TomTec QUADRA 4 User manual

Quadra 4 Operator Manual

Tomtec

2

TABLE OF CONTENTS

Preface ............................................................................................................................... 9

Unpacking Instructions ..................................................................................................... 10

Locating the Quadra 4 ..................................................................................................... 10

Section I - General Information ................................................................. 11

Specifications & Technical Information ............................................................................ 12

Warnings, Cautions, Notes, & Symbols ........................................................................... 13

Introduction ...................................................................................................................... 14

Quadra 4, Front View ............................................................................................ 15

Quadra 4, Side Views ............................................................................................ 16

Quadra 4 (with stackers), Rear View ..................................................................... 17

Quadra 4 (without stackers) .................................................................................. 18

Quadra 4 Access Panel ......................................................................................... 19

Compressor & Pneumatics .................................................................................... 20

Section II - Operational Functionality ...................................................... 21

Pipetting System .............................................................................................................. 21

Quadra 4 General Information ......................................................................................... 22

Quadra 4 Product Line ..................................................................................................... 23

Section III – Quadra Command System Op Manual ................................ 24

1.0 Introduction ................................................................................................................ 25

1.1 What's New ..................................................................................................... 25

Version 4.8.0 ......................................................................................................... 25

Version 4.7.7.30 .................................................................................................... 25

Version 4.7.7.29 .................................................................................................... 25

1.2 Major Changes to the Quadra 4 Command Software ...................................... 26

1.2.1 Drag and Drop Operations ........................................................................... 26

1.2.2 Simplified Dialogs ......................................................................................... 26

1.2.3 Shuttle Labware Labels ................................................................................ 27

1.2.4 Labware and Program Function Icon Changes ............................................ 28

1.2.5 Tip Load Counter .......................................................................................... 29

1.2.6 PSID2 Mirror Rack Checking ........................................................................ 30

1.3 Quadra 4 - Getting Started .............................................................................. 32

1.3.1 Preparing the Quadra to run a program: ...................................................... 33

2.0 Main Screen .............................................................................................................. 34

2.1 Labware - Components Area .......................................................................... 35

2.2 Shuttle Layout Area ......................................................................................... 36

2.2.1 Shuttle Position Data Dialog ......................................................................... 36

2.3 Pump Volume Box ........................................................................................... 37

2.4 Program Operations Box ................................................................................. 38

2.5 Program Steps Area ........................................................................................ 39

2.6 Menu Bar ......................................................................................................... 40

2.6.1File Menu ................................................................................................... 40

Quadra 4 Operator Manual

Tomtec

3

2.6.2Edit Menu ................................................................................................... 40

2.6.3 System Menu .............................................................................................. 42

2.6.4 Database Menu ........................................................................................... 43

2.6.5 Tools Menu .................................................................................................. 43

2.6.6 Utilities Menu ............................................................................................... 44

2.6.7 Options Menu .............................................................................................. 44

2.6.8 View Menu ................................................................................................... 45

2.6.9 Reports Menu .............................................................................................. 45

2.6.10Help Menu ................................................................................................ 46

3.0 Program Operations ................................................................................................... 48

3.1 Alert Timer ....................................................................................................... 48

3.2 Arm Plate Transfer Operation.......................................................................... 49

3.3 Aspirate Sample .............................................................................................. 50

3.4 AutoTrap Operations ....................................................................................... 52

3.5 Delay Program ................................................................................................ 53

3.6 Dispense Sample ............................................................................................ 54

3.7 Empty Sample ................................................................................................. 56

3.8 External Device ............................................................................................... 58

3.9 GOSUB Program ............................................................................................. 59

3.10 GOTO Program ............................................................................................. 60

3.11 Load Tips ...................................................................................................... 61

3.12 Lockout Shuttle Position ................................................................................ 62

3.13 Loop .............................................................................................................. 62

3.14 Magnetic Nest ............................................................................................... 63

3.15 Mix Sample.................................................................................................... 64

3.16 Move Arm ...................................................................................................... 66

3.17 Move Shuttle ................................................................................................. 67

3.18 Move Stage ................................................................................................... 68

3.19 Nitrogen Dry .................................................................................................. 69

3.20 Pause ............................................................................................................ 70

