Toptech Systems MultiLoad II User manual

M

Mu

ul

lt

ti

iL

Lo

oa

ad

d

I

II

I

U

Us

se

er

r

G

Gu

ui

id

de

e

I

In

nc

cl

lu

ud

di

in

ng

g:

:

M

Mu

ul

lt

ti

iL

Lo

oa

ad

d

I

II

I

M

Mu

ul

lt

ti

iL

Lo

oa

ad

d

I

II

I

S

SM

MP

P

M

Mu

ul

lt

ti

iL

Lo

oa

ad

d

I

II

I

S

SC

CS

S

M

Mu

ul

lt

ti

iL

Lo

oa

ad

d

I

II

I

M

Mo

ob

bi

il

le

e

Part # 6017

Firmware Version 3/4.31.37

October 2017

2

Firmware Version 3/4.31.37

Copyright Notice

Copyright © 2006 –2017 Toptech Systems, Inc.

The information contained in this document is proprietary and confidential. No part of this document may be copied, reproduced, or

transmitted in any medium without the express written permission of Toptech Systems, Inc.

Disclaimer

Toptech Systems assumes no responsibility for damages resulting from installation or use of its products. Toptech Systems will not be liable

for any claims of damage, lost data, or lost time as a result of using its products.

Logos are registered trademarks of Toptech Systems, Inc.

Copyright © 2007-2017 Toptech Systems, Inc. All Rights Reserved.

3

Table of Contents

CHAPTER 1 BEFORE YOU BEGIN................................................................................................................. 13

1.1 Who Should Use This Guide ................................................................................................................ 13

1.2 How This Guide Is Organized............................................................................................................... 13

1.3 Documentation Conventions................................................................................................................ 14

1.3.1 Screen Samples .................................................................................................................................. 14

1.3.2 Procedures........................................................................................................................................... 14

1.4 Information Alerts.................................................................................................................................. 15

1.5 Typographical Conventions ................................................................................................................. 16

CHAPTER 2 SYSTEM DESCRIPTION ............................................................................................................ 17

2.1 Overview................................................................................................................................................. 17

2.2 System Overview................................................................................................................................... 18

2.3 Three Operating Modes......................................................................................................................... 19

2.3.1 Local Control Mode.............................................................................................................................. 19

2.3.2 Remote Control Mode.......................................................................................................................... 19

2.3.3 UAP Mode............................................................................................................................................ 19

2.4 System Components............................................................................................................................. 20

2.5 MultiLoad II RCU.................................................................................................................................... 20

2.5.1 RCU enclosures available with MultiLoad II........................................................................................ 20

2.5.2 RCU enclosures available with MultiLoad II SMP ............................................................................... 20

2.6 External FCM (Flow Control Module)................................................................................................... 21

2.7 FCM II...................................................................................................................................................... 22

2.8 Internal I/O Board................................................................................................................................... 24

2.9 Internal 2-Meter I/O Board..................................................................................................................... 25

2.10 Navigating the System:......................................................................................................................... 26

2.10.1 Menus and Screens......................................................................................................................... 26

2.10.2 Field Modification and Data Entry.................................................................................................... 27

2.11 Switch Access Control.......................................................................................................................... 29

2.11.1 Type 1 Program / W&M switches .................................................................................................... 30

2.11.2 Type 2 Program / W&M switches .................................................................................................... 31

2.11.3 Type 3 Program / W&M switches .................................................................................................... 32

2.11.4 Program Mode / W&M DIP / Security Bypass Switch ..................................................................... 33

2.11.5 Program Mode / W&M Field Switches............................................................................................. 34

2.12 Getting Started....................................................................................................................................... 35

2.13 Configuration Parameters..................................................................................................................... 36

2.14 MultiLoad II Configuration Tool ........................................................................................................... 37

2.15 Factory Defaults..................................................................................................................................... 37

CHAPTER 3 GUI CONFIGURATION TOOL.................................................................................................... 38

3.1 Overview................................................................................................................................................. 38

3.2 Access from TMS 5 GUI ........................................................................................................................ 39

3.3 Screen Navigation ................................................................................................................................. 41

3.4 Menu Functions ..................................................................................................................................... 42

3.4.1 File Functions ...................................................................................................................................... 42

3.4.2 Edit Functions...................................................................................................................................... 42

4

Firmware Version 3/4.31.37

3.5 Tool Functions....................................................................................................................................... 42

3.6 BOL Ticket Builder ................................................................................................................................ 42

3.6.1 Download Registers............................................................................................................................. 42

3.6.2 Upload Registers ................................................................................................................................. 43

3.7 Reload Language................................................................................................................................... 44

3.8 Extract and View Transaction .............................................................................................................. 44

3.9 Create BOLs from Transactions .......................................................................................................... 44

3.10 MultiLoad II Reports .............................................................................................................................. 45

3.10.1 Configuration Report........................................................................................................................ 45

3.10.2Flow Control Modules Report.......................................................................................................... 46

3.11 Local Mode Only Parameters ............................................................................................................... 47

3.11.1 Driver Prompts................................................................................................................................. 47

3.11.2 Product Configuration...................................................................................................................... 48

