Bernhard Rapid Facer User manual

1

© Bernhard and Company Limited

RAPID FACER MANUALRAPID FACER MANUAL

RAPID FACER

User Guide &

Instruction Manual

Please read this manual carefully before using the Rapid Facer.

This manual should be kept in a safe place for future reference.

RF1000 Bedknife Front Facing Device

2

RAPID FACER MANUAL

RAPID FACER

Contents

RF1000 Bedknife Front Facing Device

Welcome to the Bernhard Rapid Facer (RF1000). If cared for and operated

correctly this machine will give you years of good service.

This manual will enable you to obtain the best results from your Rapid Facer so

please read it thoroughly before using your machine.

If you have any service or operational issues please contact your distributor or

phone our technical support hotline

Technical Helpline (USA only) 1-888 474 6348

Rest of World: UK Head Oce, England (+44) 1788 811600

Email: support@bernhard.co.uk

Technical FAQs can be found on our web site: www.bernhard.co.uk

When ordering spare parts please quote the machine type and serial number.

THE MANUFACTURERS ACCEPT NO RESPONSIBILITY FOR ANY SITUATION ARISING FROM THE

FITTING AND/OR USE OF NON-ORIGINAL SPARE PARTS.

Overview 3

Safety 4

Description 5

On-site / Workshop Requirements 5

Setting Up 6

Operation 9

Maintenance 11

Repairs 11

Part Numbers and Reference Diagrams 12

Rapid Facer – ENG/1040.4/RB

Please quote this serial number on all

correspondence:

Serial #:

BERNHARD AND COMPANY LIMITED

Bilton Road • Rugby • England • CV22 7DT

Tel +44 1788 811600 • Fax +44 1788 812640

Email: [email protected]

USA Toll Free 1-888 GRIND IT (1-888 474 6348)