3.21 Pressure Control ........................................................................................... 71

3.22 Program Note ................................................................................................ 71

3.23 Quit ................................................................................................................ 72

3.24 Restack Plates .............................................................................................. 72

3.25 Serial Dilution ................................................................................................ 73

3.26 Shaker Nest ................................................................................................... 75

3.27 Shuck Tips..................................................................................................... 77

3.28 Shuttle Layout Change .................................................................................. 77

3.29 SPE Pressure Vacuum Operation ................................................................. 78

3.30 SPE Vacuum Box Operation ......................................................................... 80

3.31 Stacker Operations ........................................................................................ 81

3.32 Target Method ............................................................................................... 82

3.33 Timed Dispense ............................................................................................ 84

3.34 Vacuum Box Operation ................................................................................. 85

3.35 Vacuum Control ............................................................................................. 86

3.36 Wash ............................................................................................................. 87

3.37 Program Operations Common Options ......................................................... 89

Quadra 4 Operator Manual

Tomtec

4

3.37.1 Additional Options ...................................................................................... 89

3.37.2 Dip Tips ...................................................................................................... 90

3.37.3 Select Shuttle Position ............................................................................... 90

3.37.4 Stage Operations ....................................................................................... 91

3.37.5 Touch Off .................................................................................................... 93

4.0 Database Editor ......................................................................................................... 94

4.1 The Menu Bar .................................................................................................. 95

4.2 The Plate Panel ............................................................................................... 96

4.3 The Fixture Panel ............................................................................................ 97

4.4 The Touch Off Panel ....................................................................................... 98

4.5 Importing Plates-Reservoirs-Fixtures .............................................................. 98

5.0 Options ....................................................................................................................... 99

5.1 User Preferences ............................................................................................ 99

5.2 Default Plates ................................................................................................ 101

5.3 Default Reservoirs ......................................................................................... 102

5.4 Configure Model ............................................................................................ 103

5.5 Configure Com Port ....................................................................................... 104

5.6 Set User Defined Output Names ................................................................... 105

5.7 Set Arm Position Names and Heights ........................................................... 106

5.8 Displayed Fixtures ......................................................................................... 106

5.8.1 Edit Display and Order of Fixtures .............................................................. 107

5.9 Current File Settings Options ........................................................................ 108

5.9.1 Logging Options ......................................................................................... 108

5.9.2 Runtime Database Usage Options ............................................................. 109

5.10 View Preferences ........................................................................................ 110

6.0 Utility ........................................................................................................................ 111

6.1 Shuttle/Stacker .............................................................................................. 111

6.2 Stage ............................................................................................................. 112

6.3 Pinch Tubes .................................................................................................. 114

6.4 Pump ............................................................................................................. 115

6.5 System .......................................................................................................... 116

6.6 Trap Operations ............................................................................................ 116

6.7 Miscellaneous ................................................................................................ 118

6.8 Arm - Vacuum Box ........................................................................................ 119

6.9 Status ............................................................................................................ 120

6.10 Pump Calibration Tables ............................................................................. 121

6.11 Utility User Outputs ..................................................................................... 124

7.0 Tools ........................................................................................................................ 125

7.1 Tools Serial Dilution Wizard .......................................................................... 125

7.1.1 Setup .......................................................................................................... 125

7.1.2 Set Source Row/Column ............................................................................ 126

7.1.3 Set Sample Aspirate Volume and Height, Row, and Column Offsets ......... 127

7.1.4 Set Initial Dilution Row/Column .................................................................. 128

7.1.5 Serial Dilution ............................................................................................. 128

Quadra 4 Operator Manual

Tomtec

5

8.0 Technical Tips .......................................................................................................... 129

8.1 Introduction.................................................................................................... 129

8.2 Pre-Planning .................................................................................................. 129

8.3 Labware ........................................................................................................ 129

8.4 Labware Location .......................................................................................... 129

8.5 Writing The Protocol ...................................................................................... 130

9.0 System Parameters .................................................................................................. 132

