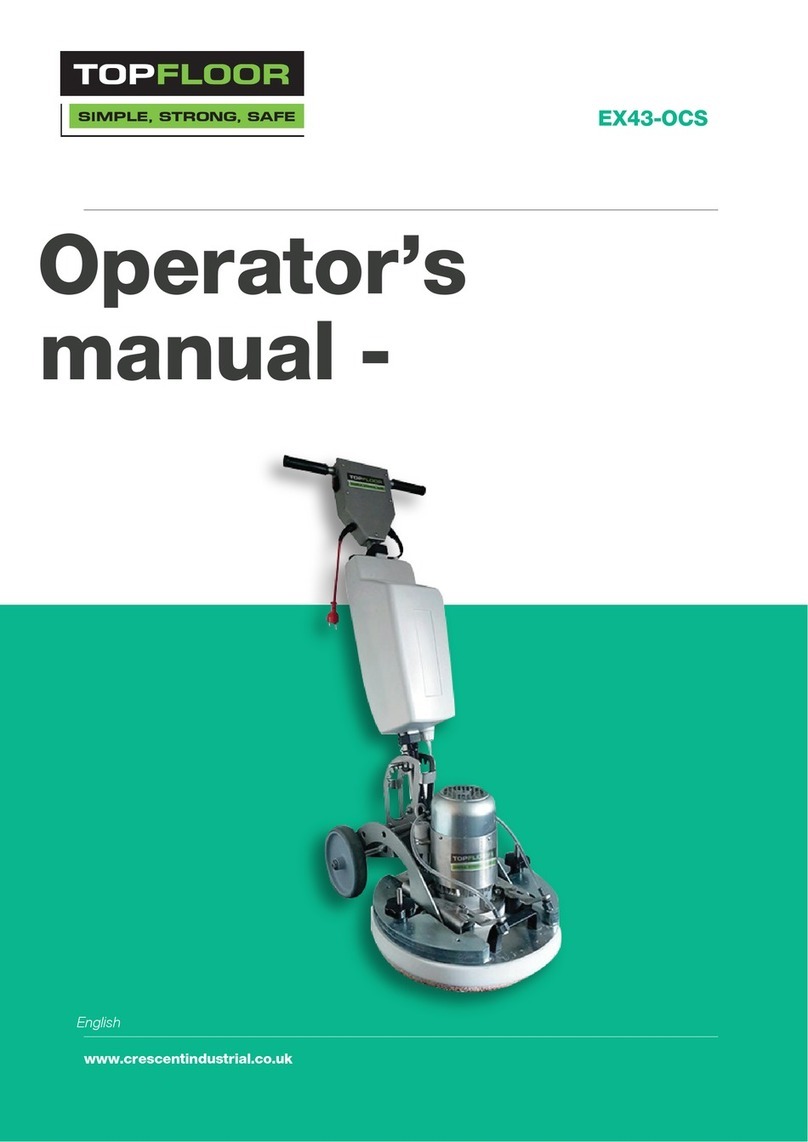

Topfloor EX30-OCS User manual

EX30-OCS

www.crescentindustrial.co.uk

Operator’s

manual -

English

www.crescentindustrial.co.uk

EX30-OCS

A copy of these instructions must be made available to everyone involved in putting this machine into

use, and its operation, maintenance and servicing!!

Original instructions for use in accordance with

Annex 1 (Paragraph 1.7.4.) of the Machinery

Directive 2006/42/EC

All rights reserved. No part of this document may be reproduced, stored in a database or retrieval

system or published in any form or in any way, electronically, mechanically, by print, photocopy,

microfilm or any other means without the prior written permission of Crescent Industrial

This also applies to all accompanying drawings and diagrams. Crescent Industrial shall retain the

right to modify machine components at any time with no obligation to inform the purchaser in

advance or directly. The contents of this manual may also be subject to change without notice.

For information about the machine’s settings, maintenance work and repairs that is not provided

in this user manual, please contact the supplier’s technical services department. This user manual

was compiled with the utmost care. Crescent Industrial cannot, however, accept any responsibility

for any errors it may contain or the possible consequences thereof.

