight enough

to eliminate any slack.)

4. Follow Pretensioning Instructions.

TABLE A: TORQUE TO PROOF-LOAD THE CABLE

MODEL REQUIRED TORQUE

TC05 15 INCH-POUNDS (1.69 NEWTON-METERS)

Pretensioning of cables

1. Remove one of the guide shafts to gain access to the terminals to

adjust the cable tension.

2. Block the load some distance from the end of travel to keep the cyl-

inder from bottoming.

3. Apply pressure 15 to 20 percent higher than the actual pressure

required to move the load.

NOTE: Load pressure is defined as the actual pressure required to

move the load. When the load is stopped externally before the pis-

ton bottoms, the relief valve or regulator setting becomes the load

pressure.

When pressurized, one cable will become tight while the other

becomes slack. Manually take up the slack in the cable. Release

the pressure and block the load from the other side. Repeat the

manual adjustment on the other cable. Release pressure and

remove the blocks. Reinstall the guide shaft which had been

removed. Return the regulator to its original setting.

The cylinder is now pretensioned. Additional manual adjustment

should not be required. It is suggested however, that the cable ten-

sion be checked periodically.

Alternate Method: If the load cannot be blocked for cable preten-

sioning as stated above, tighten the bracket terminal lock nuts with

a torque wrench to total pretensioning torque as stated in Table B.

TABLE B: TORQUE FOR UNBLOCKABLE LOADS

MOD-

EL

PRETENSIONING

TORQUE +

STARTING TORQUE

OF TERMINAL NUTS =

TOTAL PRETENSION-

ING TORQUE

TC05 2.5 IN-LBS. + 10.0 IN.-LBS. = 12.5 IN.-LBS.

0.282 N-M + 1.130 N-M = 1.412 N-M

TO REBUILD THE CYLINDER

1. Remove the track cable cylinder from machinery.

2. Remove the Guide Shafts(15) then disconnect Cables(1) from

Bearing Block(17) and remove Pulleys(4) on both ends of track

cable cylinder.

3. Remove one Head(5) from track cable cylinder by removing the

four Cap Screws(10).

4. Pull Piston(13) towards the removed Cylinder Head(5) and remove

from the Tube(11).

5. Disconnect Cables(1) from Piston(13).(See Cable Assembly/

Disassembly Instructions ). Then remove the other Cylinder Head(5)

from Tube(11) and disengage Cable(1) from it.

6. Install new U-cups(12) Pistons(13).

7. See Cable Assembly/Reassembly Instructions below. Always lubri-

cate seals with oil when installing.

Drawing repeated for reference

8. Put one Cable(1) end through each Cylinder Head(5). Reattach one

head tube and connect the end of one Cable(1) to the Piston(13).

Then connect the other Cable(1) to the Piston(13).

9. Push Piston(13) back into Tube(11) by gently tucking in the

U-cup(12). Mount Cylinder Head(5) back on cylinder with the Cap

Screws(10). Replace Pulleys(4) and connect Cables(1) to Bearing

Block(17).

10. Pretension Cables(1) according to the pretensioning instructions.

11. Operate track cable cylinder back and forth by hand several times to

be sure it is properly assembled before applying pressure.

12. Reinstall track cable cylinder on machinery.

IMPORTANT NOTE: Apply(Blue) Loctite® #242 or equivalent to thread-

ed cable terminal before connecting to the piston.

