Contents

Safety.......................................................................3

GeneralSafety...................................................3

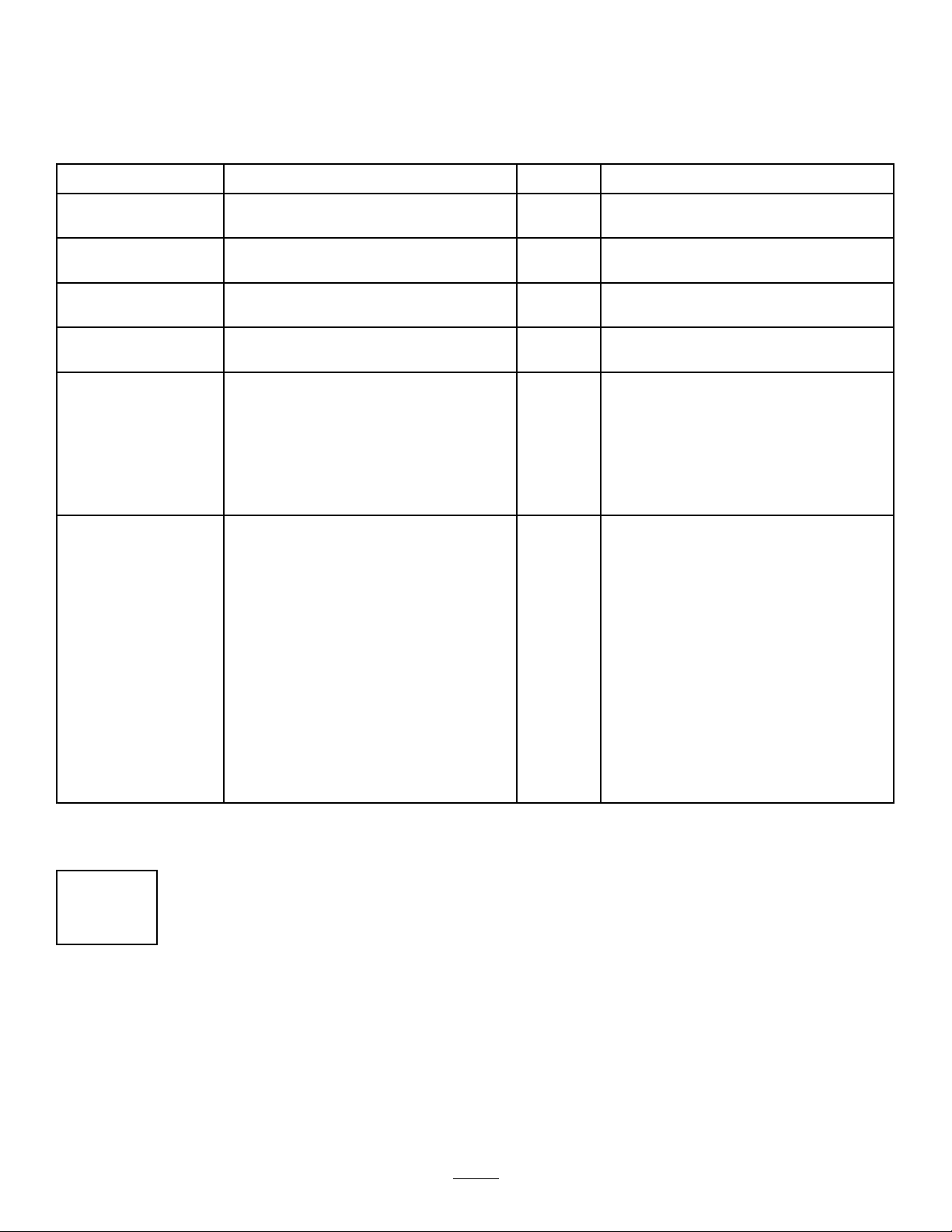

SafetyandInstructionalDecals..........................4

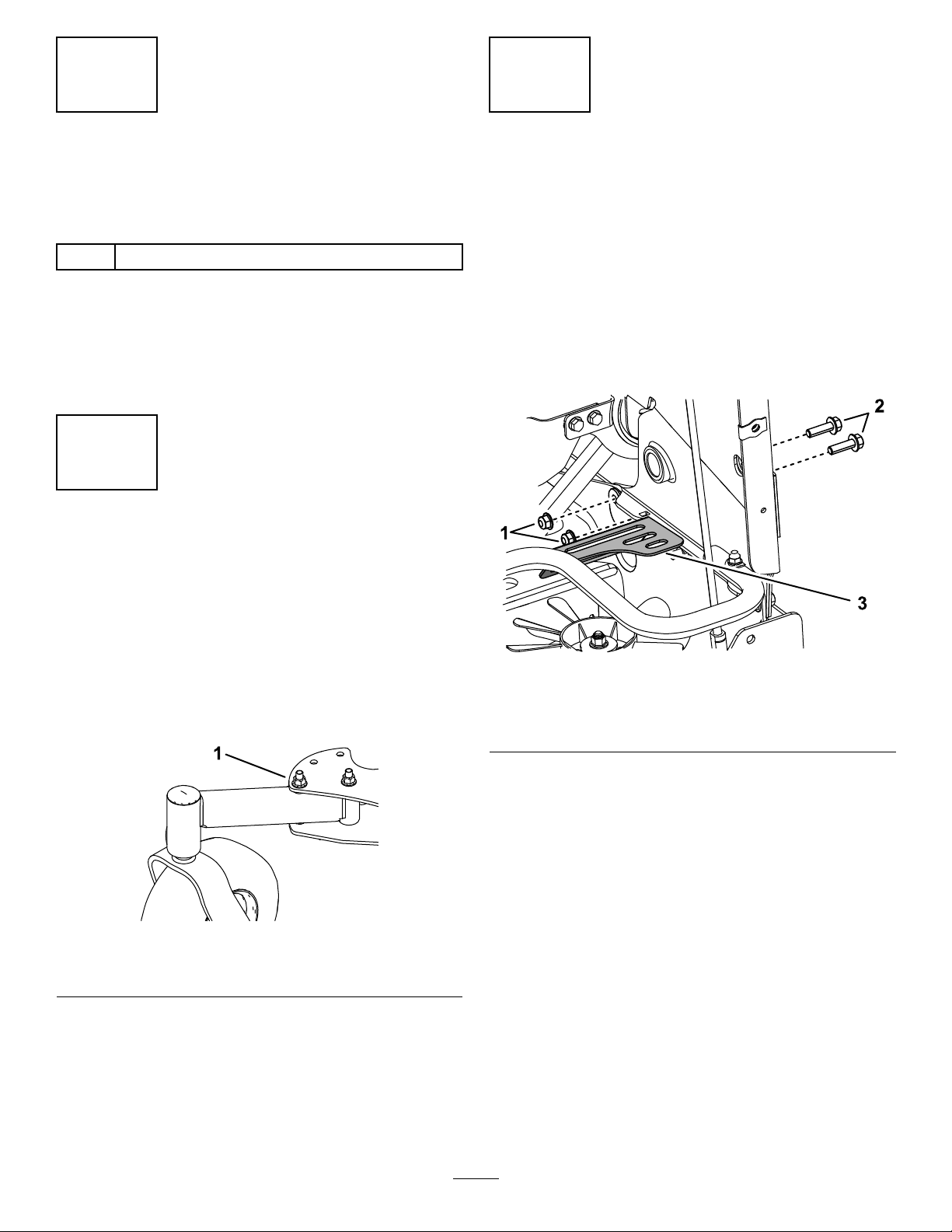

Setup........................................................................5

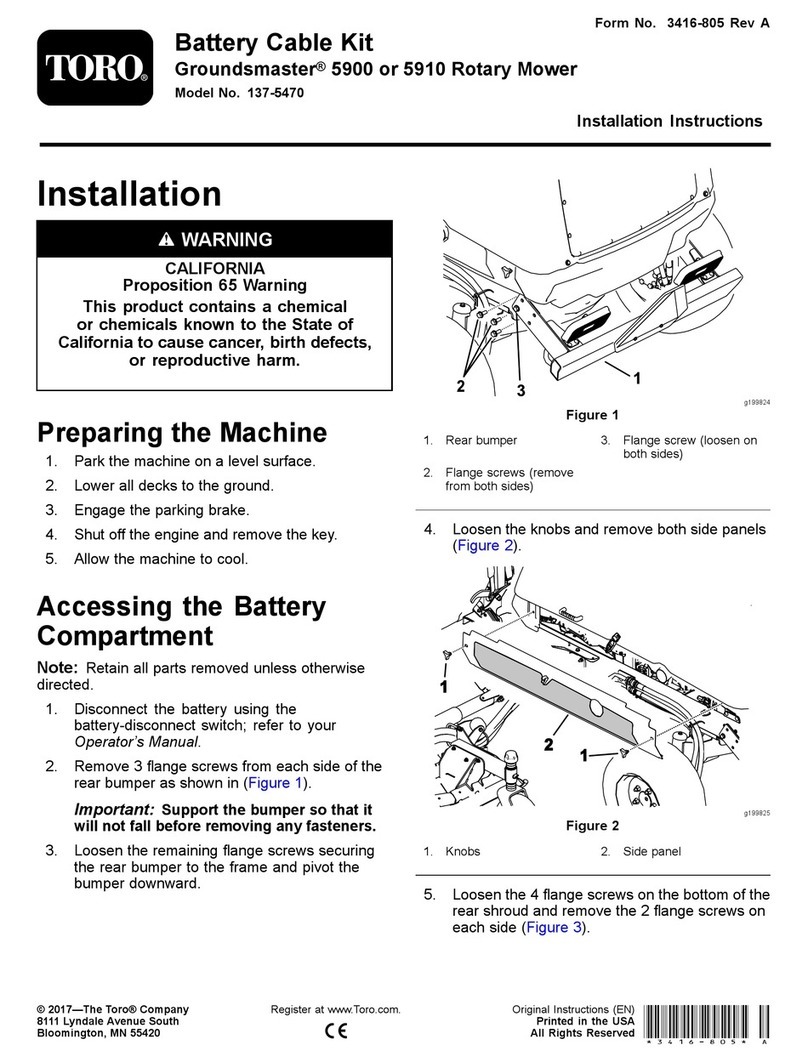

