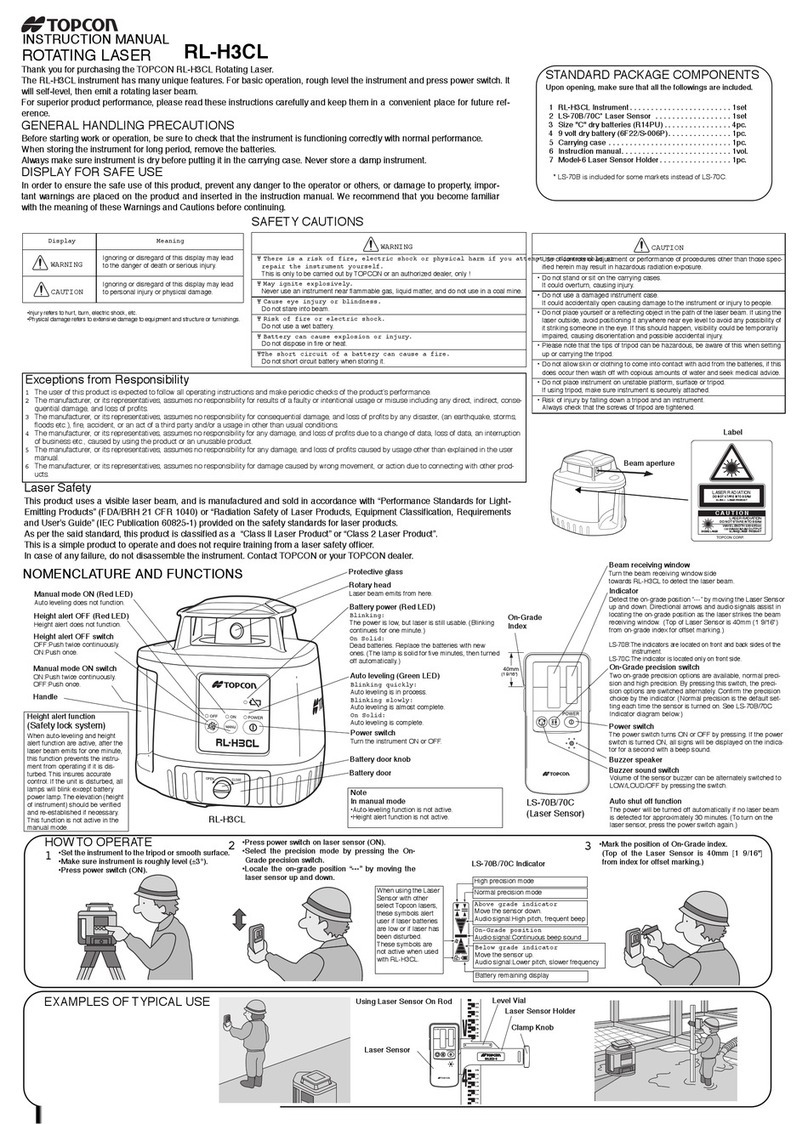

Use the table below to determine operation errors indicated by blinking lamps on the control panel.

If corrective action listed does not correcterror, please contact your local Topcon dealer.

Operating procedure

(Setting slope) Key

operation Lamp display

(Refer to the right illustration)

1PressPowerswitchON.

You canset the slopeafter auto-leveling is completed. Power switch During auto-leveling : Lamp B (Green) blinks.

Afte r auto-leveling is completed. : Lamp B (Green) lights.

2Presseither Slope key once. The laser beam begins

to move in t he direction of the arrow on th e key. Afterauto-level-

ing is completed.

Slope key Lam p E (Green ) blinks quickly.

3PressSlope key again to stop the laser beam. Slope key Lam p E (Green ) lights.

4PressSlope key to fine a djust the slope.

Beam movement begins slowly, then increases

depending on how long the Slope key is pressed.

The blinking speed of the lamp provides a visual indi-

cation of t he beam movement speed.

Slope key When Slope key is not pressed: Lamp E (Green) lights.

Slope key Lamp E (green) Beam movement

Press for a shorter time : Blinks slowly : Moves slowly

↓↓↓

Press for a longer time : Blinks quickly : Moves quickly

5PressPowerswitchOFF to cancel the slope setting. Power switch Alllamps are OFF.

Operating procedure

(Recalling slope) Key

operation Lamp display

(Refer to the right illustration.)

1To recall the previous slope setting (the setting before

power was OFF), press Power switch ON while press-

ing either the righ t or left Slope key. The slope can

then be a djusted as de scribed in step 4above.

