Toro Pro Sneak 360 User manual

Other Toro Lawn Mower Accessories manuals

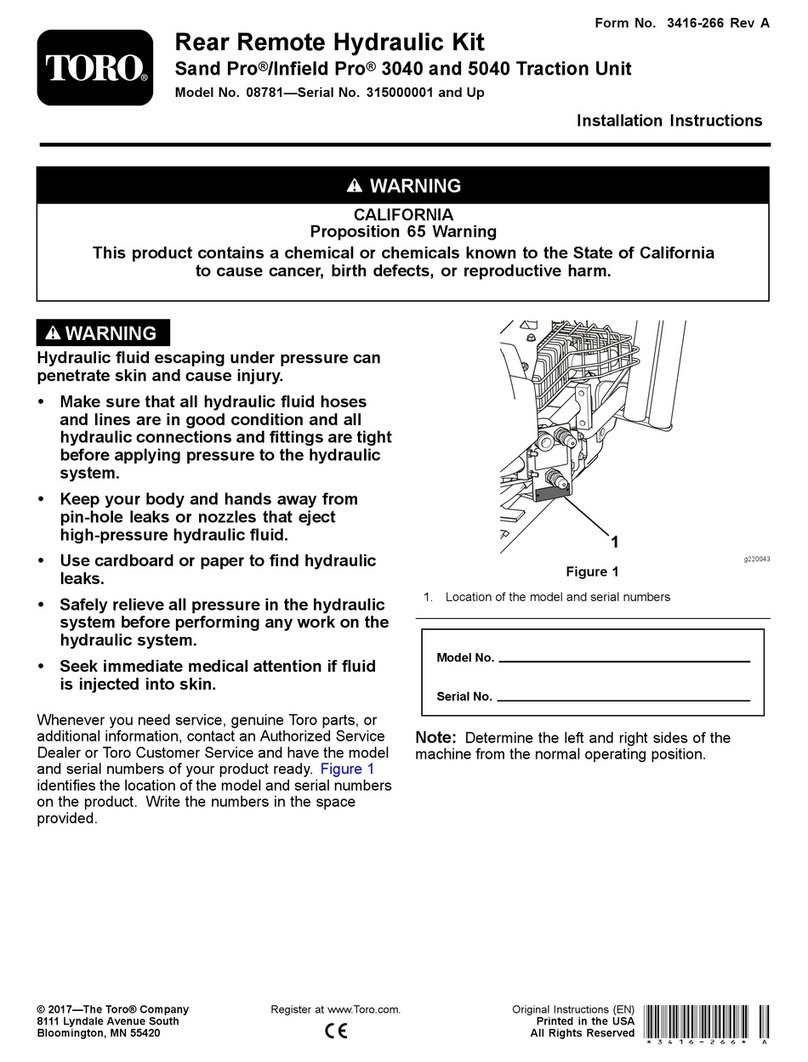

Toro

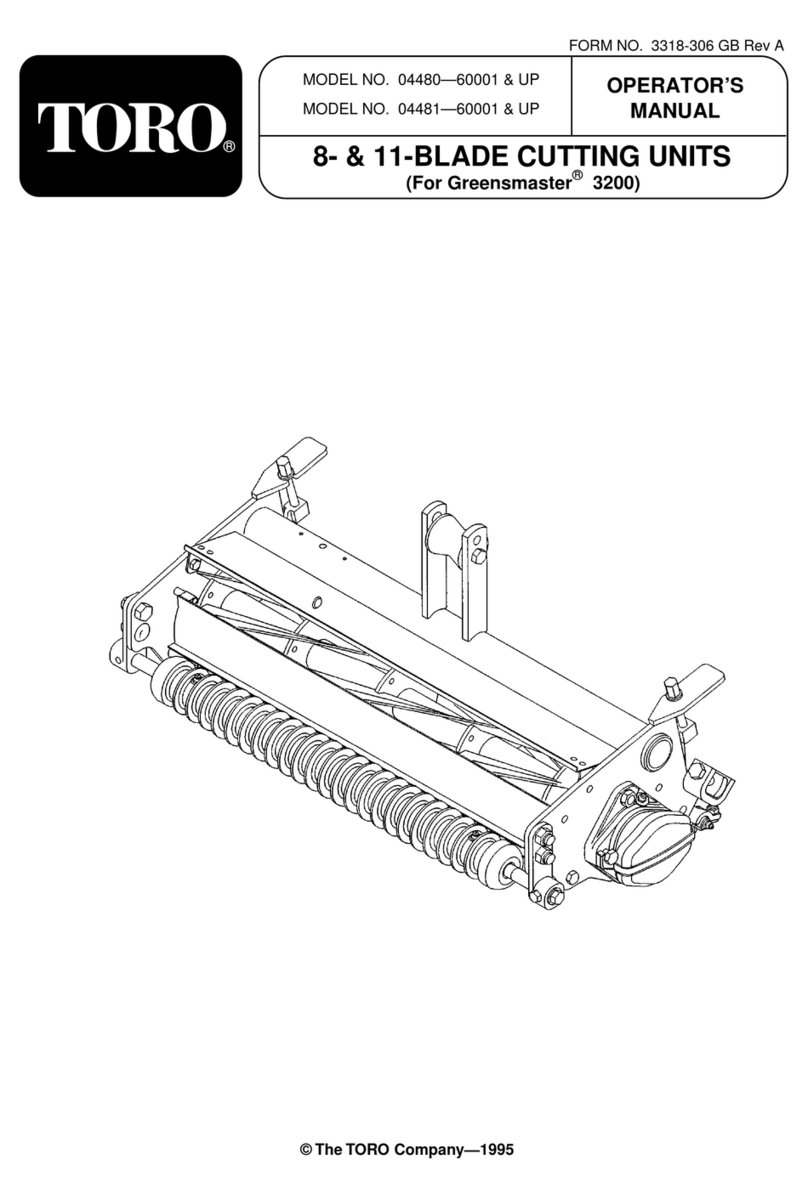