3

© Bernhard and Company Limited

RAPID FACER MANUAL

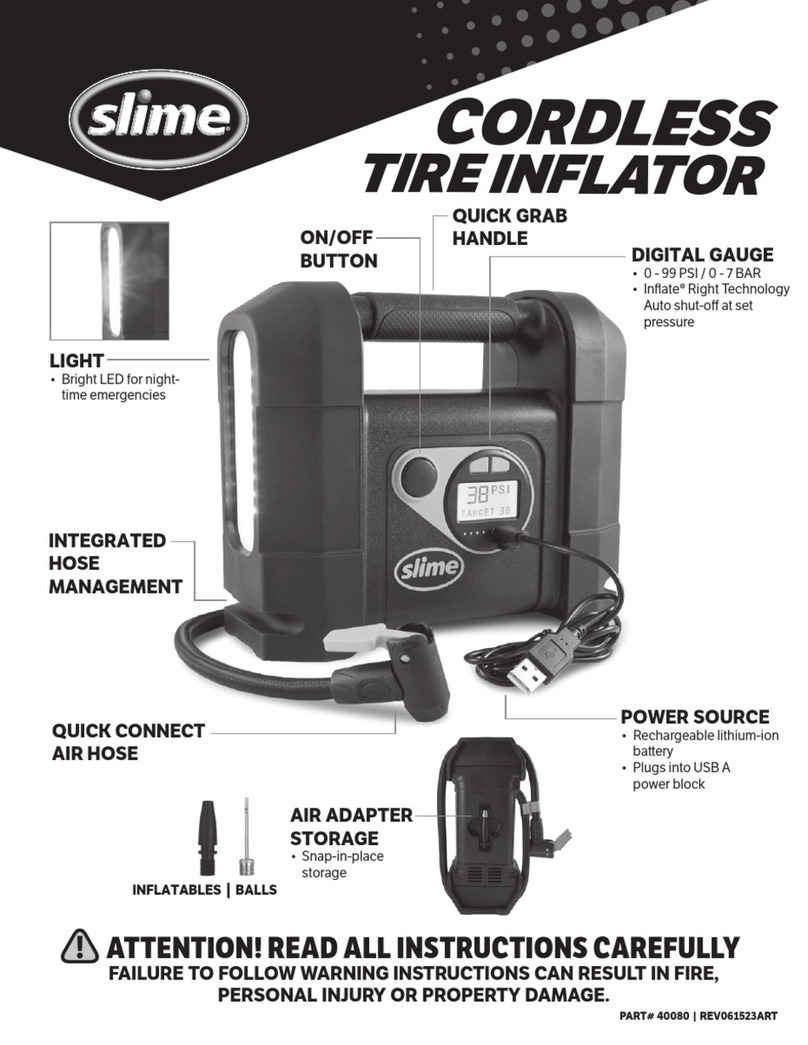

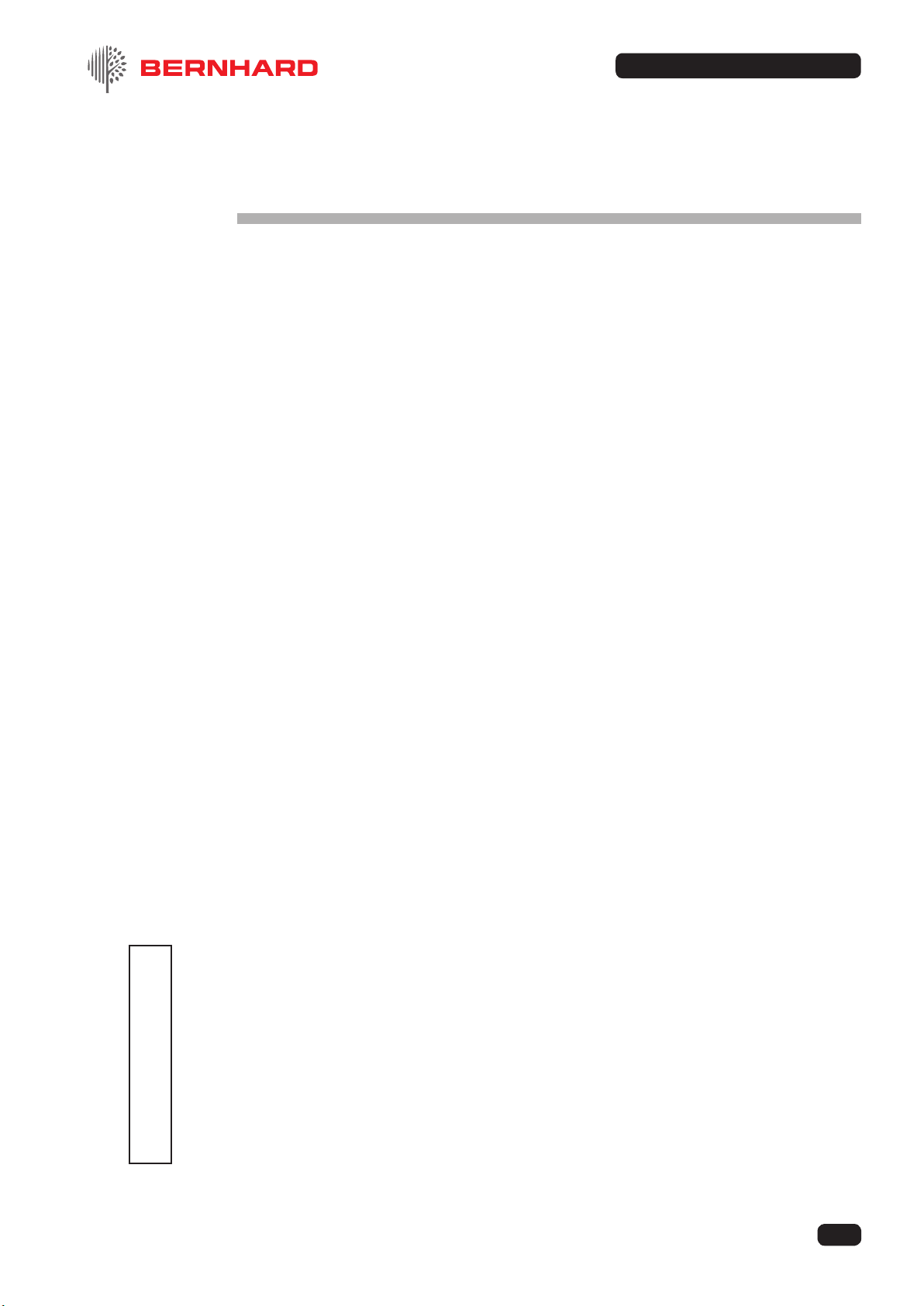

Angle grinder locking screw

Grinder trigger

Swivel elbow air-line tting

Grinder head height

adjust

Grinder head 'in-out' adjust

Magnetic clamp

Eccentric ne

height adjust Height adjust

lever

Grinding

carriage

Grinding

slide rail

Two reel guide

pins on either

side of grinding

disc

4

© Bernhard and Company Limited

RAPID FACER MANUAL

1.1 IMPORTANT

The air supply must NOT be connected when:

a) attaching the Rapid Facer RF1000 to the bedknife

b) setting up the Rapid Facer RF1000

c) removing the Rapid Facer RF1000 from the bedknife.

WARNING: THE MAGNETS ARE VERY POWERFUL

1.2 Always support the angle grinder carriage whilst carrying the Rapid Facer RF1000.

Do NOT hold the Rapid Facer RF1000 by the magnets when attaching the machine to the

bedknife.

1.3 Always wear eye protection when operating the Rapid Facer RF1000

1.4 When operating the Rapid Facer RF1000 never:

a) leave rags or tools on the machine

b) wear loose clothing that could become caught in the grinding disc or chuck.

Always keep long hair tied back.