9.1 System Parameters – Stage.......................................................................... 133

9.2 System Parameters – Shuttle ........................................................................ 134

9.3 System Parameters – Pump.......................................................................... 135

9.4 System Parameters – Miscellaneous ............................................................ 136

9.5 System Parameters - System Info ................................................................. 137

9.6 System Parameters - Shuttle Alignment Utility .............................................. 138

9.7 System Parameters - View System Parameters ............................................ 139

9.8 Vacuum Calibration ....................................................................................... 140

10.0 File Management ................................................................................................... 141

10.1 File Management – Plate & Fixture Databases ........................................... 143

10.2 File Management – Configuration Database ............................................... 145

10.3 File Management – Curve Database ........................................................... 146

10.4 File Management – System Parameters Database ..................................... 148

11.0 Tomtec FileSystem Watcher Service ..................................................................... 149

11.1 FileSystem Watch Marketing Information .................................................... 149

11.1.1 System Security ....................................................................................... 149

11.1.2 File System Monitoring ............................................................................. 150

11.1.3 Program step logging ............................................................................... 150

11.1.4 Why use CFR11 ....................................................................................... 150

11.1.5 Installation ................................................................................................ 151

11.1.6 FDA CFR11 Documentation ..................................................................... 151

11.2 FileSystem Installation Information .............................................................. 154

11.2.1 Overview .................................................................................................. 154

11.2.2 Installation ................................................................................................ 154

11.2.3 Configuration ............................................................................................ 155

11.2.4 Usage ....................................................................................................... 156

11.2.5 OS Requirements ..................................................................................... 157

11.2.6 Quick Start ................................................................................................ 158

11.3 Providing 21CFR Part 11 Security for the Quadra 4 .................................... 159

Section IV – Pipettor Heads .................................................................... 163

1.0 Quadra 4 Air Displacement Pipettor Heads ............................................................. 163

1.1 Quadra 450µL Disposable Tips .................................................................... 163

1.2 Organic to Aqueous Pipetting ....................................................................... 163

1.3 Non Contact Dispensing ............................................................................... 164

1.4 Clearing Tip Residual ................................................................................... 164

2.0 Quadra 450µL Tip Design ........................................................................................ 164

2.1 Loading the 450µL Disposable Tips .............................................................. 164

Quadra 4 Operator Manual

Tomtec

6

2.2 Adjusting Tip Load Switch ............................................................................. 165

3.0 Quadra 4 Positive Displacement Pipettor Heads .................................................... 166

4.0 Quadra 4 Disposable Multi Volume Head (DMV) .................................................... 167

5.0 Setting the Zero Volume Adjustment for Air Displacement Pipettor Heads ............ 170

6.0 Quadra Shuttle ........................................................................................................ 172

7.0 Stackers .................................................................................................................. 172

8.0 Quadra Stage .......................................................................................................... 173

Section V - Suggested Pipetting Methods & Recommendations ........ 175

1.0 Aspirating ................................................................................................................ 175

2.0 Pipeline Pipetting .................................................................................................... 175

3.0 Dispensing .............................................................................................................. 176

4.0 Mixing ...................................................................................................................... 176

5.0 Titration ................................................................................................................... 176

6.0 Bubbling .................................................................................................................. 177

7.0 Injection ................................................................................................................... 177

Section VI - Pipetting with the Positive Displacement Pipettor Head . 178

1.0 Pipetting 0.5µl with Positive Displacement .............................................................. 178

2.0 Dispensing 0.5µl spots - Aqueous ........................................................................... 178

3.0 Dispensing 0.5µl spots – DMSO ............................................................................. 179

4.0 Protocol Verification ................................................................................................ 179

Section VII - Bioanalytical Applications ................................................. 180

1.0 Aqueous and Organic Pipetting .............................................................................. 180

2.0 Protein Precipitation, Liquid/Liquid, And SPE ......................................................... 180

3.0 Protocol Or Program Security ................................................................................. 181

4.0 Calibration For The Quadra 4 ................................................................................. 181

Section VIII - Quadra 4 Accessories ....................................................... 184

1.0 Custom Reservoirs.................................................................................................. 184

