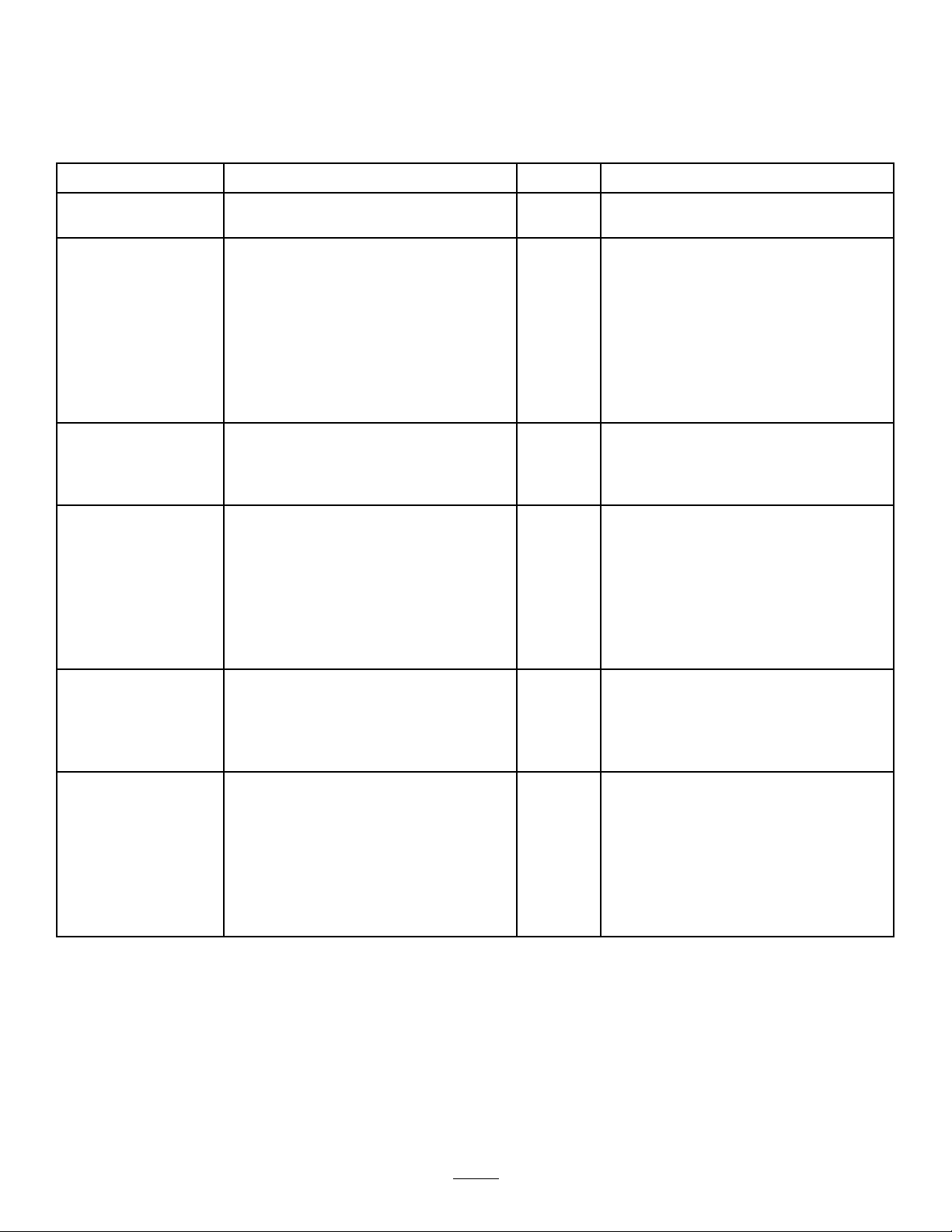

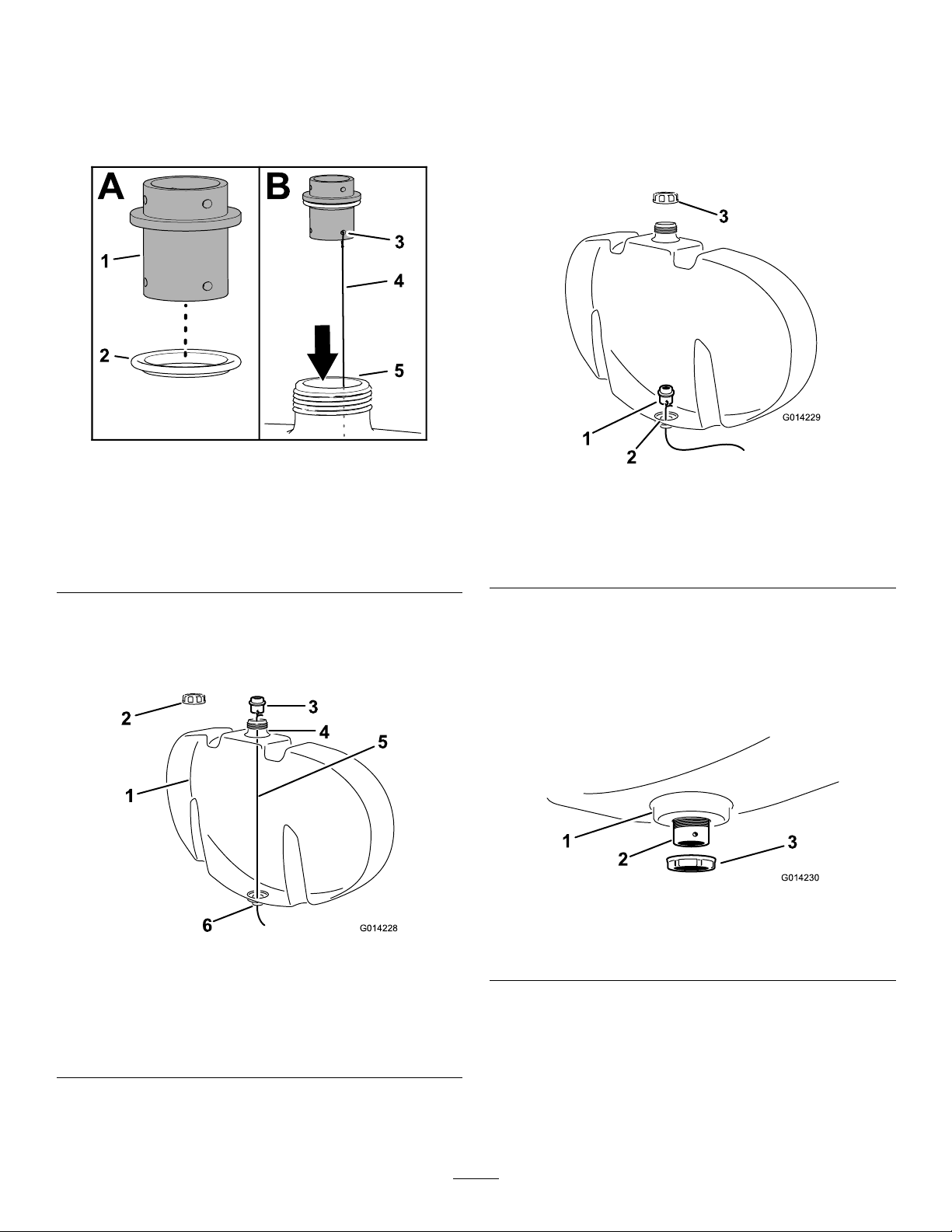

ProcedureDescriptionQty.Use

Delaytimer1

Locknut(#10–24)2

Fuse(40A)1

Relay1

Powerrelay1

Flange-headbolt(#10-24x1/2inch)2

3-positionswitch(withindicator

light—2015andbeforeturfsprayers)1

7

3-positionswitch(withoutindicator

