GB

8

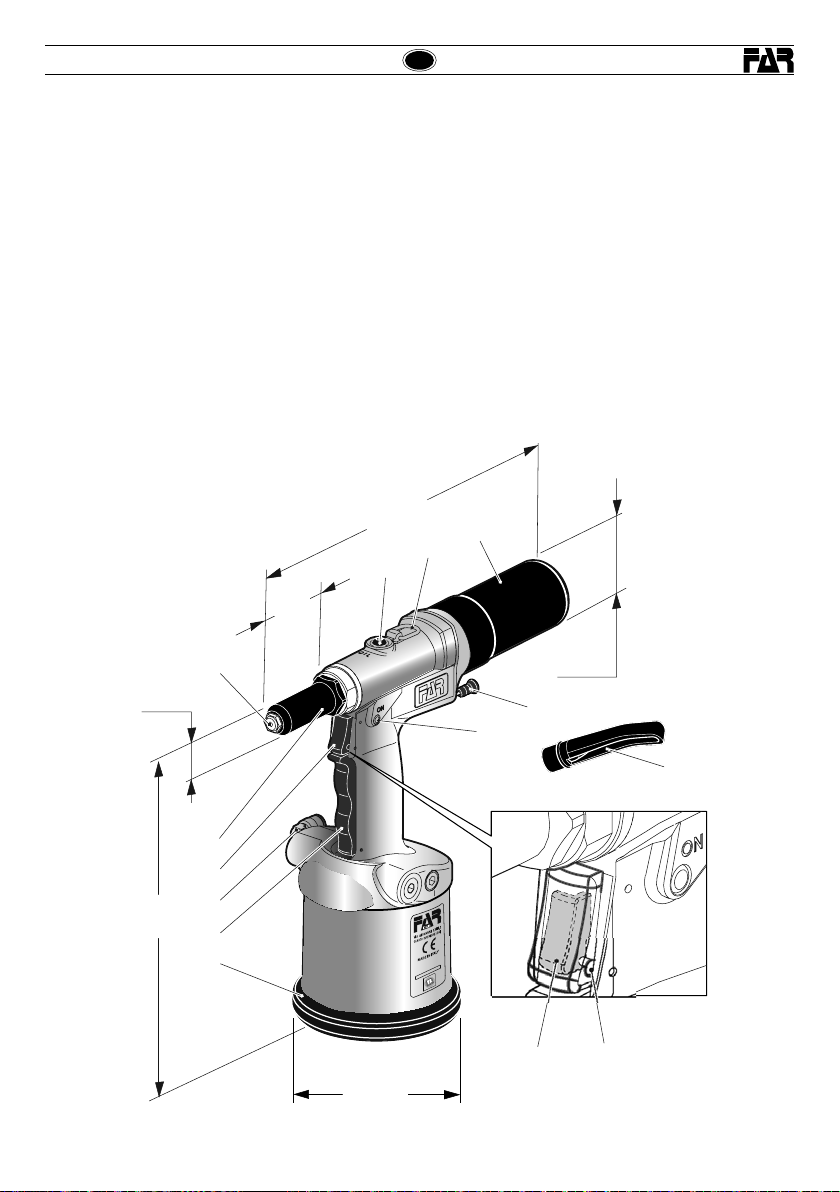

RAC 181

Company name and

address

Lot number

Designation of the tool

TOOL IDENTIFICATION

The riveting tool RAC 181 is identified from a marking that

showscompanynameandaddressofmanufacturer,designation

of the tool, CE. Always refer to the information on the riveting

tool when requesting technical service.

INSTRUCTIONS FOR USE I

INDEX

GUARANTEE ............................................................................. 14

SAFETY MEASURES AND REQUIREMENTS........................14

TOOL IDENTIFICATION .......................................................14

TECHNICAL DATA ...............................................................15

MAIN COMPONENTS..........................................................15

HOW TO USE YOUR RIVETING TOOL.................................16

MAINTENANCE AND CHANGE OF SIZE...............................18

TOOPING UP THE OIL-DYNAMIC CIRCUIT.........................19

DISPOSAL OF THE RIVETING TOOL ......................................... 19

SAFETY MEASURES AND REQUIREMENTS

CAUTION!!!

All the operations must be done in conformity

with the safety requirements, in order to avoid

any consequence for your and other people’s

security and to allow the best tool work way.

• Read the instructions carefully before using the tool.

•For all maintenance and/or repairs please contact

FAR s.r.l. authorized service centers and use only

original spare parts. FAR s.r.l. may not be held liable

for damages from defective parts caused by failure

to observe what above mentioned (EEC directive

85/374).

The list of the service centres is available on our website

http://www.far.bo.it ( Organization )

• The tool must be used only by expert workers.

• A protective visor and gloves must be put on when using

the tool.

• Use equipment recommended in the maintenance chapter

to do any maintenance and/or regulation of the tool.

• For topping up the oil, we suggest using only fluids in

accordance with the features specified in this working book.

• If any drop of oil touches your skin, you must wash with

water and alkaline soap.

• The tool can be carried and we suggest putting it into its box

after using.

• The tool needs a thorough six-monthly overhaul.

• Repairing and cleaning operations must be done when the

tool is not fed.

• If it is possible, we suggest a safety balancer.

• If the A-weighted emission sound pressure level is more

than 70 dB (A), proper hearing protections have to be worn

(anti-noise headset, etc.).

• The workbench and the work surface must be always clean

and tidy. Messiness could cause injury to persons.

• Do not allow unauthorized persons to use the working tools.

• Make sure that the compressed air feeding hoses are properly

sized for their use.

• Do not carry the connected tool by pulling the hose. The pipe

must be far from any heating sources or from cutting parts.

• Keep the tools in good conditions; do not remove either safety

parts or silencers.

• After repair and/or adjustment operation, make sure to remove

the adjusting spanners.

• Before disconnecting the compressed air hose from the tool

make sure that there is no pressure in the hose.

• These instructions must be carefully followed.

GUARANTEE

FAR riveting tools are covered by a 12-month warranty. The

tool warranty period starts on the date of delivery to the

buyer, as specified in the relevant document. The warranty

covers the user/buyer provided that the tool is purchased

through an authorized dealer and only if it is used for the

purposes for which it was conceived. The warranty shall

not be valid if the tool is not used or maintained as specified

in the instruction and maintenance handbook. In the event

of defects or failures, FAR S.r.l. shall undertake solely to

repair and/or replace the components it judges to be faulty.

RAC 181

Air & Allied Sales (Pacific) Pty Ltd