3.11.3 Driver Access ID.............................................................................................................................. 49

3.11.4 Hazard Statements.......................................................................................................................... 50

3.12 Other Configuration Tool Functions.................................................................................................... 50

3.12.1 FCM GUI Display............................................................................................................................. 51

3.13 Windows MultiMate Configuration Tool.............................................................................................. 52

3.13.1 Installation........................................................................................................................................ 52

3.13.2 Connection to the MultiLoad II......................................................................................................... 54

3.13.3 Download Parameter Prompt File ................................................................................................... 56

3.13.4 Create a Configuration File.............................................................................................................. 57

3.13.5 Download a Configuration File From a MultiLoad II ........................................................................ 59

3.13.6 Upload a Configuration File TO a MultiLoad II ................................................................................ 60

3.13.7 Update the Firmware Image in a MultiLoad II.................................................................................. 61

CHAPTER 4 GENERAL CONFIGURATION.................................................................................................... 64

4.1 Overview................................................................................................................................................. 64

4.2 Communication Setup........................................................................................................................... 64

4.3 Network Setup........................................................................................................................................ 67

4.3.1 Host Setup........................................................................................................................................... 68

4.3.2 Modbus Setup & Modbus Slave Device Configuration........................................................................ 69

4.3.3 Termserver Setup................................................................................................................................ 72

4.3.4 Webpage Setup................................................................................................................................... 73

4.3.5 Network Printer Setup.......................................................................................................................... 73

4.3.6 TDS/UAP Interface Setup.................................................................................................................... 74

4.3.7 E-Mail Setup ........................................................................................................................................ 75

4.3.8 NTP Server Setup................................................................................................................................ 77

4.3.9 FTP Server Setup................................................................................................................................ 77

4.4 RCU General Setup................................................................................................................................ 79

4.4.1 Security Accounts Setup...................................................................................................................... 81

4.5 RCU Setup.............................................................................................................................................. 82

4.6 Security Setup........................................................................................................................................ 87

4.6.1 Password Security Setup..................................................................................................................... 89

4.6.2 Group Parameter Level Setup............................................................................................................. 90

4.6.3 External Access Level Setup............................................................................................................... 91

4.7 Trace Setup ............................................................................................................................................ 92

4.8 Equipment Setup ................................................................................................................................... 94

4.8.1 Bay Setup ............................................................................................................................................ 96

5

Firmware Version 3/4.31.37

4.8.2 Preset Setup........................................................................................................................................ 99

4.8.3 Meter Setup ....................................................................................................................................... 110

4.8.4 Component Setup.............................................................................................................................. 121

4.8.5 Additive Setup.................................................................................................................................... 128

4.8.6 Sampler Setup................................................................................................................................... 128

4.9 Tank Setup ........................................................................................................................................... 129

4.10 FCM Type Setup................................................................................................................................... 131

4.11 Alarm Setup.......................................................................................................................................... 132

4.11.1 Bay Alarm Setup............................................................................................................................ 136

4.11.2 Preset Alarm Setup........................................................................................................................ 137

4.11.3 Meter Alarm Setup......................................................................................................................... 138

4.11.4 Component Alarm Setup ............................................................................................................... 140

4.11.5 Additive Alarm Setup ..................................................................................................................... 141

4.11.6 Sampler Alarm Setup..................................................................................................................... 142

4.11.7 Tank Alarm Setup......................................................................................................................... 143

4.12 Local Product Definition and Assignment........................................................................................ 143

4.13 Product Setup ...................................................................................................................................... 144

4.14 Defining Base Components................................................................................................................ 145

4.14.1 Defining Base Component Recipes............................................................................................... 146

4.14.2 Defining an Additive....................................................................................................................... 147

4.14.3 Defining a Sampler ........................................................................................................................ 150

4.15 Defining Saleable Products................................................................................................................ 151

4.16 Preset Product Setup.......................................................................................................................... 154

4.16.1 Preset Name.................................................................................................................................. 155

4.16.2 Component Assignment ................................................................................................................ 155

4.16.3 Additive Assignment ...................................................................................................................... 156

4.16.4 Sampler Assignment...................................................................................................................... 156

4.16.5 Authorized Products Assignment .................................................................................................. 158

4.17 Tank Product Setup............................................................................................................................. 159

4.18 Configuration Tool Product Register Configuration Screen........................................................... 160

4.19 Configuration Tool Recipe Configuration Screen............................................................................ 161

4.20 Access IDs............................................................................................................................................ 161

4.20.1 Sampler Batch Access (SCS ONLY)............................................................................................. 162

4.21 Customer Logo Setup......................................................................................................................... 162

4.21.1 Loading a built in customer logo.................................................................................................... 164

4.21.2 Uploading a Custom .BMP Customer Logo................................................................................... 164

4.22 System Date and Time ........................................................................................................................ 165

4.23 Printing ................................................................................................................................................. 165

4.24 GPS Sites (ML II Mobile Only) ............................................................................................................ 168

4.25 Reports Setup ...................................................................................................................................... 169

CHAPTER 5 PRODUCT FLOW CONTROL................................................................................................... 171

5.1 Overview............................................................................................................................................... 171

5.2 Single Product Delivery ...................................................................................................................... 172

