4

PreparingtheCuttingUnit

Partsneededforthisprocedure:

1Extendedsplinedinsert(right-handthreads)

1Extendedsplinedinsert(left-handthreads)

2Flangelocknut(3/8inch)—Model133-0151only

Procedure

Note:Youmaydiscardallremovedpartsunless

otherwisestated.

1.Removeallcuttingunitsfromthetractionunit;

refertoyourOperator’sManual.

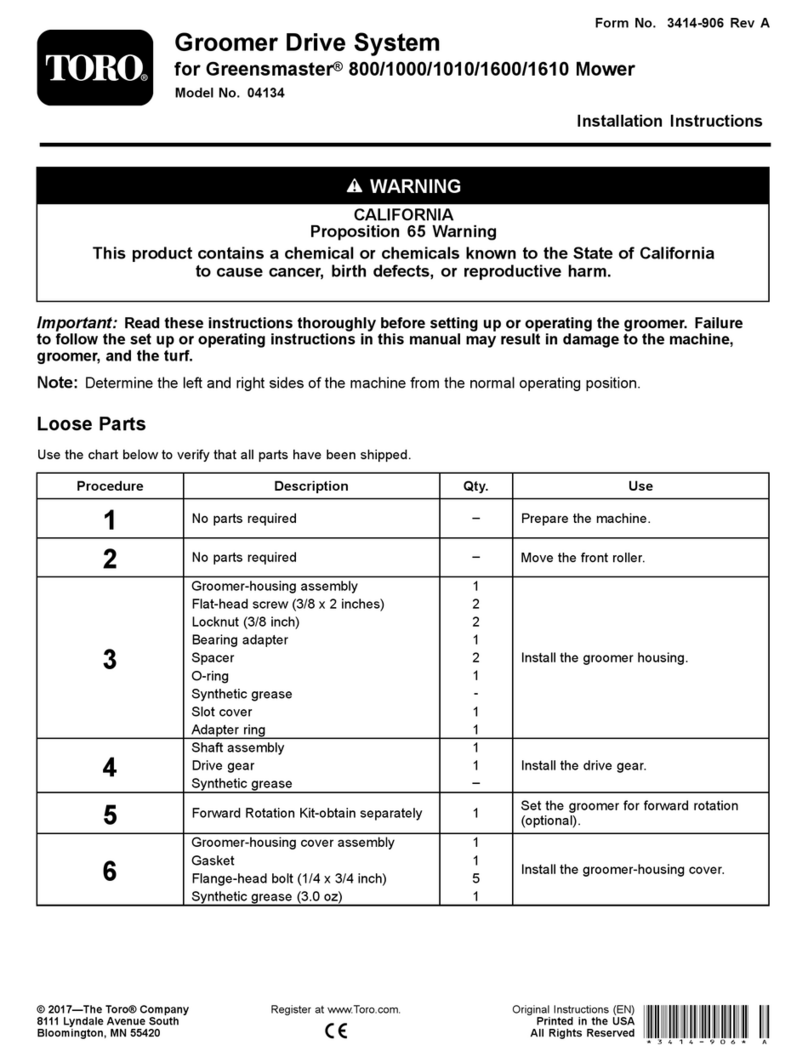

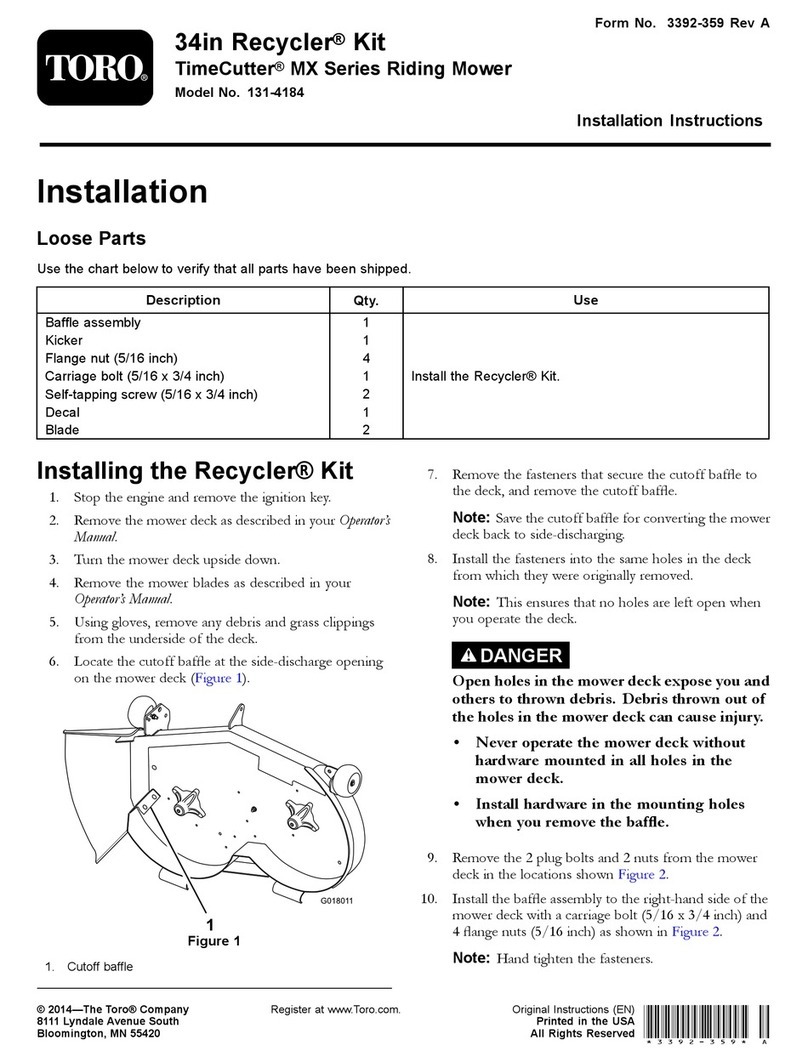