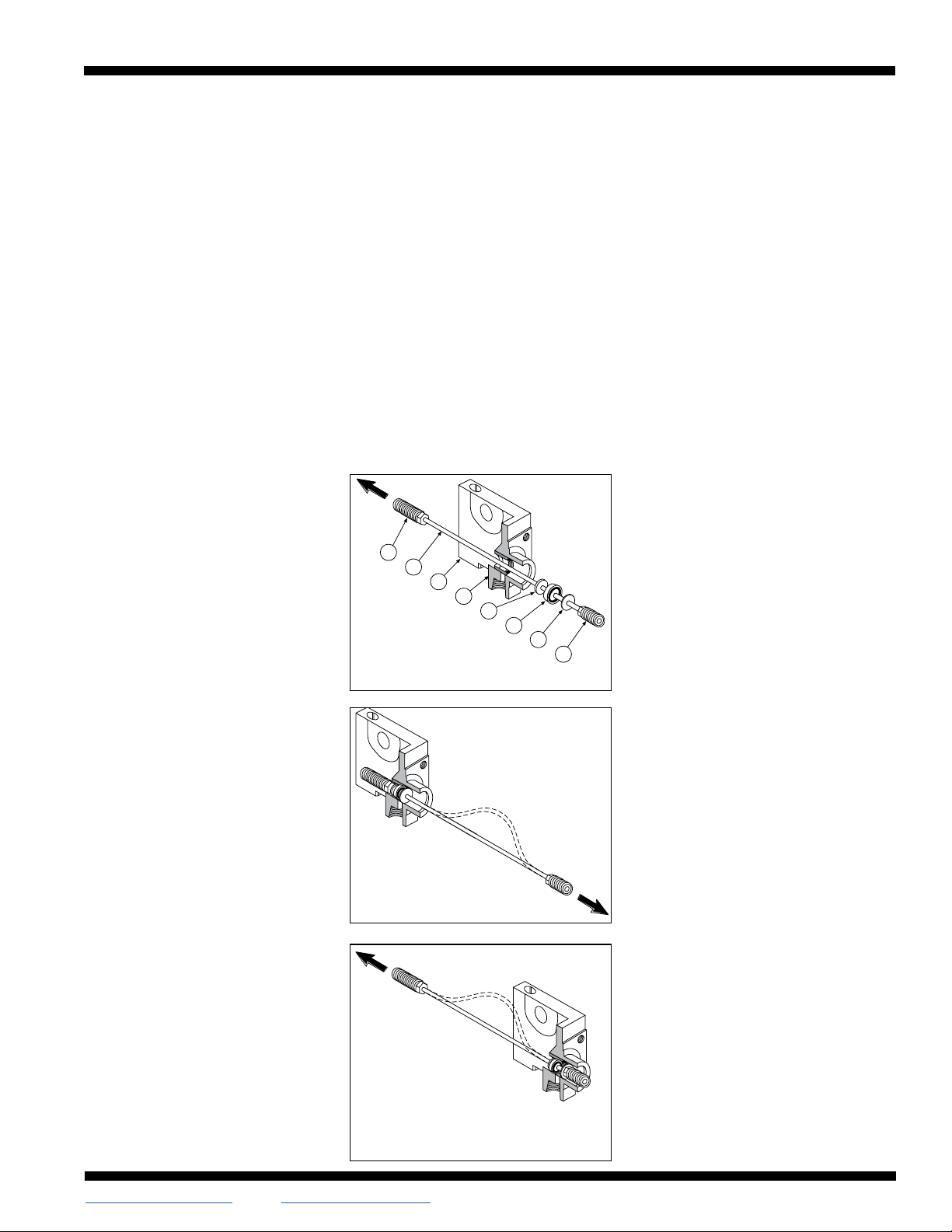

SNAP IN/OUT CABLE ASSEMBLY INSTRUCTIONS

Tolomatic cylinders with 1/2-, 3/4- and 1-inch bores are designed to

allow assembly and disassembly of Cables from the heads without the

use of tools. This eliminates the possibility of damaging the cable or

seals as well as providing for quick repair times.

Disassembly

1. Holding onto cylinder Head(6), pull Piston

Terminal(1) until bracket terminal in(8) is

against Washer(4).

2. Put a small amount of slack in Cable(7)

as shown in Figure 2.

3. Impart a “snap” action to Piston

Terminal(1).

4. With the imparting snap action, Washer(2)

will release allowing the removal of the

complete cable assembly.

Reassembly

1. Holding onto cylinder Head(6), string

Bracket Terminal(8) through Gland(5)

until Washer(4), U-cup(3) and Washer(2)

are held flush against one another by

Piston Terminal(1).

2. Put a small amount of slack in Cable(7)

as shown in Figure 3.

3. Impart a “snap” action to Bracket

Terminal(8).

4. With the snap, Washer(2) with snap into

Gland(5).

5. Move the cable in the opposite direction

as shown in Figure 3, to verify if

Washer(2) is seated in Gland(5). If not,

repeat steps 1-4.

MAINTENANCE

Keep the cylinder as clean as possible around pulleys, glands, etc.

Pneumatic service should be adequately lubricated with SAE 10 or 20

grade non-detergent oil. Pulleys have permanently lubricated bearings

and will require no maintenance. Check the cylinder’s cables periodical-

ly to help prevent premature or unexpected failures.

Your Tolomatic Cable Cylinder will give you many cycles of trouble free

service. However, should a leak occur, a rebuilding kit may be obtained

which enables you to replace all the seals in a cylinder to return it to

normal operating condition.

NOTE: Every Tolomatic Cable Cylinder has its stroke length indicated on

the identification tag shipped with the cylinder. Refer to this stroke mea-

surement when ordering replacement parts for the cylinder.