5.2.1 High Flow........................................................................................................................................... 173

5.2.2 1st Stage Trip ..................................................................................................................................... 174

5.2.3 2nd Stage Trip..................................................................................................................................... 174

5.2.4 Final Trip............................................................................................................................................ 174

5.2.5 2”-3” Digital Control Valves................................................................................................................ 175

6

Firmware Version 3/4.31.37

5.2.6 Adaptive Digital Control Algorithm..................................................................................................... 175

5.2.7 Two Stage Valves.............................................................................................................................. 175

5.2.8 Analog Valves.................................................................................................................................... 176

5.3 Sequential Blending (Excluding SMP)............................................................................................... 176

5.3.1 Sequential Blending Configuration .................................................................................................... 177

5.4 Ratio Blending (Excluding SMP)........................................................................................................ 180

5.4.1 Ratio Blending Configuration............................................................................................................. 181

5.5 Side-Stream Blending (Excluding SMP)............................................................................................ 184

5.5.1 Simple Side-Stream Blender Configuration....................................................................................... 185

5.6 Hybrid Blending (Excluding SMP) ..................................................................................................... 186

5.6.1 Multiple Side-Streams........................................................................................................................ 186

5.6.2 Sequential Blending with Side-Stream.............................................................................................. 187

5.6.3 Ratio Blending with Side-Stream....................................................................................................... 188

5.7 Proving Side-Stream Meters (Excluding SMP)................................................................................. 191

5.8 Line Flush (Excluding SMP) ............................................................................................................... 191

5.9 Ratio Blending Considerations (Excluding SMP) ............................................................................ 194

5.10 Calibration Using Meter Factor Linearization................................................................................... 195

5.10.1 Single Meter Factor ....................................................................................................................... 197

5.10.2 Rules for Meter Factors ................................................................................................................. 197

CHAPTER 6 ADDITIVE CONTROL ............................................................................................................... 198

6.1 Overview............................................................................................................................................... 198

6.2 Piston Injector Cycles......................................................................................................................... 198

6.3 Additive Port Assignment................................................................................................................... 199

6.3.1 Additive Output Port and Input Port Assignments............................................................................. 199

6.4 Additive Units....................................................................................................................................... 200

6.5 Additive Control Methods................................................................................................................... 200

6.5.1 Method 1 –Piston Only ..................................................................................................................... 200

6.5.2 Configuring a Piston Only Additive.................................................................................................... 201

6.5.3 Method 2 –Piston with Input (Feedback Switch) .............................................................................. 201

6.5.4 Configuring a Piston with Input Additive............................................................................................ 202

6.5.5 Method 3 –Pulser Input..................................................................................................................... 203

6.5.6 Configuring a Pulser Input Additive ................................................................................................... 203

6.5.7 Method 4 –Analog Additive............................................................................................................... 204

6.5.8 Configuring a Analog Additive ........................................................................................................... 204

6.5.9 Method 5 –Common Meter with Multiple Additives .......................................................................... 204

6.5.10 Additive Block Valves Only............................................................................................................ 206

6.5.11 Configuring a Common Meter with Multiple Additives................................................................... 207

6.6 General Additive Setup....................................................................................................................... 210

6.7 Additive Calibration............................................................................................................................. 217

6.7.1 Additive Cal. Function........................................................................................................................ 217

6.7.2 Automatic Calibration Function.......................................................................................................... 218

6.7.3 Piston Type Additive Calibration........................................................................................................ 222

6.8 Calculate Additive Vol/Inject .............................................................................................................. 223

6.9 Remote Additive Calibration .............................................................................................................. 225

6.10 Additive Status Screen........................................................................................................................ 230

6.11 Additive Flush Features...................................................................................................................... 231

6.11.1 Basic Flush Features..................................................................................................................... 231

6.11.2 Techniques for Flushing Dye......................................................................................................... 233

7

Firmware Version 3/4.31.37

6.11.3 Block Valves and Flush Pumps..................................................................................................... 234

CHAPTER 7 SWING ARM SETUP AND OPERATION (EXCLUDING SMP) ............................................... 237

7.1 Overview............................................................................................................................................... 237

7.2Swing Arm Operation.......................................................................................................................... 238

7.3 Relay and Switch Logic....................................................................................................................... 238

7.4 Swing Arm Configuration ................................................................................................................... 240

CHAPTER 8 DIAGNOSTICS.......................................................................................................................... 242

8.1 Overview............................................................................................................................................... 242

8.2 Card Reader (Excluding SMP)............................................................................................................ 243

8.3 iBUTTON Reader (Excluding SMP).................................................................................................... 245

8.4 Loopback test ...................................................................................................................................... 245

8.5 Serial Port test ..................................................................................................................................... 248

8.6 PTB Serial Test .................................................................................................................................... 249

8.7 Network test ......................................................................................................................................... 249

8.8 Keypad test .......................................................................................................................................... 250

8.9 Display test........................................................................................................................................... 252

8.10 Unicode test ......................................................................................................................................... 253

8.11 FCM Communications......................................................................................................................... 254

8.12 PCM Communications......................................................................................................................... 255

8.13 FCM Health Status............................................................................................................................... 256