2.Removethecarriageboltsandlocknuts

securingtheheight-of-cut(HOC)bracketstothe

cutting-unitsideplates(Figure2).

Note:Savethecarriageboltstoinstallthenew

height-of-cutbrackets.

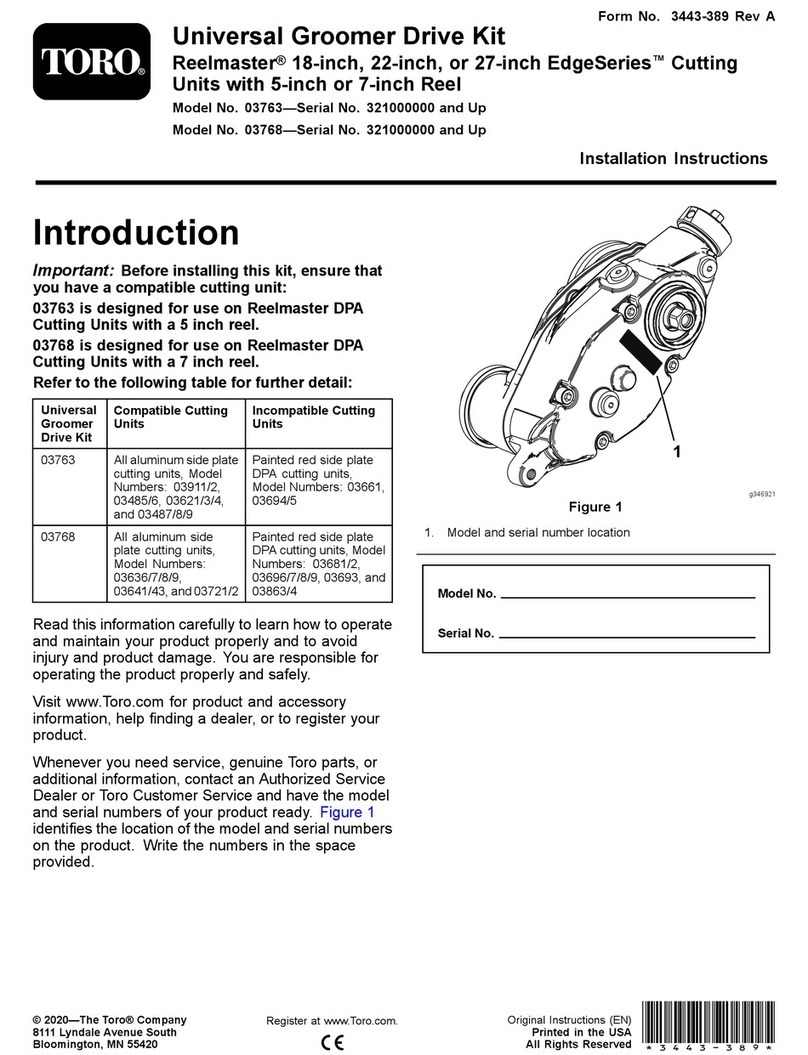

g035987

Figure2

1.Height-of-cutbracket4.Screw

2.Carriagebolt5.Frontroller

3.Locknut

3.Loosenthescrewssecuringtheheight-of-cut

bracketstothefront-rollershaft(Figure2).

