® Copyright, Lube1, 2019, all rights reserved. / Misprints and technical changes reserved / Date: 2019-04

2

Content

General information.....................................................................................................................................3

Description of the machine..........................................................................................................................4

Description of the control panel...................................................................................................................4

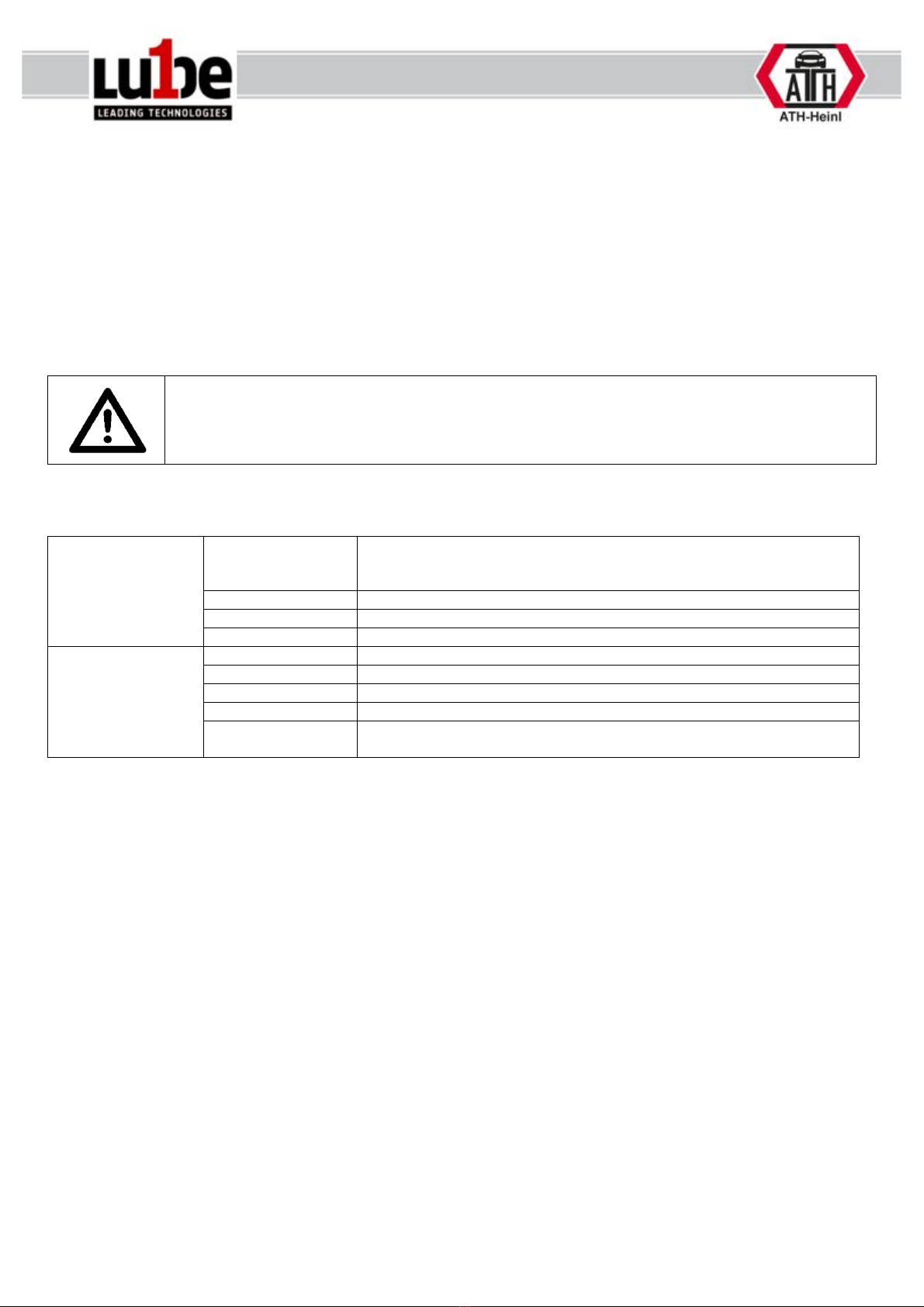

Technical Data ............................................................................................................................................5

Dimension drawing......................................................................................................................................5

INSTALLATION...............................................................................................................................................6

Transport & Storage Conditions..................................................................................................................6

Location.......................................................................................................................................................7

OPERATION OF THE MACHINE ...................................................................................................................8

Manual.........................................................................................................................................................8

Basic informations.......................................................................................................................................9

General information about automatic oil change.......................................................................................10

EXECUTION of an automatic transmission oil change .................................................................................11

Preparation and implementation ...............................................................................................................11

Change oil types, change oil in device......................................................................................................11

TIPPS and Lube1 Recommendations for older vehicles / transmissions......................................................12

1st tip Vehicles with high mileage .............................................................................................................12

2nd tip Gear unit with heavy wear / dirt.....................................................................................................12

PROCEDURE Filter change on the machine................................................................................................12

CONNECTION scheme machine to automatic transmission ........................................................................13

Flush before oil change.............................................................................................................................13

Correct filling level (drain oil).....................................................................................................................16

Correct filling level (add oil) after gearbox filter change ............................................................................17

Completion of the oil change.....................................................................................................................19

Emptying (recommendation after each service)........................................................................................19

System settings / Calibration.....................................................................................................................20

MAINTENANCE ............................................................................................................................................23

Safety regulations for oil............................................................................................................................23

Care instructions .......................................................................................................................................24

Troubleshooting.........................................................................................................................................24

Disposal.....................................................................................................................................................24

DECLARATION OF CONFORMITY / KONFORMITÄTSERKLÄRUNG .......................................................26

ORDER LIST.................................................................................................................................................27

Machine Parts ...........................................................................................................................................29

Standard-Adapter......................................................................................................................................29

Special-Adapter.........................................................................................................................................30

Lube1 - Oils / Automatic-Gear Boxes........................................................................................................31

Lube1 – Oils / Power Steering...................................................................................................................31

Lube1 - Oils / Engines...............................................................................................................................31

Lube1 - Oil-Analysis ..................................................................................................................................32

Lube1 – Special Cleaner...........................................................................................................................32

Lube1 - Accessories / Various...................................................................................................................32

Lubegard - Products/Additives ..................................................................................................................33

ANNEX..........................................................................................................................................................34

Circuit diagram ..........................................................................................................................................34

Electric-Plan ..............................................................................................................................................35

NOTES..........................................................................................................................................................38