2

No. of contacts: 22 to 120

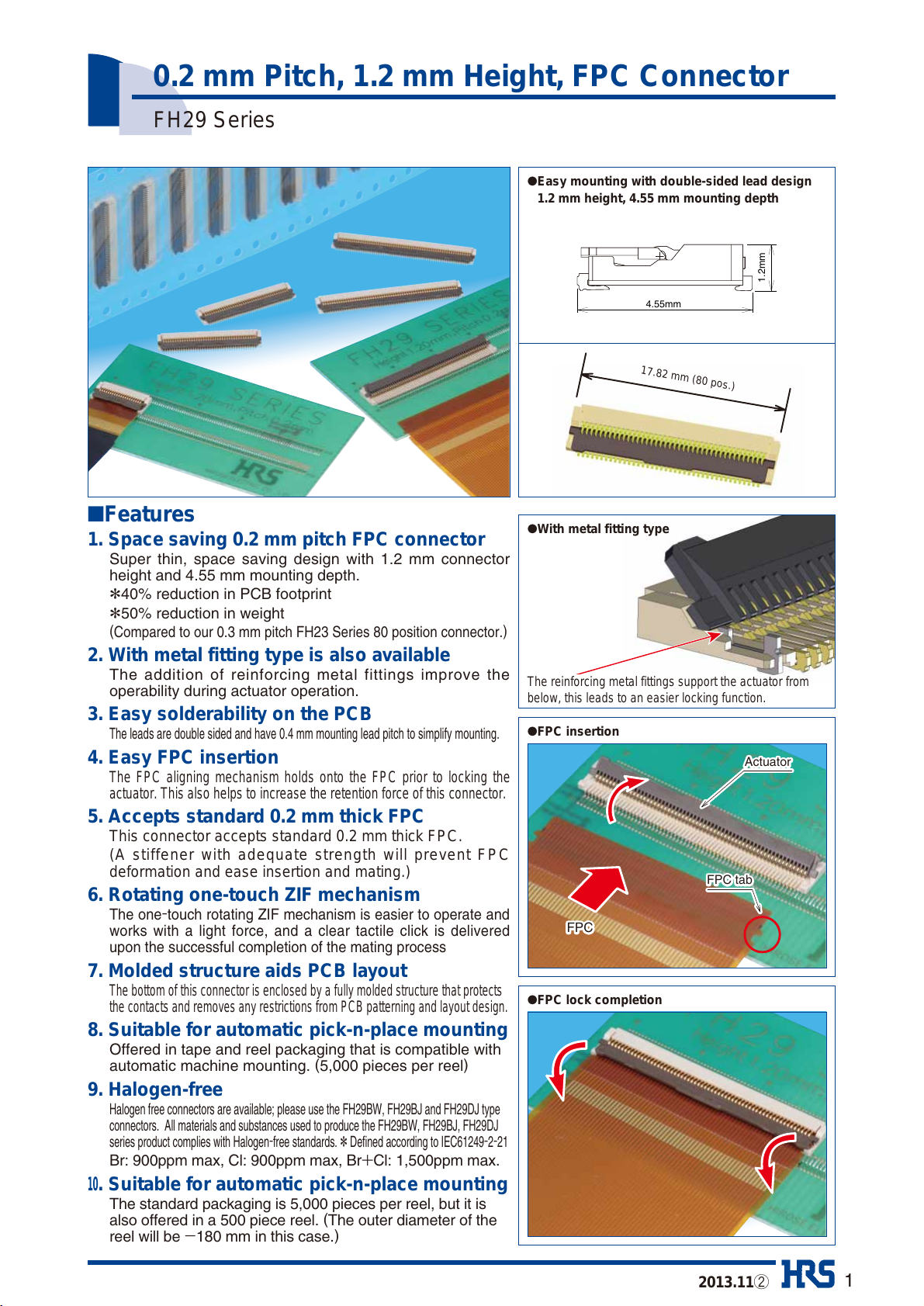

Contact pitch: 0.2 mm

Terminal type

SHW: SMT double-sided lead horizontal mount type

Plating specifications

(05) Gold plating with nickel barrier, 5,000 pieces per reel

(99) Gold plating with nickel barrier, 500 pieces per reel

-----------

Temperature: -55 ➝+15 to +35 ➝+85 ➝+15 to +35°C

Time: 30 ➝2 to 3 ➝30 ➝2 to 3 minutes

5 cycles

1) Reflow: peak temperature 250°C max, 60 seconds max at above 230°C.

2) Manual soldering: 350ç ± 10ç for 5 seconds.

DC 100 V

1 mA

20 mating cycles

500 Mø min.

No flashover or insulation breakdown

100 mø max.

* including FPC conductor resistance

Contact resistance: 100 mø max.

No damage, cracks, or parts dislocation.

No electrical discontinuity of 1 μs or longer.

Contact resistance: 100 mø max.

No damage, cracks, or parts dislocation.

No electrical discontinuity of 1 μs or longer.

Contact resistance: Maximum of 100 mø max.

No damage, cracks, or parts dislocation.

Contact resistance: Maximum of 100 mø max.

Insulation resistance: . Minimum of 50 Mø min.

No damage, cracks, or parts dislocation.

Contact resistance: Maximum of 100 mø max.

Insulation resistance: Minimum of 50 Mø min.

No damage, cracks, or parts dislocation.

No deformation of components affecting

performance.