4.Removetheexistingheight-of-cutbracketsand

thefrontrollerfromthecutting-unitsideplates

(Figure2).

Note:Savethefrontrollerforlaterinstallation.

5.Restrainthereelforremoval;refertoRestraining

theReelforRemovingThreadedInserts(page

18).

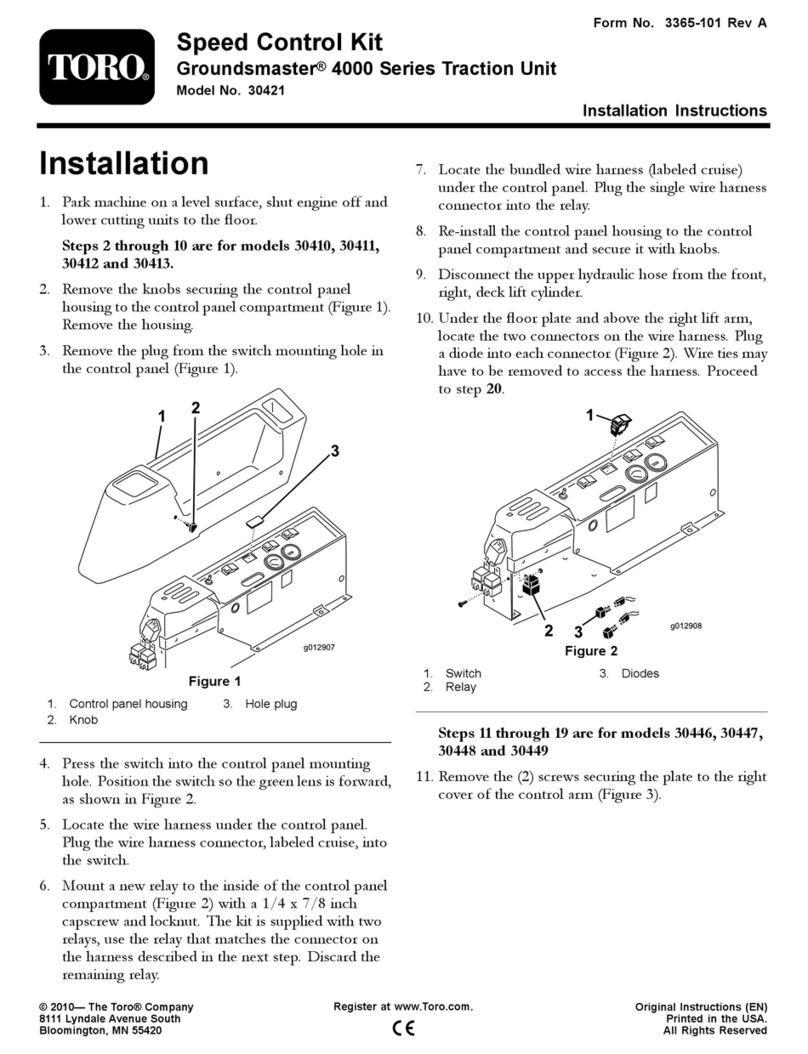

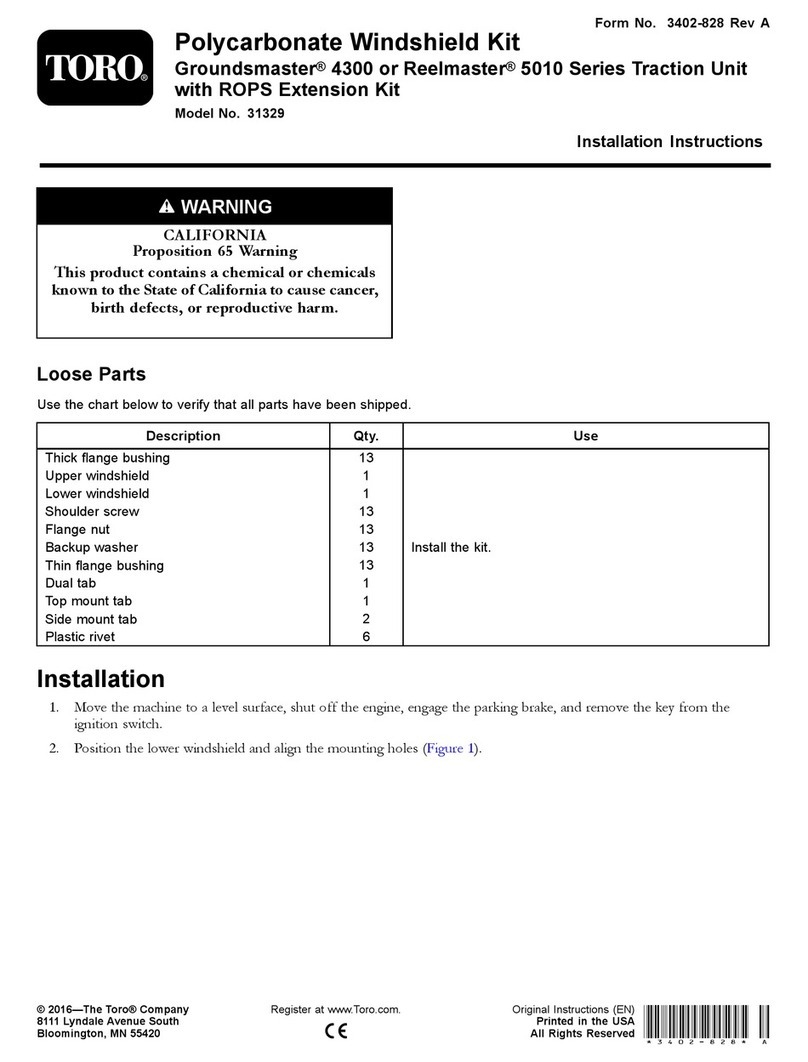

6.Removetheexistingsplinedinsertfromeach

endofthereelshaftusingthereeldriveshaft

tool(PartNo.TOR4112forthe5-inchreeland

PartNo.TOR4074forthe7-inchreel).Refer

toFigure3.

Important:Thesplinedinsertontheleft

sideofthecuttingunithasleft-handthreads.

Thesplinedinsertontherightsideofthe

cuttingunithasright-handthreads.

Important:Cleanthethreadsintheendof

thereelshaftofanydebrisorgreasebefore

installingthekitsplinedinsertandgroomer

box.