Specifications – Safety - Usage - Maintenance

www.crescentindustrial.co.uk

EX30-OCS

ADDRESSES ................................................................................................... 04

FOREWORD ................................................................................................... 04

1. INTRODUCTION ........................................................................................ 05

2. GENERAL DESCRIPTION ........................................................................... 05

3. MACHINE OVERVIEW ............................................................................... 06

4. INTENDED USE ......................................................................................... 07

5. TECHNICAL DETAILS ................................................................................ 08

5.1 SPECIFICATIONS ................................................................................. 08

5.2 PARTS SUBJECT TO WEAR .................................................................. 08

5.3 NOISE EMISSION ................................................................................ 08

6. SAFETY ..................................................................................................... 09

6.1 GENERAL ........................................................................................... 09

6.2 SPECIFIC SAFETY INSTRUCTIONS ........................................................ 10

7. STORAGE ................................................................................................. 11

8. TRANSPORT ............................................................................................. 12

9. GETTING DOWN TO WORK! ................................................................... 12

9.1 PRELIMINARY CHECKS ..................................................................... 12

9.2 GETTING DOWN TO WORK! ............................................................... 12

9.3 BALLAST PLATES - ADDITIONAL WEIGHT ........................................... 12

10. MAINTENANCE ...................................................................................... 13

10.1 LUBRICANTS ................................................................................... 13

10.2 MAINTENANCE SCHEDULE .............................................................. 13

10.3 REPLACING A PAD ........................................................................... 13

11. TROUBLESHOOTING .............................................................................. 14

12. WARRANTY CONDITIONS ..................................................................... 15

13. REPAIRS .................................................................................................. 15

14. END OF SERVICE LIFE ............................................................................. 15

15. PARTS ..................................................................................................... 16

16. EU DECLARATION OF CONFORMITY .......................................................16

USER MANUAL EX30-OCS

TABLE OF CONTENTS

www.crescentindustrial.co.uk

EX30-OCS

ADDRESSES

Design, Production, Sales and Service:

Crescent Industrial Ltd

Berrington House

Berrington Road

Leamington Spa

CV31 1NB

Tel: 0845 33 77 695

www.crescentindustrial.co.uk

FOREWORD

This manual is intended for everyone involved in putting this machine into use, and its operation,

maintenance and servicing. These people must:

• Possess the necessary level of knowledge and qualifications to do their work.

• Have read and understood this user manual.

• Follow all given safety instructions.

• If necessary, have access to sufficient right-sized and good-quality tools.

This user manual, the type plate and stickers placed on the machine contain important safety

information and as such form an integral part of the delivery. Store this manual in a safe place

and pass it on if the machine is sold.

www.crescentindustrial.co.uk

EX30-OCS

1. INTRODUCTION

Congratulations with the purchase of your Topfloor orbital cleaning machine, stripping,

polishing, sanding and removing paint, coatings, adhesive residues, etc. You now have a machine

specifically designed for your intended use at your disposal. It is built in accordance with the latest

insights and most up-to-date techniques, and, provided the instructions in this manual are

followed correctly, it will give years of trouble-free use. The aim of this manual is to familiarise

yourself with operating the machine and to provide instructions for working with it safely and

guidelines for periodic maintenance. Make sure you are familiar with the contents of this manual

before starting to work with the machine so that you can use all its features optimally and safely.

This user manual, the type plate and stickers placed on the machine contain important safety

information and as such form an integral part of the delivery. If they are damaged or lost, they

must be replaced. Copies can be obtained from your supplier.

The machine is pre-assembled on delivery and is completely ready for carrying out

scrubbing/buffing/polishing work. Make sure you know how to do this work before you start

using the machine. On delivery, verbal instructions will be given about operating the machine,

safety procedures and necessary maintenance. If this is not possible, the buyer is responsible for

providing correct instructions. The machine offers a large number of possibilities for treating a

floor. Topfloor offers product training on all oscillating floor cleaning machines that are

purchased or hired. Go to www.crescentindustrial.co.uk to where all product specification data

sheets and useful video guides on how to operate the machine can be found on the product page.

2. GENERAL DESCRIPTION

EX30-OCS Oscillating Floor Cleaning Machine is designed for easily cleaning floors along

the edges, and in corners and smaller spaces. After fitting special pads, these machines can also

be used for (solvent-free!) stripping or sanding/polishing parquet floors.

The plastic surround bumper makes it possible to work in tight corners. These floor treatment

machines are unique because of the Topfloor method: the high number of oscillations of 2,800

a minute. This makes the effect of the pads unrivalled.

www.crescentindustrial.co.uk

EX30-OCS

The machine is easy to use and requires no effort, because it is as if it hovers over the floor.