1PreparingtheMachine.....................................5

2InstallingtheWheelWeightKit

(Optional)........................................................5

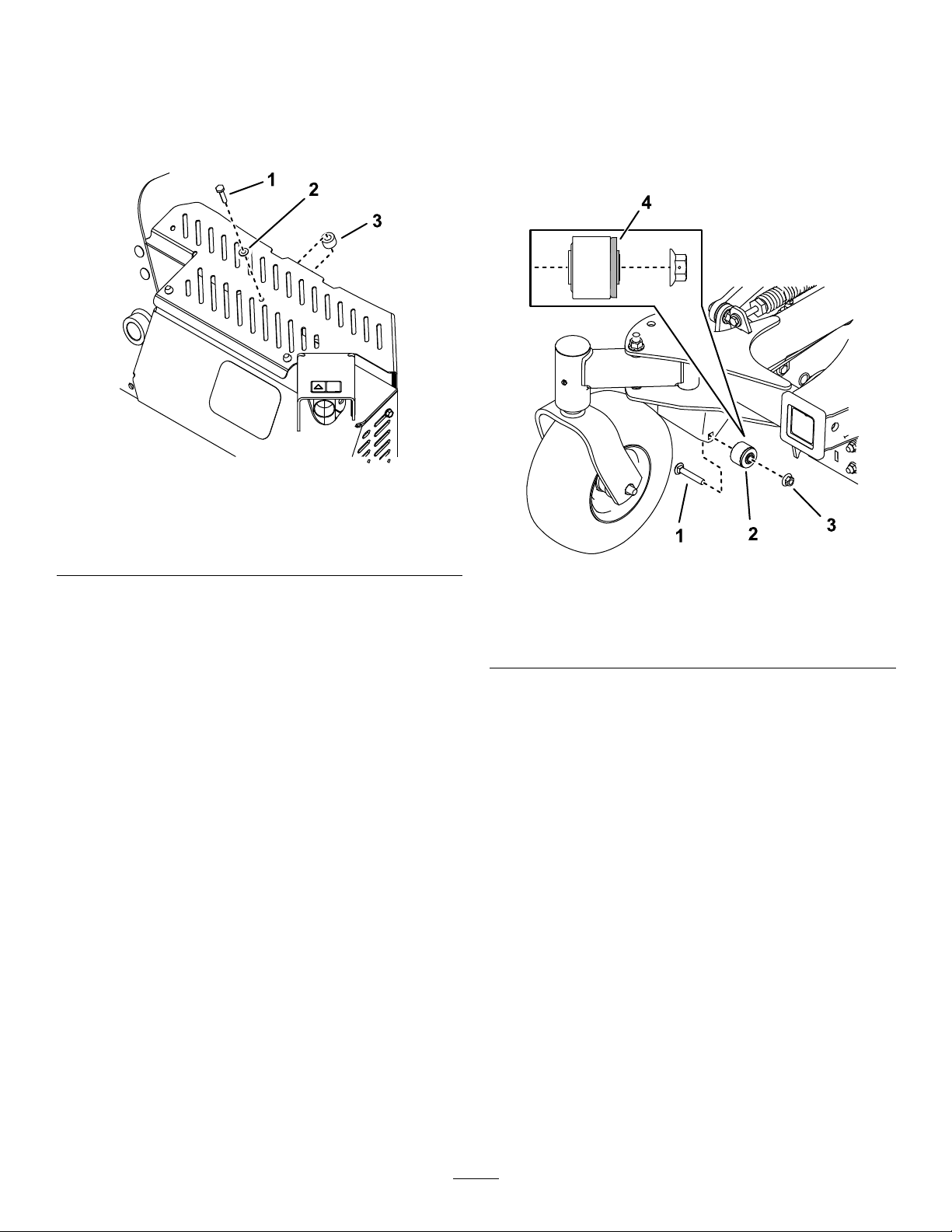

3PositioningtheCasterWheels.........................6

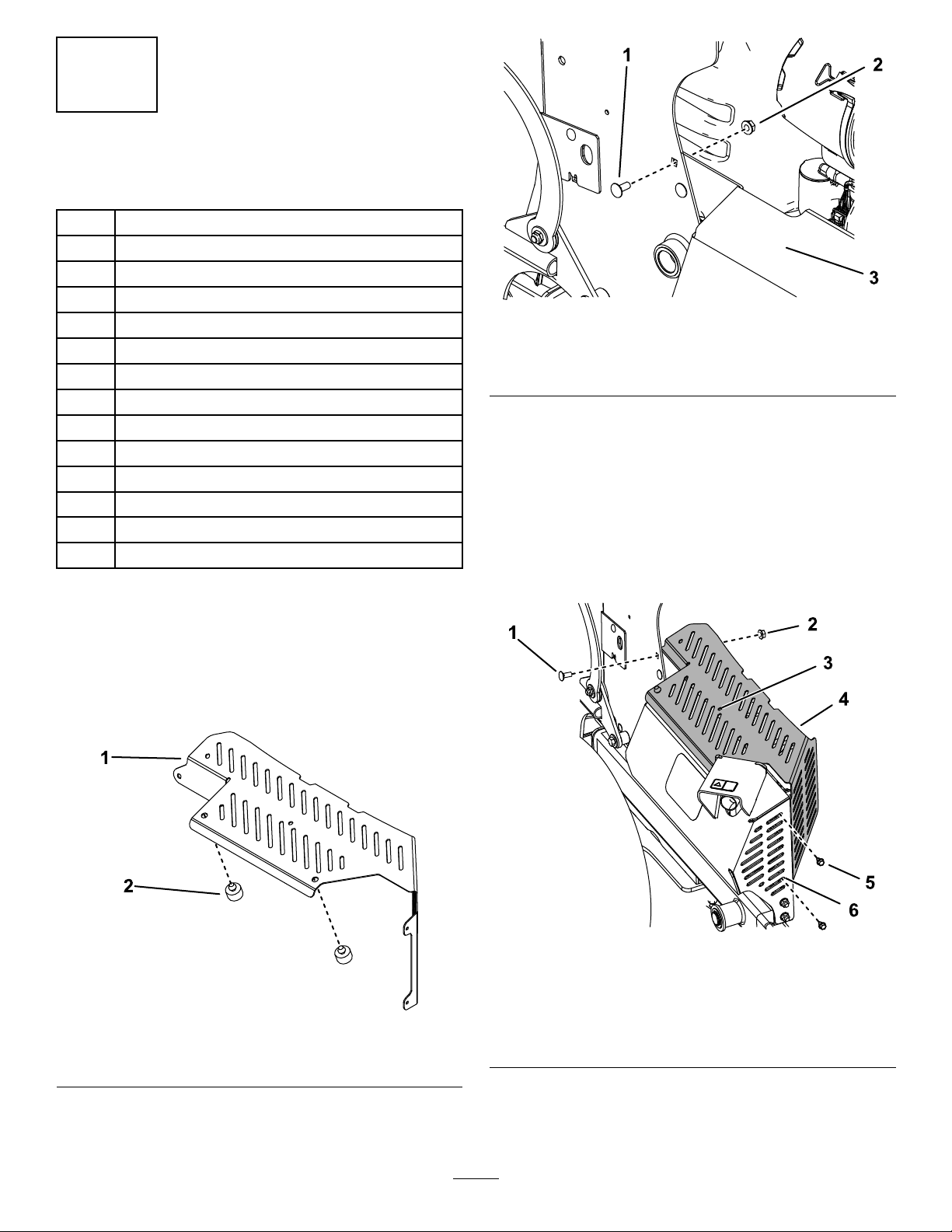

4RemovingtheRightFanGuard........................6

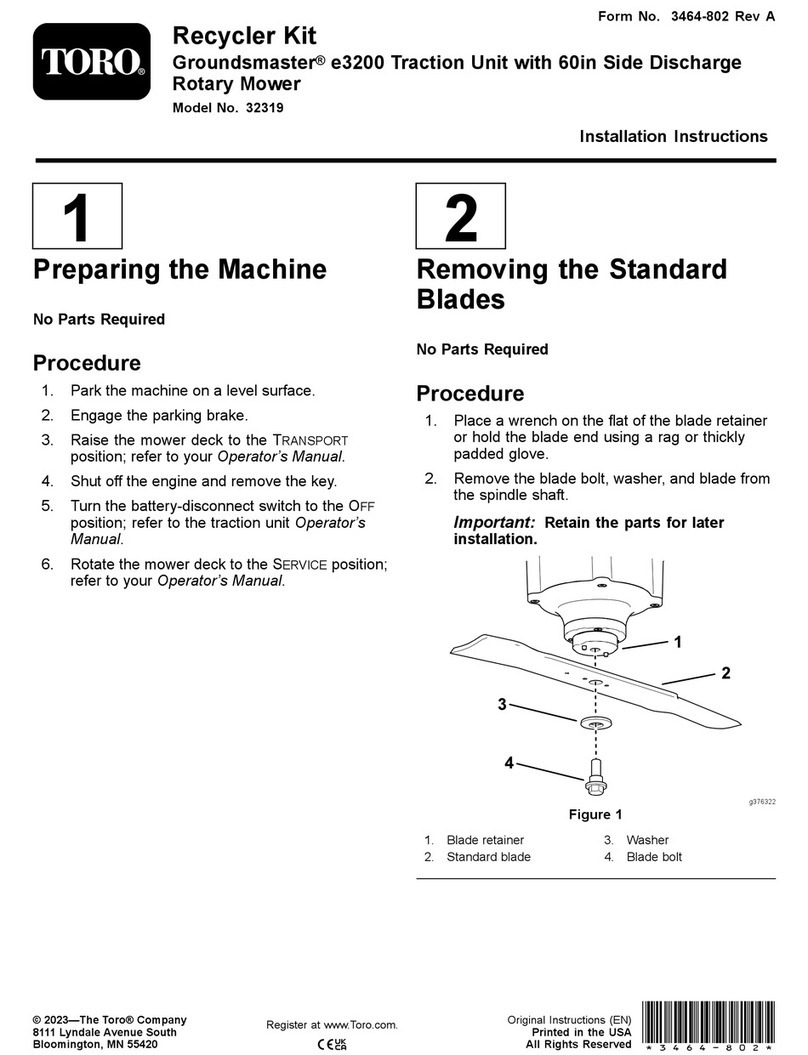