Toro 04480 User manual

Toro

Toro Groundsmaster 4500-D User manual

Toro

Toro 136-9045 User manual

Toro

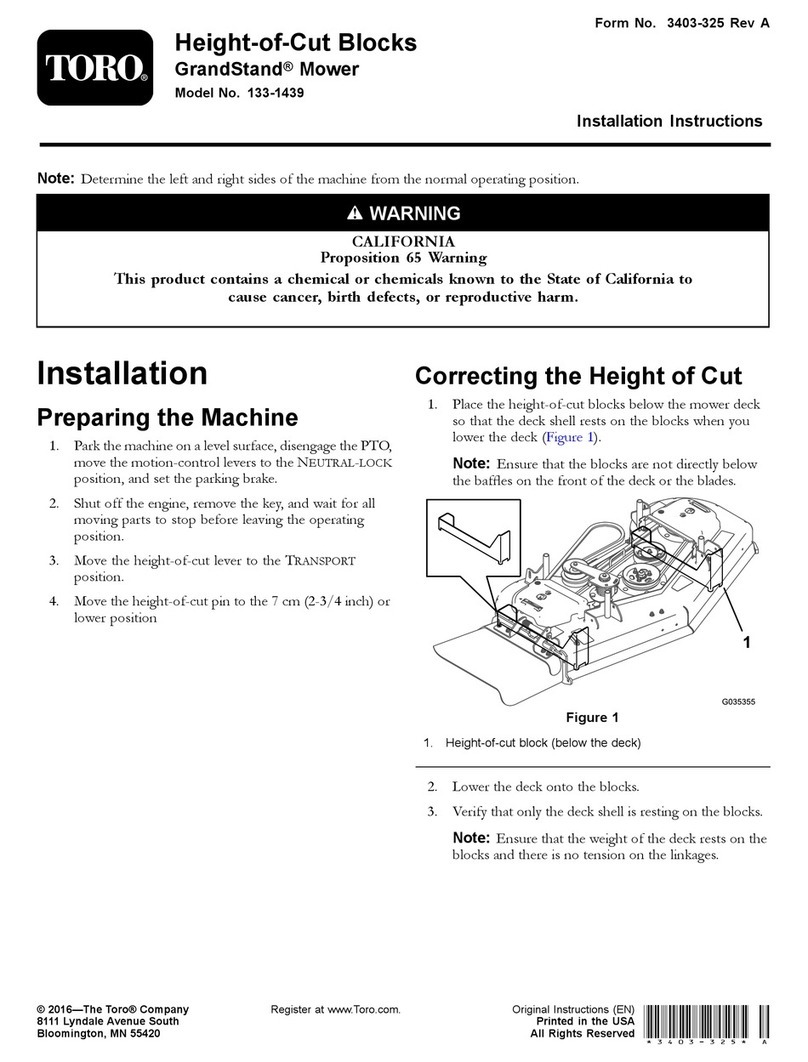