1.5 The disc causes hot sparks. Make sure no ammable materials are close.

1.6 Never use the machine for any purpose other than that for which it is designed.

1.7 Always use the correct grinding discs.

1.8 Never t a disc while the air line is connected.

1.9 Never use the Rapid Facer RF1000 when the cutting unit is set up on a Reel Grinder.

1.10 We advise the wearing of ear defenders.

1.11 Keep your ngers clear of the reel blades when operating the Rapid Facer RF1000.

1.12 The air grinder must not be removed from and used independently of the tool holder.

1. Safety

5

© Bernhard and Company Limited

RAPID FACER MANUAL

2. Description

2.1 The Rapid Facer RF1000 consists of an air driven angle grinder attached to an accurate

slide rail. This is xed to the base of a bedknife by two powerful magnets. It is used to

grind the front face of the blade to sharpen it.

2.2 The angle grinder carriage is attached to the slide rail supported on rollers. These are

adjustable to reduce backlash to a minimum. The rollers also allow the grinding head to

traverse along the rail. The grinding head produces an accurately ground cutting edge on

the bedknife. This cutting edge will also be parallel to the rotational axis of cutting reel.

2.3 The adjustable handle (part 15) allows the grinding disc to be set for a wide choice of

clearance angles on the front face of the bedknife.

2.4 Two reel pins (part 39) are attached to the grinder carriage. These deect the reel blades

and allow the disc to sharpen the bedknife without damaging the reel blades.

2.5 As with other Bernhard reel and bedknife grinding machines this grinding action takes

place where the grass is cut. This is the key to the excellent results produced by our

equipment.

3. On-Site

/

Workshop Requirements

3.1 AIR SUPPLY

Consistent with industry ‘Best Practice’, Bernhard recommend that the air supply for ALL

air powered tool is tted with:

• An in-line air lter and water separator • An in-line lubricator

for trouble-free service life of the Rapid Facer.

If water gets into the tool and it will lay there whilst the tool is not is use, and may result in

corrosion which may cause seizure. This may invalidate your warranty.

It should be supplied to the air motor by a securely attached exible hose which allows free

movement of the grinding head along the slide rail.

3.2 AIR FLOW RATE

The air motor operates best on an airow rate of 9 cubic feet/min. (0.25 cubic metres/min).

The air motor is designed for a maximum air pressure of 6 bar (90 psi).

3.3 An isolating valve must be available to cut o the air supply to the machine. This must be

sited close to the machine.

3.4 It is useful to have a pressure regulator in the air line.

6

© Bernhard and Company Limited

RAPID FACER MANUAL

4. Setting Up

4.1 NOTE: The Rapid Facer RF1000 as shipped will need some minimal assembly before use.

4.2 PRELIMINARY CHECKS

4.2.1 Ensure that the air supply is not attached to the angle grinder motor.

4.2.2 Ensure that the eccentric pillars (parts 23 & 24) are correctly adjusted. They are set to

reduce backlash and allow free movement of the grinding head along the rail. These are

preset on new machines.

4.2.3 Ensure that the correct grade and size of grinding of disc (part 42) is tted to the angle

grinder. This is factory supplied.

4.2.4 Ensure that the grinding disc (part 42) is concentric with the disc holder (part 41). This is

factory set.

4.2.5 Ensure that the grinding disc (part 42) is securely attached and that neither the disc nor the

disc holder (part 41) are damaged.

4.2.6 Ensure that the angle grinder (part 40) is securely attached to the carriage. Check that the

disc is set between the reel pins (part 39) and is free to rotate.