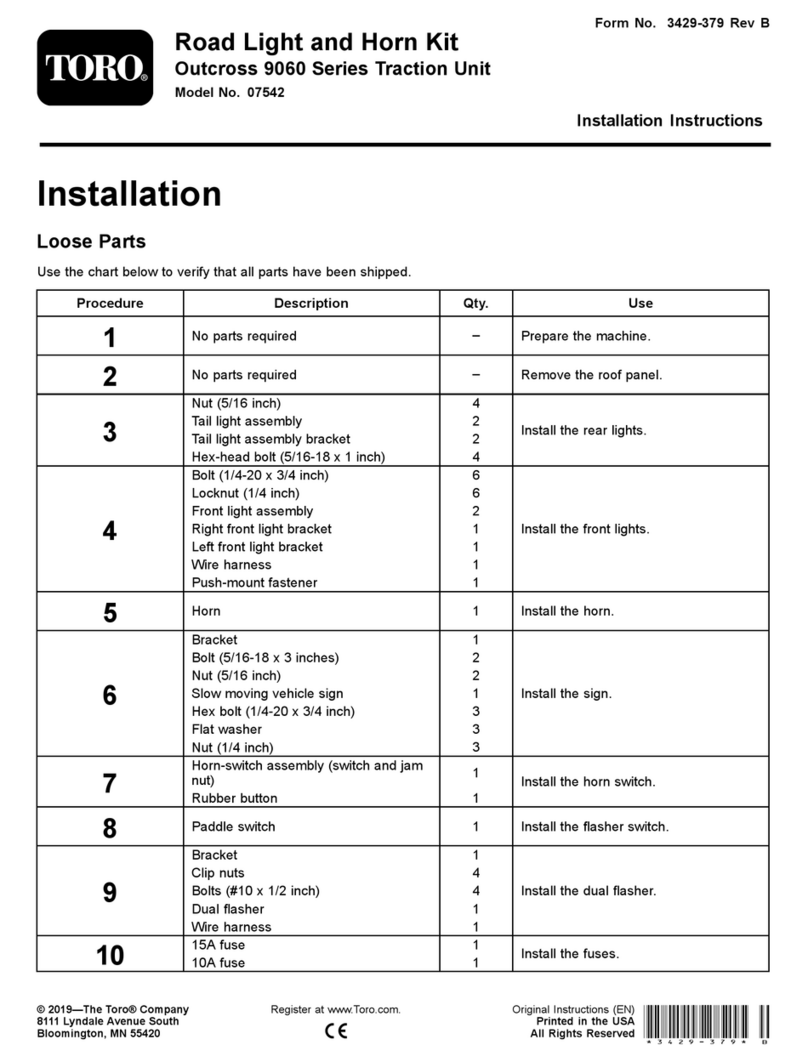

g221766

Figure3

Rightsideofcuttingunitshown

1.Extendedsplinedinsert(Torqueto115to128N∙m(85to

95ft-lb))

2.Applymedium-strengthremovablelockingcompoundto

thethreads.

7.Restrainthereelforinstallation;referto

RestrainingtheReelforInstallingThreaded

Inserts(page19).

8.Forthereelmotorsideofthecuttingunit

only:Applymedium-strengththread-locking

compound(suchasBlueLoctite®243)tothe