Toro GrandStand 133-1439 User manual

Toro

Toro 30104 User manual

Toro

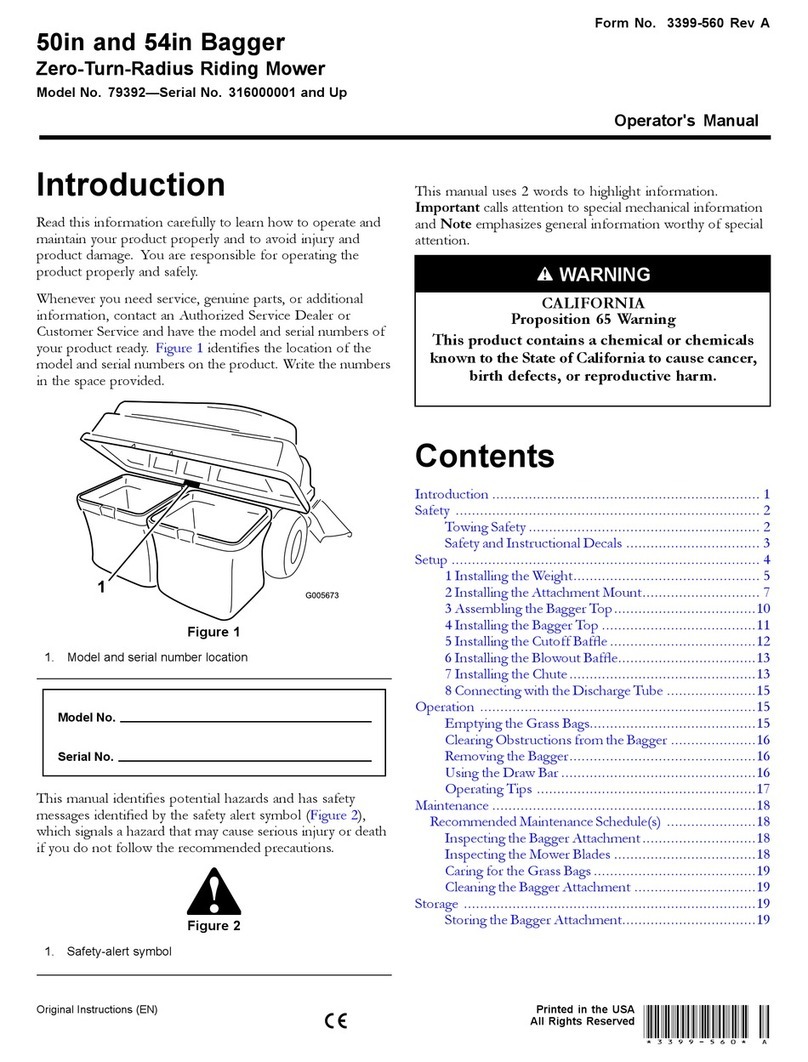

Toro 79392 User manual

Toro

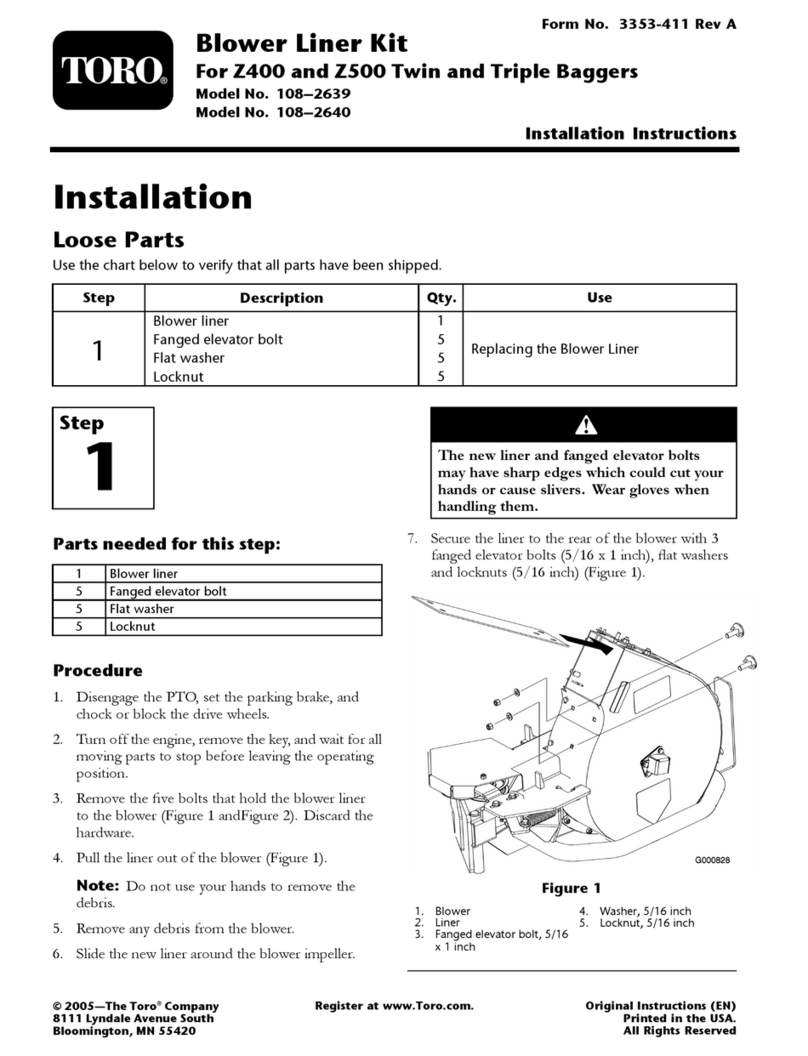

