67

OPERATION MANUAL OPERATION MANUAL

WWW.THETOOLSHED.CO.NZWWW.THETOOLSHED.CO.NZ

SAFETY GUIDELINES

• DO NOT use the power tool or machinery

in rainy conditions or wet areas where the

power tool or machinery could get wet.

Water in this power tool or machinery can

lead to electric shock.

• Only use the power tool or machinery

when the plug correctly matches the

power outlet. Modifying plugs greatly

increases the risk of electric shock.

• Keep the power cord away from anything

that could damage it such as sharp edges,

moving parts or heat. A damaged power

cord increases the risk of electric shock.

• Only operate outdoors with the use of an

outdoor extension lead. Not all extension

leads are suited to outdoor use and using

one which is not can greatly increase the risk

of electric shock.

• Avoid body contact with grounded or

earthed surfaces. Surfaces such as radiators,

ranges, pipes, and refrigerators can increase

the risk of electric shock due to your body

being earthed or grounded.

• Never carry the power tool by the cord,

or yank the cable from the power outlet.

This can damage the internal wiring and may

become a hazard.

WARNING

Electric shock can cause serious injury

or, in some cases be fatal.

Electrical Safety

• Use the correct tool for the job. Forcing

a tool to do a job it was not designed for

increases the risk of accident or injury.

• Disconnect tools and machinery from

power, or remove batteries before doing

any maintenance or adjustments, or

before storing the tools and machinery.

This reduces or removes the risk of a power

connection that causes the tool or machinery

to accidentally re, which can help prevent

injury or accident.

• Check the general condition of the power

tool for damage or any problems that

could aect the way the tool or machine

works. An unrepaired tool or machine can

lead to accident and injury. Only have your

tool or machine repaired with genuine parts

from The ToolShed.

• Only use the power tool and machinery

with genuine parts or accessories that are

designed to be used with this power tool

and machinery. Failure to do so could result

in accident or injury or damage your tool or

machinery.

• Store your tool or machinery out of reach

of children, and away from untrained

personnel when not in use. Use by some-

body untrained, or a child, could lead to

accident or serious injury.