light—2016andafterturfsprayers)1

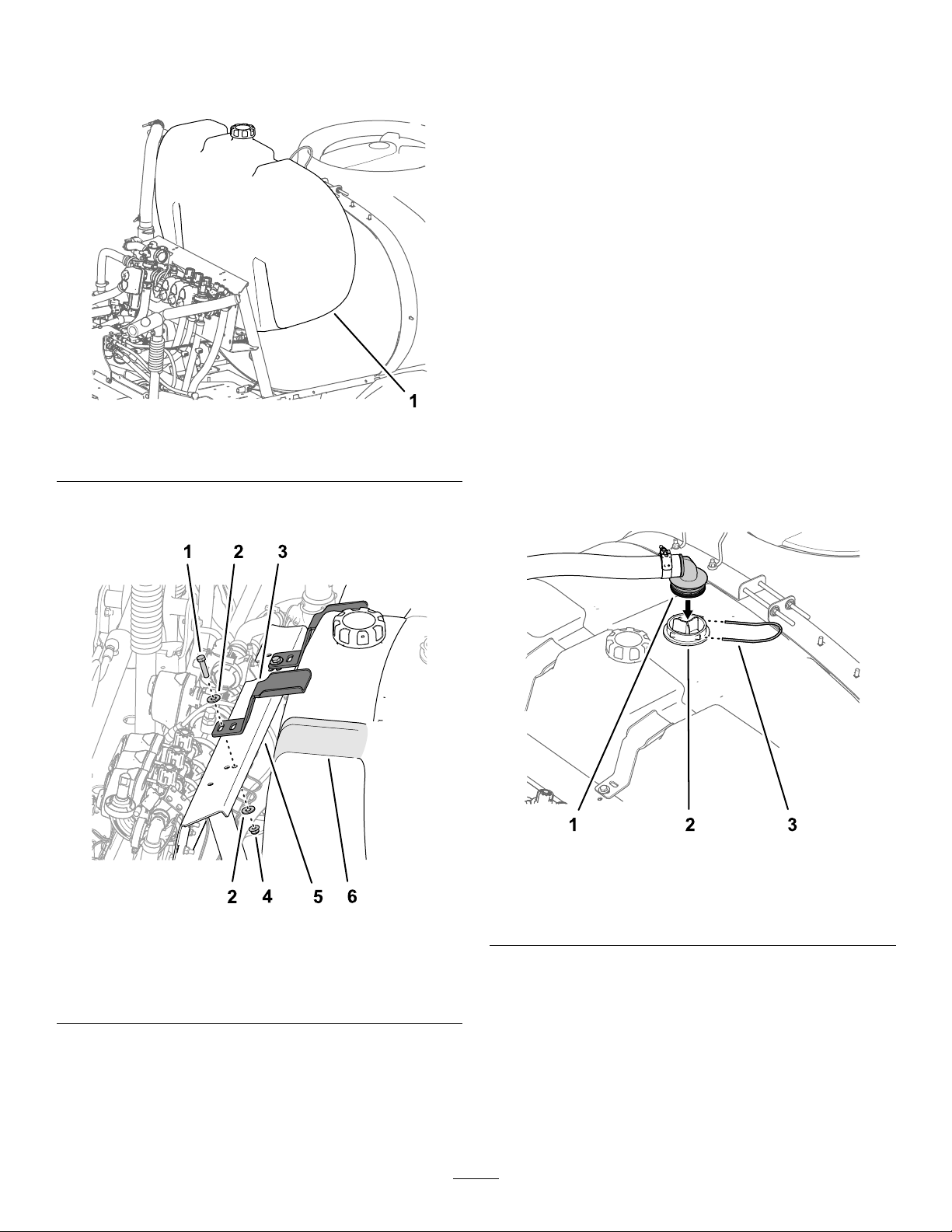

Installthedelaytimeranddashswitch.

8Nopartsrequired–Finishtherinsetankkitinstallation.

1

PreparingtheMachine

NoPartsRequired

PreparingtheSprayerSystem

CAUTION

Chemicalsarehazardousandcancause

personalinjury.

•Readthedirectionsonthechemicallabels

beforehandlingthechemicalsandfollow

allmanufacturerrecommendationsand

precautions.

•Keepchemicalsawayfromyourskin.

Shouldcontactoccur,washtheaffected

areathoroughlywithsoapandcleanwater.

•Weargogglesandanyotherprotective

equipmentrecommendedbythechemical

manufacturer.