Toro 108-2639 User manual

Toro

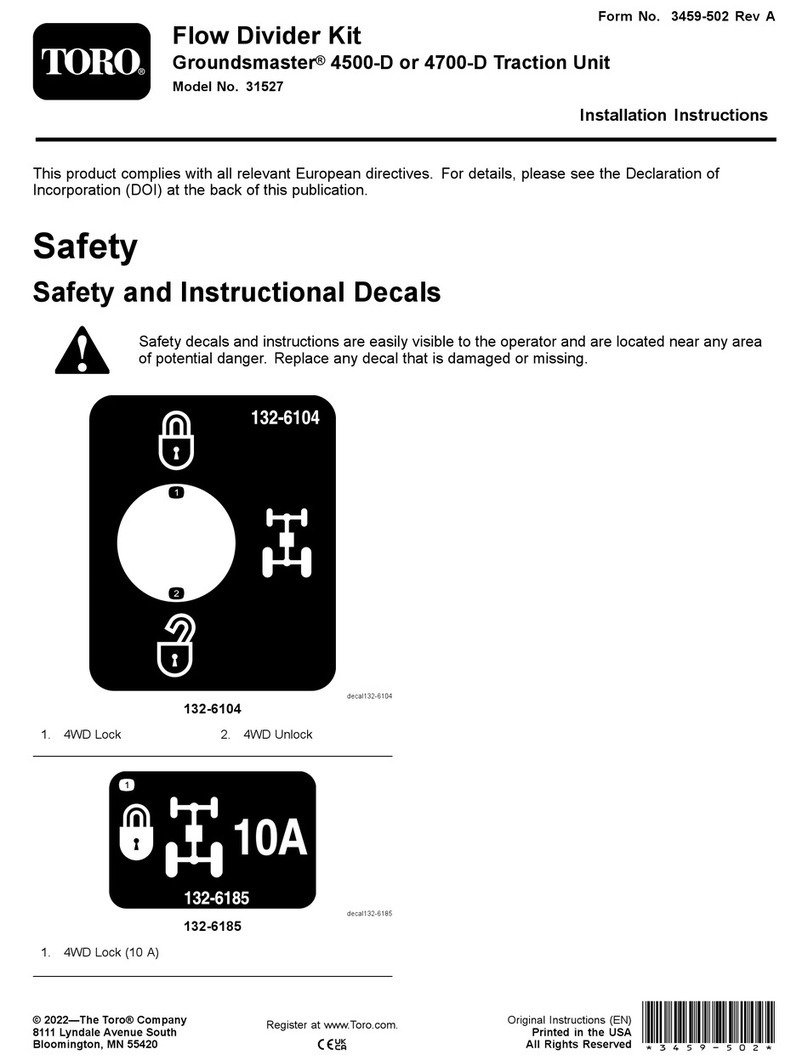

Toro 31527 User manual

Toro

Toro Groundsmaster 360 Series User manual