8.14PCM Health Status............................................................................................................................... 257

8.15 RCU Diagnostics.................................................................................................................................. 258

8.16 Bay Diagnostics................................................................................................................................... 259

8.17 Preset Diagnostics .............................................................................................................................. 260

8.18 Meter Diagnostics................................................................................................................................ 261

8.19 Digital Control Valve Test................................................................................................................... 264

8.20 Component Diagnostics ..................................................................................................................... 267

8.21 Additive Diagnostics ........................................................................................................................... 268

8.22 Sampler................................................................................................................................................. 269

8.23 Tanks (SCS Only)................................................................................................................................. 270

8.24 Custom Logic....................................................................................................................................... 272

8.25 Modbus Device .................................................................................................................................... 272

8.26 GPS Diagnostics (MultiLoad II Moble Only)...................................................................................... 273

CHAPTER 9 WEIGHTS AND MEASURES.................................................................................................... 275

9.1 Overview............................................................................................................................................... 275

9.1.1 Weights and Measures...................................................................................................................... 275

9.2 Access Restrictions to W&M Parameters ......................................................................................... 275

9.3 Weights & Measures change log and metrological parameter security........................................ 276

9.4 Volume Correction Factor Features .................................................................................................. 276

9.5 Net and Mass Calculations................................................................................................................. 277

9.5.1 Net Pulse Output ............................................................................................................................... 278

9.5.2 Mass Pulse Output ............................................................................................................................ 278

9.5.3 Deliver in Gross or Net or Mass......................................................................................................... 278

9.5.4 API Table VCF Calculators................................................................................................................ 278

9.5.5 Display of Net Volume and Related Data.......................................................................................... 278

9.5.6 API MPMS Chapter 11.1-2004/Adjunct to IP 200/04/Adjunct to ASTM D 1250-04 .......................... 279

8

Firmware Version 3/4.31.37

9.5.7 Configuring for Temperature Correction (CTL).................................................................................. 279

9.6 MultiLoad Straight Delivery (Single Component) Calculations ...................................................... 300

9.7 MultiLoad Sequential Blending Calculations.................................................................................... 301

9.8 MultiLoad Ratio Blending Calculations............................................................................................. 303

9.9 MultiLoad Side-stream Blending Calculations................................................................................. 305

9.10 MultiLoad Sequential with Ratio Blending Calculations ................................................................. 307

9.11 MultiLoad Sequential with Side-stream Blending Calculations...................................................... 310

9.12 MultiLoad Ratio with Side-stream Blending Calculations............................................................... 313

9.13 Temperature Calibration for Meters................................................................................................... 316

9.14 Temperature Compensation and VCF Calculator ............................................................................ 318

9.15 Pressure Calibration for Meters......................................................................................................... 319

9.16 Density Calibration.............................................................................................................................. 321

9.17 Relative Density Calibration............................................................................................................... 322

9.18 API Gravity Calibration........................................................................................................................ 323

9.19 BSW1 Calibration................................................................................................................................. 324

9.20 BSW2 Calibration................................................................................................................................. 324

CHAPTER 10 VIEWS AND INQUIRIES........................................................................................................... 326

10.1 Overview............................................................................................................................................... 326

10.2 Viewing Alarms.................................................................................................................................... 326

10.3 Viewing Totalizers ............................................................................................................................... 327

10.3.1 Viewing Preset Totalizers.............................................................................................................. 327

10.3.2 Viewing Meter Totalizers ............................................................................................................... 329

10.3.3 Viewing Component Totalizers...................................................................................................... 330

10.3.4 Viewing Additive Totalizers............................................................................................................ 331

10.3.5 Viewing Sampler Totalizers........................................................................................................... 332

10.4 Viewing Temperatures ........................................................................................................................ 333

10.5 Viewing Pressures............................................................................................................................... 333

10.6 Viewing Density ................................................................................................................................... 334

10.7 Viewing Relative Density .................................................................................................................... 335

10.8 Viewing BSW1...................................................................................................................................... 336

10.9 Viewing BSW2...................................................................................................................................... 336

10.10 Viewing API Gravity......................................................................................................................... 337

10.11 Viewing Transactions...................................................................................................................... 338

10.12 View Sampler Batch Reports (SCS Only)...................................................................................... 342

10.13 View Weights and Measures Change Log..................................................................................... 343

10.14 View MultiLoad II Message Log...................................................................................................... 346

10.15 View MultiLoad II Audit Log............................................................................................................ 346

10.16 View MultiLoad II FCM Mapping..................................................................................................... 348

10.17 View Firmware Information............................................................................................................. 349

CHAPTER 11 SD CARD................................................................................................................................... 350

11.1 Overview............................................................................................................................................... 350

11.2 View Directories/Files.......................................................................................................................... 350

11.3 Load Configuration.............................................................................................................................. 353

11.4 Save Configuration.............................................................................................................................. 354

11.5 Load Logo ............................................................................................................................................ 355

11.6 Load Firmware ..................................................................................................................................... 356

11.6.1 Corrupt Flash Memory................................................................................................................... 357

9

Firmware Version 3/4.31.37

11.6.2 Load Configuration and Totalizers................................................................................................. 357