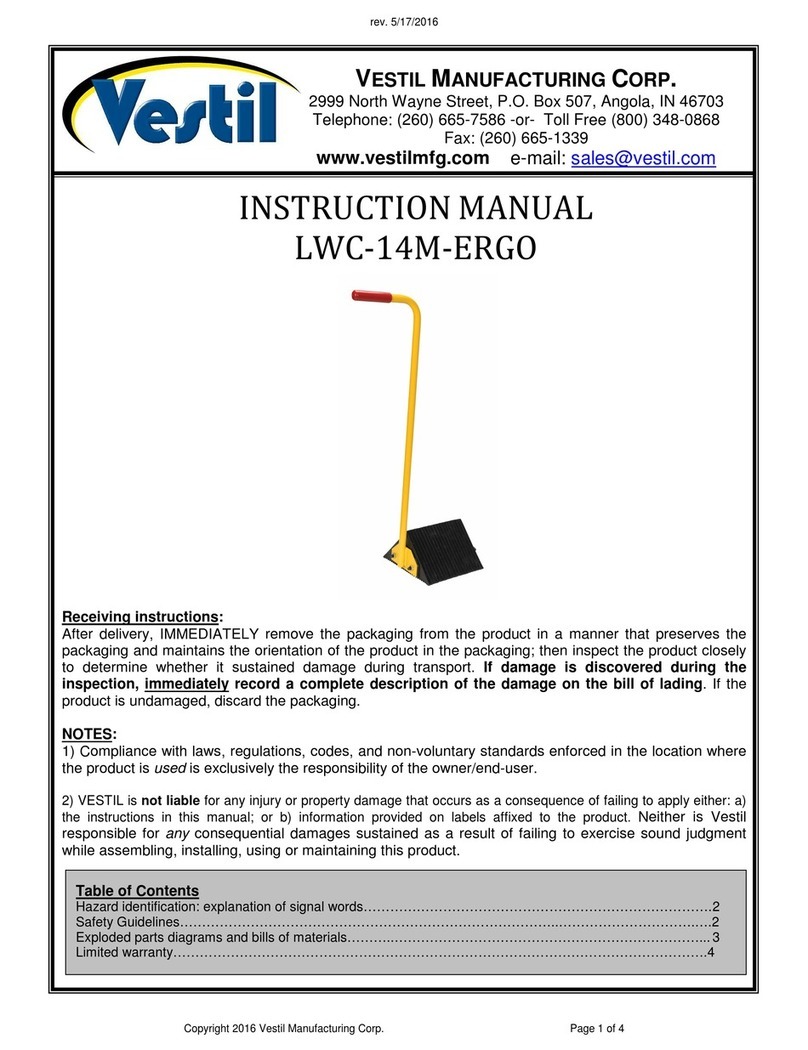

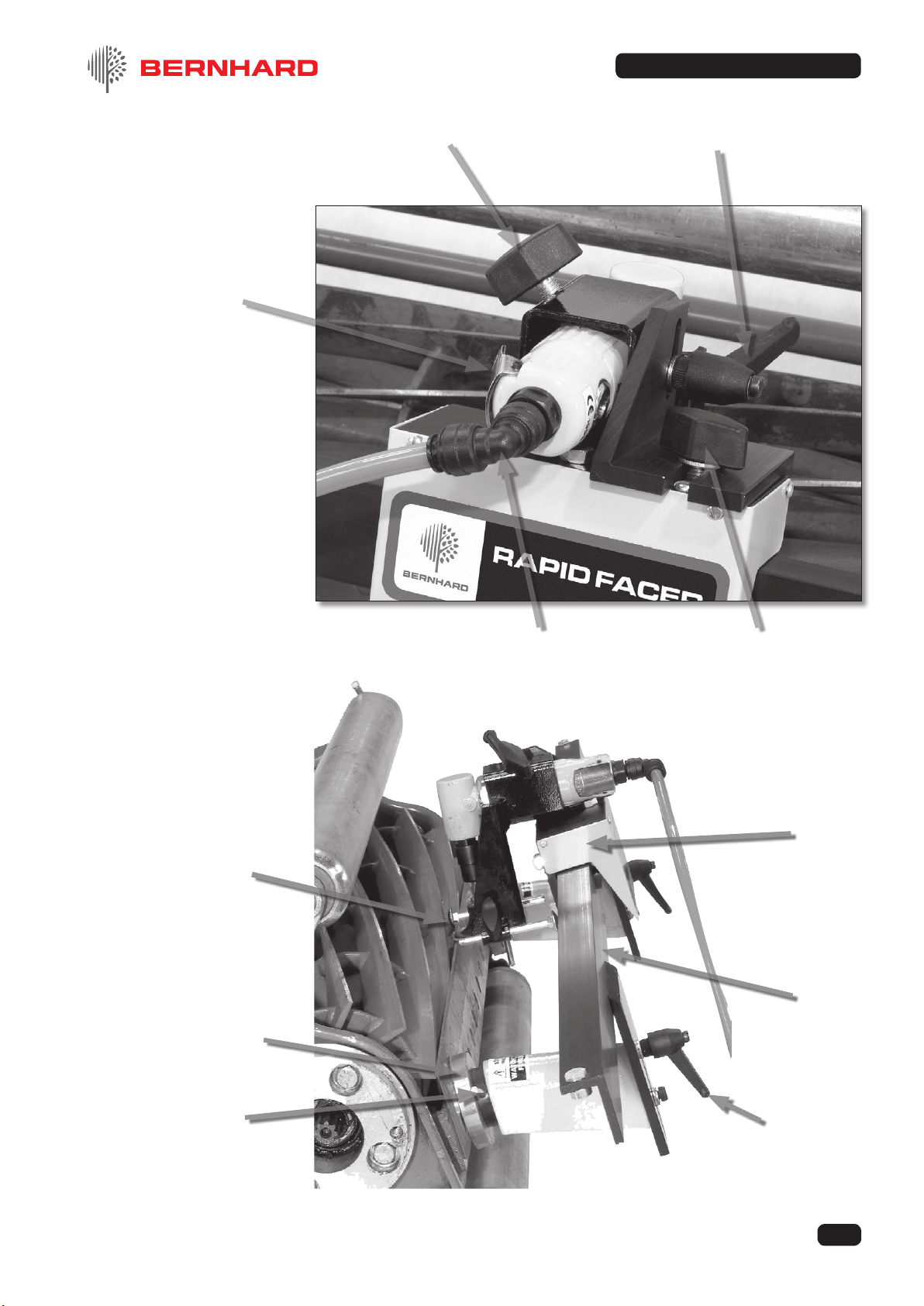

Mount Plate / Magnet assemblies

to rail, coloured dot facing coloured

dot as shown above.

Socket cap screws may be

tightened using the 3mm allen key

provided.

To complete the assembly t the

grinding head on to the slide unit.