Toro

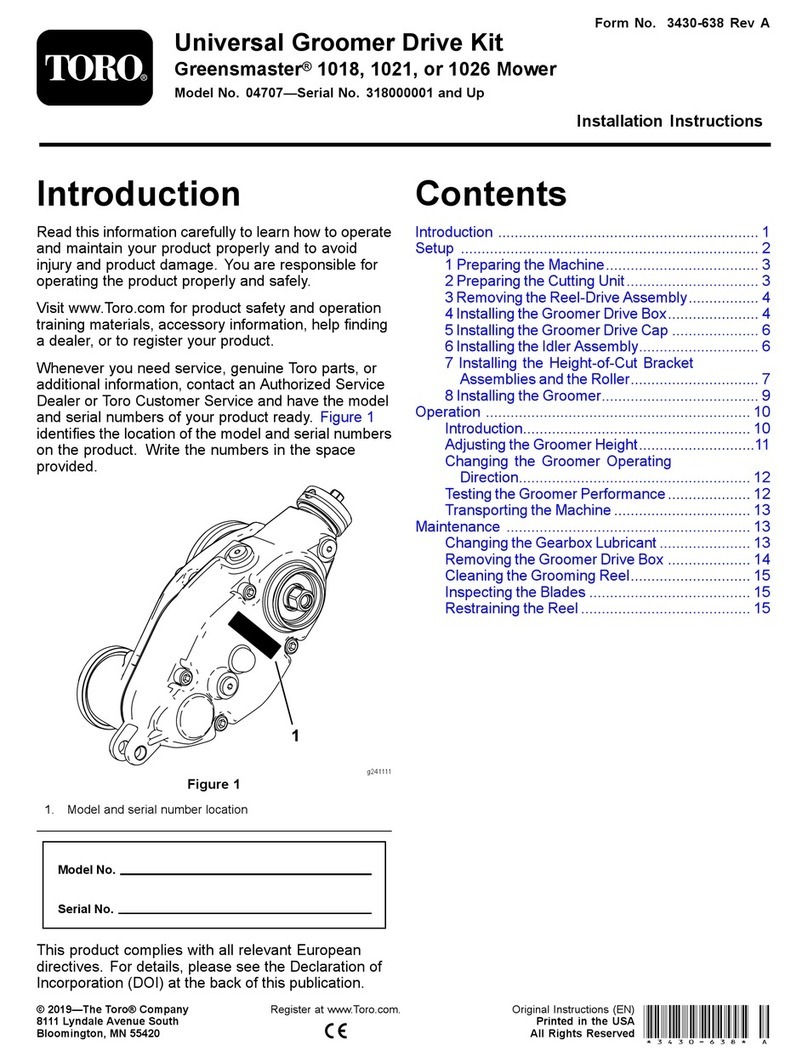

Toro 04707 User manual

Toro

Toro Wheel Horse 78361 User manual

Toro

Toro CT Series User manual

Toro

