Trelawny LPS55 User manual

LPS55 Scabbler / Tamper

Operation and Maintenance Manual

www.trelawnyspt.co.uk

OPERATION

Foreword

Thank you for purchasing the LPS 55.

This manual contains the necessary

maintenance information for you to ensure

proper operation and care for your machine.

It is essential for you to read through these

manuals thoroughly.

In the unlikely event that you experience

problems with your LPS 55, please do not

hesitate to contact your local dealer or agent.

We always welcome feedback and comments

from our valued customers.

General Information

Before operating the LPS 55 Scabbler/

Tamper, this manual must be read and

understood by the operator, if in any doubt

ask your supervisor before using this

equipment. Failure to follow these instructions

could result in damage to the LPS 55

Scabbler / Tamper and/or personal injury.

Trelawny SPT Ltd disclaims all responsibility

for damage to persons or objects arising as a

consequence of incorrect handling of the tool,

failure to inspect the tool prior to starting work

for damage, or other faults that may influence

the operation or safe working of the tool, or

failure to follow the safety regulations listed or

applicable to the job site.

The tool is primarily designed for concrete

reduction and for the removal of laitance from

concrete.

The LPS 55 is also available as a Tamper and

can subsequently be fitted with a Tamper

head for the compaction of soil, tarmac or

aggregate.

This tool must not be used in a fixture.

A VL LRS 55 is also available as a vibration

reduced Compactor or Scabbler version.

All versions can be used both indoors and out.

Safety

Always, read through these instructions first

before use.

We advise you to carry out a risk assessment

and to implement measures such as; limiting

exposure time [i.e. actual trigger time, not total

time at work], job rotation, ensuring the tools

are used correctly, ensuring the tools are

maintained according to our

recommendations, and ensuring that the

operators wear personal protective equipment

[PPE] particularly gloves and clothing to keep

them warm and dry. Employers should

consider setting up a programme of health

surveillance to establish a benchmark for

each operator and to detect any early

symptoms of vibration injury.

We are not aware of any PPE that provides

protection against vibration injury by

attenuating vibration emissions.

See ‘Specifications’ section for vibration

emission data.

Further advice is available from our Technical

Department.

Starting Work

Prior to operating the tool check: -

That all fittings are secure, free from air leaks

and that air hoses are in good condition.

That all parts of the tool are fully screwed

together and secure, if you are in any doubt

ask your supervisor before using this

equipment.

That the air pressure is correct for this tool

6.2 bar (90 psi.).

That a liberal amount of lubricant has been

put into the air inlet of the tool. (See

recommended lubricants)

Before operating the tool ensure that the tool

is not near your chin or face.

Safe use of this tool requires a solid stance

and secure foothold; the operator must adopt

a firm and stable position at all times.

On start up, the tool will rise two to three

inches (75mm).

To operate the tool pull the lever towards the

handle grip.

Let the tool do the work; allow a period of time

to become accustomed to the tool. The tool

does not require any down force to operate;

excessive pressure will prevent the tool from

working effectively. Maintain contact with the

work surface with sufficient pressure only to

keep the tool under control.

Bush Hammer style headed pistons are best

suited to concrete reduction and for laitance

removal; these may reduce the likelihood of

damage to the aggregate, ensuring that a

stronger bond is created with the next layer.

Cruciform headed pistons are suited to the

reduction of concrete or where a smoother

finish is required; these will reduce the

aggregate as well as the concrete surface.

To switch off, simply release the throttle

lever.

Do not press down on the tool, excessive

pressure will prevent the tool from working to

its full capacity and will increase the vibration

emissions.

IMPORTANT

Before operating this equipment, the

operator should read this manual.

Whenever possible, he/she should be

trained how to operate the machine by an

experienced person.

Trial and error is not the safe way to

become familiar with this piece of

equipment.

Always observe safe working practices

and local safety regulations at all times.

Do not allow the tool to run unattended.

Do not allow the tool to run continuously

whilst not in contact with the surface being

prepared.

Do not modify this tool in any way, as

this will invalidate the warranty and could

lead to serious injury.

Do not use this tool in potentially

explosive environments.

Do not drag this tool by the air hose.

Do not use petrol (gasoline), thinners or

any other high flash point solvent to clean

the tool.