11.7 Format SD-Card ................................................................................................................................... 358

11.8 Dump Diagnostic Data ........................................................................................................................ 359

11.9 Export Reports..................................................................................................................................... 360

11.9.1 Configuration Report...................................................................................................................... 360

11.9.2 Transaction, Meter, and Sampler Report ...................................................................................... 360

11.10 Configuration ................................................................................................................................... 361

CHAPTER 12 OPERATION.............................................................................................................................. 363

12.1 Overview............................................................................................................................................... 363

12.2 Phases of Operation............................................................................................................................ 363

12.3 Driver Card or Keypad Access........................................................................................................... 363

12.4 Remote Control Operation.................................................................................................................. 364

12.4.1 Authorization Phase....................................................................................................................... 364

12.4.2 Access Screen............................................................................................................................... 364

12.4.3 Load Status Values........................................................................................................................ 371

12.4.4 End Load Phase ............................................................................................................................ 373

12.4.5 TMS BOL....................................................................................................................................... 373

12.5 Local (Standalone) Operation ............................................................................................................ 373

12.5.1 Access ID Database ..................................................................................................................... 373

12.5.2 Product Database.......................................................................................................................... 374

12.5.3 Meter Ticket Printing...................................................................................................................... 374

12.5.4 Miscellaneous Tasks ..................................................................................................................... 375

12.5.5 Configuring MultiLoad II for Local Mode........................................................................................ 375

12.5.6 Operation in Local Mode................................................................................................................ 376

12.5.7 Local Authorization ........................................................................................................................ 376

12.5.8 Meter Ticket................................................................................................................................... 377

12.5.9 Switching Back to Remote Mode................................................................................................... 377

12.6 Automatic Proving Function .............................................................................................................. 378

12.6.1 Using the Proving Feature............................................................................................................. 378

12.7 Ending Sampler Batch (SCS Only) .................................................................................................... 383

12.7.1 End Sampler Batch While Idle....................................................................................................... 383

12.7.2 End Sampler Batch During Transaction ........................................................................................ 384

CHAPTER 13 CUSTOM LOGIC....................................................................................................................... 385

13.1 Overview............................................................................................................................................... 385

13.2 Custom Logic Groups......................................................................................................................... 386

13.2.1 Input/Output................................................................................................................................... 387

13.2.2 Real Time Values .......................................................................................................................... 388

13.2.3 Read/Write Configuration Parameters........................................................................................... 403

13.2.4 Real Time Alarms .......................................................................................................................... 412

13.2.5 Operations ..................................................................................................................................... 412

13.2.6 Timers/Counters ............................................................................................................................ 415

13.2.7 Scaling........................................................................................................................................... 416

13.2.8 Range Checking ............................................................................................................................ 416

13.2.9 Real Time Totalizers...................................................................................................................... 417

13.2.10 Networking..................................................................................................................................... 418

CHAPTER 14 WEB INTERFACE..................................................................................................................... 422

10

Firmware Version 3/4.31.37

14.1 Overview............................................................................................................................................... 422

14.2 Login..................................................................................................................................................... 422

14.3 Website................................................................................................................................................. 422

14.4 Message Log........................................................................................................................................ 424

14.5 W&M Change Log................................................................................................................................ 424

14.6 Audit Log.............................................................................................................................................. 424

14.7 Files on the SD-Card ........................................................................................................................... 425

14.8 Upload Files To the SD-Card.............................................................................................................. 425

14.9 Transaction Viewer.............................................................................................................................. 426

14.10 FCM Mapping Report....................................................................................................................... 427

14.11 Simulator Page................................................................................................................................. 428

14.12 Configuration Report....................................................................................................................... 429

14.13 Transaction Report.......................................................................................................................... 430

CHAPTER 15 MULTILOAD HELP................................................................................................................... 431

15.1 Overview............................................................................................................................................... 431

15.2 How To Use .......................................................................................................................................... 431

CHAPTER 16 FIRMWARE REVISION HISTORY............................................................................................ 432

16.1 Overview............................................................................................................................................... 432

16.2 Firmware Changes............................................................................................................................... 432

11

Firmware Version 3/4.31.37

Table of Figures

Figure 2.1 FCM II Modules ............................................................................................................................... 23

Figure 2.2 Type 1 Program / W&M Switches.................................................................................................... 30

Figure 2.3 Type 2 Program / W&M Switches.................................................................................................... 31

Figure 2.4 Type 3 Program / W&M Switches.................................................................................................... 32

Figure 2.5 CPU Board Rev 1.0 Program and W&M DIP Switches................................................................... 33

Figure 2.6 CPU Board Rev 2.0 Program and W&M DIP Switches................................................................... 34

Figure 3.1 File Selection Screen....................................................................................................................... 39

Figure 3.2 Bay Configuration Menu .................................................................................................................. 40

Figure 3.3 RCU Configuration Menu................................................................................................................. 41

Figure 3.4 Download Window........................................................................................................................... 43

Figure 3.5 Upload Window................................................................................................................................ 43

Figure 3.6 Transaction Window........................................................................................................................ 44

Figure 3.7 Bill of Lading (BOL) Window............................................................................................................ 44