•When the Power switch is ON without the Slope key

pressed, the laser beam will return to level.

Slope key

+

Power switch

When Slope key is not pressed: Lamp E (Green) lights.

SlopekeyLamp E (green) Beam movement

Press for a shorter time : Blinks slowly : Moves slowly

↓↓↓

Press for a longer time : Blinks quickly : Moves quickly

CHECKS AND ADJUSTMENTS

Checking and adjusting calibration

Checking cone error Error Code

1

Horizontal calibration of the laser beam can be checked by theuser.

[Checking]

1Setupa tripod approx. 50m(160ft) from a wall. Mount the instrument on the

tripod, facing the X1 side toward the wall.

2Turnthe instrument on andallow auto-leveling to complete.

3Put the laser sensor in fine detection mode by pressing the On-Grade preci-

sion switch.

4By using the laser sensor, markthe center position of laser beam on thewall.

(X1)

5Turn off the instrument.

Loosen the tripod screw,rotate the instrument 180 degrees and re-secure it

on the tripod. The X2 side of the instrument faces toward the wall.

Whenrotatingthe instrument, avoid changingtheheight.

6Turnthe unit on againand allow auto-leveling to complete.

7By using the laser sensor, markthe center position of laser beam on thewall.

(X2)

8If the difference value of marked two laser beam heights(difference value of

X1 and X2) are less than 7mm, adjustments are not needed. The difference

valueis greater than 7mm, adjustthe instrument as described in right. *

9Check the X1 (handle) side as the same way.

X1

X2

[To calibrate the X axis ]

1Face theX1 side ofthe instrument (panel side) toward awall, press the Power

switch while pressing the height alert OFF switch.

Then the height alert OFF lamp will light, and manual mode ON lamp will blink.

2Press the height alert OFF switch to calibratethe X axis. The manual mode

ON lamp will light. When auto-leveling finishes, the laser beam will emit.

3Usingthe laser sensor, mark the on-gradeheight of laser beam ona wall.

4Rotate the instrument 180 degrees to face X2 side toward a wall.

5In the sam e way as step 3, mark theon-grade heightoflaserbeam on awall.

6By pressing the manual mode ON switch (laser beam moves up), or Power

switch (laserbeam moves down), adjustthe on-grade height of thebeamuntil

itis precisely centeredbetween themarksmade insteps 3and 5 .

7PresstheheightalertOFF switchto memorizethe newlaser beam calibration.

The height alert OFF lamp will blink. Power will shut off automatically when the

calibration memorization is complete.

[To calibrate the Y axis ]

1Face the Y1 sideof the instrument (handle side) toward a wall, press the

Power switch while pressing the height alert OFF switch.

Then the height alert OFF lamp will light, and manual mode ON lamp will blink.

2Press the Power switch again. The auto leveling lamp will light.

3Press the height alert OFF switch to calibratethe Y axis. The auto leveling

lamp will light.

4Usingthe laser sensor, mark the on-gradeheight of laser beam ona wall.

5Rotate the instrument 180 degrees to face Y2 side toward a wall.

6In the sam e way as step 4, mark theon-grade heightoflaserbeam on awall.

7By pressing the manual mode ON switch (laser beam moves up), or Power

switch (laserbeam moves down), adjustthe on-grade height of thebeamuntil

itis precisely centeredbetween themarksmade insteps 4and 6.

8PresstheheightalertOFF switchto memorizethe newlaser beam calibration.

The height alert OFF lamp will blink. Power will shut off automatically when the

calibration memorization is complete.

*If the difference value is greater than 60mm (2 3/8 inches), contact your

Topcon dealer.

laser sensor

Wall

Approx. 50m

X1 Laser beam

Laser point of X1

Approx. 50m

X1

X2

X1

To discontinue calibration the instrument, press the Power

switch while pressing the height alert OFF switch.

Y1Y2

[Checking]

1Set up the laser centered between two walls approximately 40m (131ft) apart. Orient the instrument

so one axis,either X orY, is facing the walls.

2Locate and mark the position of the rotating laser beam on both walls using the laser sensor.

3Turn offthe instrument and move the instrument closer towall A(1m to 2m /3 ft to 6ft).

Donot change the axisorientation of the instrument. Turn the instrument on.

4Againlocateand marktheposition of the rotatinglaser beam on both walls using the lasersensor.

5Measurethe distancebetween the firstand second marks on each wall.

If the difference between each set of marks is less than 4mm (5/32 of an inch), no error exists.

Perform the following check after completing horizontal calibration procedure.

Cone error

Datum position

23

Lamp Indication Error Code Corrective Action

Lamp B, C and D blink in turn Auto-leveling range

error Correct tilt of the instrument until it less

than 3 degrees.