Should the tag be missing, measure the length of the cylinder including

the heads at both ends. If there are no switches present on the cylinder,

check the piston for a magnet to see if it is a Reed Switch model. If it is,

consult the Tolomatic Cable Cylinder catalog dimensional drawings for

“stroke-plus” length and subtract 1.62 inches for cylinders with 1/2-

inch 3/4-inch and 1-inch bores and .375 inches

for all larger bore Reed Switch models to deter-

mine the stroke length.

Parts Sheet #1001-4009_06_TC05ps TC05 Instructions – 3

8

7

6

5

4

3

2

1

FIGURE 1.

FIGURE 2.

FIGURE 3.

All brand and product names are trademarks or registered trademarks of their

respective owners. Information in this document is believed accurate at time of print-

ing. However, Tolomatic assumes no responsibility for its use or for any errors that

may appear in this document. Tolomatic reserves the right to change the design or

operation of the equipment described herein and any associated motion products

without notice. Information in this document is subject to change without notice.

Visit www.tolomatic.com for the most up-to-date technical information

3800 County Road 116, Hamel, MN 55340 USA

http://www.Tolomatic.com • Email: Help@Tolomatic.com

Phone: (763) 478-8000 • Fax: (763) 478-8080 • Toll Free: 1-800-328-2174

© 2022 Tolomatic 202201311120

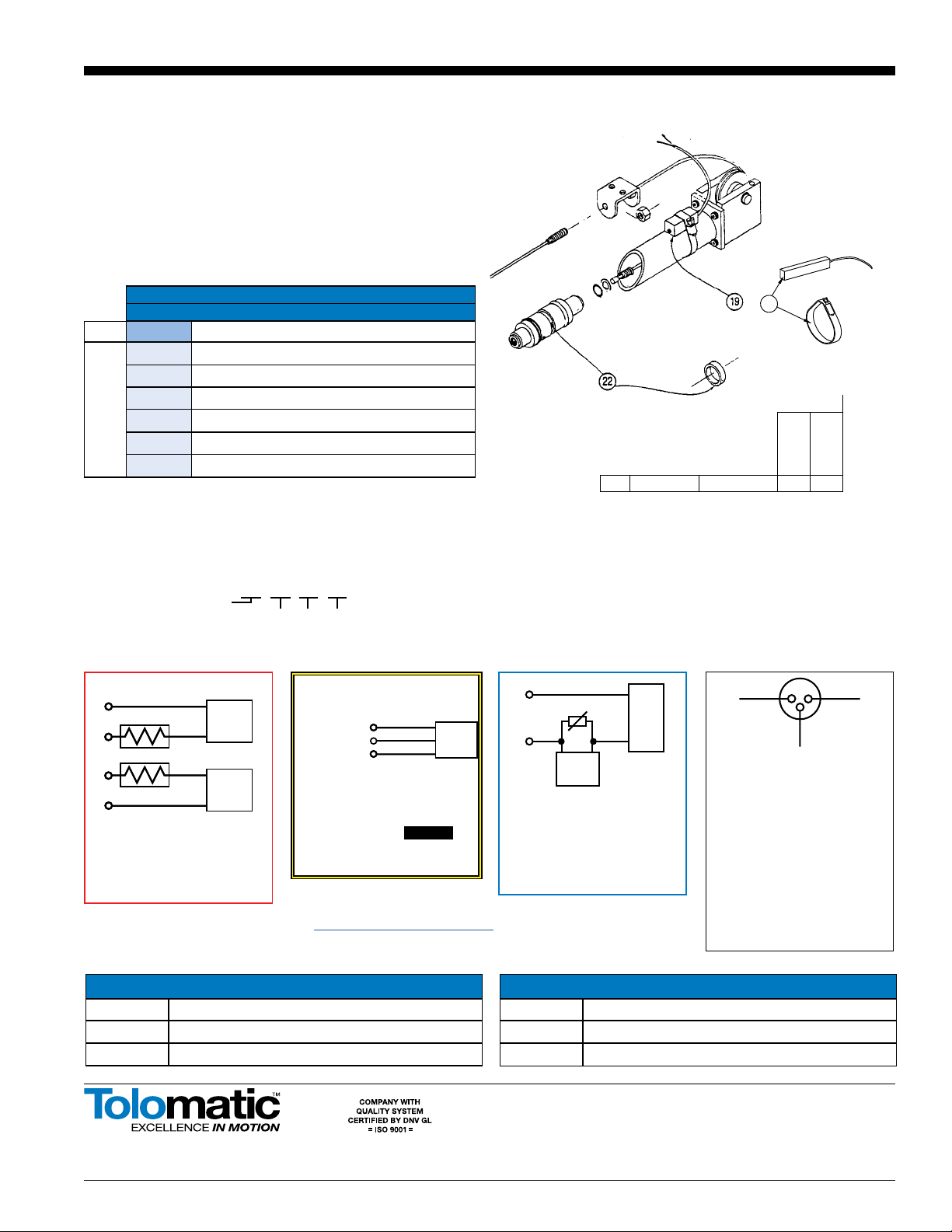

Parts Sheet #1001-4009_06_TC05ps TC05 Switches– 4

REED SWITCH FORM A

LABEL COLOR: RED

10VA MAX. 200 VDC

500MA MAX. CURRENT

Universal Switch Wiring Diagrams and Label Color Coding

TRIAC SWITCH

LABEL COLOR: BLUE

MAX. 1AMP. CONT.

CURRENT @ 86°F

MAX. .5AMP. CONT.

CURRENT @ 140°F

PEAK SURGE CURRENT 10AMP.

QUICK-DISCONNECT

(APPLIES TO ALL SWITCH TYPES)

An Important Note Regarding Field

Retrofit of Quick-Disconnect Couplers:

If replacing a Quick-Disconnect switch

manufactured before

7-1-97 it will also be necessary to

replace or rewire the female-end cou-

pler with the in-line splice

Female Connector 5M

For complete Reed and TRIAC Switch Performance Data, refer to the

Tolomatic Pneumatic Products Catalog.

Loctite® is a registered trademark of the Loctite Corporation, www.loctite.com