1.1 Keeping Participate Matter in Suspension ..................................................... 184

1.2 Stirring Reservoir ........................................................................................... 184

1.3 Constant Level Reservoir .............................................................................. 185

1.4 Shaker Nest................................................................................................... 185

1.5 Live Bottom Reservoir ................................................................................... 185

1.6 Thermal Retention Reservoir ........................................................................ 185

1.7 Peltier Nest .................................................................................................... 186

1.8 SPE Vacuum Box .......................................................................................... 186

1.9 Filtration System for the Quadra 4 ................................................................. 186

1.10 Auto Regulated Mini Vacuum Trap .............................................................. 187

1.11 Fully Automated Filtration System ............................................................... 187

Section IX - Pipetting Recommendations .............................................. 188

1.0 Tip# 1 ........................................................................................................... 188

2.0 Tip #2 ........................................................................................................... 188

Quadra 4 Operator Manual

Tomtec

7

3.0 Tip #3 ........................................................................................................... 188

4.0 Tip #4 ........................................................................................................... 188

5.0 Tip #5 ........................................................................................................... 189

Section X – Calibration of the Quadra 4® 450µL ................................... 190

1.0 Equipment Required ............................................................................................... 191

2.0 Weighing Vessels .................................................................................................... 191

2.1 Calibration Curve Procedure ......................................................................... 192

2.2 Verification of Calibration Curve Procedure .................................................. 193

3.0Evaporation ......................................................................................................... 193

4.0Pipetting To Weighing Cycle Time ...................................................................... 194

5.0Setup Procedure ................................................................................................. 194

6.0Adding the New Calibration Curve into the Quadra Command System from Data

Points 194

7.0“Calibration Template – Q4” Spreadsheet .......................................................... 195

8.0Creating a New Calibration Curve With Water .................................................... 196

9.0Creating a Verification Curve .............................................................................. 198

10.0“Calibration Template” For the Verification Curve ............................................... 200

11.0Calibration Instructions for 450 µL Head ............................................................. 201

11.1Definitions ................................................................................................. 201

11.2Liquid Used For Calibration Curve Set Volumes ................................................. 201

12.0Ambient Calibration Conditions ........................................................................... 201

12.1Importing an Existing Calibration Curve .................................................... 201

Section XI - Some Properties of Liquids That Affect Pipetting Accuracy

................................................................................................................... 202

1.0 The relationship between liquid and gaseous states of a solvent have an effect on

pipetting ......................................................................................................................... 202

2.0 Additional properties of liquids that might have an effect on pipetting ................... 202

3.0 To compensate for these properties of liquids, the aspirate and dispense steps have

options to improve performance ..................................................................................... 203

Section XII - Head Removal, Installation and Alignment ...................... 204

1.0 Top Rear View ......................................................................................................... 204

2.0 Top Front View (Open Panel) .................................................................................. 205

3.0 Head Installation ...................................................................................................... 206

5.0 450µL Backfill Head Back View .............................................................................. 208

6.0 Tip Block Assembly ................................................................................................. 209

7.0 55µL SV Head ......................................................................................................... 210

8.0 384 SV Tip and Seal Assembly ............................................................................... 211

Section XIII – Routine & Preventive Maintenance by Operator ........... 212

Maintenance and Schedule

....................................................................................... 212

Routine & Preventive Maintenance by Operator ............................................................ 212

Quadra 4 Operator Manual

Tomtec

8

1.0 Lubrication Kit ......................................................................................................... 212

2.0 Cleaning the Pipettor Tips ........................................................................................ 213

3.0 Fuse Replacement ................................................................................................... 214

WARRANTY .................................................................................................................. 215

RETURN POLICY .......................................................................................................... 215

QUADRA 4 DECONTAMINATION FORM ..................................................................... 216

Tomtec Contact Information - If You Need Help ... ........................................................ 217

Quadra 4 Operator Manual

Tomtec

9

Preface

This manual provides general information, installation and operation instructions for

the TOMTEC QUADRA 4®.

Every effort has been made to avoid errors in text and diagrams, however, TOMTEC

assumes no responsibility for any errors or omissions which may appear in this

manual.