Toro Groundsmaster 31511 User manual

Toro

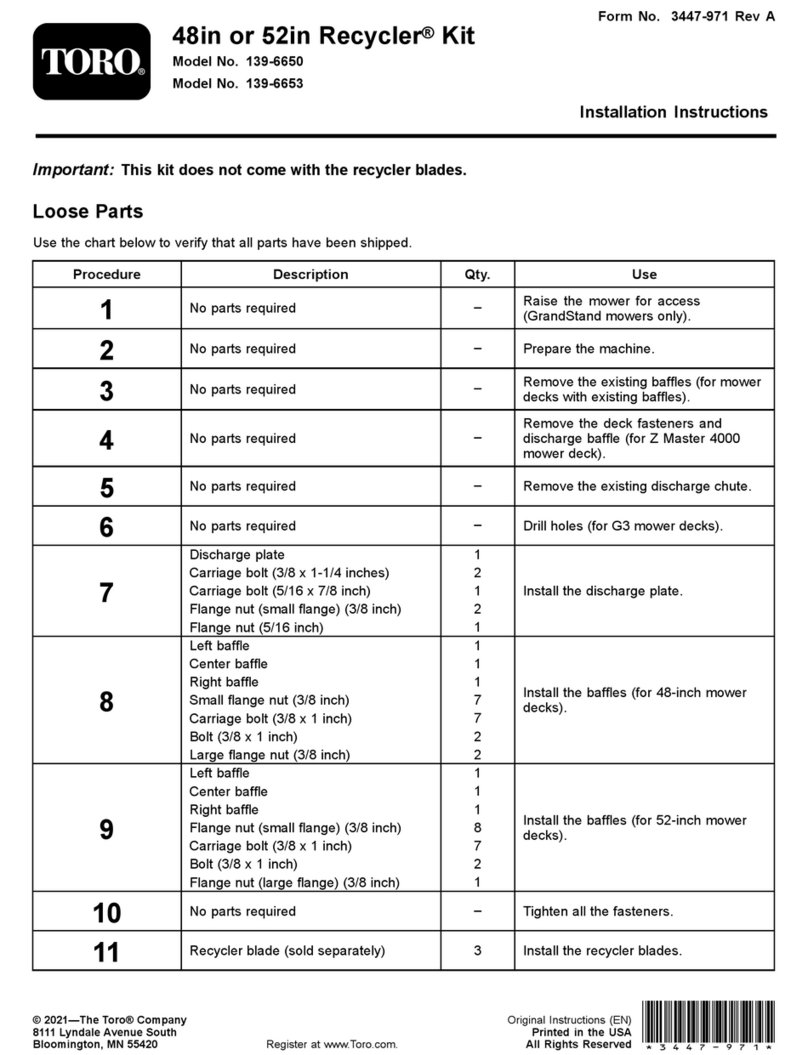

Toro 139-6650 User manual

Toro

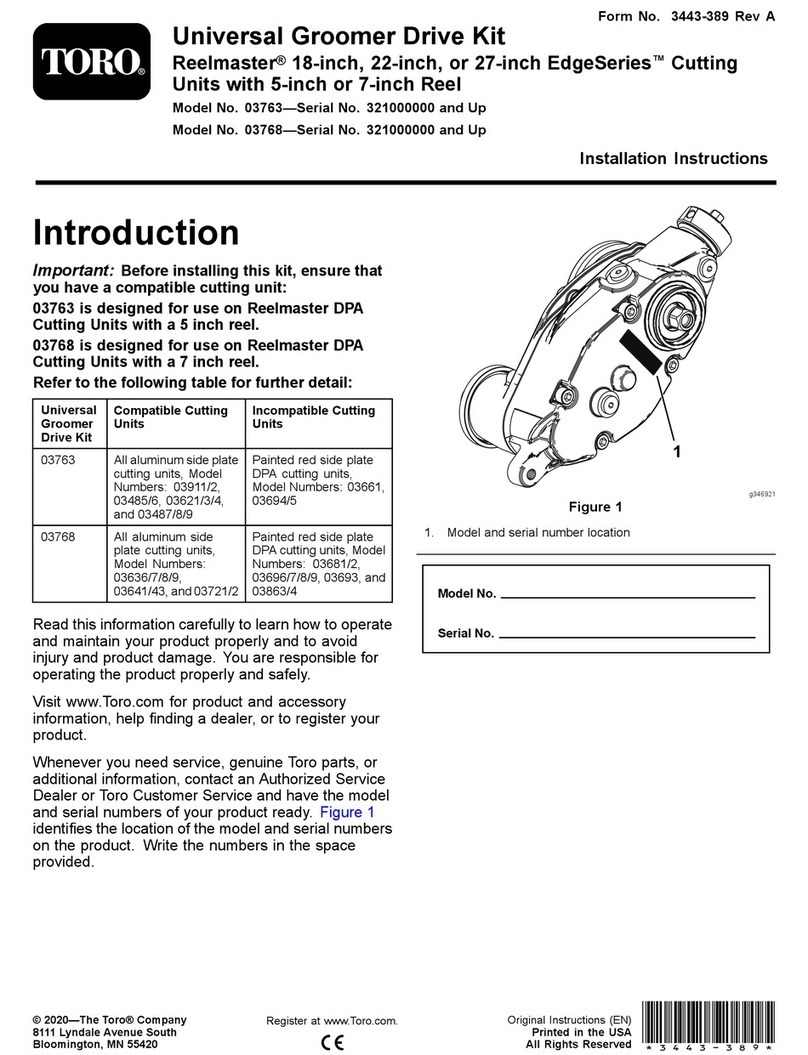