The basis of the machine is a robust, sturdy stainless steel frame on which the pad holder with

oscillating rubbers is attached. A large-size eccentric electric motor that drives the pad holder is

mounted on the frame. When in operation, the machine is guided over the floor on a wheelset

by pushing a stainless steel shaft ending in a T-handle that can be adjusted to suit any height

3. MACHINE OVERVIEW

1. On/off switch

2. Power cable

3. Shaft

4. Shaft adjustment locking lever

5. Electric motor

6. Type plate

7. Oscillating rubber

8. Ballast plate (small)

9. Pad holder with plastic

bumper

10. Pad

www.crescentindustrial.co.uk

EX30-OCS

4. INTENDED USE

The EX30-OCS floor treatment machine is designed for:

• Cleaning

• Stripping

• Polishing

• Sanding

• Levelling

• Buffing

small and medium-sized hard and water-resistant floor surfaces using task-specific pads and/or

accessories. The duty cycle is 100% for normal professional use. Machines fitted with an IP54

plug can be used with (scrubbing) water.

Topfloor has – not yet - tested and approved the use of the machine for other purposes. With

respect to other possible uses, contact Topfloor IN ADVANCE to discuss whether the machine

is suitable. When working, the operator stands BEHIND the machine loosely holding the T-handle.

WARNING!

TOPFLOOR disclaims all responsibility in advance for damage caused as a result of

any use other than described above!!

WARNING!

These machines do NOT comply with ATEX requirements and may

NOT be used in an ATEX environment!!

According to information given on the website www.arboportaal.nl the risk of employees

suffering hearing loss starts at exposure to a noise level of 80 dB(A). Under the Working

Conditions Act, the employer must provide hearing protection if the local noise level exceeds

this value. Employees may only work in an environment with a noise level of 83 dB(A) for four

hours without hearing protection, there must not be an unacceptably high risk of hearing loss

and they may not be exposed to high noise levels during the following four hours. Employees

are obliged to wear hearing protection if they are on average exposed to a noise level of

85 dB(A) on a daily basis

5.2 Parts subject to wear

Machine parts subject to wear are not covered under the

warranty conditions due to:

1. additional contact with the product or

2. normal wear and tear during use

The parts of this machine that are subject to wear are:

• The oscillating rubbers

• The pads

5.3 Noise emission

The measured noise level of the machine when in operation is 60 dB(A). Test

results show that the machine’s noise emission when in operation depends

largely on the surface on which and the space in which it is used. Spatial echo

can lead to significantly higher noise levels. In these situations, Topfloor advises

making hearing protection permanently available.

www.crescentindustrial.co.uk

EX30-OCS

5. TECHNICAL DETAILS

5.1 Specifications

Working Surface: 30 x 20cm / 11.8 x 7.9” inches

Weight: 16 kg / 35.3 lb

Noise Level: 60 dB

Cable Length: 12m / 39ft

Movement: 2850 RPM

Voltage: 240v

Hertz: 50 Hz

Power: 0,37 kW

Protection Class: IPX54

Distance – Motor to Floor: 31 cm / 12.2”inches

Distance – Handle to Floor: 115 cm / 45.3”inches

Distance – Machine Front to-

Back of Wheel:

23 cm / 9”inches

www.crescentindustrial.co.uk

EX30-OCS

6. SAFETY

Always make sure the workplace is adequately illuminated. If necessary, place temporary

additional (construction site) lighting to maintain sufficient oversight. Everyone involved in putting

the machine into operation and its assembly, operation, maintenance and servicing, must:

• Possess the necessary level of knowledge and qualifications to do their work.

• Have read and understood this user manual.

• Follow all given safety instructions.

• If necessary, have access to sufficient right-sized and good-quality tools.

WARNING!

Almost all accidents are the result of: reduced concentration, inadvertence, negligence

or misjudgement! Be sure to work slowly and carefully!

6.1 General

WARNING!

Improper use or operating the machine without having the necessary experience

causes an immediate risk of physical injury, and damage to the machines and the

environment. Keep bystanders a safe distance away from the machine while in

operation!

WARNING!

Regular inspections and scheduled preventive maintenance reduce the chance of

malfunctions during operation. Read through the user manual carefully before

starting the machine!

Please read the user manual

carefully before starting the

machine!

Warning!

Electric Voltage!

Wear ear protection! Use a dust mask when grinding!

www.crescentindustrial.co.uk

EX30-OCS

WARNING!