Viton® is a registered trademark of the E.I. Du Pont de Newmours Co., www.dupont.com

NOTE: The side of the switch with the

groove indicates the sensing surface.

This must face toward the magnet.

DESCRIPTION

QUANTITY

ITEM PART NO.

TC05

TCM05

22. 1075-1019 MAGNET 1

REED SWITCHES

NOTE: Form A Reed Switches should not be used in TTL logic circuits. A voltage

drop caused by the L.E.D. indicator will result.For applications where TTL circuits

are used, please contact Tolomatic.

WARNING: An ohmmeter is recommended for testing Reed Switches. NEVER use

an incandescent light bulb as a high current rush may damage the switch.

Reed and TRIAC switches are only recommended for signalling position, not directly

powering soleniods. For shifting a solenoid, a relay or resistor is recommended

between it and the switch. Switch ratings must not be exceeded at any time

CONFIG. CODE ORDERING

MOUNTING HARDWARE & FE CONN. INCLUDED

ITEM

CODE

DESCRIPTION

19. BT SWITCH KIT, REED, FORM C, 5M

BM SWITCH KIT, REED, FORM C, QD MALE CONN.

RT SWITCH KIT, REED, FORM A, 5M

RM SWITCH KIT, REED, FORM A, QD MALE CONN.

CT SWITCH KIT, TRIAC, 5M

CM SWITCH KIT, TRIAC, QD MALE CONN.

NOTE: When ordered female connector & all mounting hardware is included

19

To Order Retrofit Kits

All Switch Kits come with 1 switch and mounting hardware.

Model

Switch Kit

Size Switch Type Code

SW TC __ __

SW TC 60 RT

Retrofit ordering method:

EXAMPLE:

REED SWITCH FORM C

LABEL COLOR: YELLOW

120 VDC/120 VAC MAX.

250MA MAX. CURRENT

AC

COM

LOAD

INPUT

BROWN

BROWNBLUE

BLACK

BLUE

MOV

TRACC

SWITCH

120/VAC

MAX.

REED

SWITCH

BLUE

NORMALLY OPEN

BLACK

NORMALLY CLOSED

BROWN

BROWN

BLUE

BROWN

BLUE

COMMON

REED

SWITCH

REED

SWITCH

(-)

(-)

(+)

(+) (+)

(+)

(-)

(-)

LOAD

LOAD

OR

SWITCH TYPE CODE

BT FORM C REED SWITCH WITH 5-METER LEAD

BM FORM C REED SWITCH WITH 5-METER LEAD AND QD

RT FORM A REED SWITCH WITH 5-METER LEAD

SWITCH TYPE CODE

RM FORM A REED SWITCH WITH 5-METER LEAD AND QD

CT TRIAC SWITCH WITH 5-METER LEAD

CM TRIAC SWITCH WITH 5-METER LEAD AND QD

This manual suits for next models

1

Other Tolomatic Cables And Connectors manuals