threadsofthenewlongersplinedinsert,and

secureittothereelshaft.T orquetheinsertto

115to128N∙m(85to95ft-lb).

Important:Allowthethread-locking

compoundtocurefor15minutesbefore

continuingtheprocedure.

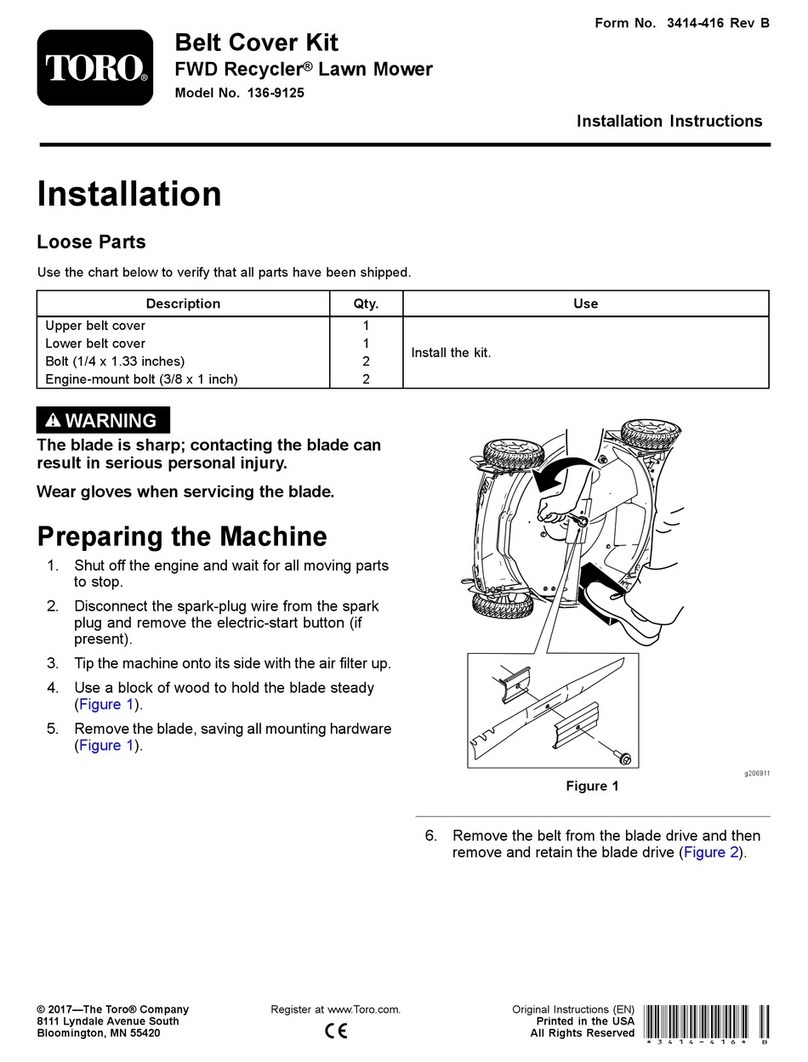

9.For7-inchcuttingunitsorifasupportrodis

installed,removethesupportrodandipthe

boltsaroundasfollows:

A.Removethe2ange-headboltssecuring

thesupportrod,andremovethesupport

rod(Figure4).

3