Toro Universal Groomer Drive Kit User manual

Toro

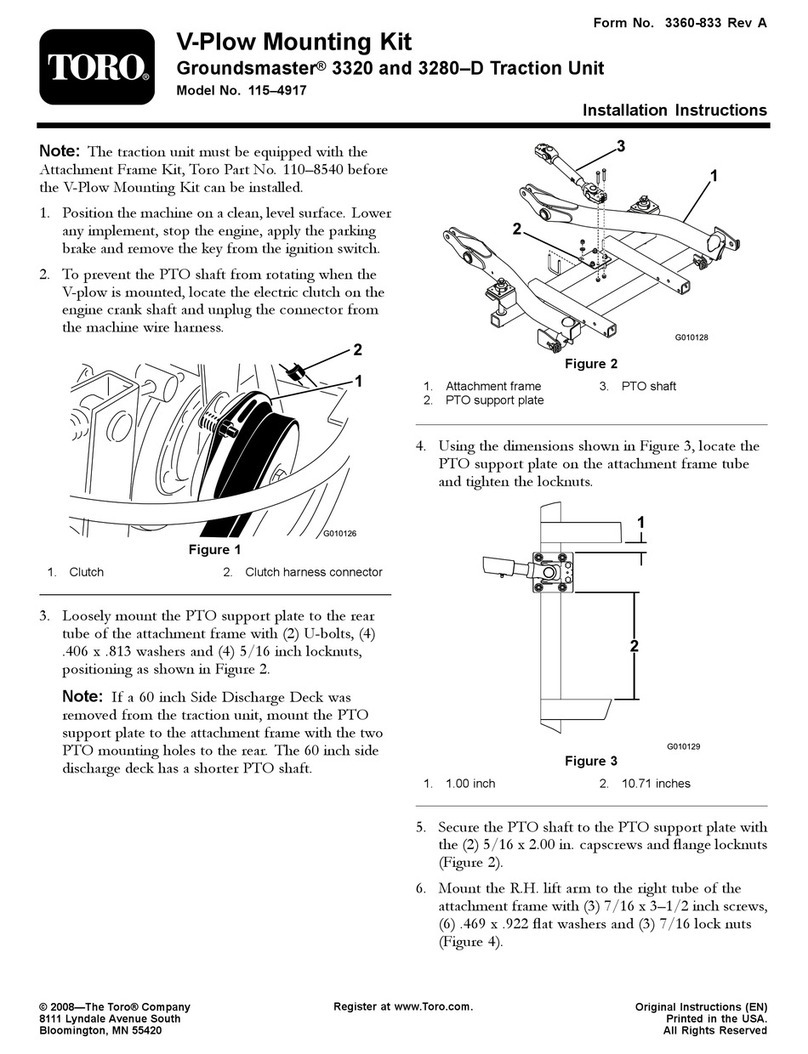

Toro 115-4917 User manual

Toro

Toro 3200 User manual

Toro