Air Supply

The compressed air supply must be free

from water and dirt. The installation of a

filter/regulator/lubricator air preparation set

(with moisture trap) adjacent to the tool is

strongly recommended.

Always clear the air hose before connection

to the tool. Ensure that no moisture

(condensation) is present in the air hose.

Ensure that a minimum 19mm (3/4”) bore

air hose is used and that all couplings are

secure; leak free and in good condition.

Limit the length of air hose to 15M (50ft).

Where extra length is necessary, for each

additional 15M (50ft) of air hose used, the

pressure drop is approximately 0.16bar

(3psi).

Correct operating pressure is 6.2bar (90

psi).

Do not let the operating pressure fall below

5.5bar (80p.s.i.) or rise above 6.9bar (100

psi) absolute maximum.

Preferably, the compressor should be able

to supply a minimum of 18.9 L/s (40cfm)

free air.

In particularly cold weather it is

recommended that a proprietary anti-freeze

lubricating oil be used.

Recommended Lubricants

Oil the tool daily before use. Put a liberal

quantity of one of the following zinc free air

tool lubricants through the air inlet. It is

recommended that an inline lubricator be

installed in the air hose adjacent to the tool.

SHELL Naturelle HF

CASTROL Carelube HTG 22

Cleaning

At intervals of no more than 100 hours use,

or if operation becomes unproductive, or if

the piston shows signs of sticking,

dismantle and clean with highly refined

paraffin. Replace any worn components as

necessary.

Immediately after cleaning, thoroughly oil

the tool with one of the recommended

lubricants.

Risk of Hand-Arm

Vibration Injury

These tools may cause Hand-arm Vibration

Syndrome injury if their use is not

managed.

Do wear Personal Protective Equipment

including safety goggles, footwear, ear

defenders and gloves.

In some environments it will be necessary to

wear facemasks or breathing apparatus.

Do be aware that this tool is not

electrically insulated.

Do ensure that this tool is lubricated daily.

Do be aware that this tool can create dust

and flying debris.

Do be aware of others working around

you.

Do keep hands and clothing away from

moving parts.

Do store this tool in a secure and dry

environment.

OPERATION / MAINTENANCE

Handled correctly the LPS 55 Scabbler/

Tamper will work quickly and efficiently.

Gloves and personal protective equipment

must be worn when using this tool.

Care must be taken to avoid damaging or

tripping over the air hose.

Maintenance

Only a competent person, in a suitably

equipped workshop, must carry out

maintenance. Disconnect the tool from the

air supply before carrying out any of the

following operations.