Coloured

dots M6 C'S'K

socket

screws

Rail

Mounting plates

and Magnet support

brackets

7

© Bernhard and Company Limited

RAPID FACER MANUAL

SAFETY PRECAUTION

4.2.7 To avoid trapped ngers do NOT hold the RF1000 by the magnets.

Ensure that the two magnets (part 12) are securely attached to the slide rail (part 1).

4.2.8 Ensure that the carriage end stops are secure.

Ensure that the carriage runs smoothly back and forth along the rail.

4.2.9 Ensure that the specied air supply is available. Check that the exible hose and push in

connector are correctly assembled.

NOTE: The air supply should have an isolating valve near the Rapid Facer RF1000.

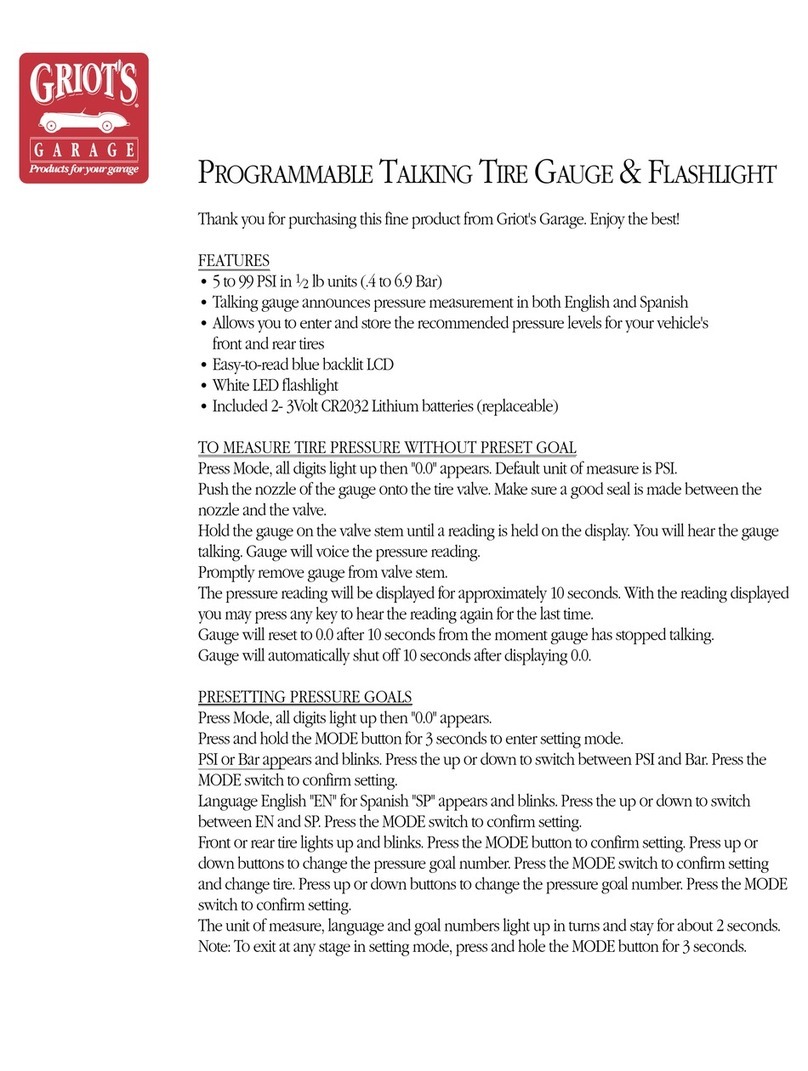

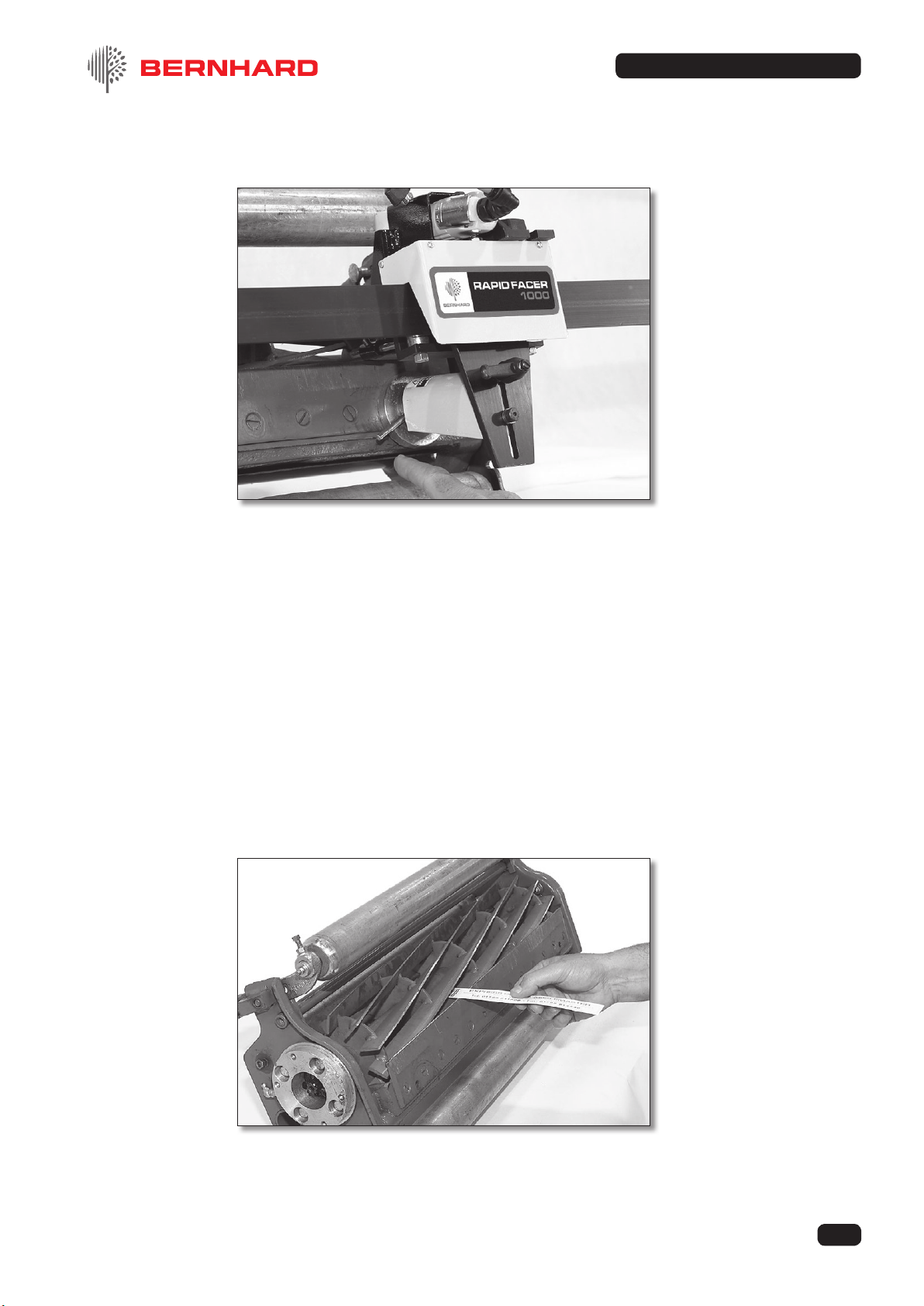

4.3 PREPARING THE RF1000 FOR WORK

SAFETY WARNING

Ensure that the power / drive to

the reel is disconnected.

To avoid pinching your ngers

do NOT hold the Rapid Facer

RF1000 by the magnets.

Carefully attach the Rapid Facer

RF1000 to the bottom of the

bedknife by the magnets. Adjust

the position of each magnet in

turn so that the disc is just clear

of the top of the cutting edge of

the bedknife at each end.

It may be necessary to slacken the locking screw (part 36) and slide the angle grinder in or

out to get the right amount of grinding disc over the bedknife. Ensure that the disc is level

with the edge of the blade and re-tighten the locking screw.

8

© Bernhard and Company Limited

RAPID FACER MANUAL

4.3.1 Two reel guide pins are attached

to the grinder carriage. These

allow the disc to sharpen the

bedknife without damaging

the reel blades. When hand

traversing the grinding head the

reel pins rotate the reel blades

clear of the grinding disc.