Electrical hazard! Wearing hearing protection and a dust mask is compulsory when

carrying out dry sanding work. This machine does NOT comply with ATEX requirements

6.2 Specific safety instructions

ATTENTION!

The machine’s plug must be removed from the power socket whenever any form of

maintenance is carried out.

This Topfloor floor cleaning machine may NOT be used for cleaning floors that release substances

that form a risk to the health of the operator or bystanders, or the environment! Only use this

Topfloor machine on a suitable floor surfaces. If you have any doubts or questions, always

contact Topfloor or your local dealer.

ATTENTION!

Verify that the switch is set to “OFF” before inserting the machine’s plug in the power

socket!! Move the machine carefully over steps/stairs.

ATTENTION!

The machine is supplied with an extension cable as standard. The reach of the machine

may not be lengthened with an additional extension cable.

Never scrub over the extension cable.

If you accidentally move the machine or scrub over the cable, switch of the machine and remove

the plug from the power socket. Check the cable carefully for damage (water can also penetrate

through small cracks in the cable!)

ATTENTION!! RISK OF ELECTRIC SHOCK!

The machine is UNSUITABLE for operating completely submerged. Attempting to do this can

cause life-threatening situations

ATTENTION!

The machine may only be used with earthed power sockets and an earth leakage

circuit breaker

www.crescentindustrial.co.uk

EX30-OCS

7. STORAGE

ATTENTION!

You are working with an electric machine and (scrubbing) water. Make sure the earthing

and earth leakage circuit breaker are working correctly!! Make sure that none of the

cables in use are damaged!! You should preferably wear shoes with rubber soles!!

The use of this floor cleaning machine is subject to applicable safety and working conditions

regulations. In addition to the instructions in this user manual, generally accepted occupational

health and safety regulations must always be followed. All forms of improper use must be avoided.

During the warranty period, a service technician approved by Topfloor may work on the machine.

ATTENTION!

Before changing parts or accessories, ALWAYS make sure

that the plug has been removed from the power socket!

ATTENTION!

Stay at least 2m away from the edge of a swimming pool,

pond or open water!!

ATTENTION!

Always be careful when using a hose/blower!

If the machine will not be used for a longer period, it is advisable to carry out the following:

• Clean the machine with a damp cloth.

• Carry out scheduled maintenance; see Section 10

• If necessary, apply a protective coating.

• Store the machine in a dry space.

www.crescentindustrial.co.uk

EX30-OCS

8. TRANSPORT

The basic machine weighs approximately 16 kilos and it can be lifted by one person.

9. GETTING DOWN TO WORK!

9.1 Preliminary checks

You are working with (scrub) water and a 220 V machine. Make sure that:

• The mains voltage is 220 V

• The earth connection functions properly

• A GFCI (Ground Fault Circuit Interruptor) is installed.

- Check the cables for damage: both the short power cable as well as the extension cord!

- If you detect any deviations: solve these first before you start to work!

- Before starting treatment with the EX30-OCS, examine the floor on colour

and shape retention.

- Before you start, check if the correct pad for the job is attached.

- Check that at least one set of weights is installed, but no more than six sets!

- The number of weights on the left and right-hand side of the motor must be equal!

9.2 Getting down to work!

• Move the machine to the location where it will be used.

• Adjust the handle to a suitable working height and make sure it is locked properly in position!

• Check whether the switch is set to OFF.

• Unwind the extension cable (if used) completely and insert the machine’s plug into

an earthed power socket.

• Push the switch to ON position. The motor will start and the pad will start to work.

• While working the machine, you can easily push it around in any direction without requiring

a large amount of force. Work in straight lines, not by moving the machine from left to right.

• Always switch off the machine immediately after stopping work so you do not damage

the floor. Remove the plug from the power socket.

www.crescentindustrial.co.uk

EX30-OCS

10.1 Lubricants

No specific lubricants are recommended for the Topfloor Oscillating Floor Cleaners.

10.2 Maintenance schedule

10. MAINTENANCE

ATTENTION!

Regular inspections and scheduled preventive maintenance reduce the chance

of malfunctions during operation.

10.2.1 Daily (before starting work)

• Check all cables for damage. Repair damaged cables before starting work!

• Check the pad for wear. A worn pad reduces the operating speed.

• After using the machine with chemical cleaning agents, wipe the machine down

with a damp cloth to prevent corrosion of the stainless steel components.

• Check for loose nuts and bolts.

10.2.2 Monthly

• Check whether the plate under the pad holder still has enough grip to hold the pad

in position.