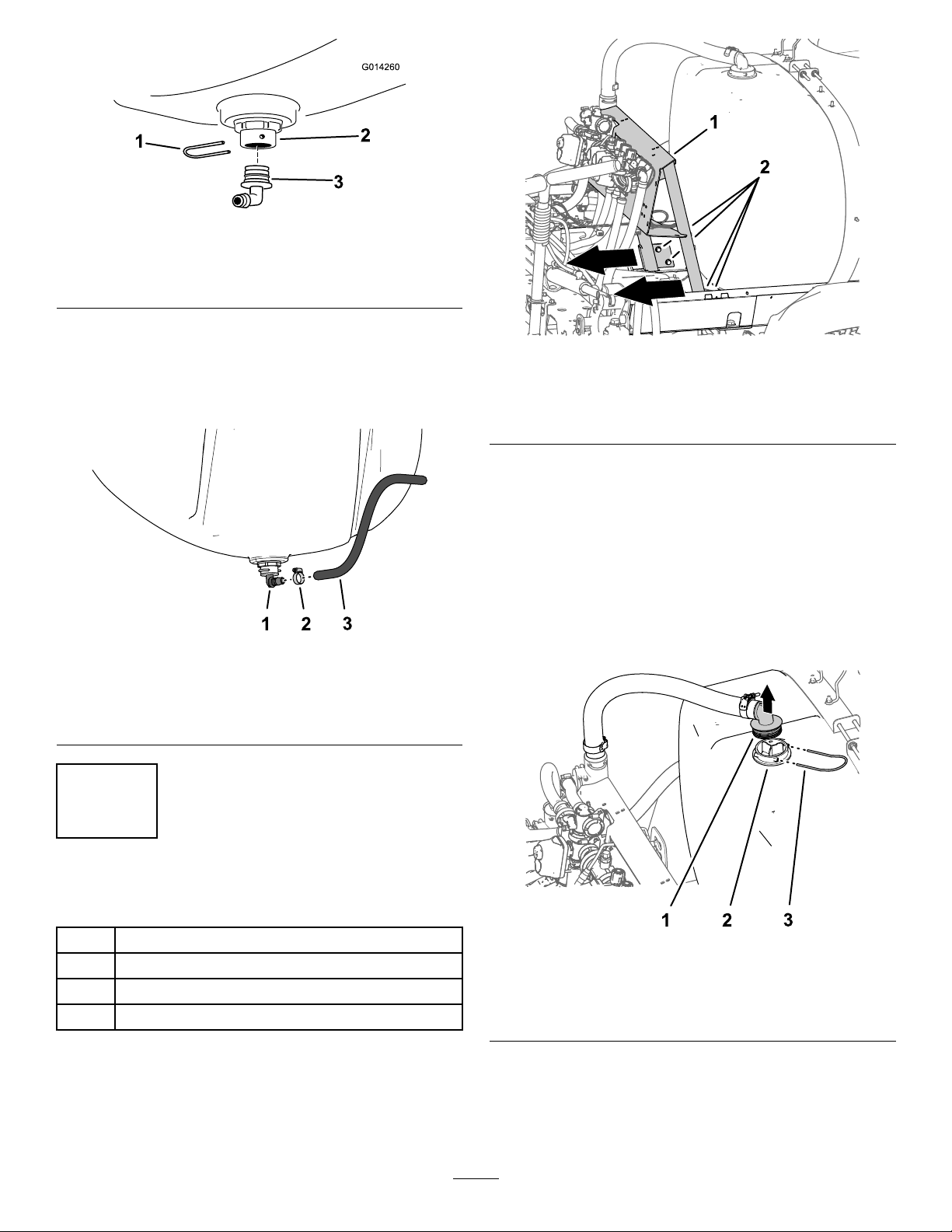

1.Movethemachinetoalevelsurface,fullypress

inthebrakepedal,settheparkingbrake,turnoff

theengine,andremovethekey.

2.Cleanthesprayer;refertoCleaningtheSprayer

intheOperator’sManualforthemachine.

Note:Takecautionwhiledisconnectingany

hosesduringtheinstallationofthiskitandhave

acatchbucketreadyforanysolutionsremaining

inthehose.