Lamp A lights Battery power error Replace all 4 batteries with new ones at

the same time.

Lamp B, C and D blink simulta-

neously Height alert error Turnpower off, rough levelthe instrument,

then turn power onagain. Check height of

laser beam as it may have changed.

Lamp D blinks quickly Calibration error Repeat calibration procedure. If error re-

peats contact your local Topcon dealer.

Lamp E(Red) lights

Lamp B, C and D blink in turn Slope setting range

error Push the slope key of the opposite side,

and align slope.

Lamp A, B, C and D blink si-

multaneously Internal error Turn power off, then on again. If error re-

peats contact your local Topcon dealer.

A

B

D

C

LS-70B

Beam detection window : 50mm (2.0 in)

Beam detection precision : High precision : ±1mm(±0.04 in)

: Normal precision : ±2mm(±0.08 in)

Beam detection

indication : Liquid crystal and buzzer

Power source : DC 9V alkaline (dry) battery

Operating time : Approx. 80 hours at +20°C (+68°F)

(Using alkaline manganese dry batteries)

Auto shut-offdelay : Approx. 30 minutes withoutbeam detection.

Operating temperature : -20°C~+50°C (-4°F~+122°F)

Dimensions : 165(L)x78(W)x26(H)mm

(6.5x3.0x1.0 in)

Weight : 0.25 kg [0.55 lbs](With drybatteries)

SPECIFICATIONS

RL-H3CS

Accuracy : ±3.6mm/50m (±15 ”)

Automatic correction range +Setting slope range : ±5°

Beam detecting range : Approx.2m~300m (6ft~980ft) diameter

Rotational speeds : 600r.p.m

Laser source : Laser diode (Visible, Red)

Laser power output : 0.8mW (Max.)

Laser class : Class 2 laser product

Power supply : Four C size alkaline

manganese drybatteries

Operating time : Approx. 60 hours at +20°C (+68°F)

Protection against

water and dust : IP56

(Based on the standard IEC60529)

Operating temperature : -20°C~+50°C (-4°F~+122°F)

Dimensions : 167(L)x182(W)x193(H)mm

(6.5x7.1x7.6 in)

Weight : 1.9kg[4.1lbs] (With drybatteries)

X2 Lase r beam

Wall A Wall B

Wall A

Approx. 40m

*If the difference value is greater than 4mm(5/32 inch), contact your Topcon dealer.

When calibration is memorizing, if the height alert lamp

continues to blink quickly and power does not shut-off auto-

matically, please contact your local Topcon dealer.

HOW TO OPERATE

1Set the instrument to the tripod or smooth surface.

2Make sure instrument is roughly level.

3Press powerswitch(ON).

4Press power switch on laser sensor (ON).

5Select theprecisionmode bypressingthe

On-Gradeprecisionswitch.

6Locate theon-grade position“---”by moving

the laser sensor up and down.

7Mark the position of On-Grade index.

(Top of the Laser Sensor is 40mm[19/16"] from

index for offsetmarking.)

LS-70B Indicator

High precision mode

Normal precision mode

Battery remaining display

Below grade indicator

Move the sensor up.

Audio signal:Lower pitch, slower frequency

Above grade indicator

Move the sensor down.

Audio signal:High pitch,frequent beep

When using the Laser

Sensor with other

select Topcon lasers,

these symbols alert

user if laser batteries

are low or if laser has

been disturbed.

These symbolsare

not active when used

with RL-H3CS.

Aligning Direction of Slope

When using the laser to set the slope, the laser

mustbe properly aligned so the slope axis of the

laserbeam isparallel to the desired direction of

slope.

The sight on top of the instrument is calibrated to

the slope axis of thelaserbeam. Follow the

stepsbelow to align thelaser to the desired

direction of slope:

1Establish a target line parallel to desired

direction of slope.

2Set up thelaser over this line(drop aplumb

bobfrom the tripod mounting screw).

3Rough align theinstrument to the directionof

slope. Make sure it is properlyorientedfor the

slope to be set.

4Using the sight, position the instrument so the

sight is centered on the target. (see illustra-

tion at right)

On-Grade position

Audio signal:Continuousbeep sound

[Setting slope]

Manual mode can beactivated

while the slope is set.

For information about Manual

mode ON/OFF, refer to "NOMEN-

CLATURE AND FUNCTIONS".

Check the beam oftenduring

slope use for slope accuracy.

Check instrument calibration peri-

odically (see below).