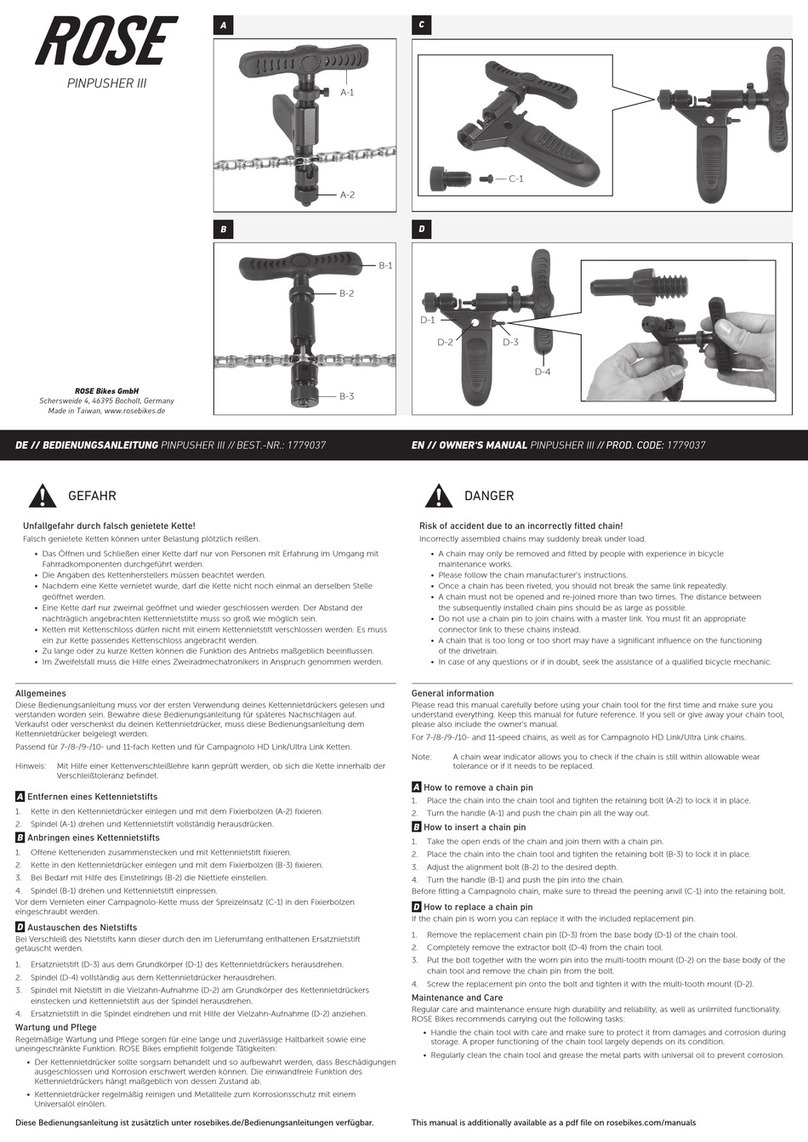

Dismantling

Clean all debris from the exterior of the tool.

Handle/Valve Body servicing

Hold main shaft in a vice, about three

inches (75mm) away from the cylinder

assembly, slacken off the locknut (10)

using a 38mm (1½) wrench on the spanner

flats. Retain the sealing washer (10a). Then

unscrew the valve body assembly from the

main shaft.

Secure the valve body assembly (14) in a

vice, holding on the main body casing.

Using a suitable spanner unscrew the

adapter (19) from the valve body, remove

the spring (21) and spring seat (20),

retrieve the valve stem (24) with its

O’Rings. Using a 6mm punch, drive out the

throttle lever pivot pin (25) and withdraw the

throttle lever (12).

Piston and Cylinder removal

(Threaded Piston)

Hold the Scabbler head (7) or Tamper foot

securely in a vice, then using a 1¼” (32mm)

spanner on the piston flats, unscrew the

Scabbler head or Tamper foot. Using a

suitable wrench on the spanner flats on the

cylinder remove the cylinder and then the

piston (6) from the cylinder (2). Remove the

piston O' Ring (not shown in the exploded

diagram) and remove cylinder wiper seal

(5) and O' Rings (3) and (4).

(Pin fit Piston)

Hold the Scabbler head (7) or Tamper foot

securely in a vice, then using a 12mm

punch drive out the retaining spiral pin (8)

and remove the Scabbler head or Tamper

foot. Using a suitable wrench on the

spanner flats on the cylinder remove the

cylinder and then the piston (6) from the

cylinder (2). Remove cylinder wiper seal (5)

and O' Rings (3) and (4).

Assembly

Before any assembly takes place, ensure

all parts are clean and have a film of air tool

oil lubrication unless otherwise stated.

Avoid lubricating oil contaminating the

threads of the cylinder (2), the main shaft

(9) and the valve body (14). These will

require securing with a thread-locking

adhesive. It is good practice to renew all the

O'Rings. Replace any parts showing signs

of wear; paying particular attention to the

small bore of the cylinder.

Handle/Valve Body Assembly

Apply general-purpose bearing grease to

the valve stem, insert valve stem (24) with

its O'Rings (22) and (23) into valve guide

followed by the spring (21). Screw in

adaptor (19) by hand and using a

32mm (1¼) spanner fully tighten. Using a

6mm punch align the hole in the throttle

lever (12) with the holes in the valve body

(14). Using a small hammer fit the throttle

lever pin (25).

Piston and Cylinder Assembly.

(Threaded Piston)

Fit a new wiper seal (5) and O' rings (3)

and (4) to the appropriate small and large

grooves on the cylinder (2). Fit a new

O' ring on to the piston (6) and insert into

the cylinder. Screw on the Scabbler head

(7) or Tamper foot until it butts up against

shoulder of piston. Hold in a vice, gripping

on the Scabbler head or Tamper foot using

the spanner flats. Fully secure using a

suitable wrench on the piston’s spanner

flats to a torque of 500lbs/ft (678Nm).