DisconnectingtheBattery

WARNING

Electricalsparkscancausethebatterygasses

toexplode,resultinginpersonalinjury.

Incorrectbatterycableroutingcoulddamage

thesprayerandcables,causingsparks.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative

(black)cable.

Batteryterminalsormetaltoolscouldshort

againstmetalsprayercomponents,causing

sparks.

•Whenremovingorinstallingthebattery,

donotallowthebatteryterminalstotouch

anymetalpartsofthesprayer.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsof

thesprayer.

•Alwayskeepthebatterystrapinplaceto

protectandsecurethebattery.

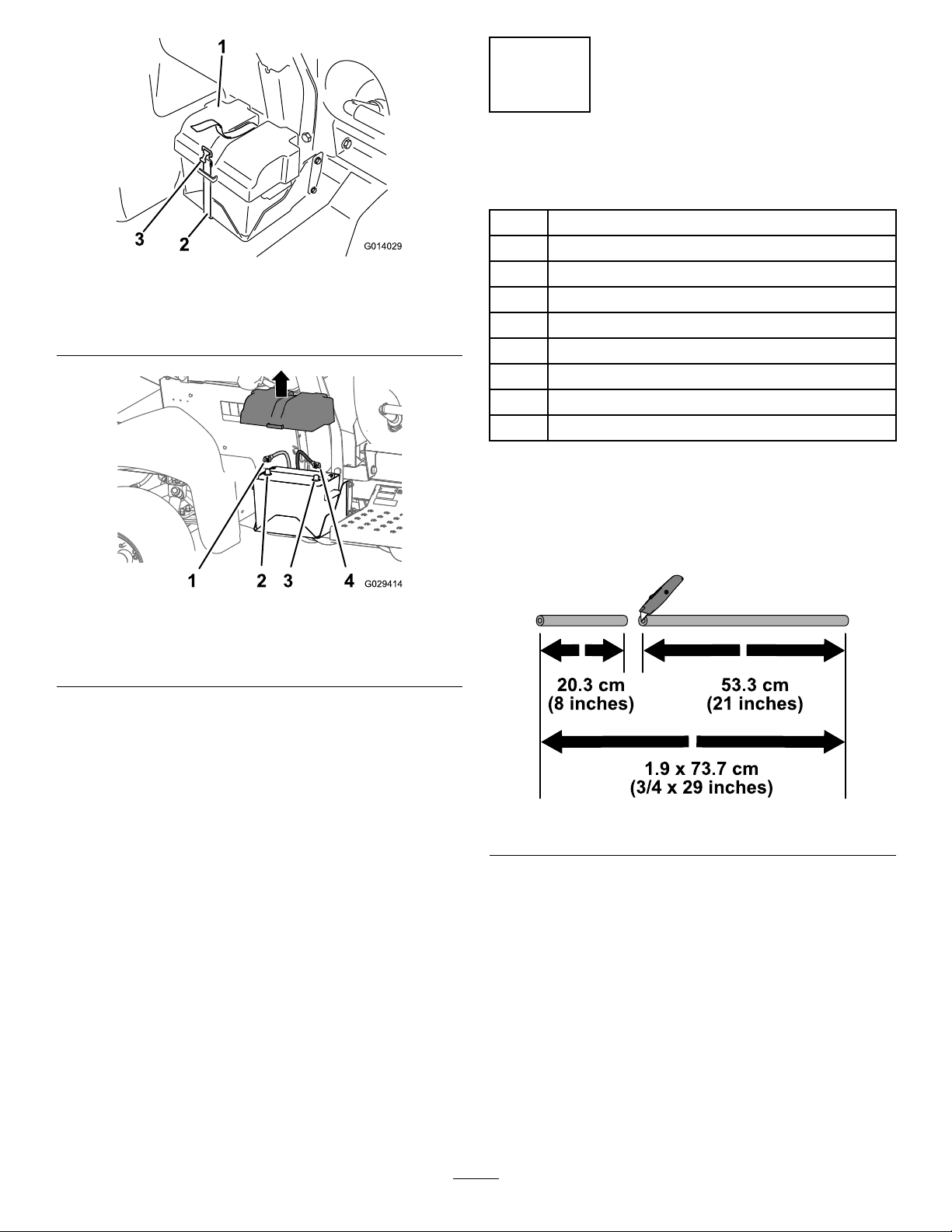

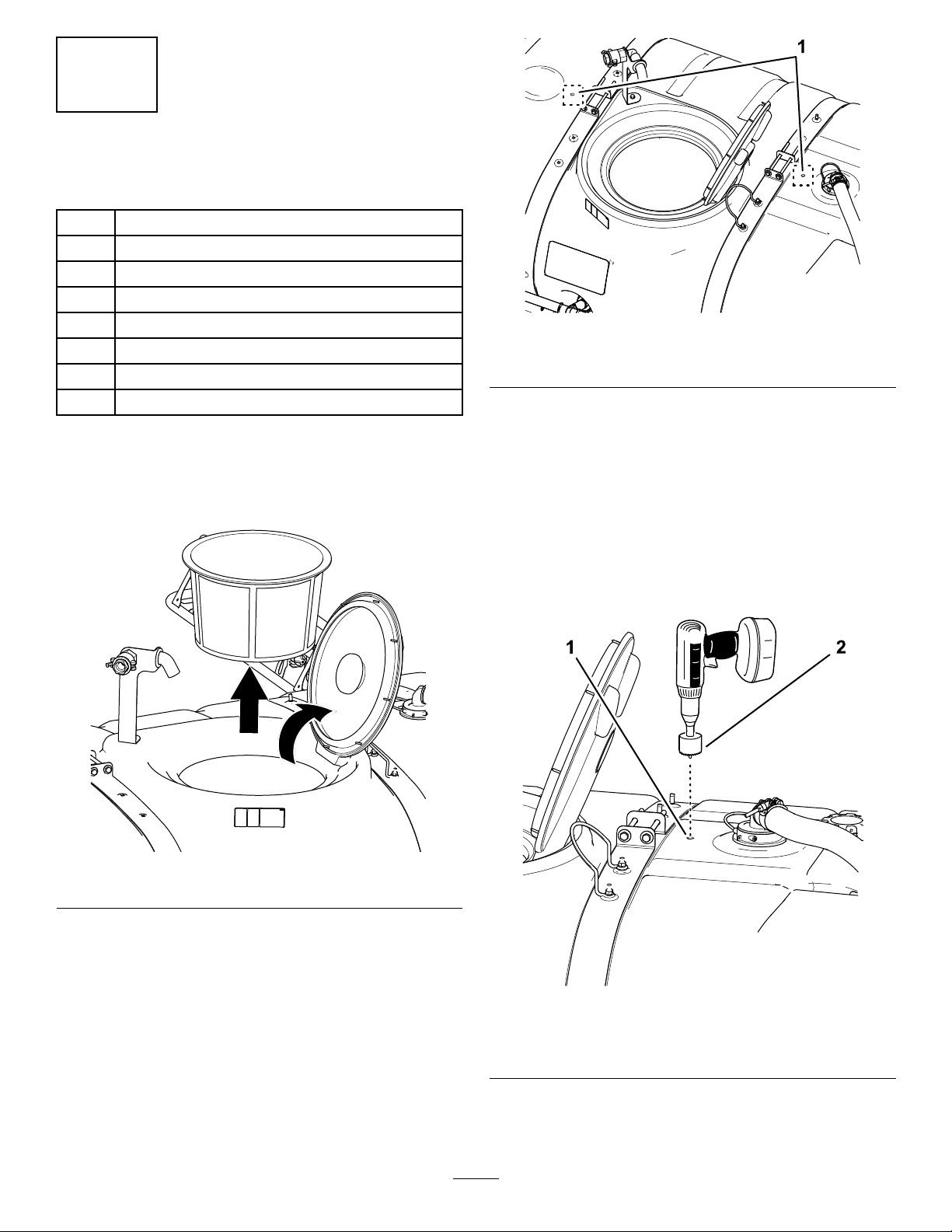

1.Removethebatterycoveranddisconnectthe

negative(black—ground)cablefromthebattery

post(Figure2andFigure3).

4