4.3.2 Slide the carriage to the left until the grinding disc is over the left end of the bedknife. Turn

the left adjustment spindle to lower the disc until it just lightly touches the bedknife.

Slide the carriage to the right until the disc is over the right end of the bedknife. Turn the

right hand adjustment spindle to lower the disc until it just lightly touches the bedknife.

Traverse the carriage along the rail and observe:

a) that the disc rubs lightly all along the top edge of the bedknife.

b) that the reel pins rotate the reel blade clear of the disc.

c) HYDRAULIC DRIVES

When grinding with the mower fully assembled it may be necessary to back o the reel,

if the reel pins are unable to turn the reel against the hydraulic pressure.

9

© Bernhard and Company Limited

RAPID FACER MANUAL

5.1 Wear safety goggles.

5.2.1 Attach the air line and turn on the air.

5.2.2 Position the grinding disc at the left end of the bedknife.

5.2.3 Start the air motor by depressing the throttle button. Hand traverse the carriage back and

forward along the rail to the right and the left.

Light sparking all along shows that the grinder disc is set correctly to cut parallel to the

bedknife.

Witness marks on the front face demonstrate whether the disc is set to grind the correct

clearance angle. The adjustable lever (part 15) allows the angle to be changed.

5. Operation

10

© Bernhard and Company Limited

RAPID FACER MANUAL

5.2.4 To increase the cut rotate the eccentric adjustment lever (item 10) on each magnet

assembly by a few degrees clockwise.

5.2.5 If the grinding disc is not in contact with the front face everywhere, a further movement of

the lever will be necessary. Finish o with a light cut.

5.2.6 NOTE: Regularly maintained blades will need very few cuts. Damaged blades will need

more.