Ensure that the threads of the cylinder and

casing assembly are clean and free of oil;

apply a bead of Loctite 243 or similar to the

first few threads of the cylinder. Hold the

casing assembly in a vice using the flats

provided and screw in the cylinder

assembly by hand, using a suitable wrench

on the spanner flats on the cylinder tighten

to a recommended torque of

135Nm (100 lbs/ft).

Piston and Cylinder Assembly.

(Pin fit Piston)

Fit a new wiper seal (5) and both O' rings

(3) and (4) to the appropriate small and

large grooves on the cylinder (2). Insert the

piston (6) into the cylinder. Fit the Scabbler

head (7) or Tamper foot until it butts up

against the front face of the piston (6). Align

the holes in the piston and Scabbler head

or Tamper foot. A ” Allen Key is a good

fit for this purpose or use a suitable piece of

wooden dowelling. Hold the spiral pin (8)

with a pair of pliers to avoid hitting the

fingers, and then using a hammer, drive in

the spiral pin centrally to secure the

Scabbler head or Tamper foot.

Ensure that the threads of the cylinder and

casing are clean and free of oil; apply a bead

of Loctite 243 or similar to the first few threads

of the cylinder. Hold the casing assembly in a

vice on the flats provided and screw in the

cylinder assembly by hand. Using a suitable

wrench on the spanner flats on the cylinder

tighten to a recommended torque of 135Nm

(100 lbs/ft).

Body Assembly

Hold main shaft in a vice, about three inches

(75mm) away from the valve assembly.

Ensure sealing washer (10a) is in place and

that the threads of the valve body (14) and

main shaft (9) are clean and free of oil; apply

a bead of Loctite 243 or a similar product to

the first few threads of the Handle and screw

on the valve body until hand tight.

Tighten the locknut (10) using a 38mm (1 ”)

wrench on the spanner flats.

Machine Storage

Storage: over 3 months.

Clean the outside of the machine and inspect

the piston and cutterhead for wear, replace

any worn parts as required. Put a liberal

amount of lubricant into the air inlet of the tool

and run the tool for a few seconds to disperse

the oil around the tools internal components.

Lubricate the exposed part of the piston and

cylinder. (See recommended lubricants)

Cover the machine to protect it:

Store the machine in a dry place.

When next used, continue as per “Starting

work section”.

Disposal

When the tool and its accessories are taken

out of service for disposal, it is recommended

that: - It is dismantled into component form,

segregated according to material composition

and disposed of using waste recycling

processes specified by local regulations.

Machinery Directive

Information

This tool has been designed and produced in

accordance with the following directives:

2006/42/EC Machinery Directive

and applicable harmonised standard:

EN ISO 1 1148-4:2012

If your company has any problem with our

products or would like to discuss the possibility

of an improvement being made to them, then

please do not hesitate to contact us. Your

comments are both important and appreciated.

SCABBLER/TAMPER

Length 1300mm (51)”

Weight 13.45kg (29.6lbs)

Blows per minute 1300

Air Pressure 6.2 bar (90psi) - (1/2” BSP Air inlet)

Air Consumption 11.61 lps (25cfm)

Sound pressure level 98.0db(A)

Vibration Level (H1)* 38.6m/s2 (k= 2.92m/s²)**

Vibration Level (H2)* 37.5m/s2 (k= 21.36m/s²)**

H1* Indicates test taken from the primary handgrip location at the trigger.

H2* Indicates test taken from the secondary handgrip location.

(K)** Equals the factor of uncertainty, which allows for variations in measurement and production.

Vibration data figures are tri-axial, which gives total vibration emission.

Risk of Hand Arm Injury

Because of various factors, the range of vibration emission during intended use can vary.

The vibration is dependent on the task, the operators grip, and feed force employed etc.

Noise level measured in accordance with: EN ISO 15744: 2008

Vibration measured in accordance with: EN ISO 28927:2012 and EN ISO 20643:2005

EXPLODED VIEW

EXPLODED VIEW

PART NUMBERS

All rights reserved. Any unauthorised use or copying of the contents or part thereof is prohibited.

This applies to trademarks, model denominations, part numbers and drawings.

Use only genuine Trelawny spares.

The use of non-Trelawny spare parts invalidates the warranty.

TROUBLE SHOOTING

Low air pressure. Ensure that the air pressure is correct at 90psi, max 100psi.Poor performance or lack of

power If tool has been left for some time without use, the

oil may dry out slightly causing a sticky residue.

Strip tool down and re-oil.