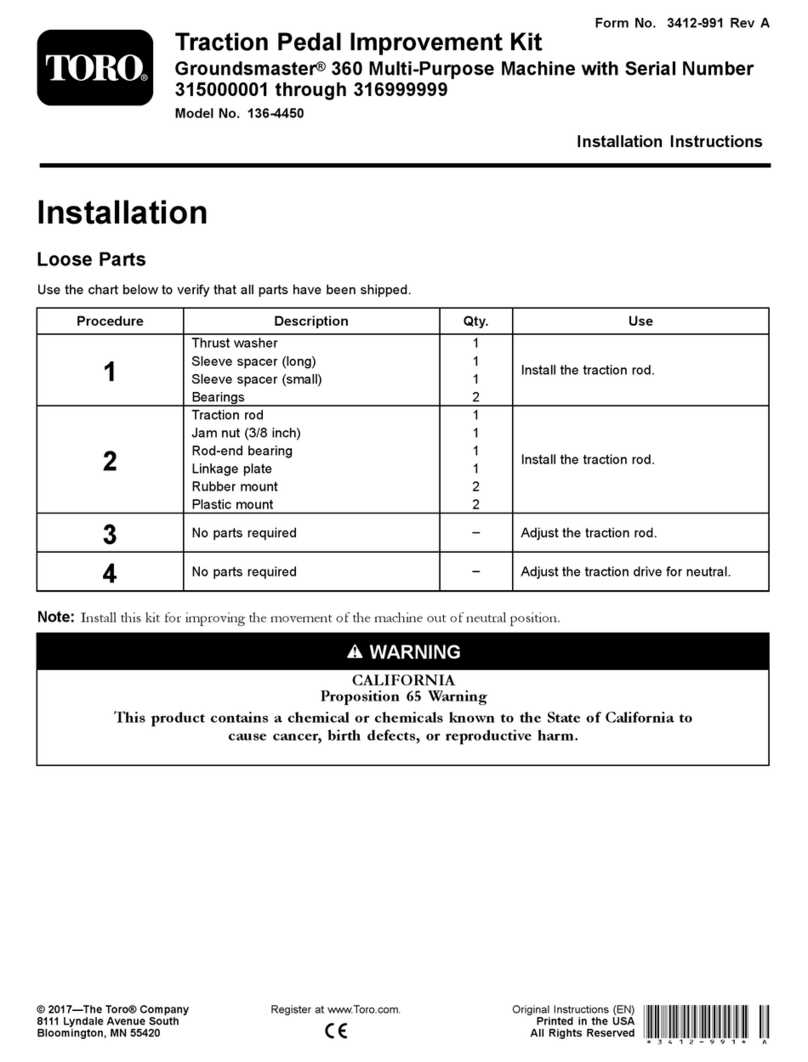

Toro Groundsmaster 136-4450 User manual

Toro

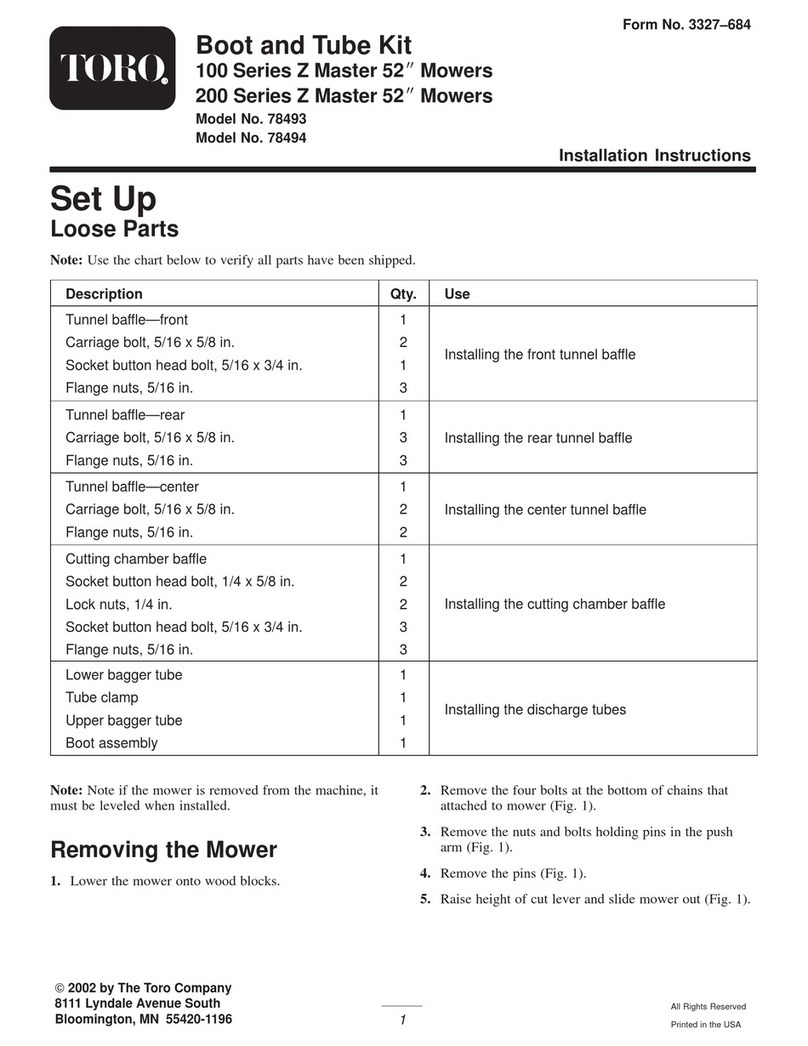

Toro 78493 User manual

Toro

Toro 08719 User manual