5.2.7 Turn o the air and disconnect the air line.

5.2.8 Check that the ground nish on the bedknife edge is satisfactory.

5.2.9 Remove the Rapid Facer from the bedknife.

5.2.10 Rotate the reel and check that the cutting clearance is correct all along the full length of

each blade.

NOTE: Set the reel to cut paper at between .002" and .004" (.05mm-.1mm) clearance.

For best results trap one Bernhard Cutting Strip between reel and bedknife.

11

© Bernhard and Company Limited

RAPID FACER MANUAL

6. Maintenance

6.1 Cleanliness is important for correct operation and long life.

After each operation wipe all dust and abrasive materials from the slide rail and bearings.

Occasionally the feed slide face will need cleaning.

6.2 The air motor and gear box should be oiled each day of use and prior to being stored

away.

6.3 The machine relies on the disc holder rubber to maintain a steady pressure for the grinding

cut. If it is cracked or weakened it should be replaced.

7. Repairs

7.1 All components are readily available from your distributor.

In case of diculty do not hesitate to call us Toll free 1-888 GRIND IT (1-888 474 6348).

7.2 A perfectly straight slide is crucial to the successful operation of this machine. A bent or

damaged rail must be replaced.

7.3 Worn pillars and bearings are easily replaced.

7.4 The angle grinder is not prone to problems but if in diculty call our technical helpline.

12

© Bernhard and Company Limited

RAPID FACER MANUAL

8. Parts List

Ref # Name of Part Qty. Old Part # New Part #

Rail Assembly

1 Rail...........................................................................................1 RF1501 A3000

2 Front Plate ............................................................................... 2 RF1502 A4057

3 M6 x 12 Hex Hd Bolt................................................................2 RF1503 A5718

4 M6 Nut ..................................................................................... 2 RF1504 A5516

5 M6 Washer ..............................................................................2 RF1505 A5320

6 M5 x 10 Csk Bolt......................................................................4 RF1506 A5130

Support Bracket Assembly

5 M6 Washer ............................................................................10 RF1505 A5320

7 Support Brkt (casting).............................................................. 2 RF1510 A4135

8 M8 Washer ..............................................................................2 RF1511 A5321

9 Belleville Spring ....................................................................... 2 RF1506 A5307

10 Eccentric Disc + Lever.............................................................2 RF1515 A9033

11 M6 x 10 x 5 Shoulder Screw.................................................... 2 A5144

12 Magnet.....................................................................................2 RF1512 A6754

13 M6 x 40 Cap Screw .................................................................2 RF1513 A5154

14 M6 Nylock Nut ......................................................................... 4 RF1514 A5517

15 Adjustable Kip Lever ...............................................................2 RF1519 A6124

Saddle Assembly

4 M6 Nut ..................................................................................... 6 RF1504 A5516

5 M6 Washer ..............................................................................7 RF1505 A5320

16 No 4 Self Tap Screw ................................................................4 RF1518 A5418

17 Saddle...................................................................................... 1 RF1530 A4118

18 Bearing ....................................................................................9 RF1536 A7708

19 Horiz. Pillar Spacer (short).......................................................1 RF1601 A9022

20 M6 x 8 C/sunk Screw............................................................... 1 RF1571 A5159

21 Horiz. Pillar Spacer (long)........................................................ 2 RF1600 A3011

22 Vertical Pillar ............................................................................2 RF1534 A9021

23 Horizontal Eccentric.................................................................1 RF1533 A9020

24 Vertical Eccentric .....................................................................1 RF1535 A9124

25 Hex. Head Bolt M6 x 40........................................................... 2 RF1573 A5722

26 Hex. Head Bolt M6 x 35........................................................... 2 RF1572 A5721

27 Hex. Head Bolt M6 x 12........................................................... 1 RF1503 A5718

28 Horizontal Pillar........................................................................2 RF1532 A9123

29 Saddle Guard (Name Plate) .................................................... 1 RF1537 A6610

30 (only on Rapid Relief unit)

Grinder Head Assembly

5 M6 Washer ..............................................................................1 RF1505 A5320

8 M8 Washer ..............................................................................1 RF1511 A5321

35 Wing Knob (M6).......................................................................2 RF1552 A6128

36 Wing Knob (M8) ......................................................................2 RF1553 A6132

37 Angle Bracket .......................................................................... 1 RF1554 A4019

38 Tool Support............................................................................. 1 RF1550 A4140

39 Reel Pin ................................................................................... 2 RF1551 A3036

40 Angle Grinder...........................................................................1 RF1560 A6749

41 Disc Holder .............................................................................. 1 RF1561 A3021

42 60 grit Disc Pack....................................................................25 RF1010 A6503

35 grit Disc Pack.................................................................... 25 RF1011 A6502

43 Grip Washer............................................................................. 1 RF1556 A5308

47 1/4 BSP x 6mm Elbow............................................................. 1 RF1566 A6708

48 1/4 BSP x 6mm Stud ...............................................................1 RF1567 A6709

49 6mm Poly-Nylon Hose............................................................. 1 RF1568 A6703