Power Tool & Machinery Use &

Care

SAFETY GUIDELINES

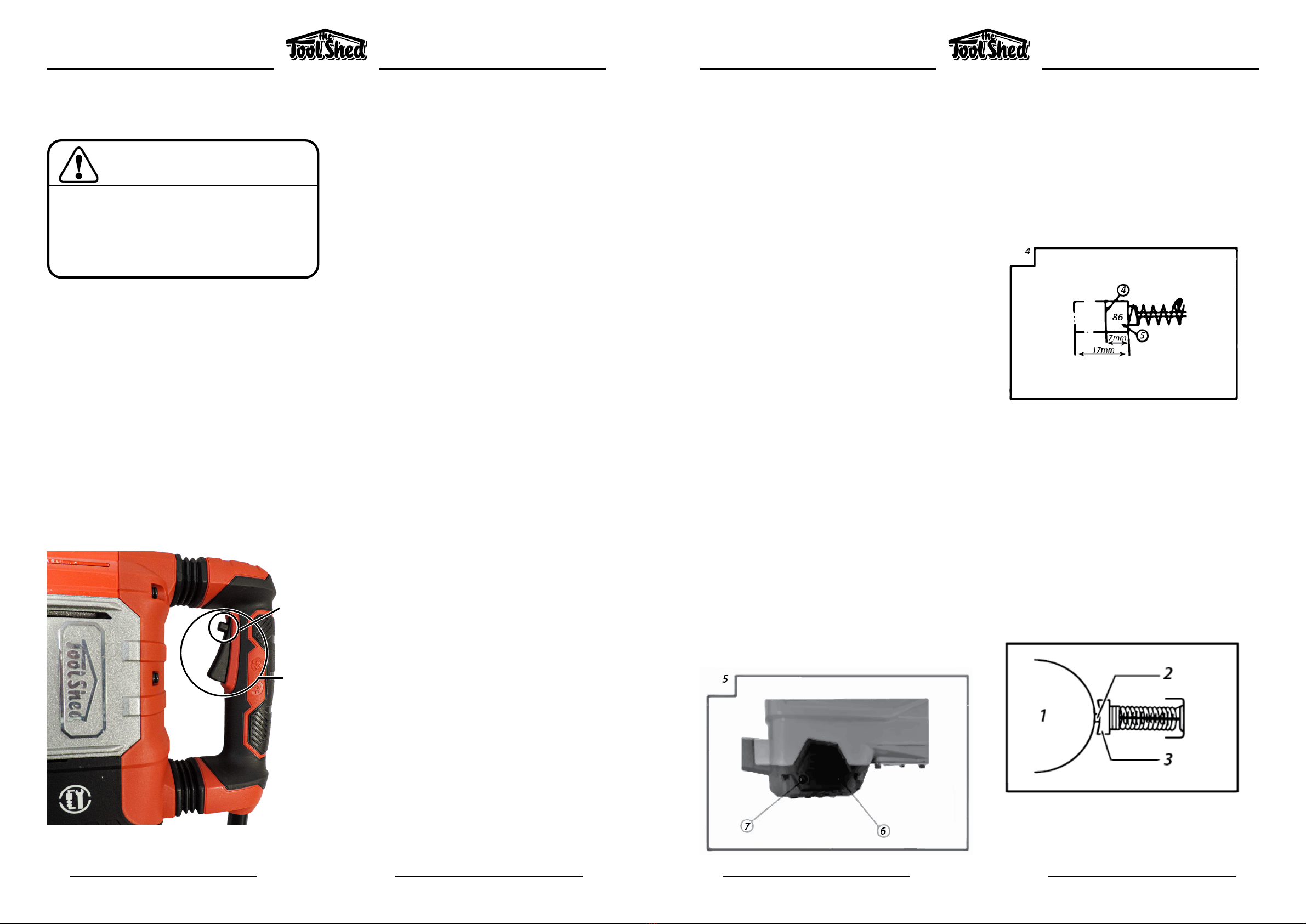

Demolition Hammer Specic

Safety

Service

• Have your tools and machinery serviced

at The ToolShed with ToolShed replace-

ment parts. This will ensure that the safety

of the power tool or machine is maintained.

• Wear ear protection. Prolonged exposure to

noise may cause hearing loss.

• Use the extra handles supplied with the

device. Loss of control may cause injury.

• Grip the tool with two hands when working

and maintain a stable posture. It is always

safer to operate the tool with two hands.

• Hold tools by insulated gripping surfaces

when performing an operation where the

cutting tool may contact hidden wiring or

its own cord. Contact with a “live” wire will

make exposed metal parts of the tool “live”

and shock the operator.

• For tasks carried out above ground level:

Ensure that the area below is clear for tasks

carried out above ground level.

• Ensure you maintain a healthy, stable posture,

as well as rm footing at all times.

• Only work with the appropriate insertion

tools. Check that the insertion tool is posi-

tioned correctly by pulling on it.

• Check the demolition breaker and the inser-

tion tool for rust and damage before each

use. Never operate the demolition breaker

if it is damaged or deformed. If you identify

damage, contact your nearest ToolShed for

replacement parts or advice.

• Under normal operation, the tool is designed

to produce vibration. The screws can come

loose easily, causing a breakdown or acci-

dent. Check tightness of screws carefully

before every operation.

WARNING

The warnings and precautions

discussed in this manual cannot cover

all possible conditions and situations

that may occur. It must be understood

by the operator that common sense

and caution are factors which cannot

be built into this product, but must be

supplied by the operator.

• It is not possible to cover every conceivable

situation you can face. Always exercise care

and use your common sense. If you get into

a situation where you feel unsafe, stop and

seek expert advise. Contact your dealer,

service agent, or an experienced user. Do not

attempt any task you feel unsure of!

• Do not let familiarity gained from the

frequent use of tools allow you to become

complacent and ignore tool safety prin-

ciples. A careless action can cause severe

injury within a fraction of a second.

Always Use Common Sense