Tool worn out, can you feel excessive side ways

movement between the piston and cylinder bore.

Replace the piston and cylinder, along with a new scraper seal.

Cutterhead worn out. Replace cutterhead

Applying to much down force. Only apply sufficient down force to stop the tool from bouncing.

Tool continues to run with

trigger released

Valve seal may have become dislodged through the

tool being disconnected with the trigger in the open

position.

Ensure that the trigger has not been taped or wired in the open

position.

Do not use quick release couplings to switch tool off.

Cutterhead seized on piston If the tool has been laid up or used with water

present, rust may have built up between the piston

and cutter.

In extreme cases it may be necessary to apply heat to release

the cutter head, otherwise a releasing agent may be sufficient.

Item

No

Part No Description Item

No

Part No Description

1411.5011 Body 17 843.0765 3/4” Claw coupling

2613.5001 Cylinder 18 819.5020 90° Adapter

3809.6599 Cylinder O’Ring (Small) 19 627.5011 Adaptor (Spring seat)

4809.6619 Cylinder O’Ring (Large) 20 627.5012 Spring Seat

5829.5001 Wiper Seal 21 712.5001 Valve Spring

6612.5005 Piston (Pin Fit) 22 809.5599 Valve Stem Seat O’Ring

612.5001 Piston (Screw Fit) 23 809.0069 Valve Stem Seal O’Ring

7441.5359 TCT tip 5 point Scabbler Head (Pin fit) - inc pin 24 618.5025 Valve Stem

441.5360 TCT tip Cruciform Scabbler Head (Pin fit) i- nc pin 448.5025 Valve Stem - including O’Rings

441.5369 TCT tip 9 point Scabbler Head (Pin fit) - inc pin 25 813.0636 Roll Pin

426.5051 TCT tip 5 point Scabbler Head (Screw fit)

426.5052 TCT tip Cruciform Scabbler Head (Screw fit) Not shown in exploded view

809.6499 Piston O’Ring (Screw fit)

8813.1050 Spirol Pin (Pin fit heads) 450.5001 100 x 100 Compactor Foot (Screw fit)

450.5011 100 x 100 Compactor Foot (Pin fit)

9624.5011 Main Shaft 450.5003 127 x 152mm Compactor Foot (Screw fit)

10 625.5012 Locknut (Main shaft) 450.5013 127 x 152mm Compactor Foot (Pin fit)

10a 810.9003 Sealing Washer 450.5006 100 x 200mm Compactor Foot (Screw foot)

11 665.5011 Trigger Guard 450.5016 100 x 200mm Compactor Foot (Pin foot)

12 649.5011 Throttle Lever 450.5007 127 Diameter Compactor Foot (Screw fit)

13 822.2000 Rubber Grip 450.5017 127 Diameter Compactor Foot (Pin fit)

14 422.5005 Valve Body 852.0812 Trigger Guard Screw

15 634.5015 Blanking Cap

16 625.5011 Locknut (Valve body handle)

Trelawny SPT Ltd

13 Highdown Road, Sydenham Industrial Estate, Leamington Spa,

Warwickshire, CV31 1XT, United Kingdom

Telephone: +44 (0)1926 883781 - Fax: +44 (0)1926 450352

Email: sales@trelawny.co.uk

© TSPT UK 2009 Part No: 735.5005 issue 4.11.16 www.trelawnyspt.co.uk

Table of contents

Other Trelawny Tools manuals

Trelawny

Trelawny VLSF1EX User manual

Trelawny

Trelawny VL203Ex Troubleshooting guide

Trelawny

Trelawny Trident Neptune User manual

Trelawny

Trelawny Vibro Lo Troubleshooting guide

Trelawny

Trelawny VL223EX Series User manual

Trelawny

Trelawny SF3EX User manual

Trelawny

Trelawny SF11EX User manual

Trelawny

Trelawny Single Scaler Standard Duty User manual

Popular Tools manuals by other brands

FUCHS LUBRITECH

FUCHS LUBRITECH Single-handed How to use

Framers Corner

Framers Corner M3 Operator's manual

Milwaukee

Milwaukee M12 2435-20 Operator's manual

HAZET-WERK

HAZET-WERK 772-2/16 operating instructions

Johnson

Johnson LEVEL UP 1920-0800D Operator's manual

Berner

Berner GEDORE 1.06 operating instructions