It is the policy of TOMTEC to improve products as new techniques and components

become available. TOMTEC reserves the right to change specifications at any time.

We welcome your comments on this publication.

TOMTEC, INC.

1000 Sherman Avenue

Hamden, CT 06514 USA

Phone: (203) 281-6790

Fax: (203) 248-5724

Toll Free for USA & Canada: 1-877-866-8323

www.tomtec.com

Quadra 4 Operator Manual

Tomtec

10

Unpacking Instructions

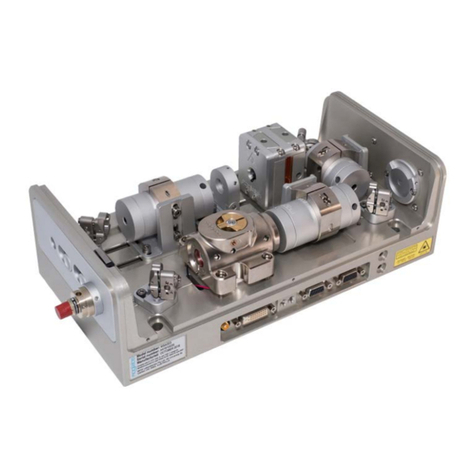

Carefully remove the Quadra 4 from the shipping carton and place on a level surface.

When moving the equipment, lift only in the locations indicated by Figure A. Do not lift or

handle the equipment by the X-Y table.

Locating the Quadra 4

When selecting a suitable place to set up your Quadra 4, please consider the

following:

The Quadra 4 should be placed on a level surface. A slanted surface can cause the

liquid to pool to one side of a well or reservoir and may impair your ability to fully

pipette out small volumes.

Be sure to leave at least four inches (10 centimeters) between the back of the

Quadra 4 and any wall or shelving that may impair the movement of air through the

cooling fans.

Although the Quadra 4 can supply its own air pressure, some accessories may

require a water source (normally DI), a vacuum source, a place to drain waste liquid,

or additional space for a vacuum trap or controller module.

For overall space requirements, please refer to the instrument dimensions under

"Physical Specifications" on page 12.

Quadra 4 Operator Manual

Tomtec

11

Section I - General Information

CAUTION: IF THE EQUIPMENT IS USED IN A MANNER NOT SPECIFIED

BY THE MANUFACTURER, THE PROTECTION PROVIDED BY THE

EQUIPMENT MAY BE IMPAIRED.

The Quadra 4 is designed for use with various liquids, aqueous

or organic solutions with a pH near neutral. As the pH of the

solution moves away from neutral, various parts may be

affected, depending on the length of time they are in contact.

The user has full responsibility for the selection of compatible

liquids and for thoroughly rinsing the system after use. Damage

resulting from improper use of liquids and lack of cleaning are

the user's responsibility and may void the warranty.

Important Note:

Powered accessories such as Vacuum Traps, Autotraps and

Shaker Nests, should not be connected with the Quadra 4

powered on. Please turn off AC power

BEFORE

connecting

these accessories.

Quadra 4 Operator Manual

Tomtec

12

Specifications & Technical Information

QUADRA 4

Environmental Specifications

Operating environment

INDOOR USE ONLY

Temperature 5ºC to 40ºC (41 ºF to 104 ºF

Humidity: 20%-90% (no condensation)

Storage environment

INDOOR USE ONLY

Temperature: 0 °C to 60 °C (32 °F to 140 °F)

Humidity: 5%-90% (no condensation)

Physical Specifications

Dimensions:

Width: 30” (762 mm)

Depth: 21” (534mm)

Height: 33” (838mm)

Weight: 200lbs (90.71kg)

Shuttle Extension: 9.5” (241mm) L/R

Shuttle Extension: 6” (153mm) (Front to Back)

Electrical Specifications

Power requirements:

100VAC NOM, 60Hz @ 4.0 AMP

105-125VAC 60Hz @ 4.0 AMP

230-240, 50Hz @ 2.0 AMP

Pneumatic Specifications

Internal Compressed Air

Quadra 4 Operator Manual

Tomtec

13

Warnings, Cautions, Notes, & Symbols

Throughout this manual, there may be blocks of text printed in bold type within boxes

or italic type. These blocks are warnings, cautions, and notes, and they are used as

follows:

WARNING:

A WARNING INDICATES THE POTENTIAL FOR BODILY HARM

AND TELLS YOU HOW TO AVOID THE PROBLEM.