Figure 3.8 Configuration Report........................................................................................................................ 45

Figure 3.9 I/O Assignment Report .................................................................................................................... 46

Figure 3.10 Prompt Configuration Menu............................................................................................................. 47

Figure 3.11 Product Configuration Screen ......................................................................................................... 48

Figure 3.12 Access ID Screen ............................................................................................................................ 49

Figure 3.13 Hazard Configuration Screen .......................................................................................................... 50

Figure 3.14 I/O Assignment Graphic................................................................................................................... 51

Figure 3.15 I/O Assignment Detail...................................................................................................................... 51

Figure 5.1 Flow Profile.................................................................................................................................... 171

Figure 5.2 Flow Profile for Single Product Delivery........................................................................................ 172

Figure 5.3 Sequential Blending Application.................................................................................................... 176

Figure 5.4 Ratio Blending Application............................................................................................................. 180

Figure 5.5 Simple Side-Stream Application.................................................................................................... 185

Figure 5.6 Simple Side-Stream Configuration ................................................................................................ 186

Figure 5.7 Multiple Side-Stream Application................................................................................................... 186

Figure 5.8 Multiple Side-Stream Configuration............................................................................................... 187

Figure 5.9 Sequential Blending with Side-Stream Application ....................................................................... 187

Figure 5.10 Sequential Blending with Side-Stream Configuration.................................................................... 188

Figure 5.11 Ratio Blending with Side Stream Application ................................................................................ 189

Figure 5.12 Ratio Blending with Side Stream Configuration............................................................................. 190

Figure 5.13 Meter Factor Linearization............................................................................................................. 195

Figure 6.1 Piston Cycle Graph........................................................................................................................ 199

Figure 6.2 Additive Injection............................................................................................................................ 200

Figure 6.3 Common Injector Valve Scheme................................................................................................... 205

Figure 6.4 Electrical Schematic using Injector Valve...................................................................................... 206

Figure 6.5 Scheme using Block Valves to Inject............................................................................................. 206

Figure 6.6 Electrical Schematic using Block Valves as Injectors ................................................................... 207

Figure 6.7 Additive Over Injection................................................................................................................... 214

Figure 6.8 Vol/Inj Calculated........................................................................................................................... 225

Figure 6.9 Basic Flush Cycle .......................................................................................................................... 232

Figure 6.10 Front Loading Dye ......................................................................................................................... 233

Figure 6.11 Mono-block Injector & Dye Point Assembly................................................................................... 234

Figure 6.12 Additive Meter in Flush Path.......................................................................................................... 235

Figure 6.13 Additive Meter and Injector Valve in Flush Path............................................................................ 236

12

Firmware Version 3/4.31.37

Figure 7.1 Swing Arm Configuration............................................................................................................... 237

Figure 7.2 Swing Arm FCM Relay Socket ...................................................................................................... 239

Figure 10.1 View Transaction Header Screen.................................................................................................. 339

Figure 12.1 Preset Control Screen ................................................................................................................... 369

Chapter 1 –Before You Begin

13

Firmware Version 3/4.31.37

CHAPTER 1 BEFORE YOU BEGIN

1.1 WHO SHOULD USE THIS GUIDE

This guide is intended for those individuals at your terminal who will set up and use the MultiLoad II system:

terminal managers, system administrators, terminal operators, technicians, and meter proving personnel,

1.2 HOW THIS GUIDE IS ORGANIZED

The MultiLoad II User Guide is organized by functional procedures. It mirrors the MultiLoad II menu structure.

Each chapter discusses a single procedure or a group of related procedures that are necessary to set up and use

the system. The following table provides an information map to the material in this guide.

Chapter

Audience

Topics Covered

1. Before You Begin

All

Conventions Used in This Guide.

2. System Description

All

System description, Remote and Local operating

modes, System components, Navigation, Data

Entry, and Getting Started.

3. GUI Configuration

Tool

System Admin, Facility

expert

Purpose, Access, Menu Functions, Navigation, and

Local Control only parameter configuration.

4. General

Configuration

System Admin, Facility

expert

Communication Setup, Equipment Setup, Product

Setup, Presets, Additive Calibration, Access IDs,

System Date and Time.

5. Product Flow

Control

System Admin, Facility

expert

Flow control configuration for single product delivery

and calibration.

6. Additive Control

Additive expert

Configuring for different additive control methods:

piston only, pulser input, etc.

7. Swing Arm Setup

and Operation

System Admin, Facility

expert

Swing arm configuration and operation.

8. Diagnostics

System Admin, Technician,

Electrician

Loopback Test; Diagnostics for Bay, Preset, Meter,

Component and Additives

9. Weights &

Measures

System Admin, Technician

Meter pulse resolution, Meter Factors/Calibration,

Temperature Calibration

10. Views and Inquiry

Operators

View presets, totalizers and meter temperatures.

11. SD Card

System Admin, Technician

How to utilize the SD Card to save/load

configurations, load firmware, dump diagnostic data,

and configure automated reports

12. Operation

Drivers, Operators

Phases of Operation, Keypad Entry, Local Control

Operation, Remote Control Operation, TMS

Authorization, SMP Ditto.