13

© Bernhard and Company Limited

RAPID FACER MANUAL

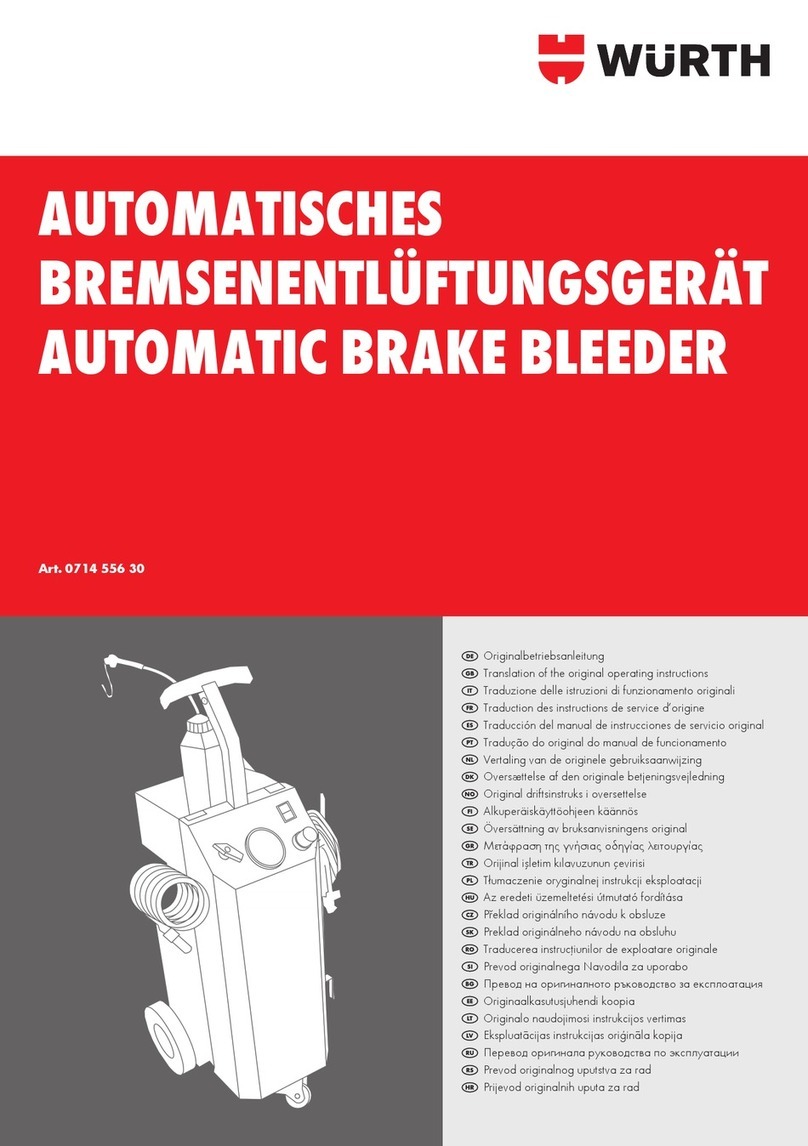

Reference Diagram • Rapid Facer Grinder Head Assembly

Grinder Head Assembly

Ref # Name of Part Qty. Old Part # New Part

5 M6 Washer 1 RF1505 A5320

8 M8 Washer 1 RF1511 A5321

35 Wing Knob (M6) 2 RF1552 A6128

36 Wing Knob (M8) 2 RF1553 A6132

37 Angle Bracket 1 RF1554 A4019

38 Tool Support 1 RF1550 A4140

39 Reel Pin 2 RF1551 A3036

40 Angle Grinder 1 RF1560 A6749

41 Disc Holder 1 RF1561 A3021

42 60 grit Disc Pack 25 RF1010 A6503

35 grit Disc Pack 25 RF1011 A6502

43 Grip Washer 1 RF1556 A5308

47 1/4 BSP x 6mm Elbow 1 RF1566 A6708

48 1/4 BSP x 6mm Stud 1 RF1567 A6709

49 6mm Poly-Nylon Hose 1 RF1568 A6703

14

© Bernhard and Company Limited

RAPID FACER MANUAL

Reference Diagram • Rapid Facer Assmebly

BERNHARD AND COMPANY LIMITED

Bilton Road • Rugby • England • CV22 7DT

Tel +44 1788 811600 • Fax +44 1788 812640

Email: [email protected]

USA Toll Free 1-888 GRIND IT (1-888 474 6348)

If you have any service or operational issues please contact your distributor

or phone our technical support hotline

Technical Helpline (USA only) 1-888 474 6348

Rest of World: UK Head Oce, England (+44) 1788 811600

Email: support@bernhard.co.uk

Technical FAQs can be found on our web site: www.bernhard.co.uk

When ordering spare parts please quote the machine type and serial number.

THE MANUFACTURERS ACCEPT NO RESPONSIBILITY FOR ANY SITUATION ARISING FROM

THE FITTING AND/OR USE OF NON-ORIGINAL SPARE PARTS.

This manual suits for next models

1

Table of contents