• Check the oscillating rubbers for cracks. Have cracked oscillating rubbers replaced!

10.2.3 Yearly

• Have the machine tested in accordance with the compulsory occupational health and

safety test (NEN 3140) for electrical machines.

10.3 Replacing a pad

If the operating speed drops, or the machine’s performance declines, the pad has probably

accumulated a large amount of dirt or is worn and it has to be cleaned or replaced. The pad is

attached to the plate with Velcro.

www.crescentindustrial.co.uk

EX30-OCS

11. TROUBLESHOOTING

1) The machine will not start:

• Check the earth leakage.

• Check the supply voltage.

• Check the cables for damage.

• Contact your supplier.

2) The machine makes a rattling sound. STOP IMMEDIATELY!!

CHECK THE MACHINE BEFORE CONTINUING WORK!!

• An oscillating rubber is loose: Tighten!

• A rubber has torn: Ensure that it is replaced!

• The eccentric bearing is worn: Ensure that it is replaced!

Proceed as follows:

• Switch the machine off.

• Remove the plug from the power socket.

• Put the handle in the highest position.

• Tip the machine backwards so that the handle rests on the ground and the pad is vertical.

• Pull the pad off the pad holder.

• Place the new pad carefully on the pad holder and push it firmly into position.

• Return the machine to the upright position.

• Put the handle back in the preferred position.

• Insert the machine’s plug in the power socket.

• Switch the machine on and continue working.

www.crescentindustrial.co.uk

EX30-OCS

12.WARRANTY CONDITIONS

In accordance with the Metaalunie Conditions, the machine has a warranty period of six months

after delivery. This means that, during this period, material and manufacturing defects will only be

repaired free of charge AFTER THEY HAVE BEEN ASSESSED BY A QUALIFIED TOPFLOOR ENGINEER’

Transportation/travelling expenses shall be for the purchaser’s account.

The warranty DOES NOT cover defects caused as a result of:

• demonstrable overloading of the machine.

• using the machine for purposes for which it is not built.

• demonstrable poor maintenance.

• not properly following the instructions in this manual.

• the use of the machine by unauthorised people.

• repairing the machine using non-OEM parts

• modifying the machine without obtaining written permission from TOPFLOOR

The warranty DOES NOT cover parts subject to wear as referred to in Section 5.

13. REPAIRS

The machine has a simple construction and parts diagrams are available on our website. Repairs

may only be carried out by competent, experienced personnel! This manual does not contain

detailed descriptions of repair procedures. If you have any questions or wish to have repairs carried

out by professionals, you can always contact TOPFLOOR.

14. END OF SERVICE LIFE

You must always comply with current local requirements and guidelines for working safely and

the responsible disposal of worn out machines! After the machine has been in use for a long time

and reached the end of its technical service life, follow the disposal procedure below:

• Clean the machine.

• Dismantle electrical components so they can be sent for recycling.

• Dismantle the plastic components so they can be handed in as separated waste.

• The remaining steel components can be sent for scrap.

Follow the ECMR (European Cleaning Machines Recycling) guidelines;

go to www.ecmr.nu for more information.

www.crescentindustrial.co.uk

EX30-OCS

15. PARTS

All parts lists are available on all Topfloor machines on the website: www.cresentindustrial.co.uk

Contact TOPFLOOR for further information about ordering parts and delivery times!! When

ordering parts, please specify the serial number specified on the machine’s the type plate.

16. EU DECLARATION OF CONFORMITY

IN ACCORDANCE WITH ANNEX IIA OF THE MACHINERY DIRECTIVE 2006/42/EC

We, TOPFLOOR., having our business address at Crescent Industrial Ltd.

We, TOPFLOOR – Industrial Floor Cleaning Machines

Crescent Industrial, Berrington House,

Berrington Road, Leamington Spa,

CV31 1NB

Declare under our sole responsibility that the product:

Brand: Topfloor

Machine: Floor preparation machine

Type: EX30-OCS

To which this declaration applies, meet all stipulations in the following directives:

Machinery Directive 2006/42/EG

Low Voltage Directive 2014/35/EU

EMC richtlijn 2014/30/EU

And in conformity with the following standards and/or other normative documents:

NEN-EN-1050:1997 Risk reduction

Drawn up in: Leamington Spa

05-04-2017

Topfloor (Crescent Industrial Ltd)

SJ Stacey, director

Crescent Industrial Ltd

Table of contents

Other Topfloor Scrubber manuals