Chapter 1 –Before You Begin

14

Firmware Version 3/4.31.37

Chapter

Audience

Topics Covered

13. Custom Logic

System Admin, analyst,

programmer

Custom logic overview, and explaination of each

logic function available.

14. Web Interface

System Admin, Terminal

personel

Explaination of all features available via the web

interface like RCU Ditto, log viewers, transaction

viewer, etc.

15. MultiLoad Help

All

Overview of the MultiLoad Help feature.

16. Firmware Revision

History

All

List of all firmware changes.

1.3 DOCUMENTATION CONVENTIONS

The following documentation conventions are used throughout this guide.

1.3.1 SCREEN SAMPLES

The field data shown are provided as samples only.

1.3.2 PROCEDURES

Procedures that should be followed in order are shown in a step-by-step format. Usually, the result of a user

action is shown on the next line. For example:

1. From the Configuration Menu, choose Equipment Setup. Press Enter. The Equipment Setup Menu

appears.

2. Select if you want to see everything (=ALL) or a specific parameter like API. Press Enter.

SELECT PARAMETER LEVEL

ALL

Input/Output

Weights & Measures

Flow Control & Rates

Blending

API

Alarms

Next Prev Exit Enter

Chapter 1 –Before You Begin

15

Firmware Version 3/4.31.37

!

3. Press Next until Meters is highlighted. Press Enter. The Meter Setup screen displays:

1.4 INFORMATION ALERTS

The Guide uses the following graphical conventions to alert the reader to different kinds of information:

Notes provide additional, supplementary, or “nice-to-know” information not actually necessary to the

current task or topic.

Cautions alert you to the possibility of unexpected results when performing an action. They are

also used to inform you of important things to keep in mind.

Warnings inform you of the possibility that damage might occur as a result of performing a certain

action or not performing a certain action. Pay close attention when you see the warning symbol!

PRE #1 MTR #1 SETUP

Flow Control Module#: 0

Side-Stream on Mtr#: 0

Side-Strm on Any Mtr: DISABLD

Meter Type: VOL PUL

Max Quad Errors: 10

Reset Quad Errors: 10000

Low Flow Alarm Rate: 10

Low Flow Alarm Time: 10.000

Excess Flw Alrm Rate: 800

Minimum Flow Rate: 50

Maximum Flow Rate: 650

Low Flow DB Rate: 40

High Flow DB Rate: 40

1st Stage DB Rate: 40

Next Prev Exit Enter

EQUIPMENT SETUP MENU

Bay

Preset

Meters

Components

Additives

Samplers

Next Prev Exit Enter

Chapter 1 –Before You Begin

16

Firmware Version 3/4.31.37

1.5 TYPOGRAPHICAL CONVENTIONS

The following typographical conventions are used throughout the Guide.

Boldface

Indicates what you are asked to key in or which button(s) to press on the MultiLoad II keypad.

Example: “Key in 00000 and press Next.”

Italic

In topic text, italic indicates a key MultiLoad II term or industry term. Example: “The display

features a pick list style of item selection.”

Italic is also used for emphasis.

Chapter 2 –System Description

17

Firmware Version 3/4.31.37

CHAPTER 2 SYSTEM DESCRIPTION

2.1 OVERVIEW

This chapter introduces you to the MultiLoad II system by defining its capabilities, describing its operating modes,

identifying its main components, and discussing navigation of the user interface.

Main topics covered are:

- System Overview

- Three Operating Modes

- System Components

- Navigating The System

- Switch Access Control

- Getting Started

- The MultiLoad II Configuration Tool (MultiMate)

Chapter 2 –System Description

18

Firmware Version 3/4.31.37

2.2 SYSTEM OVERVIEW

The MultiLoad II is designed to manage multiple loading arms delivering straight or blended products. The

system can operate in conjunction with the Toptech TMS system (remote processing mode), in Local

(standalone) mode or connected to the cloud (UAP Mode). The MultiLoad II supports:

12 loading arms

5 meters per loading arm, 6 component ratio blending.

8 components per loading arm, 8 components sequential blending.

Sequential, Ratio and Side-stream blending.(proportional as non-proportional blending)

Watercut calculation

16 additive injectors per loading arm

4 samplers per loading arm

Digital, two stage, and Analog 4-20mA control valves

RTD temperature inputs

4-20 ma input for either density, relative density, api gravity, pressure , bsw or watercut

Ethernet communications

Ethernet printing

MultiLoad II Single Meter Preset (SMP) is an economical package, designed to support single load arm/single

meter applications. The system can operate in conjunction with the Toptech TMS system (remote processing

mode) , in Local (standalone) Mode or in UAP (TDS) Mode. The MultiLoad II SMP supports:

1 loading arm

1 meter

8 components (different meter factors for each product)

No blending and no watercut.

2 additive injectors

4 samplers per loading arm

Digital, two stage, and Analog 4-20mA control valves

RTD temperature input

4-20 ma input for either density, relative density, api gravity, pressure or bsw

Ethernet communications

Ethernet printing

MultiLoad II Skid Control System (SCS) is an economical package, designed to support LACT skid meter

applications. The system can operate in conjunction with the Toptech TMS system (remote processing mode), in

Local (standalone) Mode or in UAP (TDS) Mode. The MultiLoad II SCS supports:

1 loading arm

4 meter

8 components (different meter factors for each product)

No blending, only Watercut.