CAUTION:

A CAUTION INDICATES EITHER POTENTIAL DAMAGE TO

HARDWARE OR LOSS OF DATA AND TELLS YOU HOW TO AVOID THE

PROBLEM.

NOTE: A NOTE indicates important information that helps you make better

use of your Quadra.

In this manual, there may be symbols within triangles, and they are used

as follows: The lighting flash with arrowhead symbol, within an equilateral

triangle, is intended to alert the user to the presence of un-insulated

"dangerous voltage" within the product's enclosure that may be of

sufficient magnitude to constitute a risk of electric shock.

The exclamation point within an equilateral triangle is intended to alert the

user to the presence of important operating and maintenance (servicing)

instructions in the literature accompanying the instrument.

Quadra 4 Operator Manual

Tomtec

14

Introduction

The TOMTEC Quadra 4 is a third generation liquid handling workstation with

numerous optional pipetting head configurations available with or without stackers,

formatting stage selections and protocol specific accessories. Your local TOMTEC

Sales Engineer or our Worldwide Distribution Network can offer customer assistance

in selecting the correct model, pipetting head and accessories to fit individual

requirements.

The Quadra 4 incorporates an embedded PC, 15" full Color Display, our unique

Quadra 4 Command Software, and wireless keyboard. In addition, the embedded

PC provides 4 USB ports and internet network capabilities.

This manual will describe the standard Quadra 4 Pipettor - both with or without

stackers. Additional pipetting head configurations and stage options are outlines in

APPENDIX A at the end of this manual.

An electronic copy of this manual is provided in PDF Format and is resident on the

internal hard drive in the instrument.

Login Instructions

The Quadra 4 uses the login functions available with the MS Windows 7® Operating

System installed in the embedded PC. This feature gives the user the option of

setting operational privileges and parameters for each individual using the Quadra 4.

The Quadra 4 shipped to you has a default login with administrator privileges :

administrator (PW = password)

tomtec (PW = Tomtec)

Privileges of defaults:

administrator – full application and MS Windows privileges

tomtec - operation of application programs

- create application programs

- upload and download USB ports

The Administrator can add, delete, change users, functionality, passwords, etc. by

using the MS Windows 7 functions (control panel – user accounts).

Quadra 4 Operator Manual

Tomtec

15

Quadra 4 Pictorials

Quadra 4, Front View

Quadra 4 Operator Manual

Tomtec

16

Quadra 4, Side Views

Quadra 4 Operator Manual

Tomtec

17

Quadra 4 (with stackers), Rear View

Aux.

Pres

sure

Quadra 4 Operator Manual

Tomtec

18

Quadra 4 (without stackers)

Quadra 4 Operator Manual

Tomtec

19

Quadra 4 Access Panel

(Front Access Panel)

Recommended to be used by TOMTEC Service Technicians only!

Quadra 4 Operator Manual

Tomtec

20

Compressor & Pneumatics

Pneumatic Panel Description

The front panel provides manual access to the pneumatic system. The pressure gauge

may be connected to several ports for readout.

Compressor Pressure: 30psi for 60 Hz operation.

25psi for 50Hz operation.

NOTE: Due to normal compressor pulsing, do not leave the pressure gauge connected

to the compressor for long time periods. This affects the life of the pressure gauge.

Blowout Pressure: This is set by the regulator on the right hand side of the

Quadra 4. It will range from 0psi to 5psi. A more accurate

pressure reading is available on the front display.

Elevator Pressure:

Regulatory Accessory (API) Pressure:

At system pressure (not a user adjustment).

This pressure is set by the R2 pressure regulator.

It must be less than 10psi or it will rupture the bladder in the various nests.

Switches: Elevator Override - Actuates the stacker elevators.

Compressor Bypass:

Shuts off the internal air compressor and connects system to external air

supply. External air supply must not exceed 35psi.

Table of contents