E

Target

Wall B

TOPCON CORPORATION

75-1 Hasunuma-cho, Itabashi-ku, Tokyo 174-8580, Japan

Phone: 3-3558-2520 Fax: 3-3960-4214 www.topcon.co.jp

TOPCON POSITIONING SYSTEMS, INC.

5758 West Las Positas Blvd., Pleasanton, CA 94588, U.S.A.

Phone: 925-460-1300 Fax: 925-460-1315 www.topcon.com

TOPCON CALIFORNIA

3380 Industrial Blvd, Suite 105, West Sacramento, CA 95691,

U.S.A.

Phone: 916-374-8575 Fax: 916-374-8329

TOPCON MIDWEST

891 Busse Road, Elk Grove Village, IL 60007, U.S.A.

Phone: 847-734-1700 Fax: 847-734-1712

TOPCON EUROPE B.V.

Essebaan 11, 2908 LJ Capelle a/d IJssel, The Netherlands.

Phone: 010-4585077 Fax: 010-4585045 www.topconeurope.com

TOPCON BELGIUM

Preenakker 8, 1785 Merchtem, Belgium

Phone: 052-37.45.48 Fax: 052-37.45.79

TOPCON DEUTSCHLAND G.m.b.H.

Weidkamp 180, 45356 Essen, GERMANY

www.topcon.de

TOPCON S.A.R.L.

89, Rue de Paris, 92585 Clichy, Cedex, France.

TOPCON ESPAÑA S.A.

HEAD OFFICE

Frederic Mompou 5, ED. Euro 3, 08960, Sant Just Desvern Barcelona, Spain.

Phone: 93-473-4057 Fax: 93-473-3932 www.topconesp.com

MADRID OFFICE

Avenida Burgos, 16E, 1∞28036, Madrid, Spain.

Phone: 91-302-4129 Fax: 91-383-3890

TOPCON SCANDINAVIA A. B.

Neongatan 2 S-43151 Mölndal, SWEDEN

Phone: 031-7109200 Fax: 031-7109249

TOPCON (GREATBRITAIN) LTD.

HEAD OFFICE

Topcon House Kennet Side, Bone Lane, Newbury, Berkshire RG14 5PX U.K.

Phone: 44-1635-551120 Fax: 44-1635-551170

TOPCON SOUTH ASIA PTE. LTD.

Blk 192 Pandan Loop, Pantech Industrial Complex, #07-01, Singapore 128381

Phone: 62780222 Fax: 62733540 www.topcon.com.sg

TOPCON AUSTRALIA PTY. LTD.

408 Victoria Road, Gladesville, NSW 2111, Australia

Phone: 02-9817-4666 Fax: 02-9817-4654 www.topcon.com.au

TOPCON INSTRUMENTS (THAILAND) CO., LTD.

77/162 Sinn Sathorn Tower, 37th Fl.,

Krungdhonburi Rd., Klongtonsai, Klongsarn, Bangkok 10600 Thailand.

Phone: 662-440-1152~7 Fax: 662-440-1158

TOPCON INSTRUMENTS (MALAYSIA) SDN. BHD.

Excella Business Park Block C, Ground & 1st Floor, Jalan Ampang Putra,

Taman Ampang Hilir, 55100 Kuala Lumpur, MALAYSIA

Phone: 03-42701068 Fax: 03-42704508

TOPCON KOREA CORPORATION

2F Yooseoung Bldg., 1595-3, Seocho-Dong, Seocho-gu, Seoul, 137-876, Korea.

Phone: 82-2-2055-0321 Fax: 82-2-2055-0319 www.topcon.co.kr

TOPCON OPTICAL (H.K.) LIMITED

2/F., Meeco Industrial Bldg., No. 53-55 Au Pui Wan Street, Fo Tan Road,

Shatin, N.T., Hong Kong

Phone: 2690-1328 Fax: 2690-2221 www.topcon.com.hk

TOPCON CORPORATION BEIJING OFFICE

Room No. 962 Poly Plaza Building, 14 Dongzhimen Nandajie,

Dongcheng District, Beijing, 100027, China

Phone: 10-6501-4191~2 Fax: 10-6501-4190

TOPCON CORPORATION BEIRUT OFFICE

P. O. BOX 70-1002 Antelias, BEIRUT-LEBANON.

Phone: 961-4-523525/961-4-523526 Fax: 961-4-521119

TOPCON CORPORATION DUBAI OFFICE

P.O.Box 28595, 102, Al Naily Bldg., 245 Abu Hail Road, Deira,Dubai,UAE

Phone: 971-4-2696511 Fax: 971-4-2695272

RL-H3CS 31336 90030 0210 (2b)