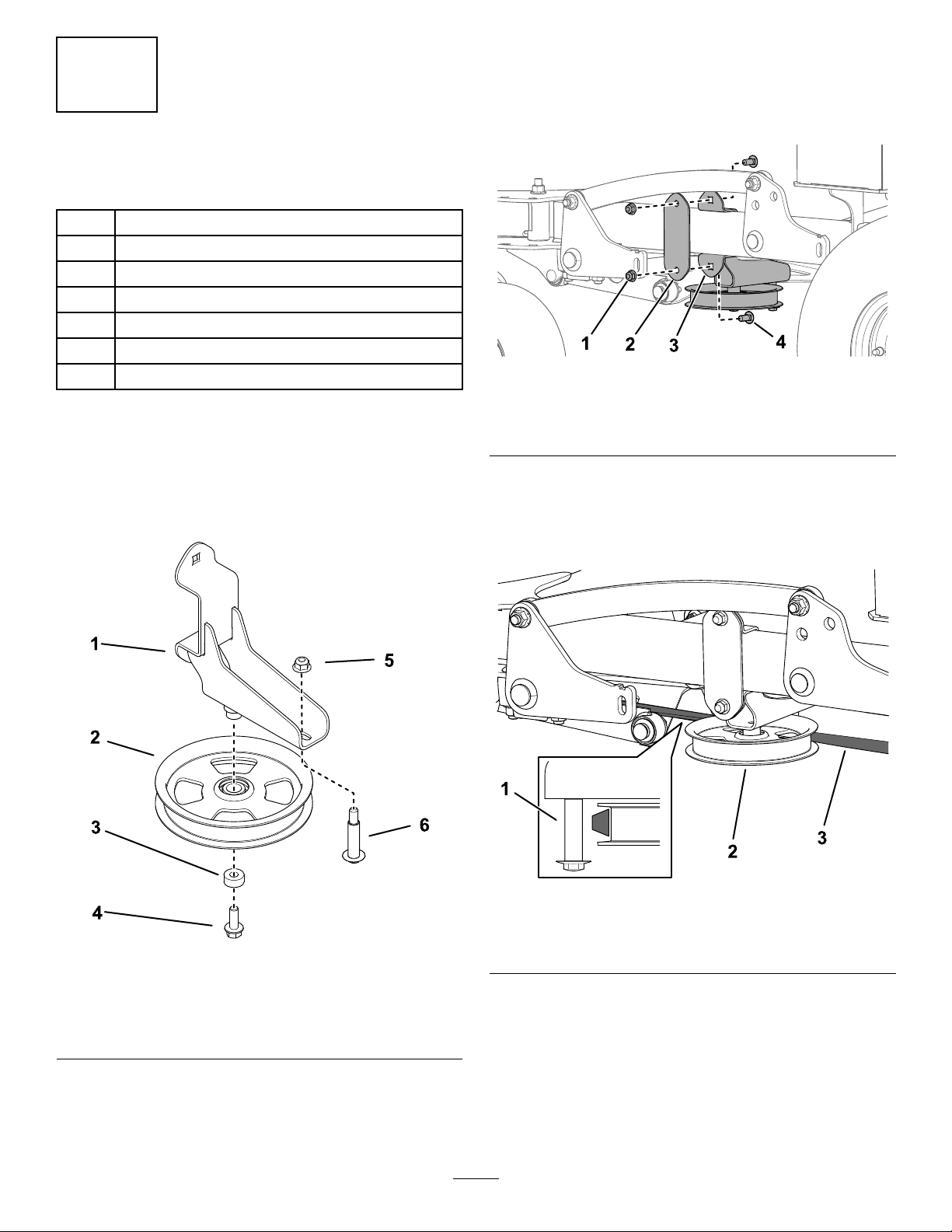

5InstallingtheIdlerPulley..................................7

6InstallingtheBlower.........................................7

Operation................................................................12

OperationSafety..............................................12

OperatingtheBlower........................................12

UsingtheKickstand..........................................12

RemovingtheBlower........................................14

OperatingTips.................................................17

Maintenance...........................................................18

MaintenanceSafety..........................................18

CheckingtheBelts............................................18

ReplacingtheBlowerBelt.................................18

ReplacingtheClutchBelt..................................19

CheckingtheHydraulicHoses..........................19

RemovingDebrisfromtheMachine..................19

Safety

GeneralSafety

Thisproductiscapableofthrowingobjects.Always

followallsafetyinstructionstoavoidseriouspersonal

injury.

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingtheengine.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepclearofanydischargeopening.Keep

bystandersandpetsasafedistanceawayfrom

themachine.

•Keepchildrenoutoftheoperatingarea.Never

allowchildrentooperatethemachine.

•Stopthemachine,shutofftheengine,andremove

thekeybeforeservicing,fueling,orunclogging

themachine.

Improperlyusingormaintainingthismachinecan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol,which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

3