20 samplers per loading arm

10 Tanks

Digital, two stage, and Analog 4-20mA control valves

RTD temperature input

Chapter 2 –System Description

19

Firmware Version 3/4.31.37

4-20 ma input for either density, relative density, api gravity, pressure or bsw

Ethernet communications

Ethernet printing

2.3 THREE OPERATING MODES

The MultiLoad II can be configured to operate in three different modes:

Local (stand-alone) Control Mode –product and access information are stored in non-volatile memory in the

MultiLoad II.

Remote Control Mode –access and product information is controlled by TMS or another remote computer

system.

UAP –Interfacing with a host-system in the cloud which has all basic TAS functionality.

2.3.1 LOCAL CONTROL MODE

In local mode, the MultiLoad II RCU will read a driver’s Prox Card (Excluding the SMP) or will prompt the driver to

enter an access ID. Next the driver will be prompted to enter a PIN code. The supplied driver card or access ID

and PIN must match a record in the driver database stored in the non-volatile memory of the MultiLoad II RCU.

Once verified, the MultiLoad II will act upon its internal configuration regarding additional prompts. The MultiLoad

II has up to 5 configurable prompts that may be presented to the driver. Once these data entry prompts have

been recorded, loading will be authorized.

Capabilities of the MultiLoad II operating in Local mode are:

- 300 access ID’s and associated PIN codes.

- 10,000 transaction archives complete with salable product, component detail and additive detail.

- 5 user-configurable custom prompts; resultant data stored with each transaction.

- 33 product recipes per meter/loading arm.

- Meter Ticket –combined ticket for all transaction liftings in user-configurable format.

- Meter, Additive, and Temperature Calibration features.

- Log of the last 1000 Weights and Measures parameter changes. Also stored on the sd-card for 90 days.

- Config Change Log of the last 500 parameter changes included W&M parameters. Also stored on the sd-

card for 90 days.

- Log of the last 500 configuration changes in the Auditlog.

2.3.2 REMOTE CONTROL MODE

When interfaced to a remote computer system, the number of driver records, customer prompts and recipes is

virtually unlimited.

2.3.3 UAP MODE

This is an interface to the cloud and has all basic functionality of a TAS-system in the cloud.

Chapter 2 –System Description

20

Firmware Version 3/4.31.37

2.4 SYSTEM COMPONENTS

The Toptech MultiLoad II family of products is available in the following configurations.

MultiLoad II –Multiple Arm, Multiple Component Blending System.

MultiLoad II SMP (Single Meter Preset) –1 Arm, Single Component Delivery System

MultiLoad II SCS (Skid Control System) –1 Arm, Multiple Component System

Field equipment is connected to the system via an internal I/O board, several external FCM (Flow Control

Modules), or a combination.

2.5 MULTILOAD II RCU

The Remote Control Unit (RCU) of the MultiLoad II is the driver interface to the system which performs all high

level process controls, contains all configuration information, totalizers, and event logs. The driver interface

contains a keypad, display, and prox card reader.

2.5.1 RCU ENCLOSURES AVAILABLE WITH MULTILOAD II

Division 2 Enclosure (with optional internal I/O Board)

Division 1/Zone 1 Explosion Proof Light (EXL) Enclosure (with optional internal I/O Board)

2.5.2 RCU ENCLOSURES AVAILABLE WITH MULTILOAD II SMP

Division 1/Zone 1 Explosion Proof Light (EXL) Enclosure (with optional internal I/O Board and/or optional

card-reader)

This manual suits for next models

3

Table of contents

Popular Control Unit manuals by other brands

DSC

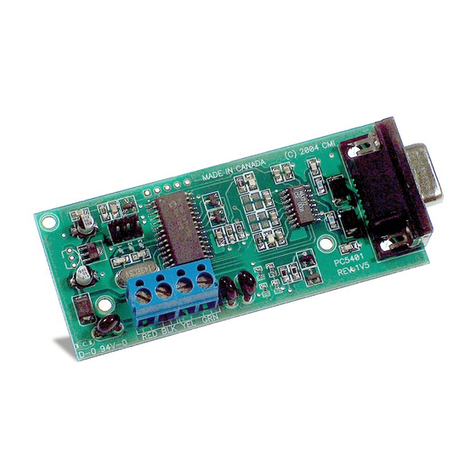

DSC Misterhouse PC5401 user manual

ProSoft Technology

ProSoft Technology MVI56E-MCM user manual

SMAR

SMAR DF46 installation manual

Kemper

Kemper 361 Installation and operating instructions

Kemper

Kemper 5850001500 Installation and operating instructions

schmersal

schmersal SRB 324ST V.3 operating instructions

Roger Technology

Roger Technology B70/2B Instruction and warnings for the installer

Britex

Britex FFV-E45 installation guide

Intermatic

Intermatic DDT40 Installation and operation manual

M-system

M-system R7M-EC16A instruction manual

resideo

resideo Braukmann D15S installation instructions

Powers

Powers HydroGuard 400 Series Repair Form