■Materials

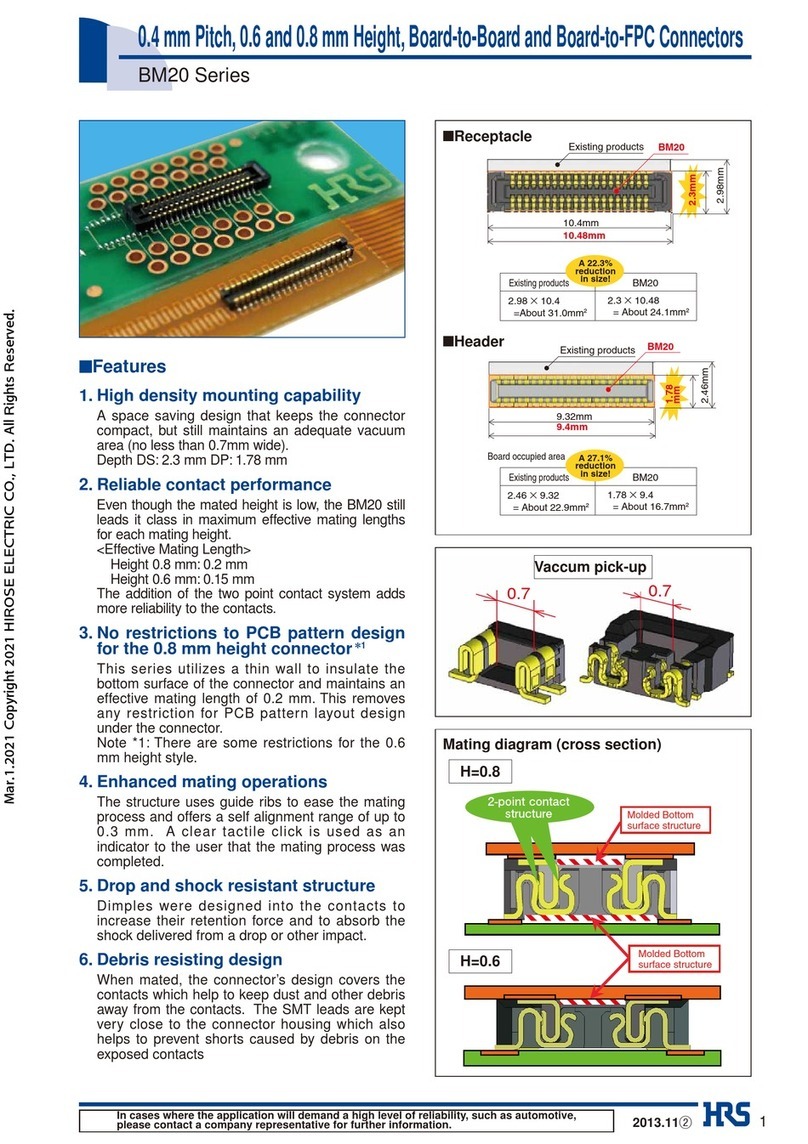

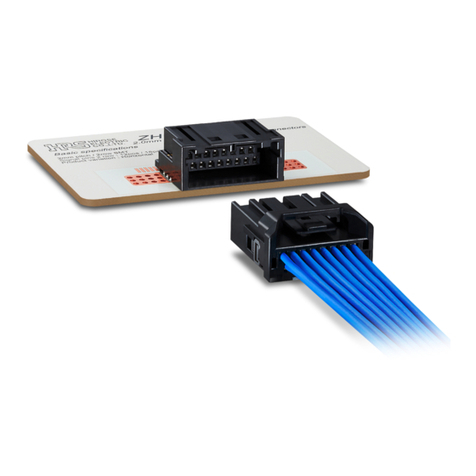

■Product Number Structure

Refer to this page when determining product specifications by model types. Please place orders with part numbers

listed in this catalog. The characteristics and specifications of the product described in this catalog are reference

values. Please make sure to check the latest delivery specifications at the time of product use.

FH 29 B W - 80S - 0.2 SHW (05)

1 2 3 6 754 8

Series name : FH

Series No. : 29

B: Standard type D: With metal fitting type

Blank: Standard

W: Halogen-free (flame retardance UL94HB)

J: Halogen-free (flame retardance UL94V-0)

1

2

3

4

5

6

7

8

Parts

Contacts

Insulator

Phosphor bronze

LCP

PA

PPS

FH29B Series : Deep brown

FH29BW Series: Light brown

FH29BJ, FH29DJ Series: Black

Beige

Gold plated

UL94V-0

UL94HB

UL94V-0

Materials Color/Finish Remarks

■Product Specifications

Rating

Rated current: DC 0.25 A (Note 1)

Rated voltage: AC/DC 40 Vrms

Operating temperature range: -55°C to 85°C (Note 2)

Operating humidity range: relative humidity 90% max

(No condensation)

Storage temperature range: -10°C to 50°C (Note 3)

Storage humidity range: relative humidity 90% max

(No condensation)

Recommended FPC spec.

Thickness = 0.2 ±0.03 mm gold plated

1.

Insulation resistance

2.

Withstanding voltage

5. Vibration

6. Shock

4. Durability

3.

Contact resistance

9. Resistance to

soldering heat

Item Specifications Conditions

Note 1: When energizing rated current to all contacts, use 70% of rated current.

Note 2: Includes temperature rise caused by current flow.

Note 3:

The term "storage" here refers to products stored for a long period prior to board mounting and use. The operating temperature

and humidity range covers the non-energized condition of connectors after board mounting and the temporary storage.

FH29 Series●0.2 mm Pitch, 1.2 mm Height, FPC Connector

7. Humidity

(steady state)

8. Temperature

cycle

AC 120 Vrms/1 minutes

96 hours at 40°C and humidity of 90 to 95%

Acceleration of 981 m/s2, 6 ms duration, sine

half-wave, 3 cycles in each of the 3 axial

directions

frequency: 10 to 55 Hz, single amplitude of

0.75/mm, 10 cycles in each of the 3 directions